Gas generator for heating asphalt aggregate

A technology for generating device and gas, which is applied in the combustion of block fuel and liquid fuel, the combustion of block fuel and gaseous fuel, the combustion of block fuel and powder fuel, etc., which can solve the problem of unsafe storage and transportation, Large pollution, insufficient combustion and other problems, to achieve the effect of good combustion effect, good cost performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

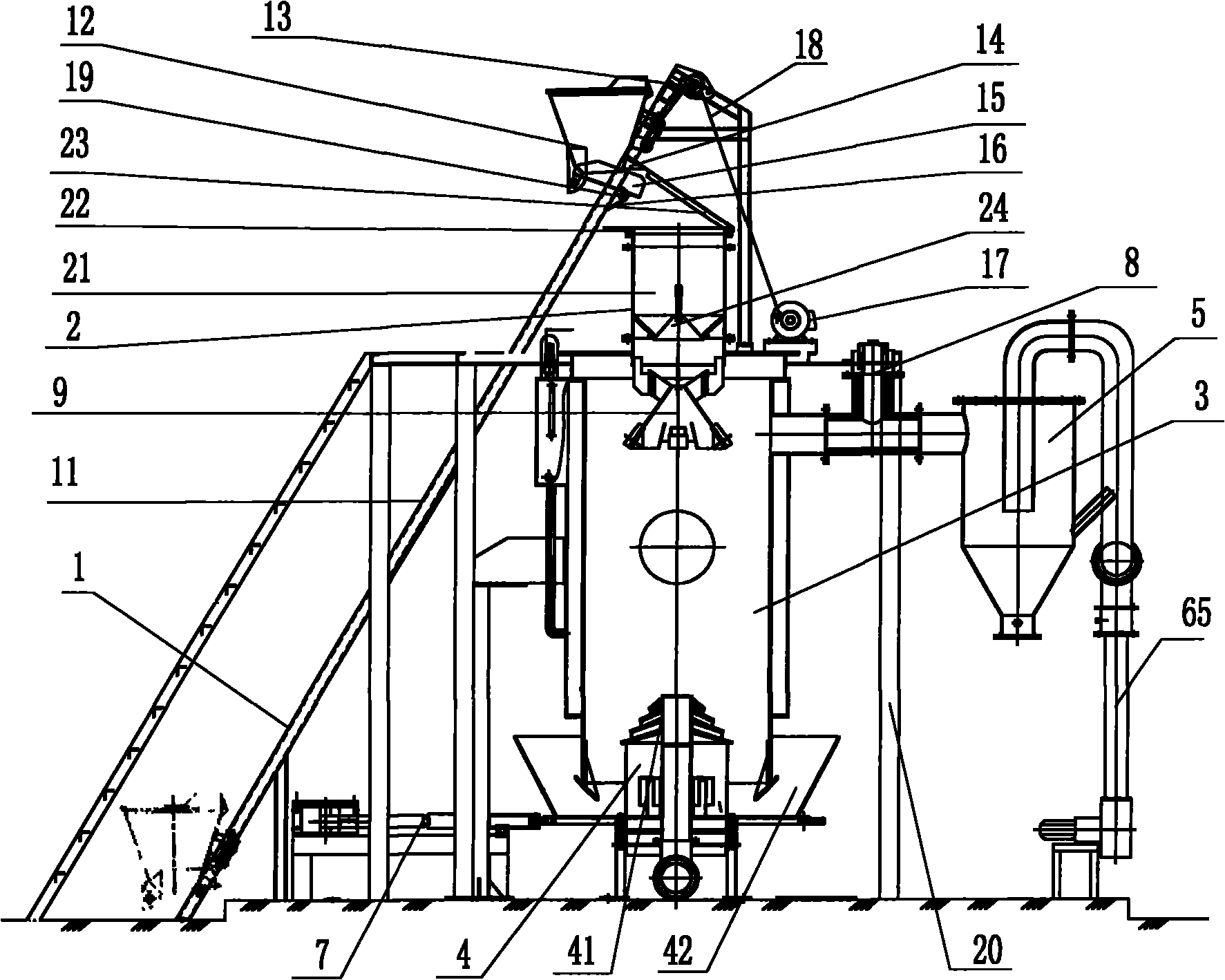

