Edible fungus liquid inoculator

A technology of inoculation machine and edible fungus, which is applied in the fields of application, horticulture, botanical equipment and methods, etc. It can solve the problems of not developing liquid inoculation machinery and staying in manual inoculation, etc., and achieves easy connection to production lines, easy operation, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

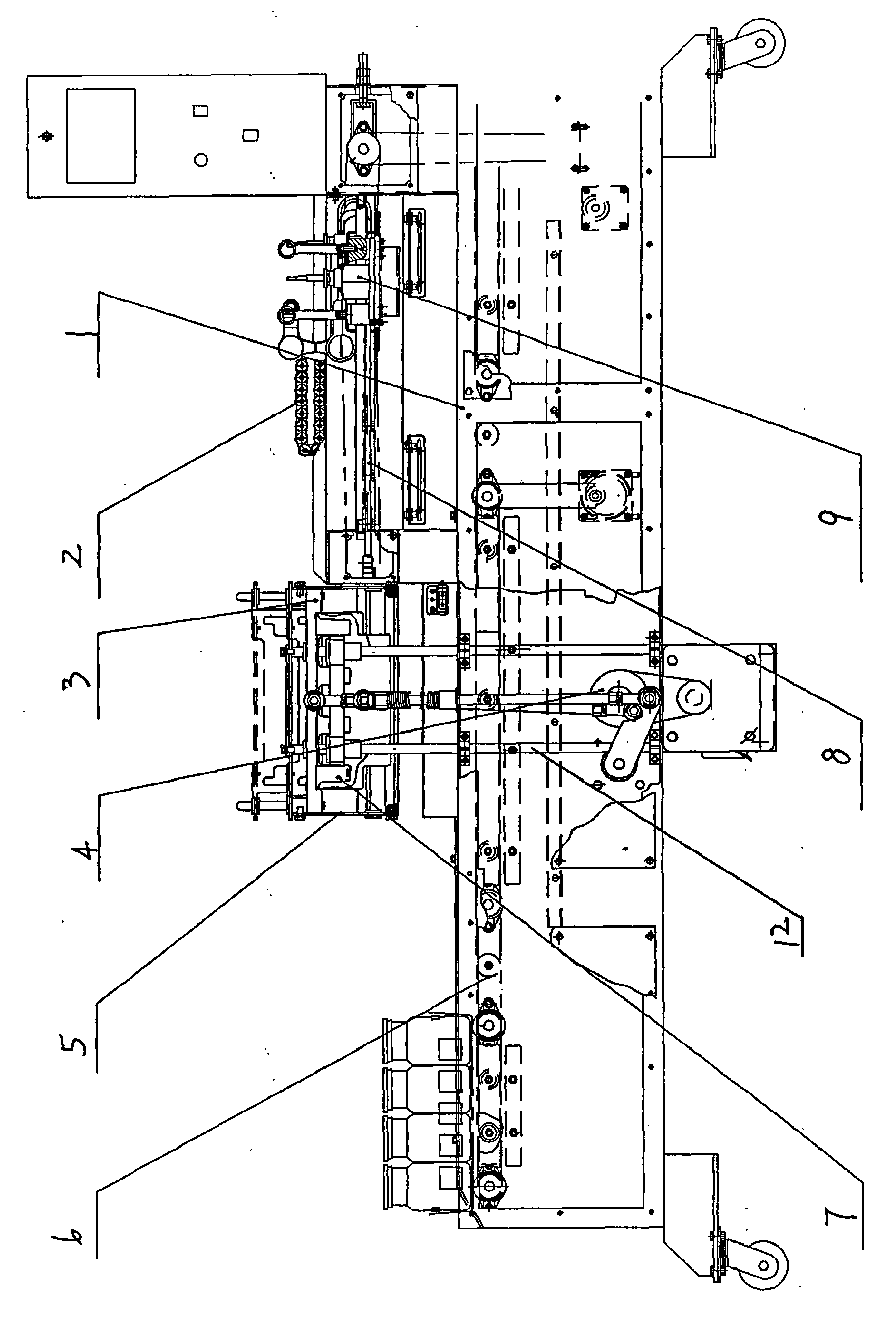

[0052] Example 1. refer to Figure 1-12 . A kind of edible mushroom liquid inoculation machine, it comprises frame 1 and is located at the conveying roller table 6 on frame 1, is also provided with pressing bottle mechanism 5, uncapping mechanism 3, capping mechanism 7 and inoculation mechanism on frame 1 piping device 8;

