Welding line ray detector of adapter tube and safety end of nuclear reactor pressure vessel

A pressure vessel, radiographic detection technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems affecting the smoothness of the motion of the airbag assembly, the unbalanced load-bearing capacity of the front and rear ends of the guide rail, and the heavy weight of a single airbag assembly, and achieves difficulty in crawling. Phenomenon, small starting resistance, small effect of friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

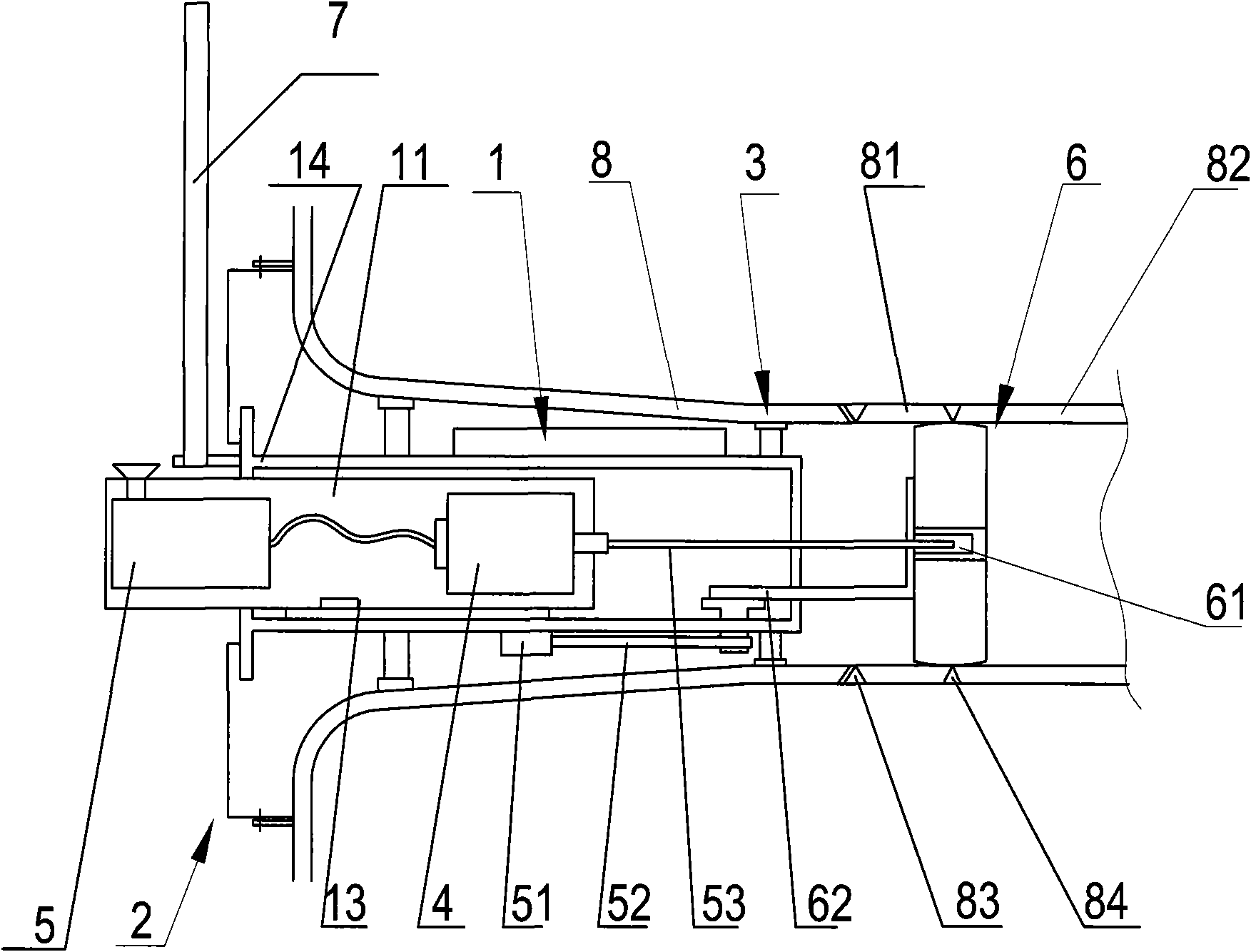

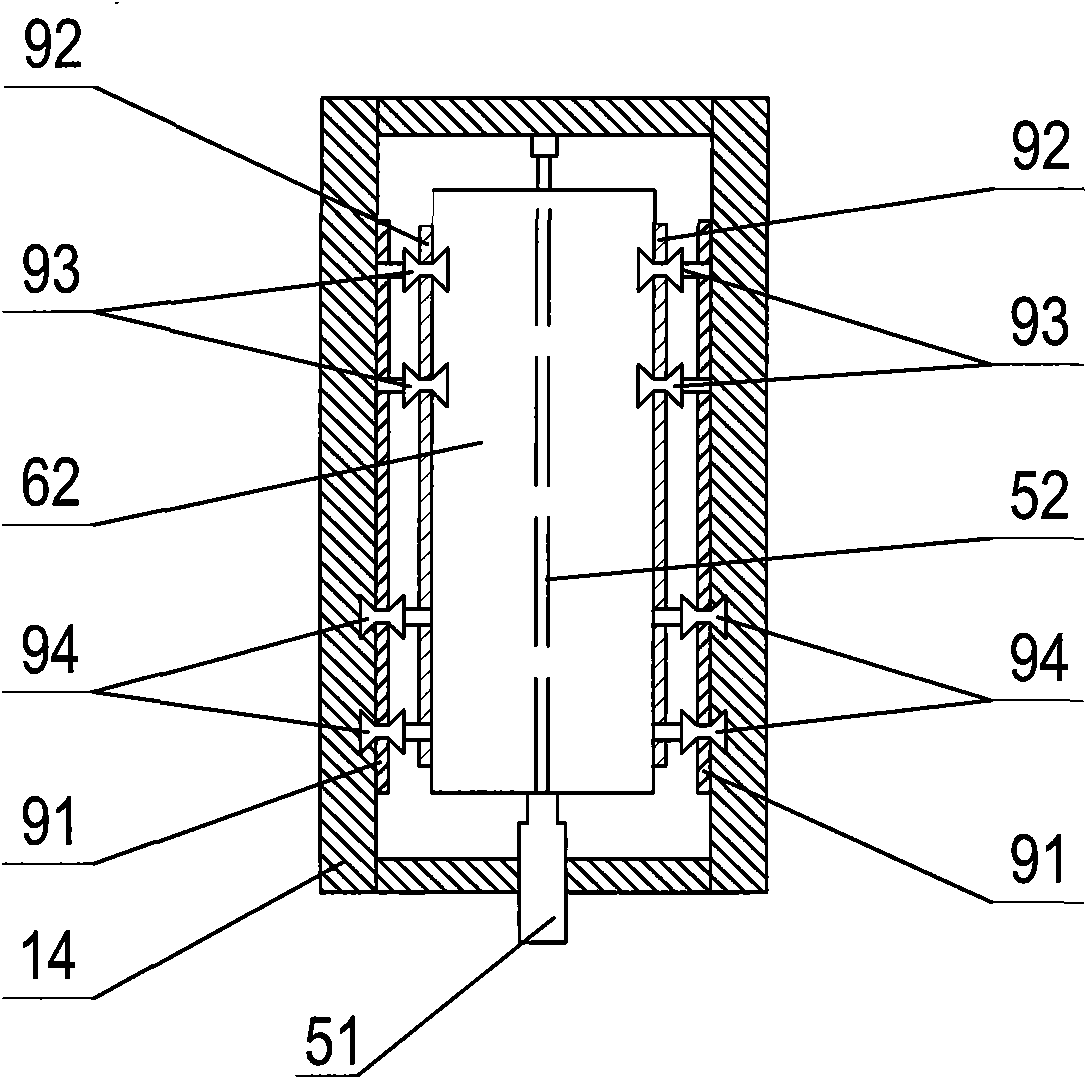

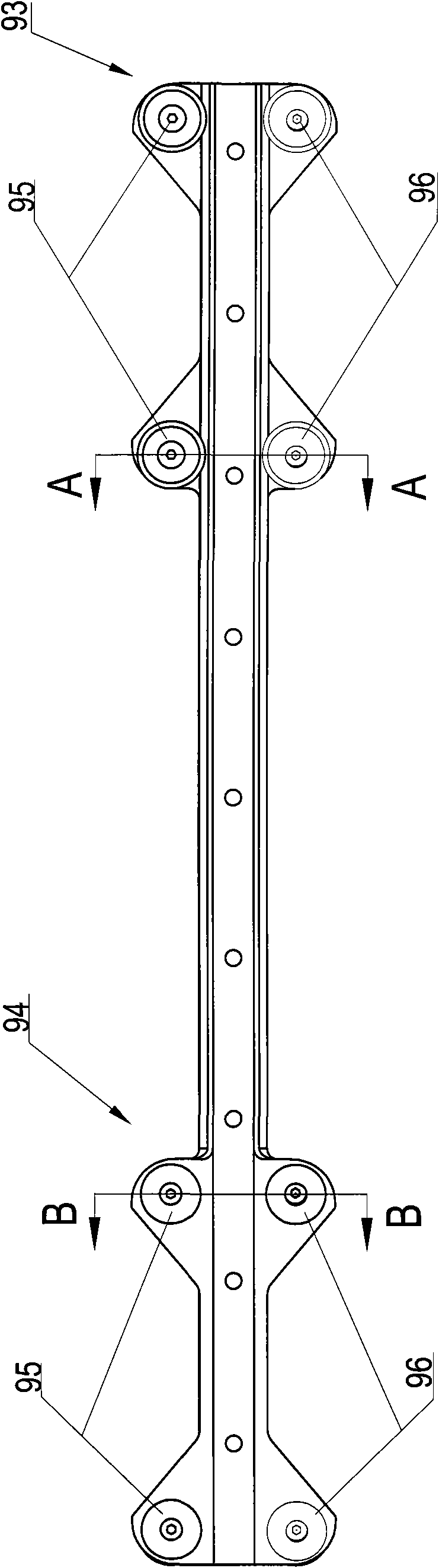

[0033] Attached below figure 1 Let me first introduce the structure and working process of the radiographic inspection equipment for the safety end weld of the nuclear reactor pressure vessel. The "front side" mentioned in the manual refers to the attached figure 1 The right side in the manual, the "rear side" mentioned in the manual refers to the attached figure 1 the left side in the manual; the "left side" and "right side" described in the figure 2 Corresponds to the left and right positional relationship shown in .

[0034] The welding seam radiographic inspection equipment is used to detect the connection weld seam between the nuclear reactor pressure vessel nozzle and the safety end 81 and the connection weld seam between the safety end 81 and the main pipeline 82, and it includes:

[0035] The main body 1 of the welding seam detection equipment, the main body 1 includes a main sealing box 11 and an outer frame 14 arranged outside the main sealing box 11 for connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com