Method for reducing casting defect of automobile brake caliper body

A technology for casting defects and automobile braking, applied in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of rising scrap rate, small process adaptability, irregular shape crystals, etc., to reduce difficulty and production costs. , the effect of reducing casting defects and broadening the control range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention are provided in conjunction with the accompanying drawings, and the present invention can be more clearly explained by the following embodiments:

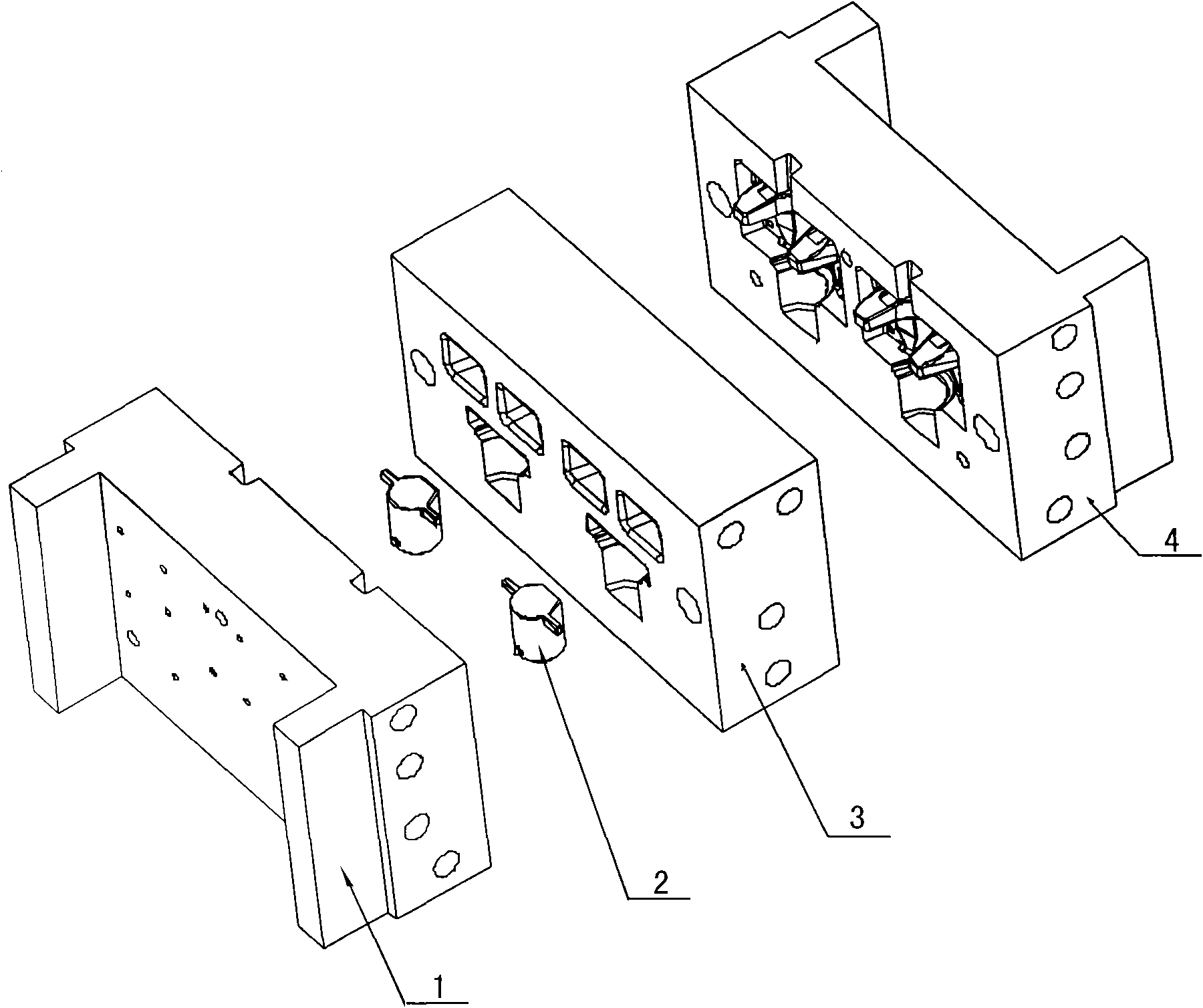

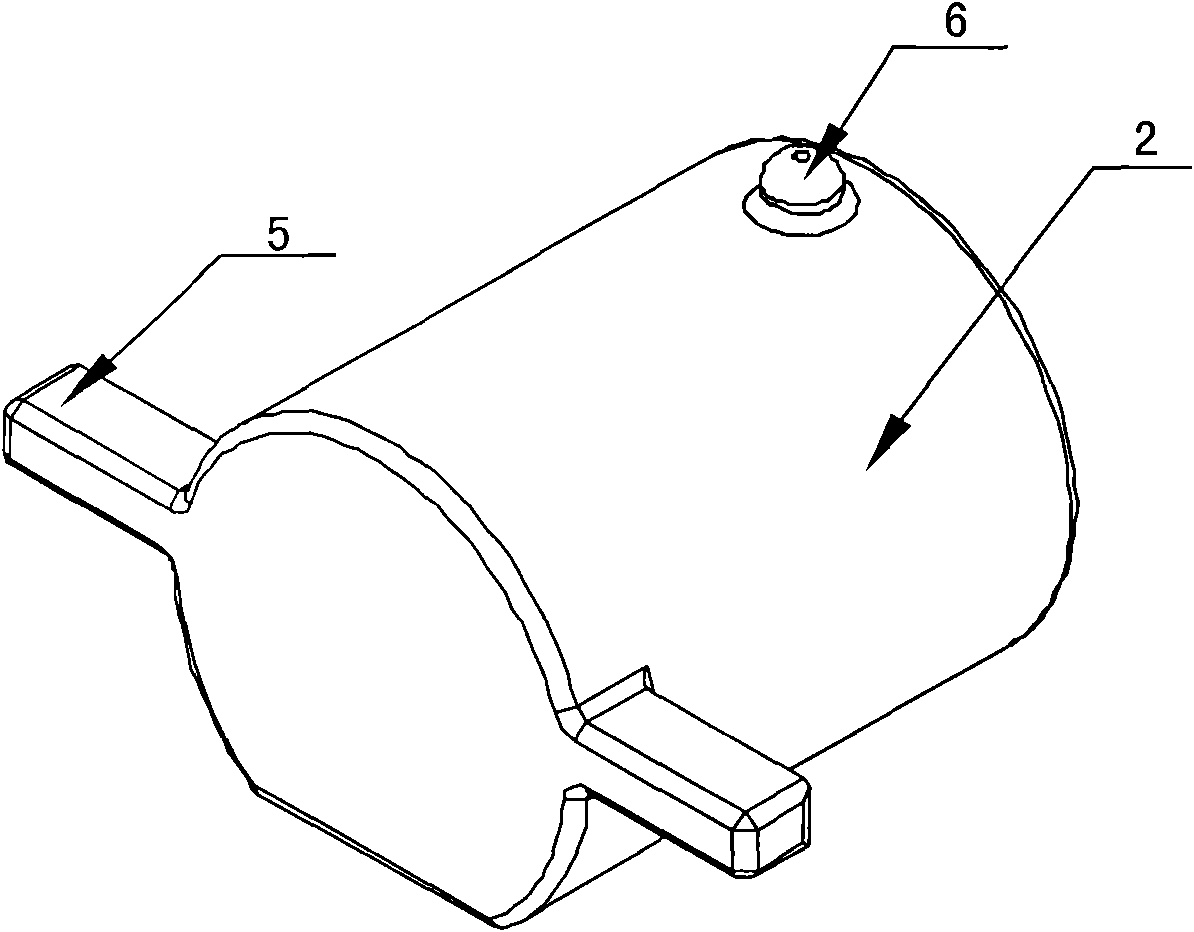

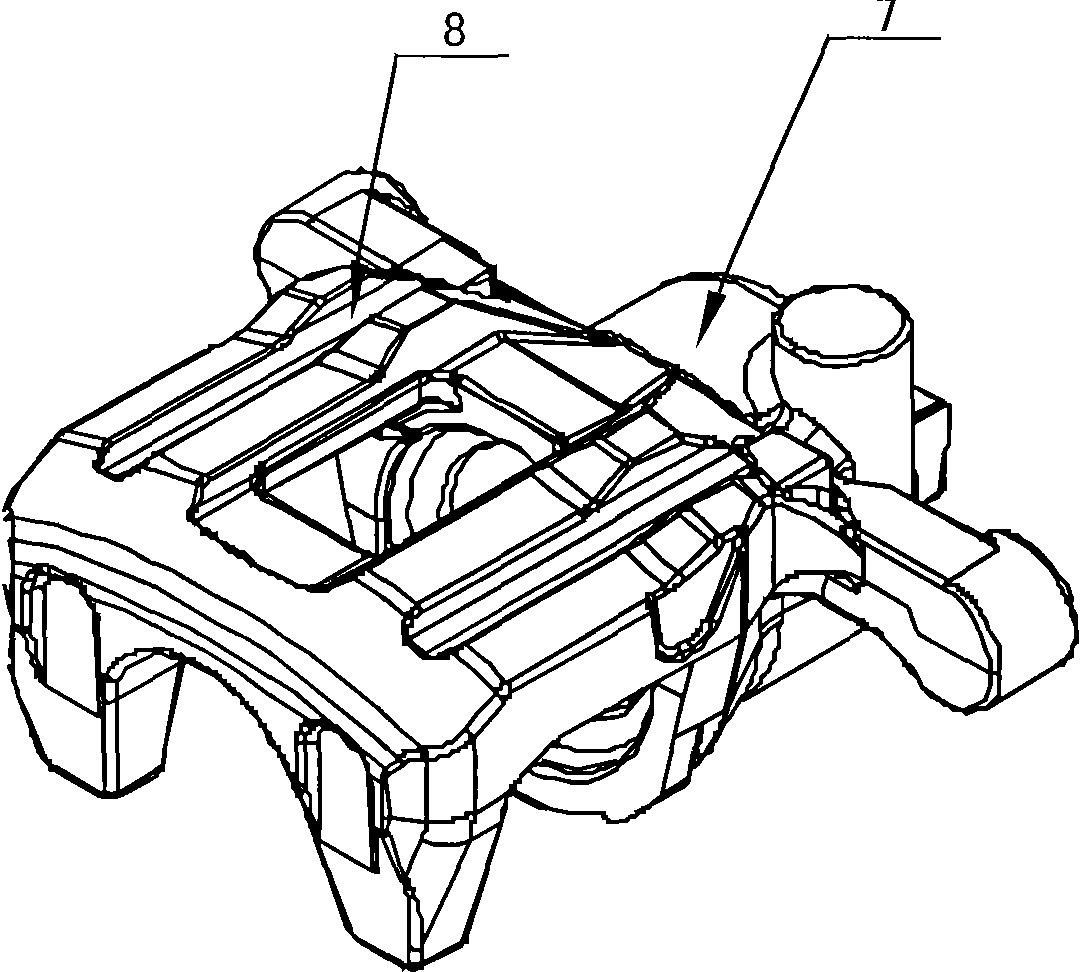

[0015] Such as figure 1 , 2 , 3, a method for reducing casting defects of automobile brake caliper body, the cavity of the brake caliper body is located in the core box movable mold B4, the brake caliper body has hot joints 8, in order to make the hot joints 8 first solidify, The cold iron 2 is arranged between the core box movable mold A1 and the fixed mold 3 before the pouring of the filled molten iron. Under cold working, it first solidifies, and the liquid shrinkage and solidification shrinkage that occurs during the solidification process are fully replenished from the riser through the feeding channel, and the shrinkage cavity is finally moved into the riser to achieve the reduction of casting defects of the automobile brake caliper.

[0016] image 3 As shown, it can be seen tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com