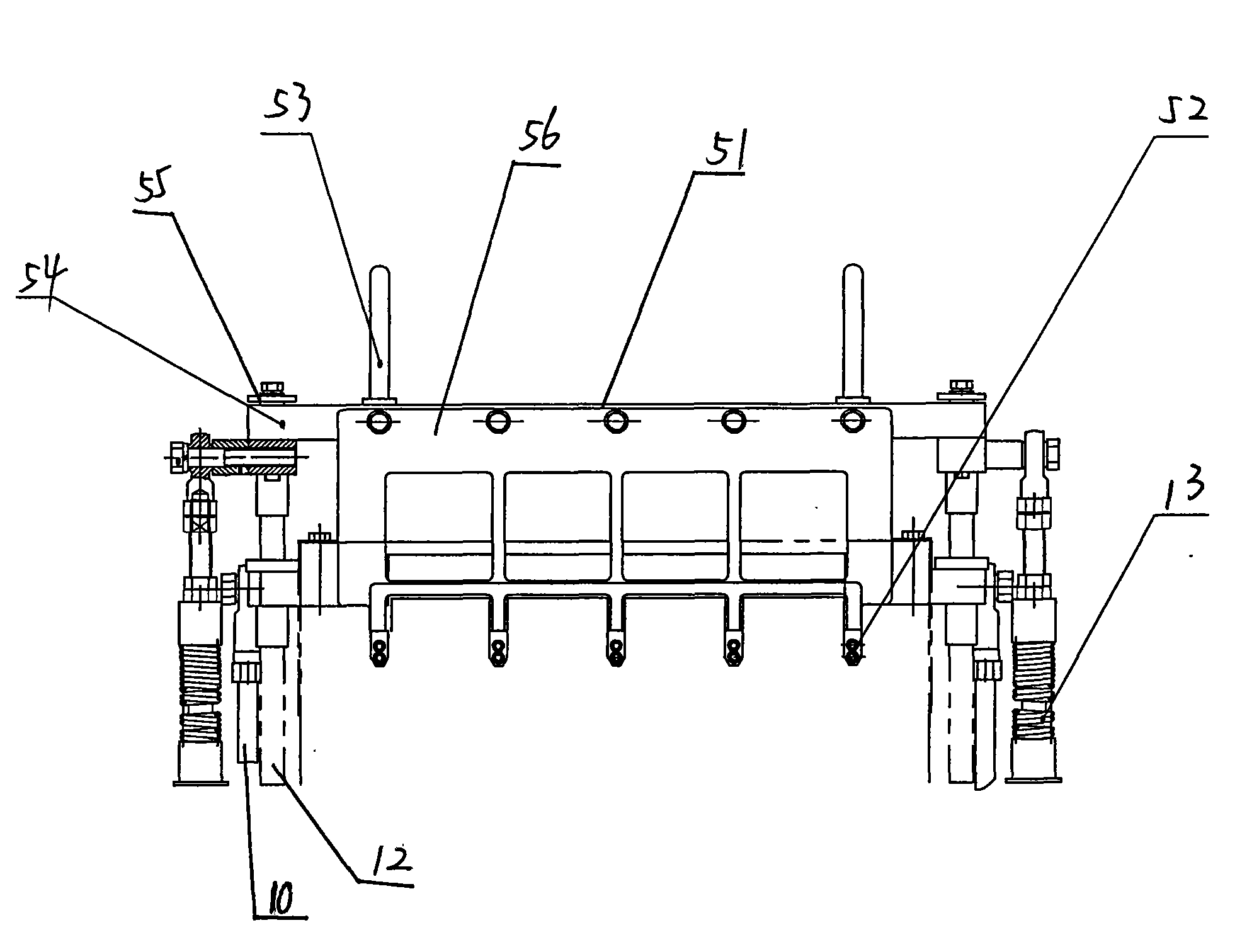

[0053] The bottle pressing mechanism 5 includes a bottle pressing bracket 51, a plurality of presser feet 52 are connected to the bottom of the bottle pressing bracket 51, and several capping mechanism guide rods 53 are fixedly arranged on the top of the bottle pressing bracket 51;

[0054] Described cap opening mechanism 3 comprises lifting foot support 31, and lifting foot support 31 is located at the below of bottle pressing support 51, and lifting foot support 31 is provided with several lifting feet 32, and the lifting foot between adjacent lifting feet 32 A top foot channel 33 is provided on the bracket 31;

[0055] The capping mechanism 7 include...

