Cooling and heating system with cooling-heating source complementor

A technology of cooling and heating, cold and heat source, used in heating and cooling combinations, refrigerators, refrigeration and liquefaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

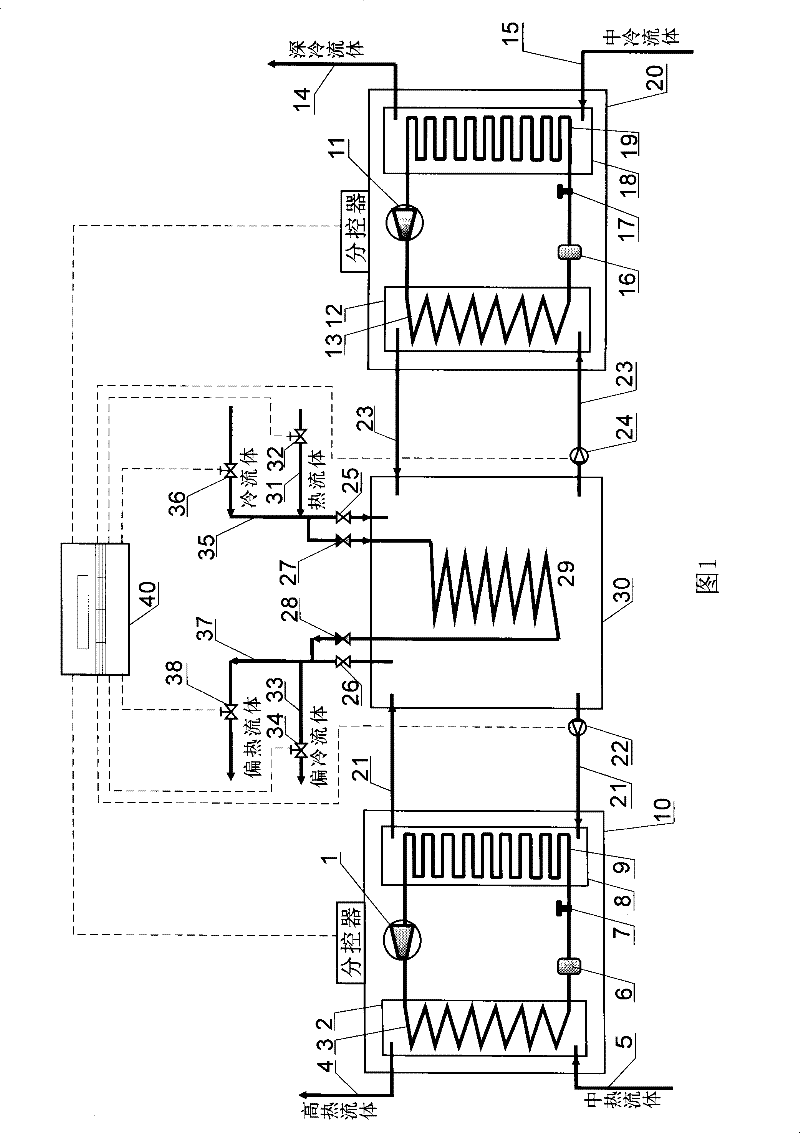

[0064] Embodiment 1: A cooling and heating system with a single compression circuit and a cold and heat source complementer. See figure 1 .

[0065] In the controllable single-compression loop heating and cooling complementary refrigeration and heating system, the heating subsystem is composed of a compression circuit, and the refrigeration subsystem is composed of a compression circuit.

[0066] The heating subsystem 10 , the refrigeration subsystem 20 , the cooling circulation pump 22 and the heat removal circulation pump 24 are started synchronously by the system controller 40 .

[0067] The working principle of the heating subsystem 10 is:

[0068] The heating subsystem compressor 1 pressurizes the gaseous heating agent and sends it to the heating subsystem condenser 2 . The heating agent becomes liquid in the cooling coil 3 of the heating subsystem and releases heat. The medium-heat fluid enters the condenser 2 of the heating subsystem from the heat-fluid inlet 5 of ...

