High-speed dumpling making machine and dumpling making method

A dumpling, high-speed technology, applied in baking, dough processing, food science and other directions, can solve problems such as high cost, blackening of dumplings, easy breakage, etc., to solve the problem of breakage, shape specification, and eliminate broken corners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

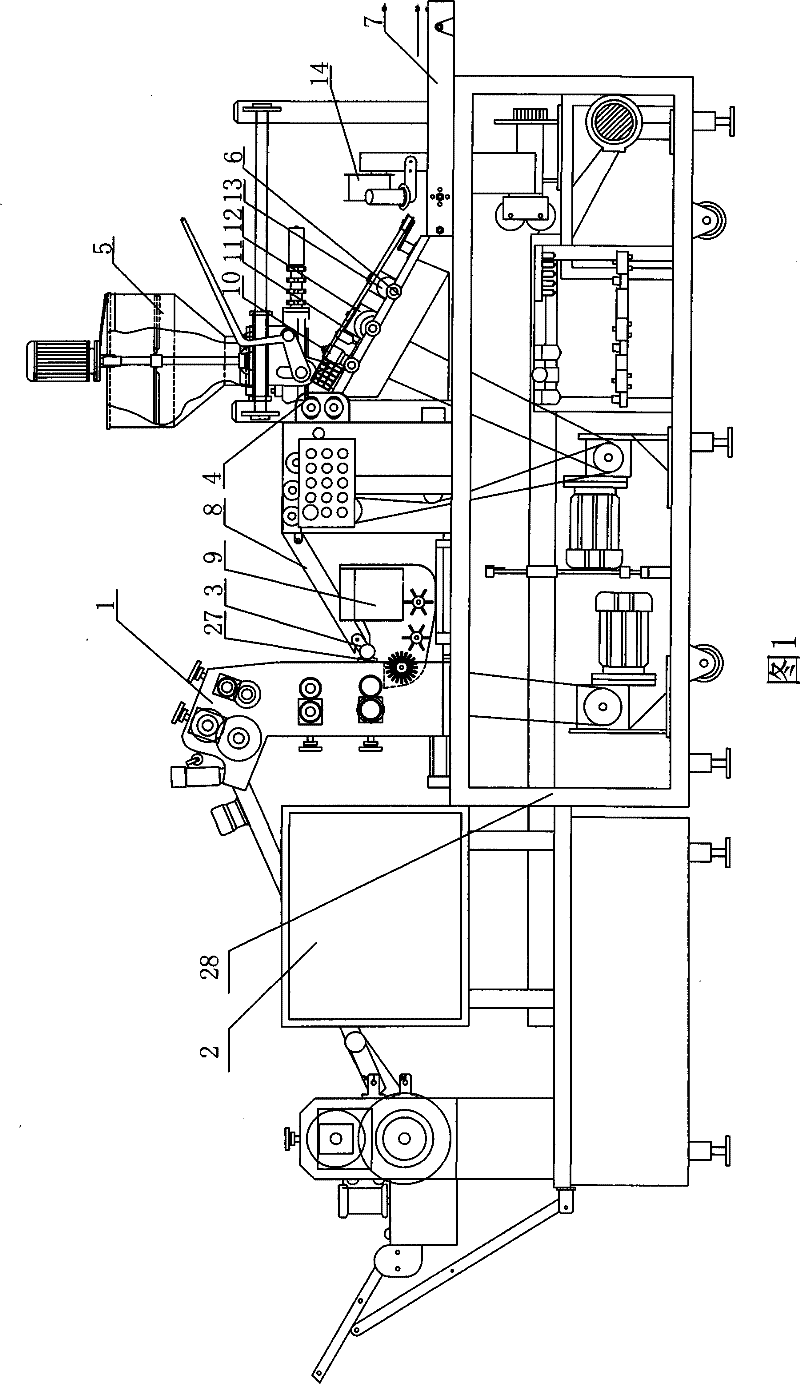

[0032] The high-speed wrapping dumpling machine comprises: a noodle pressing mechanism 1 installed on the fuselage 28, a stuffing device 5 is installed above the outlet of the noodle pressing mechanism, and a separate filling device is installed below the filling device. The molding mechanism 6.

Embodiment 2

[0034] The high-speed wrapping dumpling machine is composed of: a noodle pressing mechanism 1 with a controller 2 installed on the fuselage 28, a transmission mechanism 3 is provided at the rear of the noodle pressing mechanism, and a puller is installed on the outlet side of the transmission mechanism. Stretching die 4, above the stretching die, a stuffing device 5 is correspondingly installed, and a separate forming mechanism 6 is installed below the stuffing device.

Embodiment 3

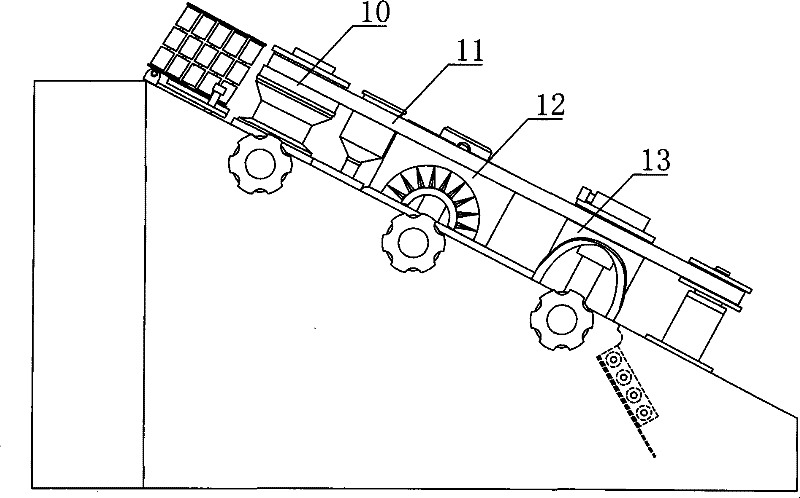

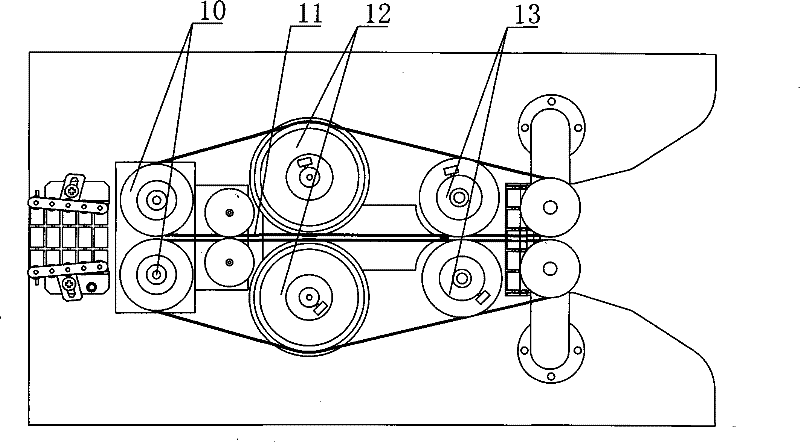

[0036] In the described high-speed wrapping dumpling machine, the separate forming mechanism includes a kneading die 10, the kneading die is connected to the forming die 12 by a traction belt 11, and the forming die is connected to a cutting die 13 by a traction belt, so The rear side of the cutting die described above is equipped with an excess edge processing mechanism 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com