Measuring device for temperature field of air-cooled condenser of power plant

An air-cooled condenser and measuring device technology, which is applied to measuring devices, electrical devices, thermometers, etc., can solve the problems of difficult installation and fixing, high temperature measurement costs, and increased wiring costs, and achieves low cost and improved intelligence. degree, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

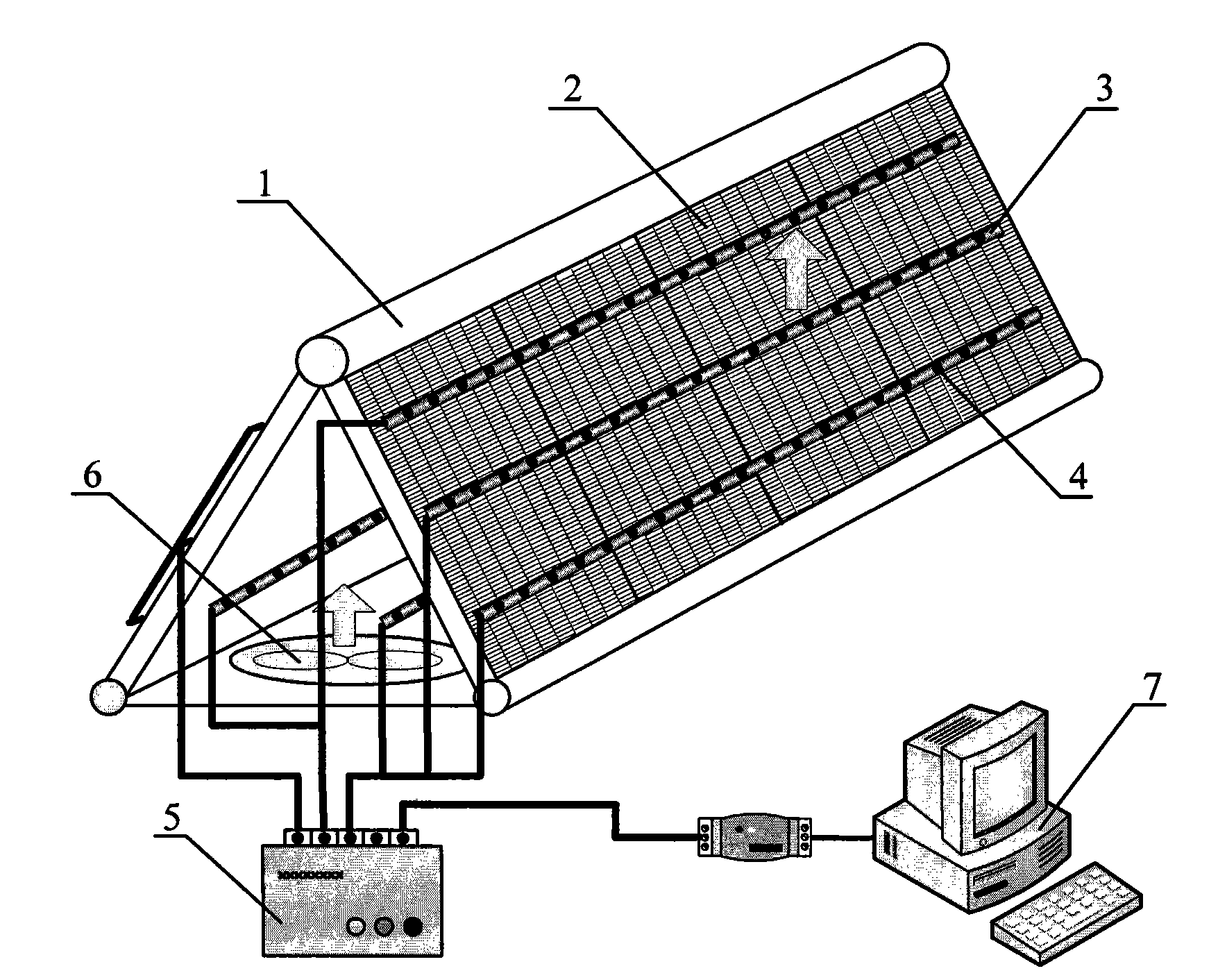

[0046] Embodiment 1: as figure 1 As shown, several temperature measuring cables 3 are respectively laid out along the inside and outside of the air-cooled radiator assembly 1 by using the temperature measuring cables 3, and the temperature measuring cables 3 are connected with the temperature collector 5, and then the temperature collector 5 is connected with the upper computer 7 phase connections. During measurement, each temperature sensor on the temperature measuring cable 3, that is, the temperature measuring point 4, will detect the temperature of the temperature measuring point 4 and upload it to the host computer 7 through the temperature collector 5 for display, storage, recording, alarm, and history. Inquiry, etc.; the host computer 7 performs operations such as setting, status detection, and reading data on all temperature collectors 5 and temperature measuring sensors; finally realizes multi-point temperature measurement on the air side of the air-cooled condenser o...