Embodiment 2

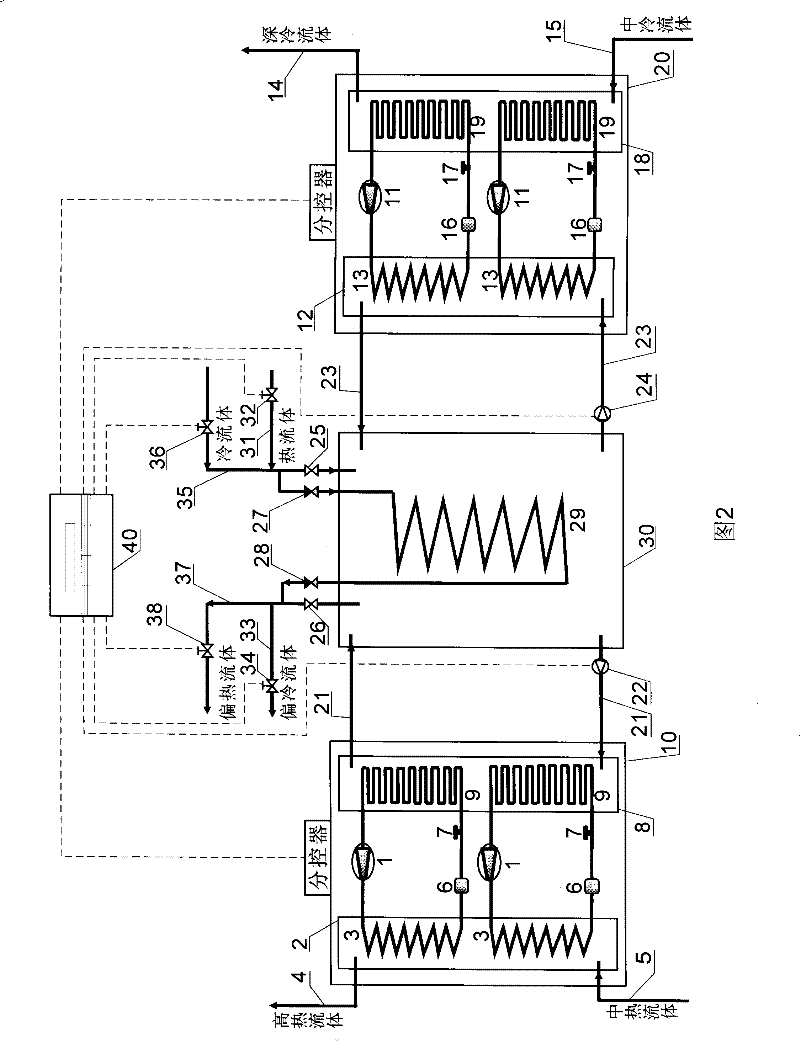

[0084] Embodiment 2: Refrigeration and heating system with dual compression circuits and cold and heat source complementers. See figure 2 .

[0085] figure 2It is a principle flowchart of the refrigeration and heating system with double compression circuit and cold and heat source complementarity. Its refrigeration and heating working principle and control principle are exactly the same as those of the refrigeration and heating system with controllable single compression circuit and cold and heat source complementarity. Here I won't go into details. The difference is: the heating subsystem has two compression circuits, which have greater power and stronger heating capacity than the single compression circuit; the cooling subsystem has two compression circuits, which have larger capacity than the single compression circuit. Power and stronger cooling capacity. The temperature difference between the cryogenic fluid and the high heat fluid in the whole system increases. Th...

Embodiment 3

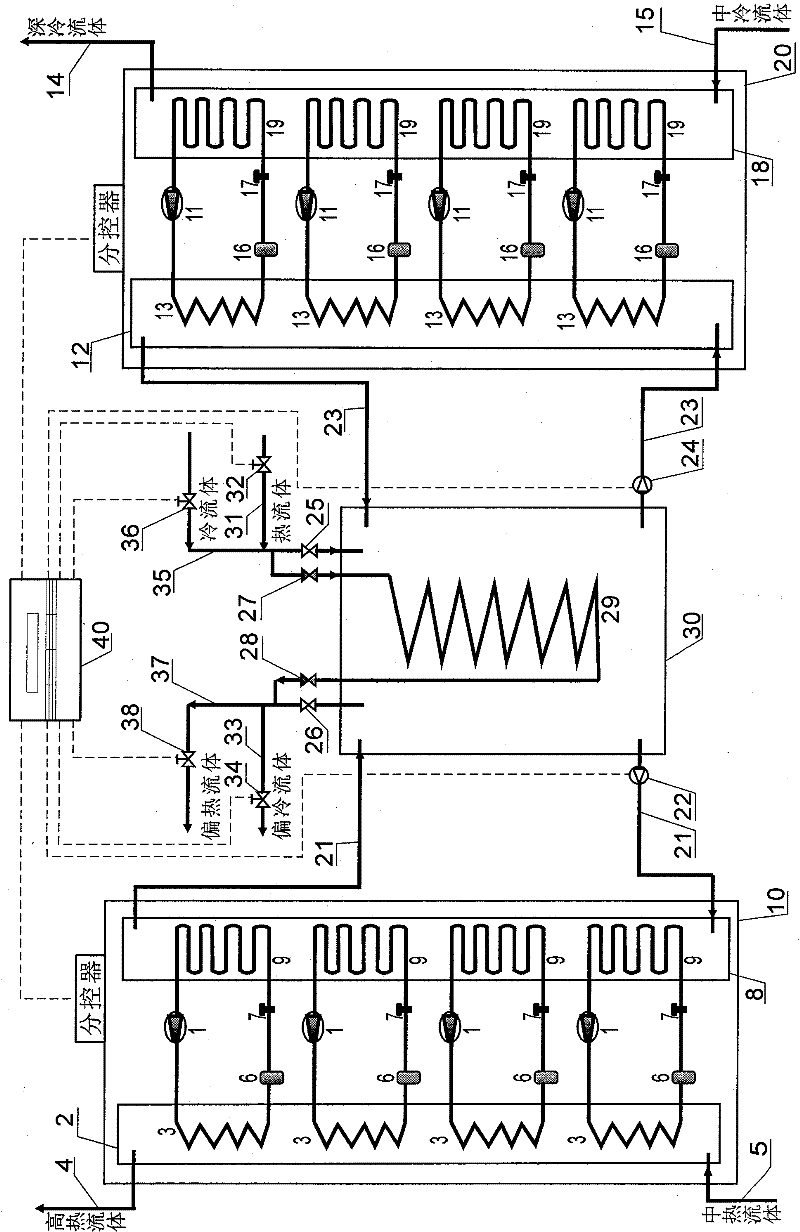

[0086] Embodiment 3: Refrigeration and heating system with four compression circuits and cold and heat source complementers. See image 3 .

[0087] image 3 It is a flow chart of the principle of the refrigeration and heating system with four compression circuits and cold and heat source complementarities. repeat. The difference is: the heating subsystem has four compression circuits, which have greater power and stronger heating capacity than the double compression circuit; the refrigeration subsystem has four compression circuits, which have larger capacity than the double compression circuit Power and stronger cooling capacity. The temperature difference between the cryogenic fluid and the high heat fluid in the whole system increases. The sub-controller of the heating subsystem regulates the working conditions of its own four compression circuits; the sub-controller of the refrigeration subsystem regulates all the working conditions of its own four compression circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com