Scraper of CuNiMo alloying isothermal quenching ductile iron scraper conveyor and preparation method

A technology for isothermal quenching ductile iron and scraper conveyor, which is applied in the direction of conveyor, transportation and packaging, process efficiency improvement, etc., can solve the problems of increasing the cost of mining per ton of coal, increasing the production cost of scraper, and reducing the life of the scraper. , to achieve the effect of lightening the load, reducing energy consumption and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

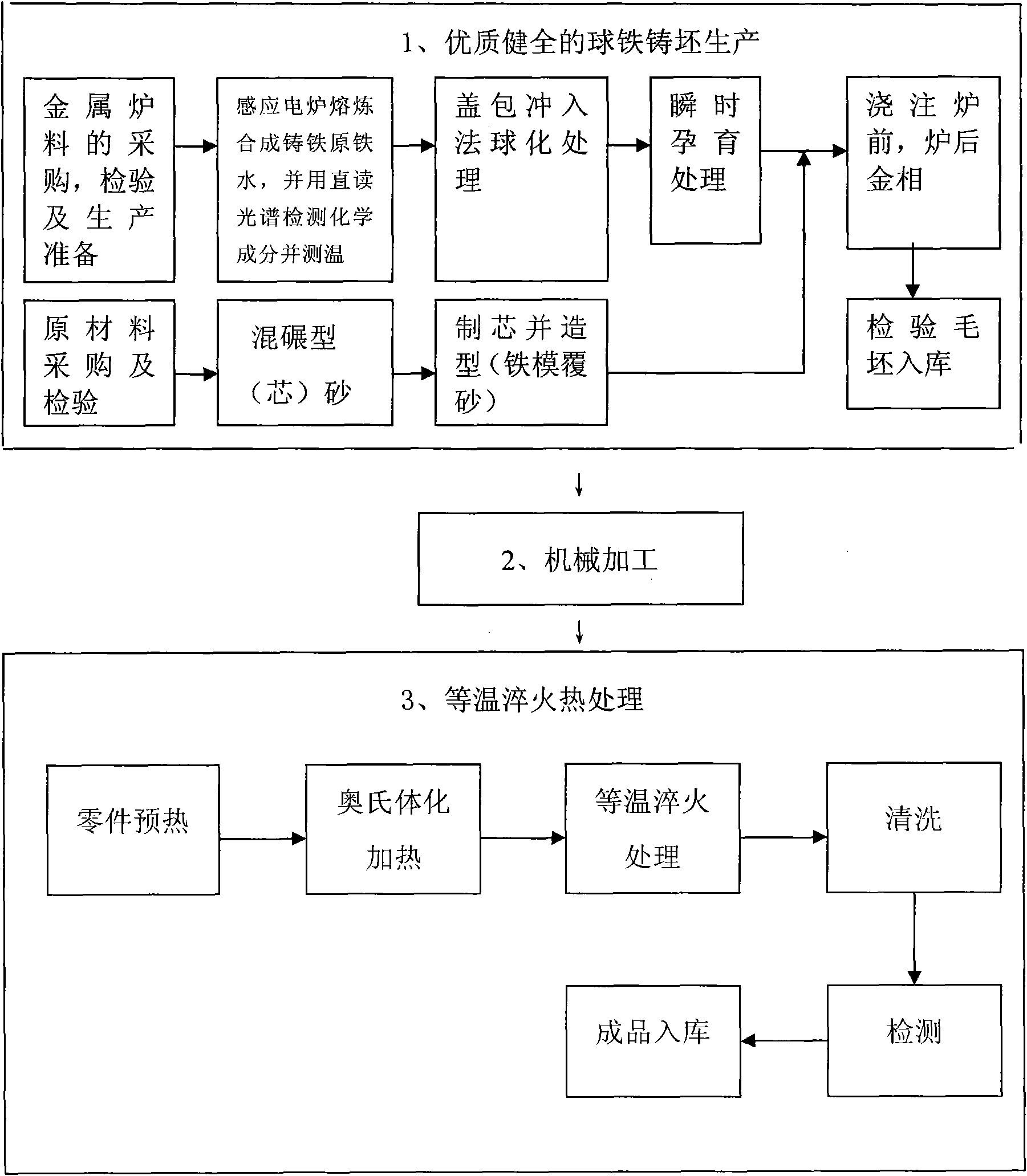

Method used

Image

Examples

Embodiment 1

[0036] A CuNiMo alloyed austempering ductile iron scraper conveyor scraper, the scraper raw material is austempering nodular cast iron, which includes the following chemical composition in weight percentage:

[0037] C 3.60, Si 2.20, Mn<0.3, P<0.03,

[0038] S <0.02, Mg 0.035, Re 0.01, Cu 0.40,

[0039] Ni 0.40, Mo 0.20, and the rest are iron.

[0040] A method for preparing a CuNiMo alloyed austempering nodular cast iron scraper conveyor scraper, comprising the following steps:

[0041] 1) CuNiMo alloying is used to produce nodular cast iron: low-carbon scrap steel is added with carburant charge, and nodular cast iron hot metal is melted in an induction furnace. The chemical composition of the nodular cast iron raw hot metal is (wt%):

[0042] C 3.40, Si 1.40, Mn<0.3, P<0.03, S<0.02,

[0043] Cu 0.40, Ni 0.40, Mo 0.20, the rest is iron;

[0044] 2) Spheroidizing nodular cast iron by pouring into the cover: the so-called spheroidizing treatment by pouring into the cover, t...

Embodiment 2

[0059]A CuNiMo alloyed austempering ductile iron scraper conveyor scraper, the scraper raw material is austempering nodular cast iron, which includes the following chemical composition in weight percentage:

