Circuit board with conductive structure

A heat-conducting structure and circuit board technology, which can be used in circuits, multi-layer circuit manufacturing, printed circuits connected with non-printed electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

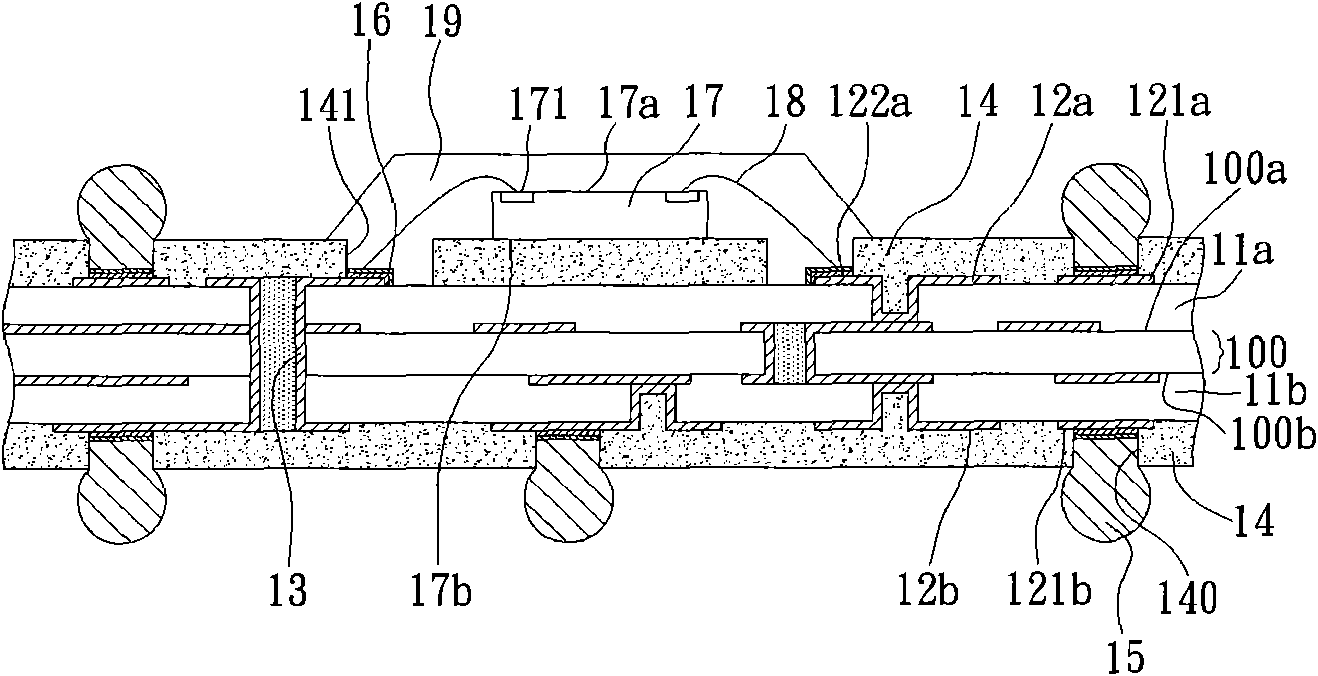

[0055] see Figure 3A to Figure 3F As shown in FIG. 2 , it is a schematic cross-sectional view illustrating the manufacturing method of the circuit board with the heat conduction structure according to the first embodiment of the present invention.

[0056] Such as Figure 3A and Figure 3A' As shown, at first, a carrier board is provided, and the carrier board is an insulating board or a circuit board 20 with lines 201. The surface 20a and the second surface 20b, and at least one through hole 200 penetrating through the first surface 20a and the second surface 20b, in the through hole 200 is formed a non-full plating metal conduction that is not electrically connected with the circuit 201 The first heat conduction structure 21a of the through hole (such as Figure 3A shown), or the first heat conduction structure 21a' that is fully plated with metal via holes (such as Figure 3A' shown), the first heat conduction structure 21a, 21a' is composed of the heat conduction hole...

