Automatic detection device for quality of brake pad

An automatic detection device and a technology for brake pads, which are used in the exploration of optical devices, the analysis of solids using sonic/ultrasonic/infrasonic waves, and the generation of ultrasonic/sonic/infrasonic waves. Low efficiency and other problems, to achieve the effect of saving manpower and material resources, good scalability, and avoiding false detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

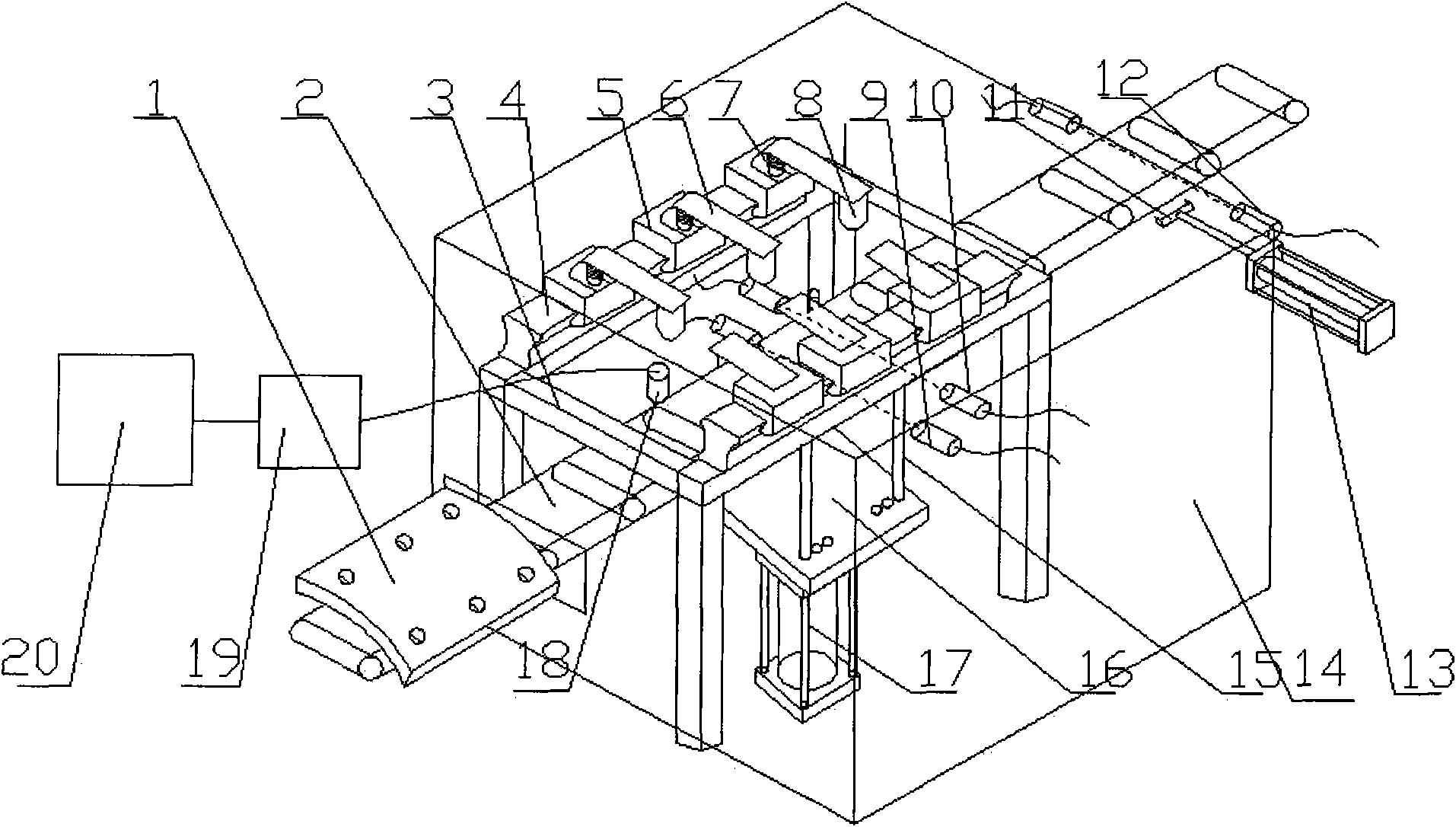

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] Principle of the present invention is:

