Method and device for correcting outer diameter of steel pipes

A correction method and technology for steel pipes, which are applied in the field of steel pipe outer diameter correction and devices, can solve problems such as affecting the appearance and quality of steel pipes, high manufacturing and maintenance costs, and increasing production costs of enterprises, saving equipment and manpower investment, simple structure, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

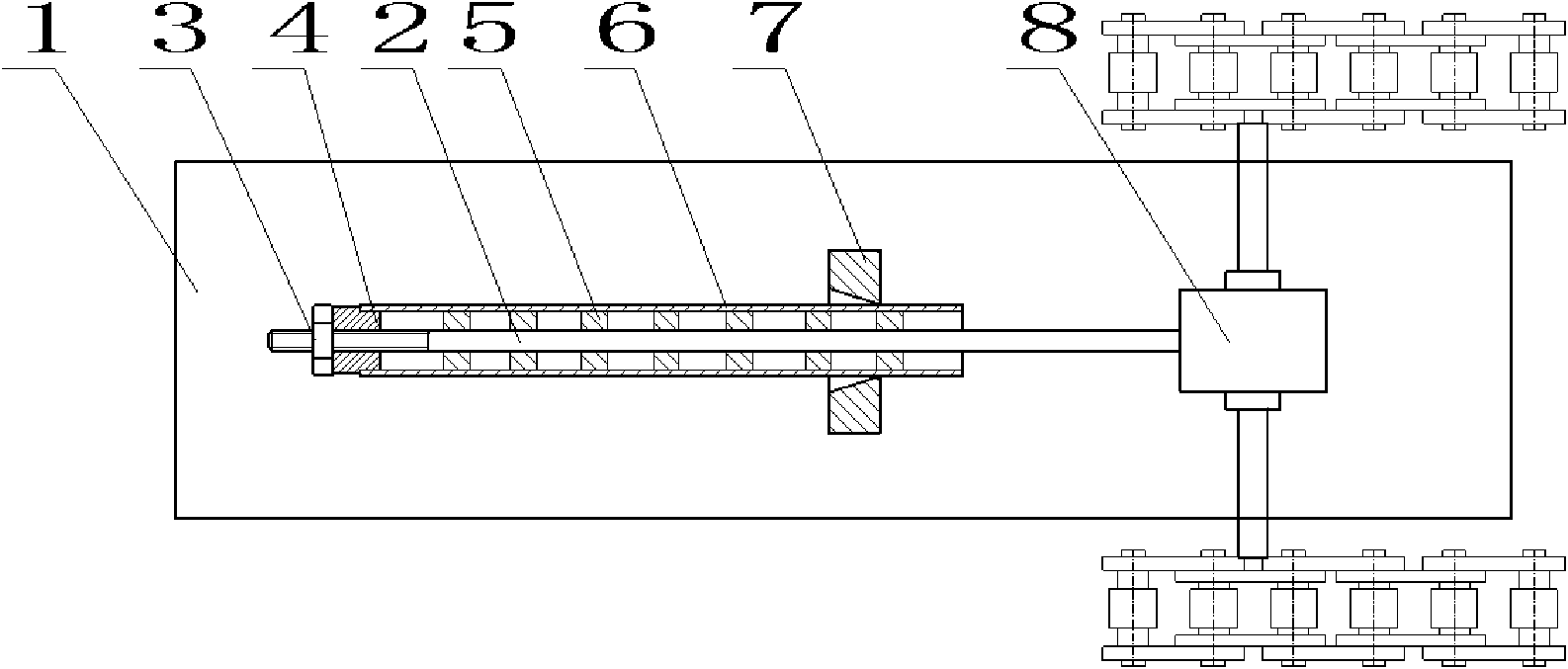

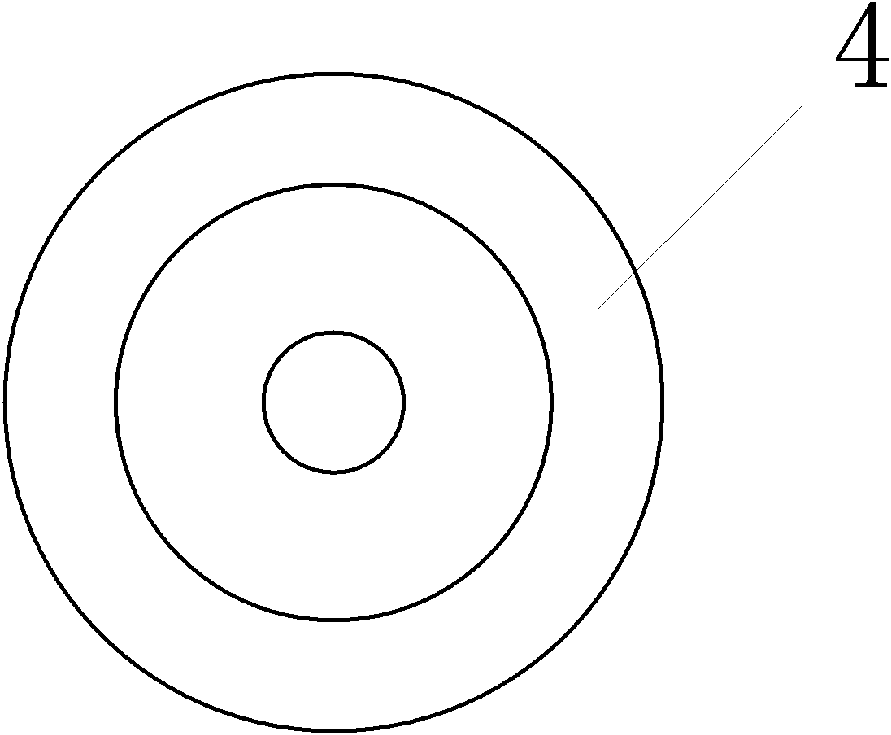

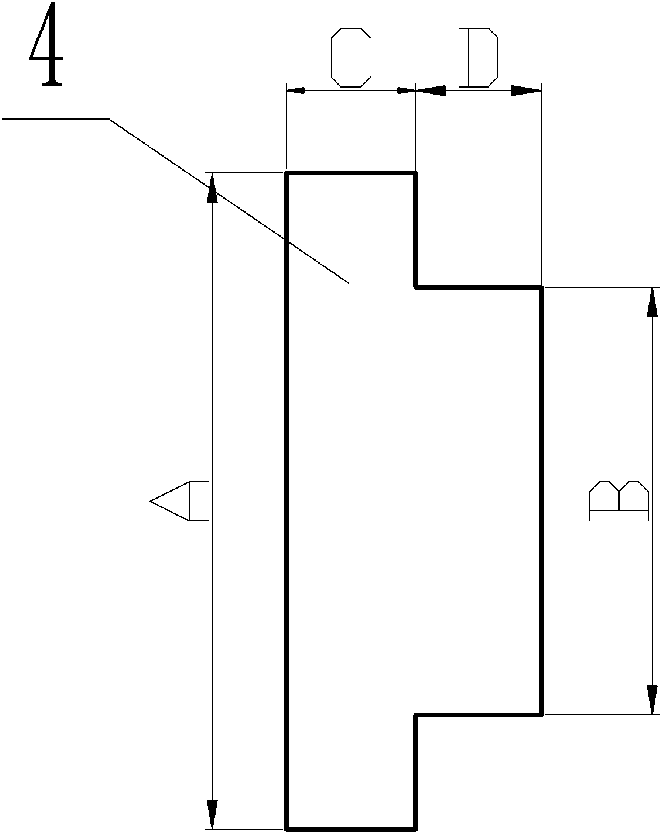

[0023] Embodiment: a method for correcting the outer diameter of a steel pipe. The method is to add a drawing device to push the steel pipe in the existing cold drawing machine; Die base to achieve the correction of the outer diameter of the steel pipe; the small pliers of the cold drawing machine pull the drawing device, and the drawing device pushes the steel pipe through the drawing die base, and the small pliers of the cold drawing machine pull a penetrating steel pipe and are equipped with a supporting component The pull rod, the support component blocks the end of the steel pipe, and pushes the steel pipe through the drawing seat with the action of the pull rod; the support component blocks the steel pipe, and uses a support special part fixed on the pull rod with a nut to block the steel pipe; The small pliers of the cold drawing machine pull a drawing rod that runs through the steel pipe, and the nylon sleeve set on the drawing rod protects the inner wall of the steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com