no. 2 example

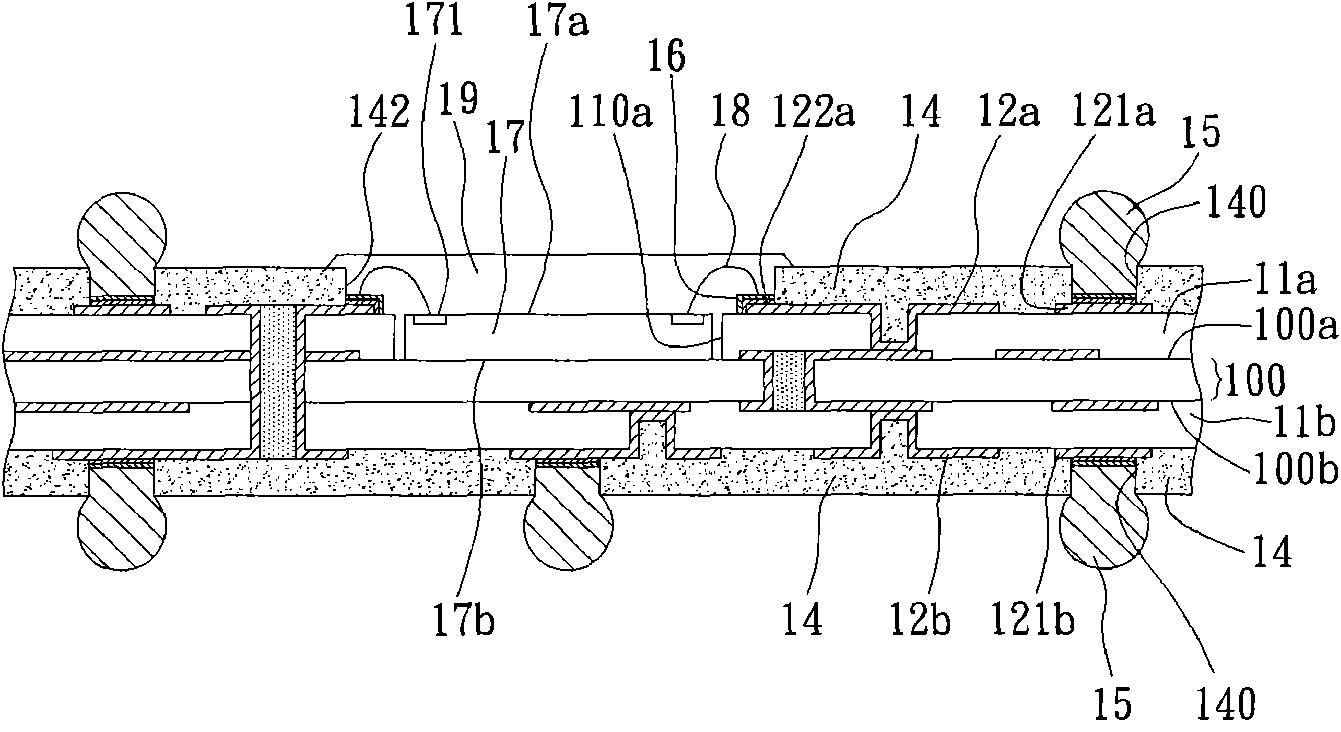

[0065] see Figure 4A and Figure 4B , is another embodiment of the present invention, wherein the Figure 4A What is shown is different from the previous embodiment in that the first and second heat conducting surfaces further include a metal layer, and the Figure 4B Shown with Figure 4A The difference is that the second heat conduction structure is a solid heat conduction blind hole.

[0066] Such as Figure 4A As shown, a metal layer 202 is formed on the surface of the circuit 201 on the first surface 20a and the second surface 20b of the circuit board 20, and covers the first and second heat conducting surfaces 211a, 212a of the first heat conducting structure 21a, so that the For example, the first and second heat conduction surfaces 211a, 212a at both ends of the heat conduction hole 210a of the non-full plated metal via hole are covered by the metal layer 202, so as to increase the contact area between the first heat conduction structure 21a and the semiconductor ...

