Mine confined water self-discharging system

A technology of pressurized water and self-drainage, applied in drainage, mining equipment, safety devices, etc., can solve the problems of unrecognizable water inrush precursor information, high power consumption for drainage with pumps, and the need for special personnel on duty, etc., to reduce labor for workers Strength, energy saving, safe and reliable manpower effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

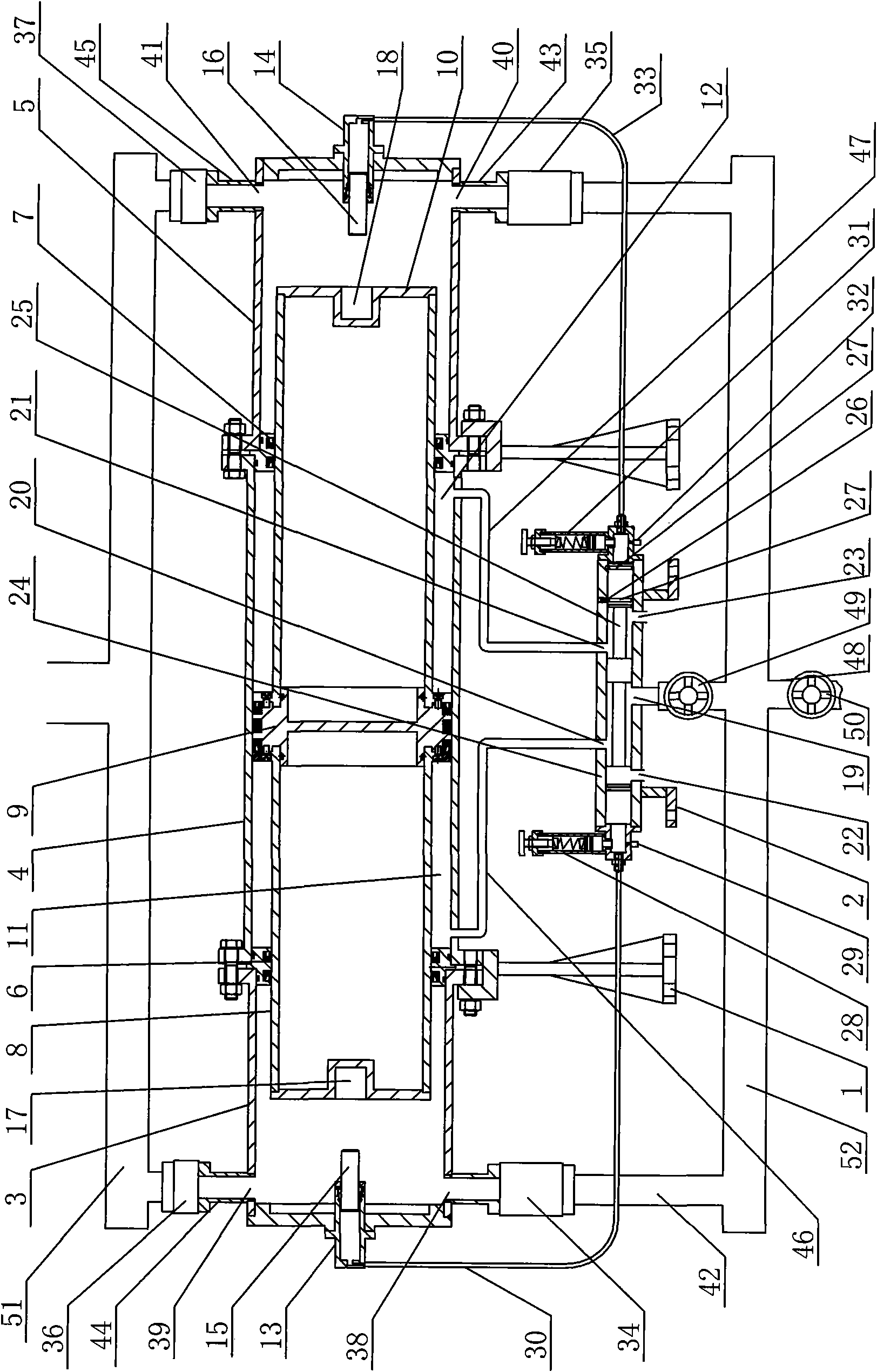

[0028] Such as figure 1 As shown, the mine pressurized water self-drainage system of the present invention includes a pressurized water pressurization device and an automatic reversing device respectively arranged on the support 1 and the support 2, and a water inlet 38 is provided on the pressurized water pressurization device. and water inlet 40, water outlet 39 and water outlet 41; the power output end of the automatic reversing device is connected with the power input end of the pressurized water booster device alternately through the water pipe 46 and the water pipe 47, and the power output of the pressurized water booster device The end is connected with the power input end of the automatic reversing device.

[0029] The pressurized water pressurization device includes a left cylinder 3, a middle cylinder 4 and a right cylinder 5, an annular left isolation block 6 is arranged between the left cylinder 3 and the inner wall of the middle cylinder 4, and the right cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com