Embodiment 2

[0058] Example 2. refer to Figure 2-3 . In the edible mushroom liquid inoculation machine described in embodiment 1, the described bottle pressing bracket 51 includes front and rear crossbeams 54, which are connected by connecting plates 55 between the front and rear crossbeams 54, and the front and rear crossbeams 54 are fixedly provided with front frame plates 56 and rear Frame plate 57, described capping mechanism guide bar 53 is fixedly arranged on front and back crossbeam 54 upper ends, and described presser foot 52 is fixed on the lower end of front frame plate 56 and rear frame plate 57; Described lifting foot support 31 is located at Below the front and rear beams 54 .

Embodiment 3

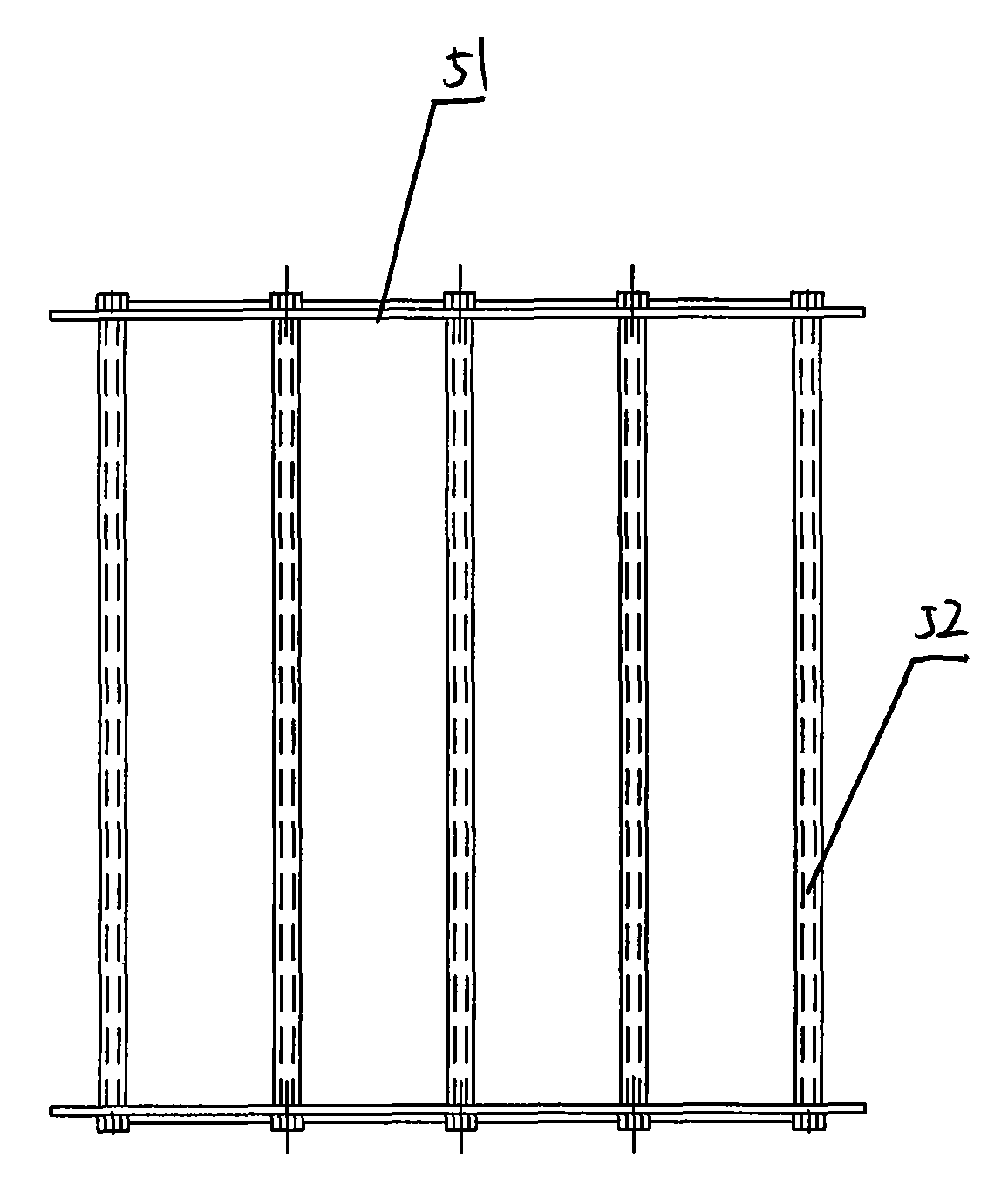

[0059] Example 3. refer to Figure 4 . In the edible mushroom liquid inoculator described in embodiment 1 or 2, the middle part of the presser foot 52 that is located on the rear frame plate 57 is a bent structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com