Embodiment 2

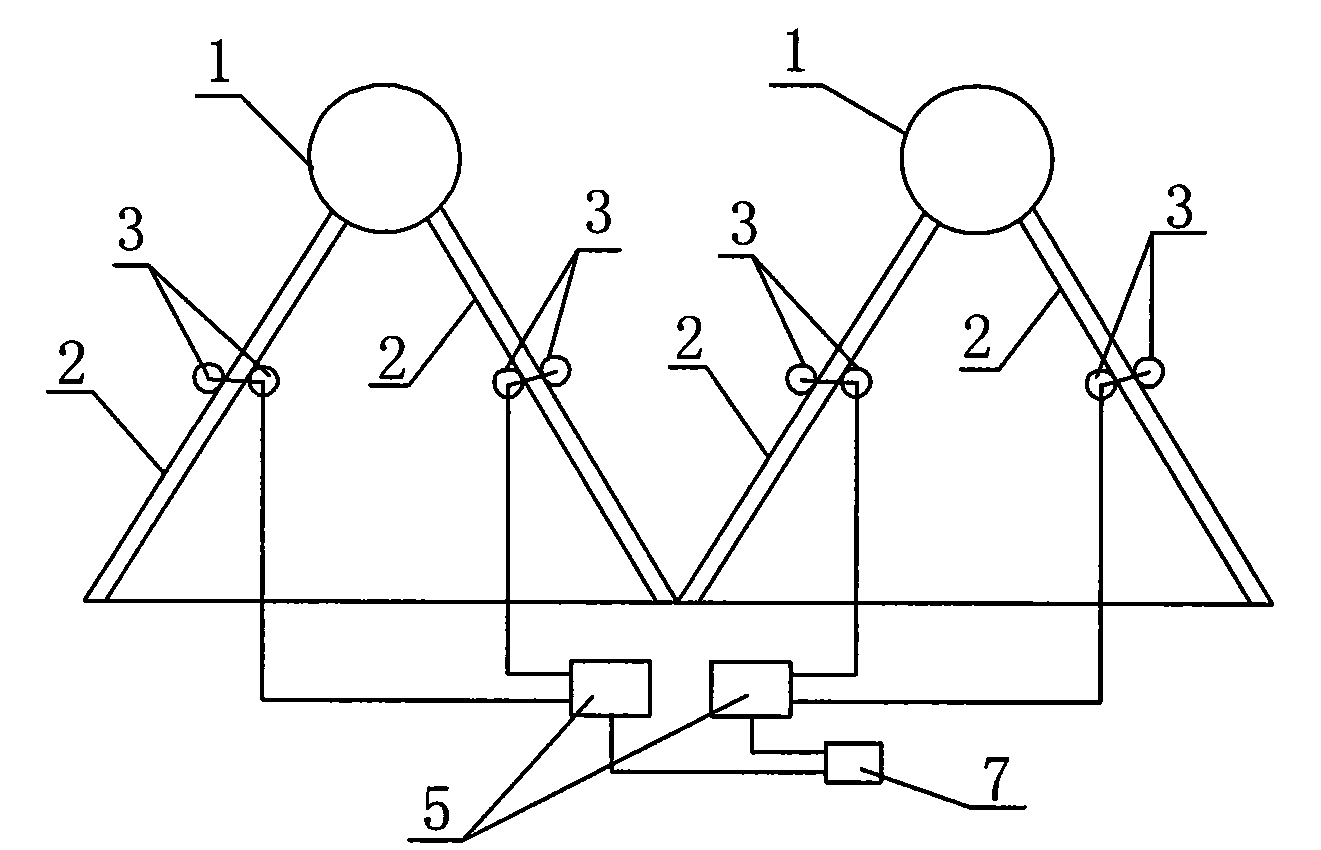

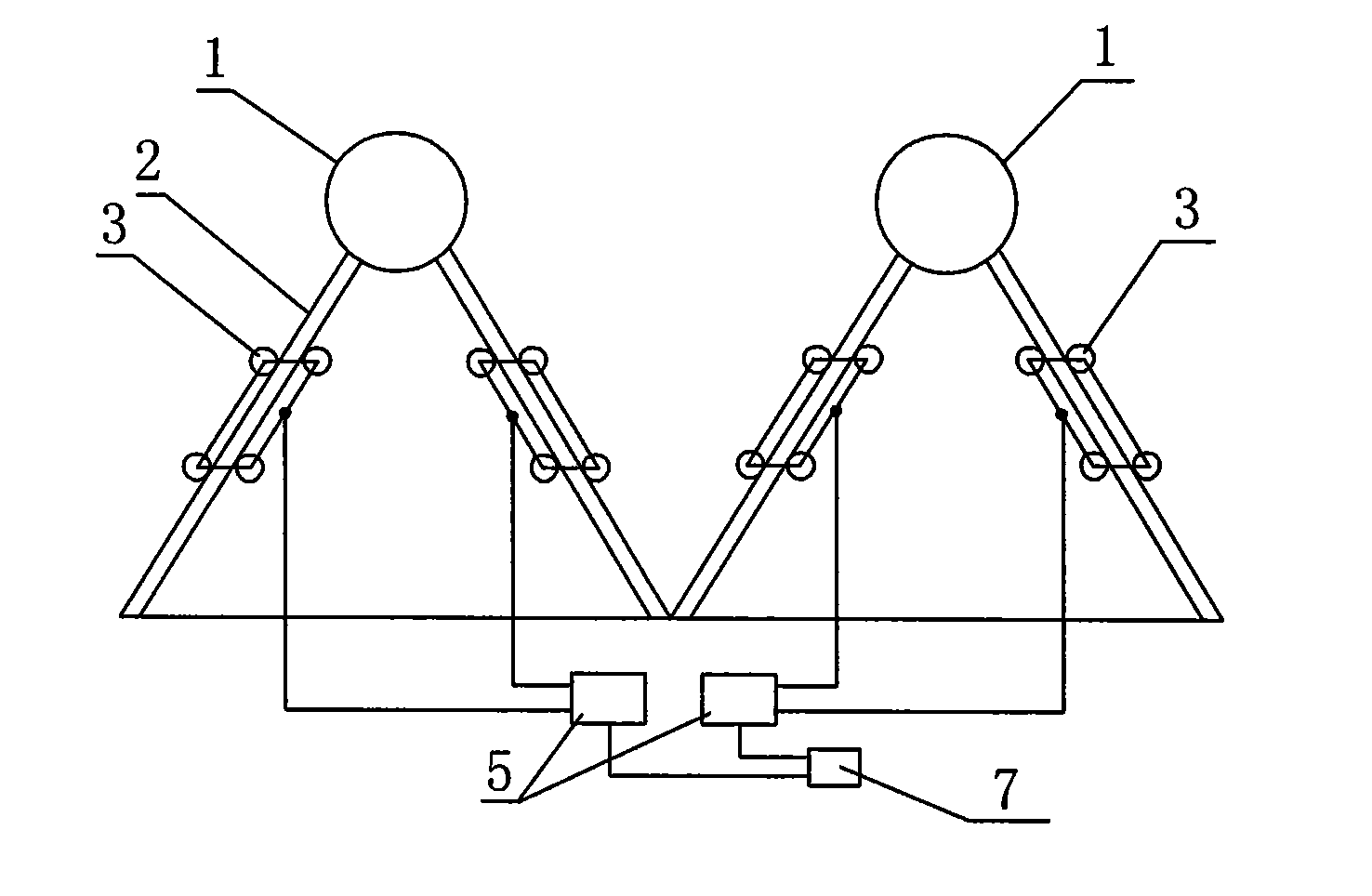

[0047] Embodiment 2: Take the 600MW generating set as an example, such as image 3 As shown, the generating set has 8 rows of air-cooled radiator assemblies 1 (only 2 groups are shown in the figure), each row of air-cooled radiator assemblies 1 has 7 fans, and the length of each row of air-cooled radiator assemblies 1 is about 90 meters. The inner side of the air-cooled radiator assembly 1 is close to the finned tube bundle 2, and two temperature measuring cables are installed, and the outer left and right sides are close to the finned tube bundle 2, and two temperature measuring cables are installed. The length of the temperature measuring cable 3 is the same as that of the air-cooled radiator assembly 1. Length, the temperature measuring cable 3 has a built-in temperature measuring point 4 (i.e. temperature sensor) every 2 meters, connects the temperature measuring cable 3 with the temperature collector 5, and then connects the temperature collector 5 with the host computer 7...

Embodiment 3

[0048] Embodiment 3, take the 200MW generating set as an example, such as figure 1 and figure 2 As shown, the generating set has 6 rows of air-cooled radiator assemblies 1 (only 2 groups are shown in the figure), and each row of air-cooled radiator assemblies 1 has 4 blowers, and the length of each row of air-cooled radiator assemblies 1 is about 40 meters; A temperature-measuring cable 3 is arranged above the outlet of the fan 6 inside the air-cooled radiator assembly 1. The temperature-measuring cable 3 is distributed with unequal temperature measuring points. The temperature measuring points are denser at the part facing the outlet of the fan 6, and sparser in other places. A temperature measuring cable 3 is arranged on the left and right sides of the air-cooling radiator assembly 1, and the temperature measuring points are equidistantly distributed. The length of the temperature measuring cable 3 is the same as that of the air-cooling radiator assembly 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com