no. 3 example

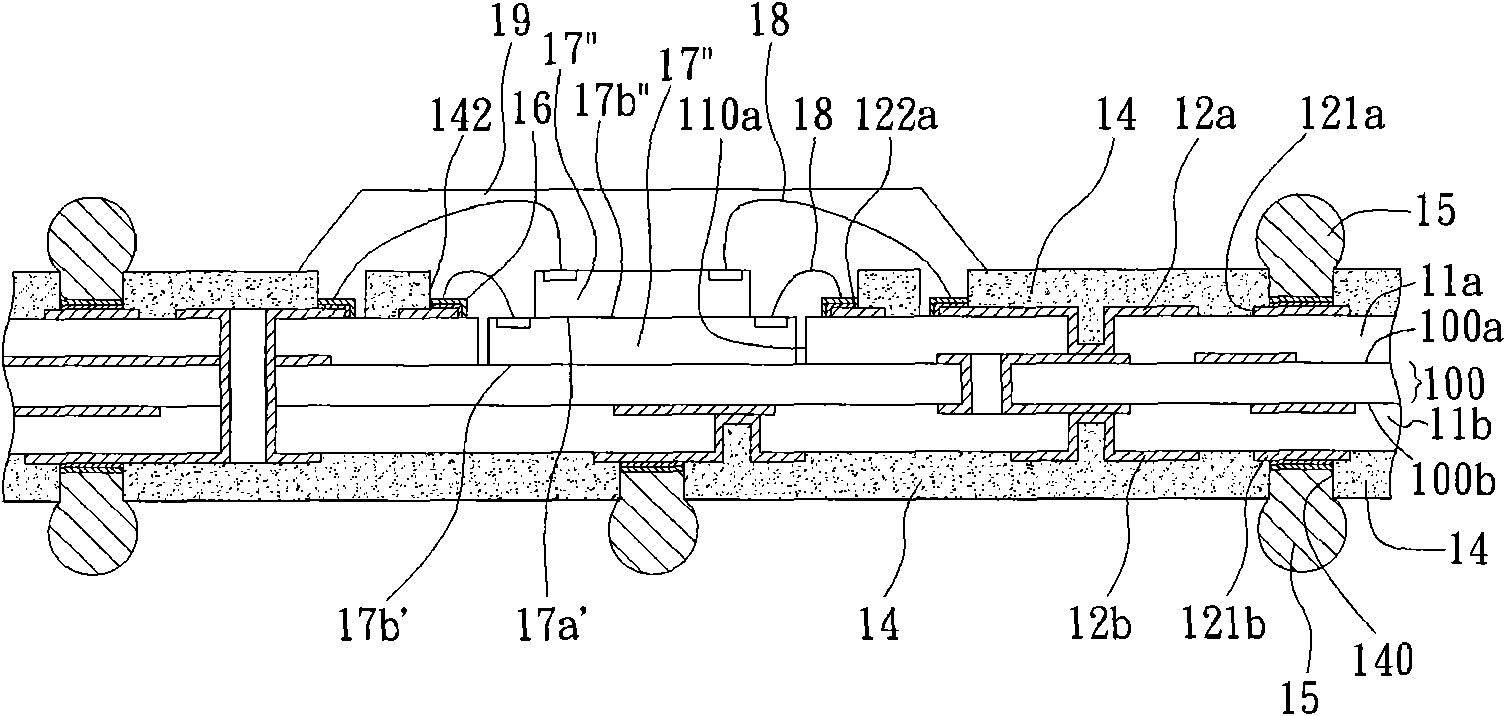

[0069] see Figure 5A to Figure 5C , is another embodiment of the present invention, the difference from the previous embodiment is that the first heat conduction structure is a solid heat conduction blind hole or a hollow heat conduction blind hole, and the second heat conduction structure is also a solid heat conduction blind hole or a hollow Thermally conductive blind vias.

[0070] Such as Figure 5AAs shown, the heat conduction hole 210a" in the circuit board 20 is a hollow heat conduction blind hole, and the second heat conduction structure 21b is also a hollow heat conduction blind hole, so that the heat conduction hole 210a" and the second heat conduction structure 21b are of the same type structure to simplify the manufacturing process.

[0071] Such as Figure 5B As shown, the heat conduction hole 210a" in the circuit board 20 is a hollow heat conduction blind hole, and the second heat conduction structure 21b' is a solid heat conduction blind hole, so that the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com