[0060] C 3.80, Si 2.80, Mn<0.3, P<0.03, S<0.02, Mg 0.055,

[0061] Re 0.02, Cu 0.80, Ni 0.80, Mo 0.40, and the rest are iron.

[0062] A method for preparing a CuNiMo alloyed austempering nodular cast iron scraper conveyor scraper, comprising the following steps:

[0063] 1) CuNiMo alloying is used to produce nodular cast iron: low-carbon scrap steel is added with carburant charge, and nodular cast iron hot metal is melted in an induction furnace. The chemical composition of the nodular cast iron raw hot metal is (wt%):

[0064] C 3.80, Si 1.80, Mn<0.3, P<0.03, S<0.02,

[0065] Cu 0.80, Ni 0.80, Mo 0.40, the rest is iron;

[0066] 2) Spheroidizing nodular cast iron by pouring into the cover: the so-called spheroidizing treatment by pouring into the cover, that is, sphe...

Embodiment 3

[0080] A CuNiMo alloyed austempering ductile iron scraper conveyor scraper, the scraper raw material is austempering nodular cast iron, which includes the following chemical composition in weight percentage:

[0081] C 3.70, Si 2.50, Mn<0.3, P<0.03, S<0.02, Mg 0.045,

[0082] Re 0.015, Cu 0.60, Ni 0.60, Mo 0.30, and the rest are iron.

[0083] A method for preparing a CuNiMo alloyed austempering nodular cast iron scraper conveyor scraper, comprising the following steps:

[0084] 1) CuNiMo alloying is used to produce nodular cast iron: low-carbon scrap steel is added with carburant charge, and nodular cast iron hot metal is melted in an induction furnace. The chemical composition of the nodular cast iron raw hot metal is (wt%):

[0085] C 3.60, Si 1.60, Mn<0.3, P<0.03, S<0.02,

[0086] Cu 0.60, Ni 0.60, Mo 0.30, the rest is iron;

[0087] 2) Spheroidizing nodular cast iron by pouring into the cover: the so-called spheroidizing treatment by pouring into the cover, that is, sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com