Patents

Literature

39results about How to "Significant technical benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

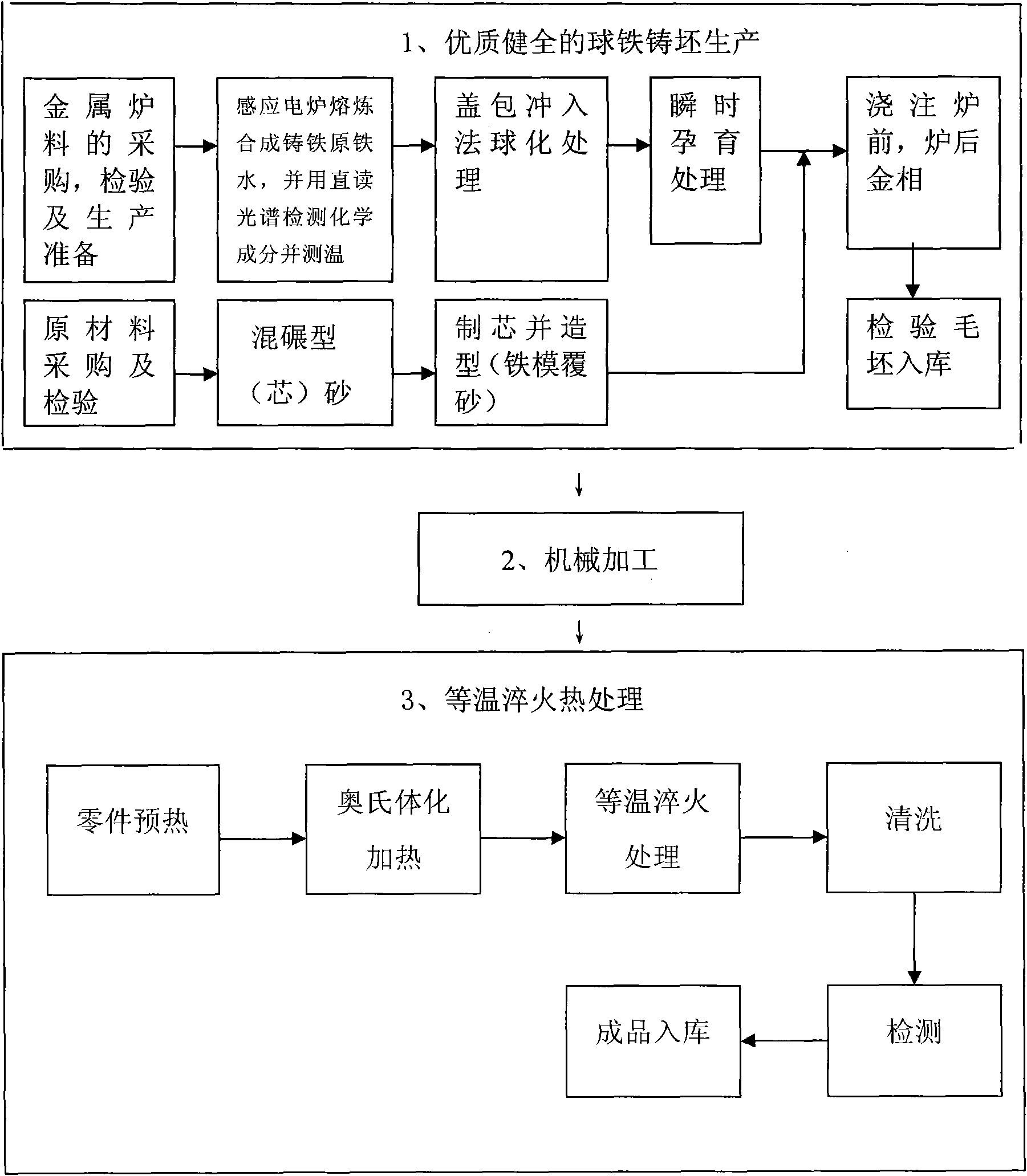

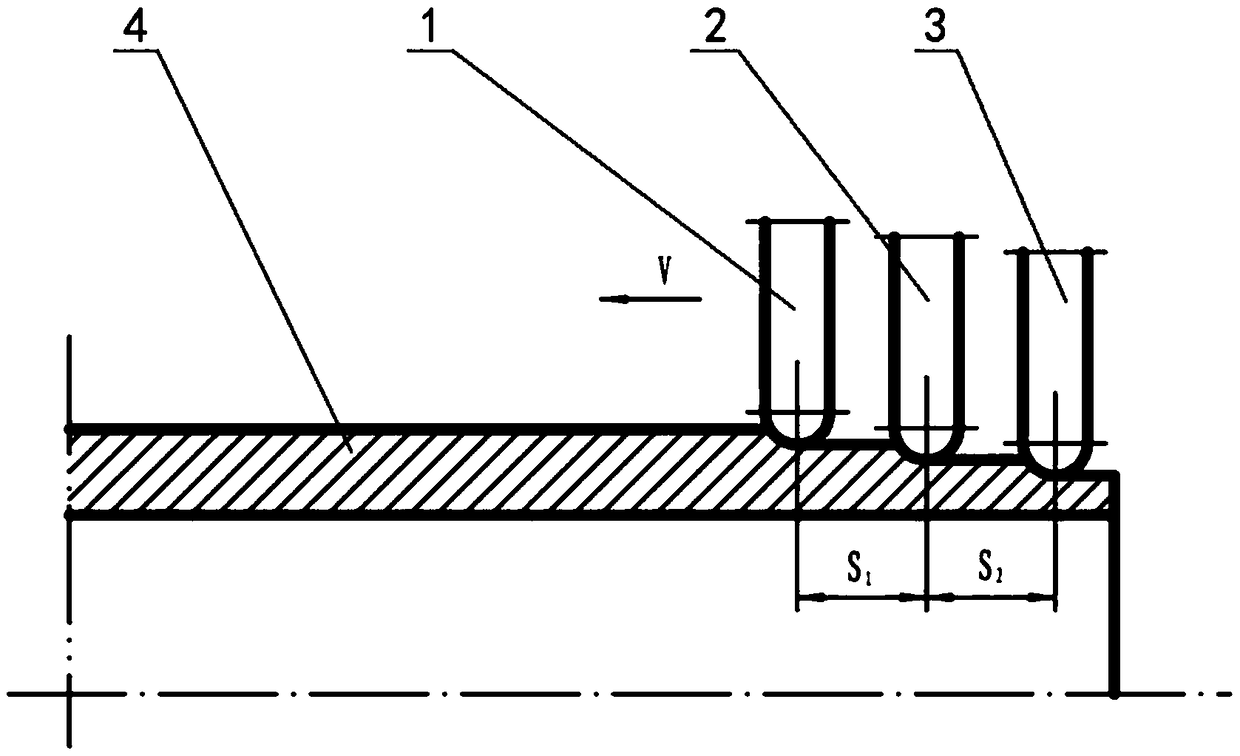

Scraper of CuNiMo alloying isothermal quenching ductile iron scraper conveyor and preparation method

InactiveCN101602433ALow costSolution to short lifeConveyorsProcess efficiency improvementSocial benefitsEconomic benefits