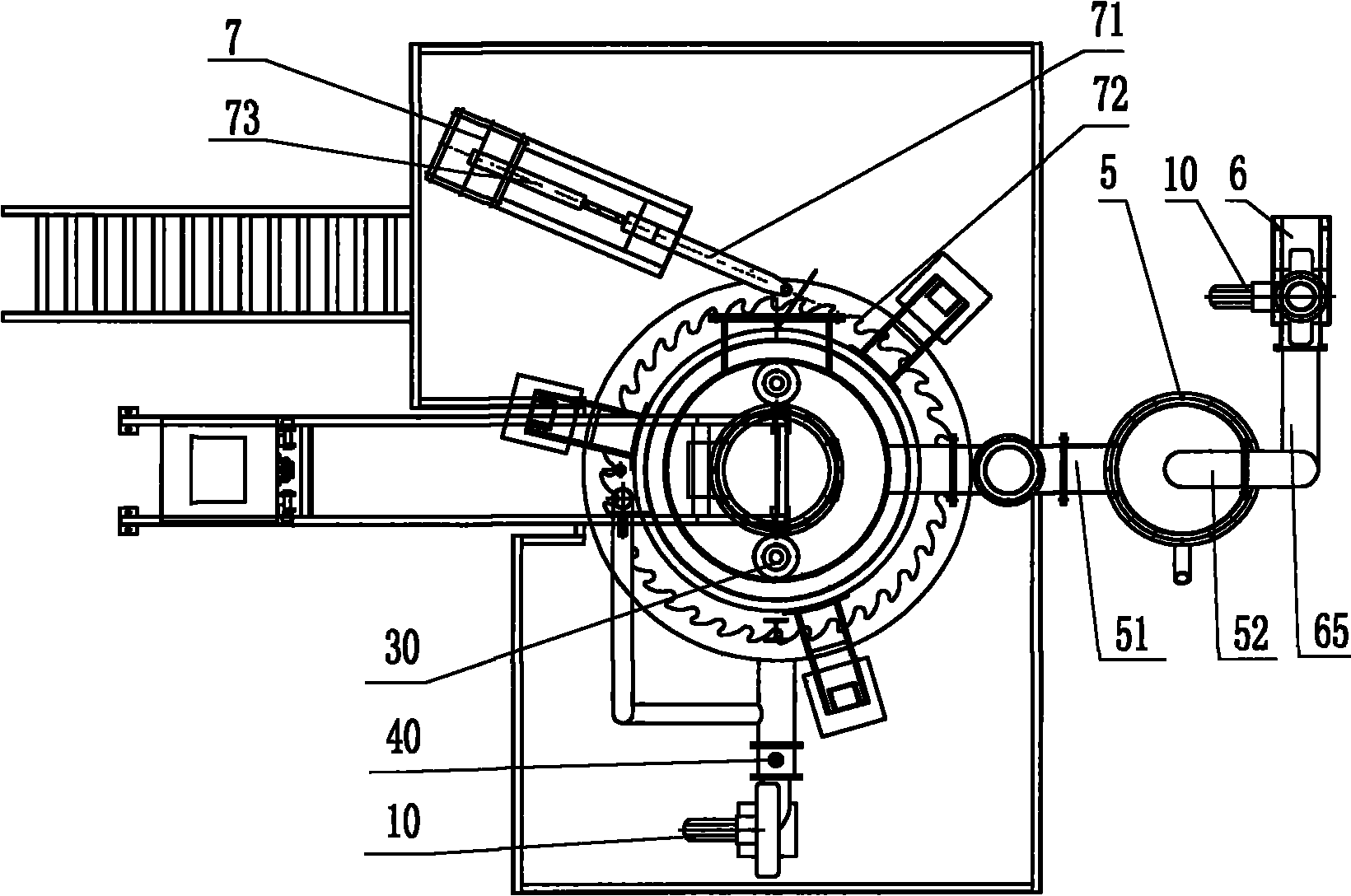

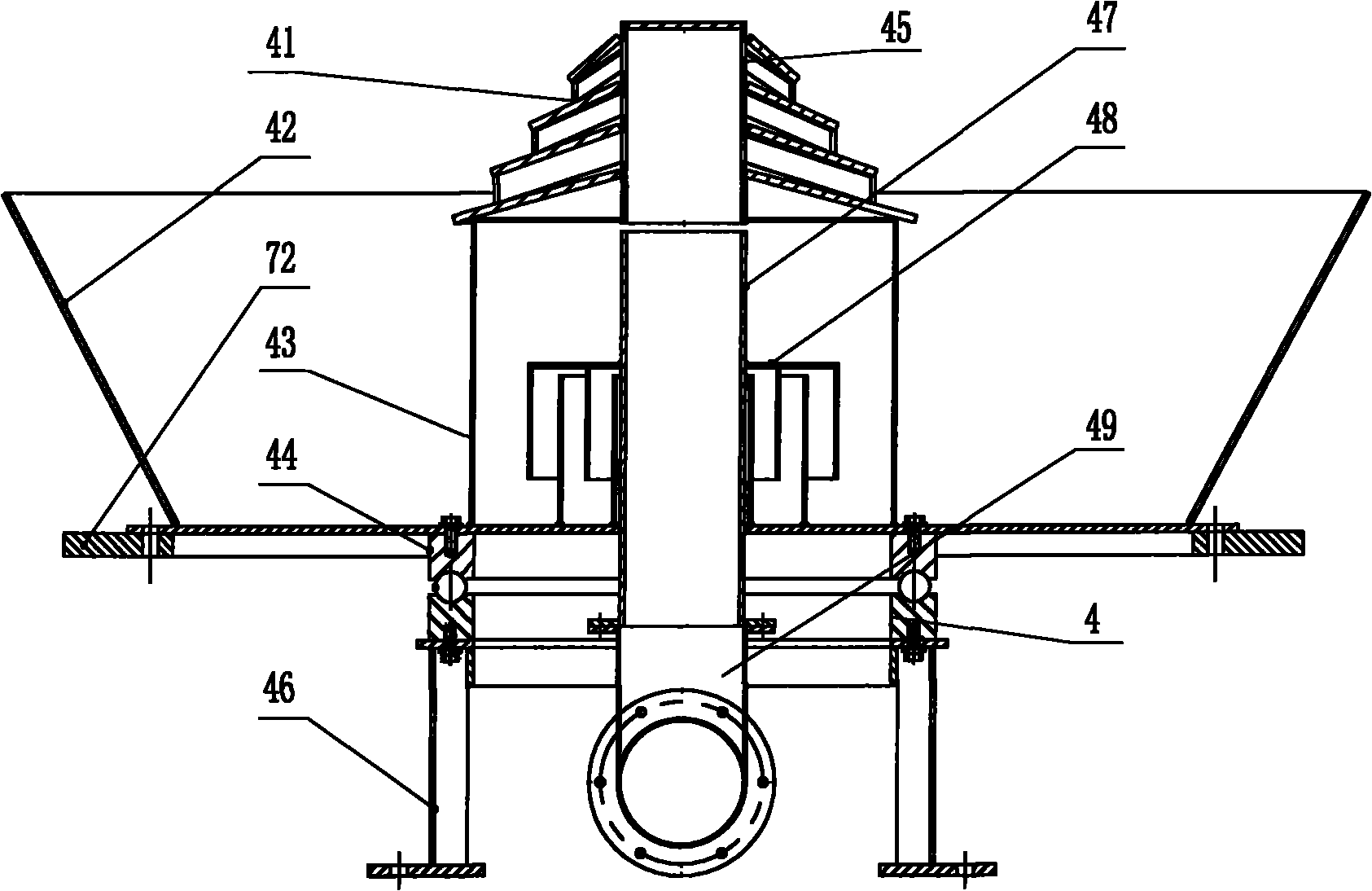

[0032] by attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 As shown, a gas generating device for heating asphalt aggregates includes a feeding mechanism 1, a water-sealed bell mechanism 2, a furnace body 3, an ash tray 4, a dust collector 5, a burner 6, and a transmission mechanism 7. Coal device 9; feeding mechanism 1 includes a lifting frame 11 welded by channel steel, two parallel and inclined channel steel grooves are opposite to each other, used as a track for the hopper 12 to run, the upper part of the channel steel is provided with a brake groove 16, and the hopper 12 goes up When reaching the top of the lifting frame 11, the stopper 19 at the bottom of the hopper 12 is stuck in the braking groove 16, the bottom of the hopper 12 is provided with a discharge chute 15 and a shift fork 14, the top of the lifting frame 11 is provided with a pulley 13, and the wire rope 18 passes through the pulley 13 One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com