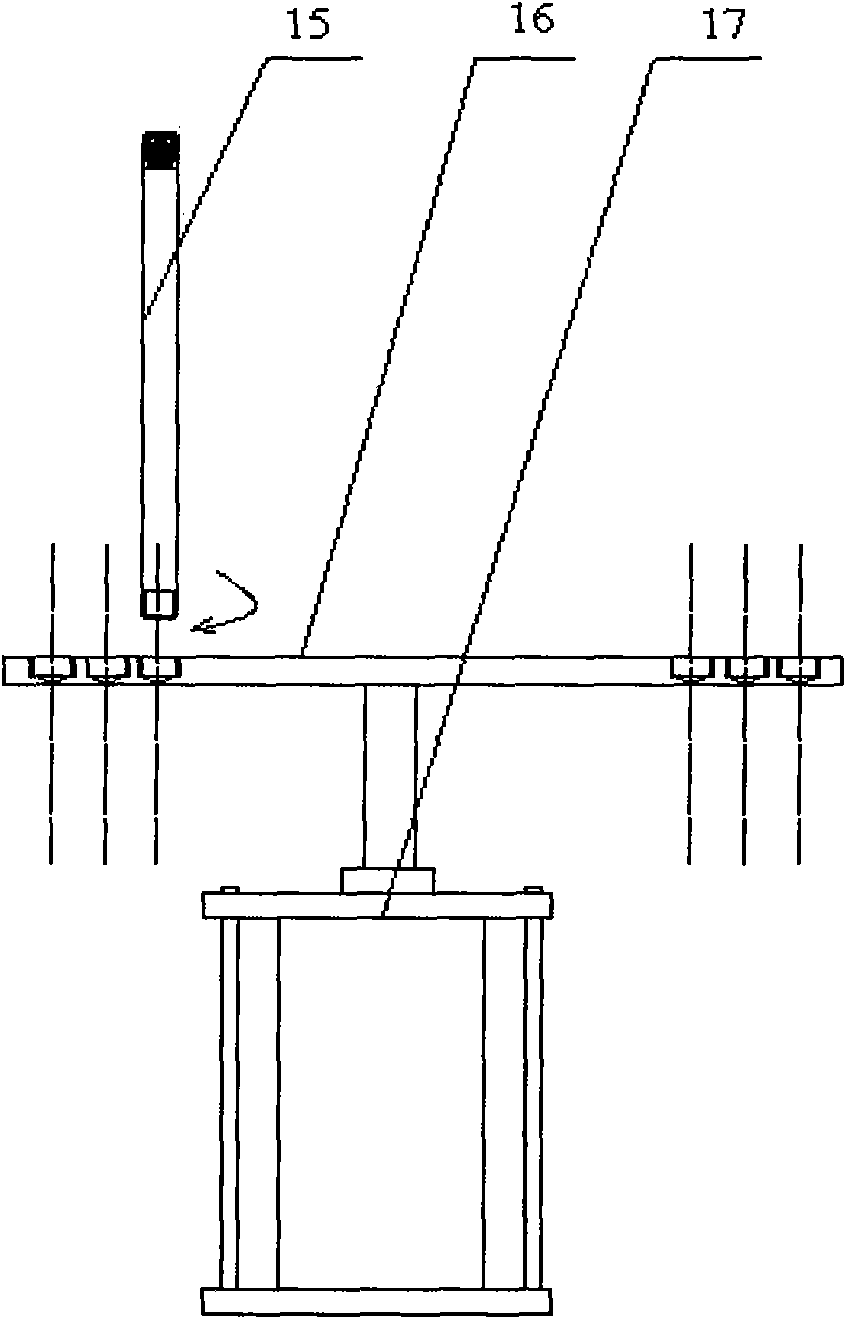

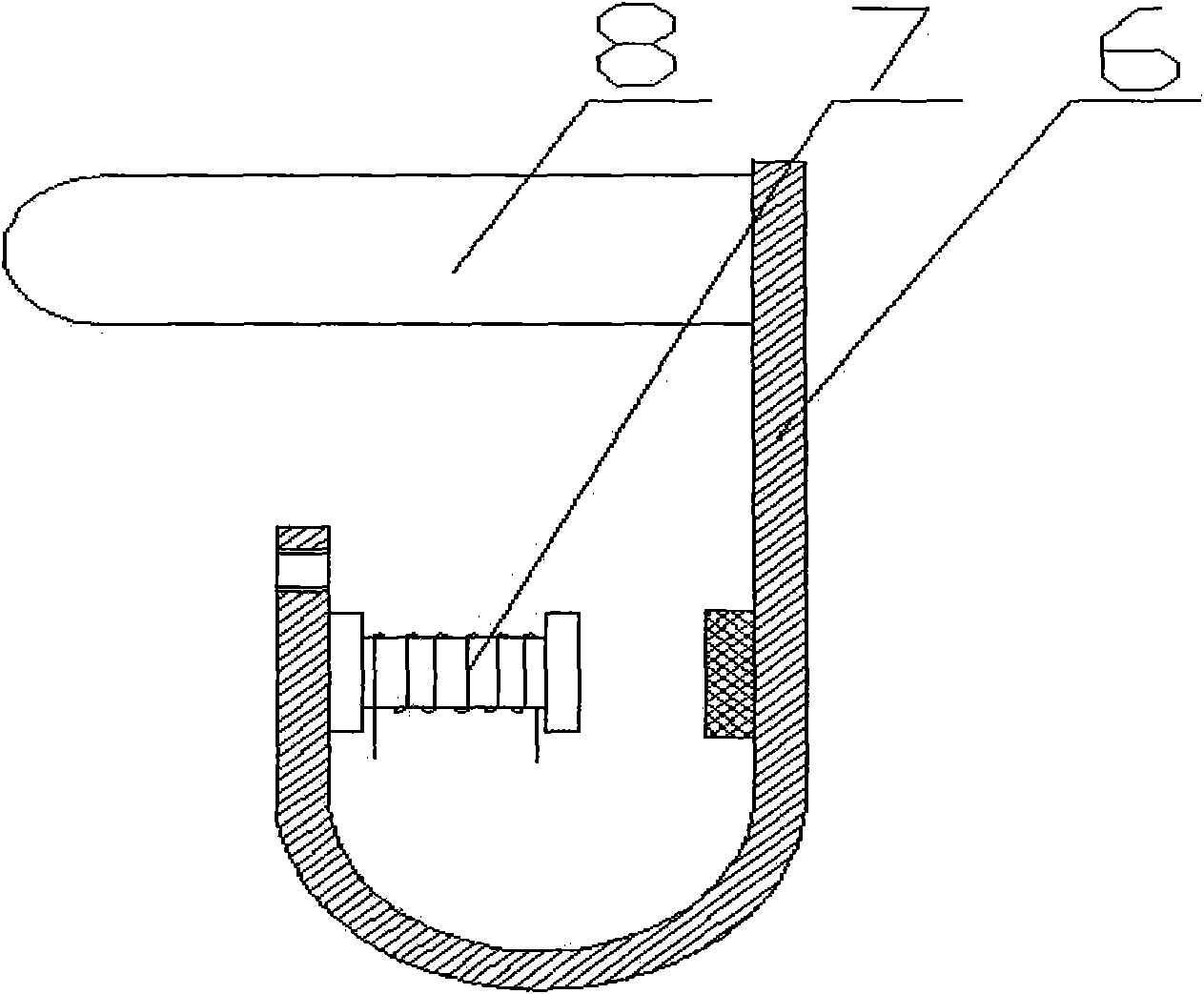

[0019] The brake pad transmission mechanism transmits the brake pads to be inspected. A soundproof box is fixed in the middle of the transmission module. The transmission mechanism transmits the brake pads to be inspected through the soundproof box. Knock at each location point, and place a pickup for collecting the sound signal of the knock in the soundproof box. The pickup is controlled by a microcontroller to collect the sound of each knock and transmit the sound signal to the computer, which processes the data and analyzes it. Determine whether the workpiece is defective. A brake pad screening module is placed horizontally at the end of the transmission mechanism to remove brake pads with defective quality.

[0020] The sound obtained by hitting the workpiece actually reflects the frequency response ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com