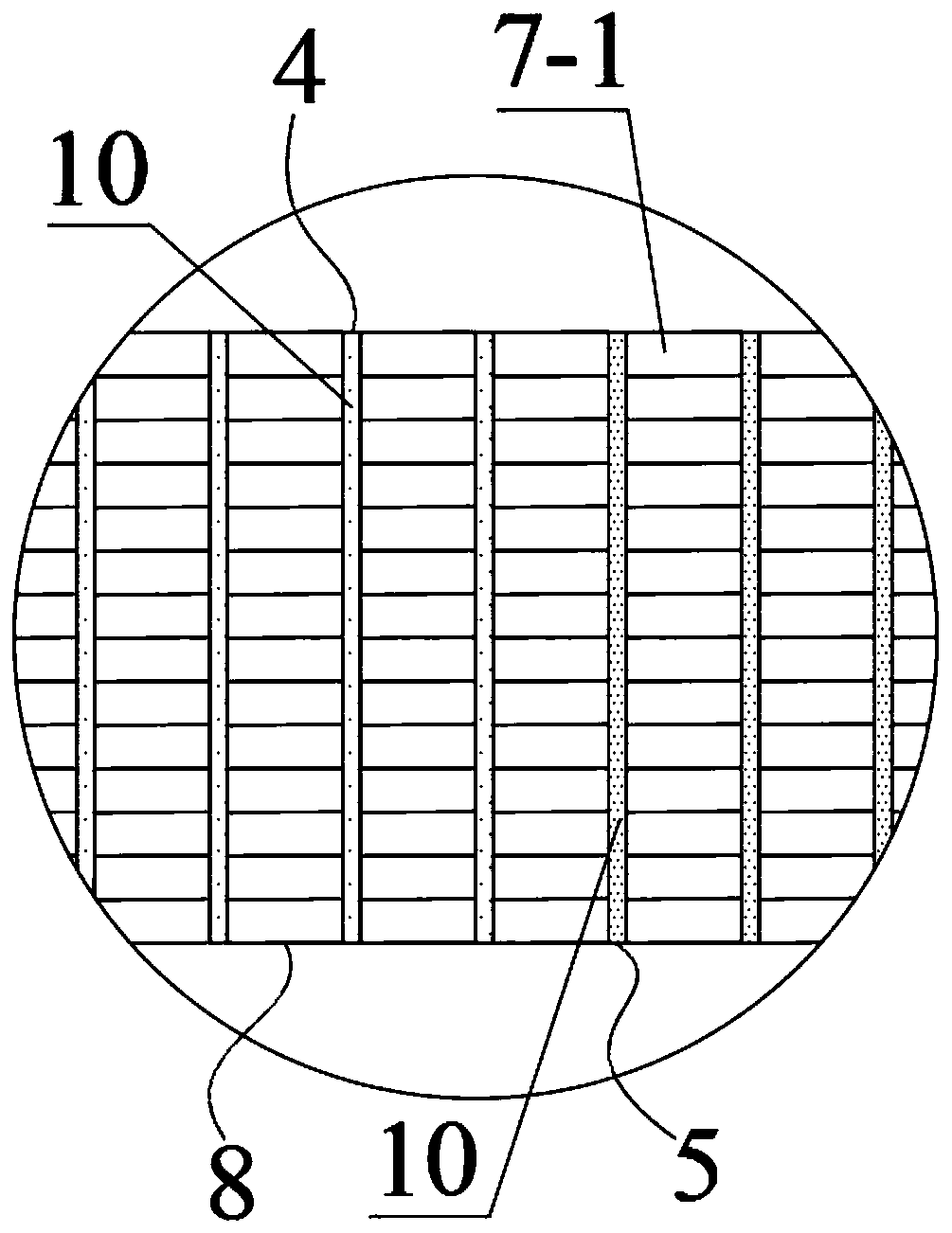

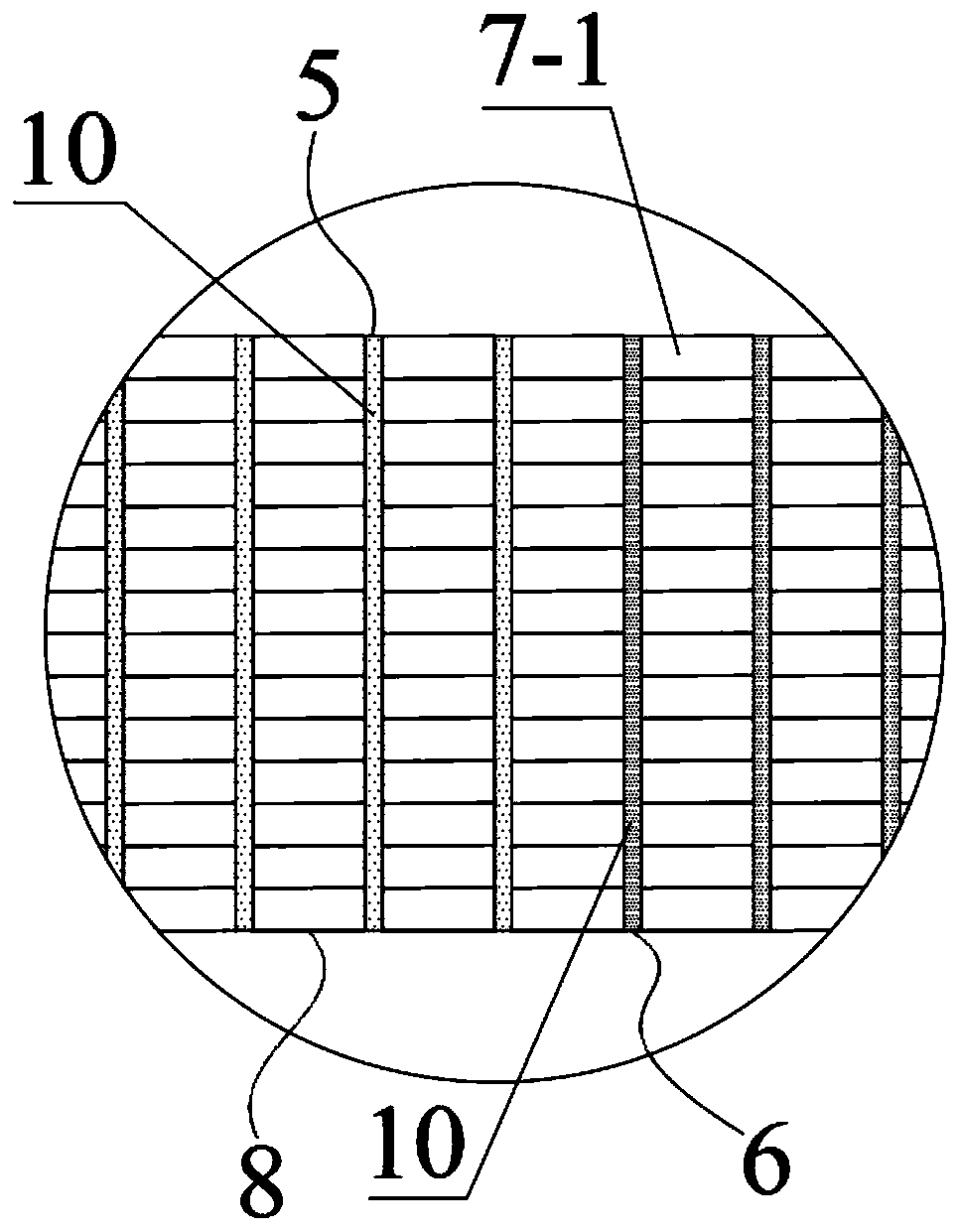

The invention discloses a scraper of a CuNiMo alloying isothermal quenching ductile iron scraper conveyor. The raw material of the scraper is isothermal quenching ductile iron, and the ductile iron comprises the following chemical components in percentage by weight: 3.60 to 3.80 percent of C, 2.20 to 2.80 percent of Si, less than 0.3 percent of Mn, less than 0.03 percent of P, less than 0.02 percent of S, 0.035 to 0.055 percent of Mg, 0.01 to 0.02 percent of Re, 0.40 to 0.80 percent of Cu, 0.40 to 0.80 percent of Ni, 0.20 to 0.40 percent of Mo, and the balance of iron. The scraper has the following advantages: the cost of the scraper of the invention is nearly one third less than that of a forged scraper, the energy consumption is greatly reduced, the load of a driving device is lightened at the same time, and the scraper has long service life and remarkable technical benefit, economic benefit and social benefit.

Owner:宣化冶金工业有限责任公司

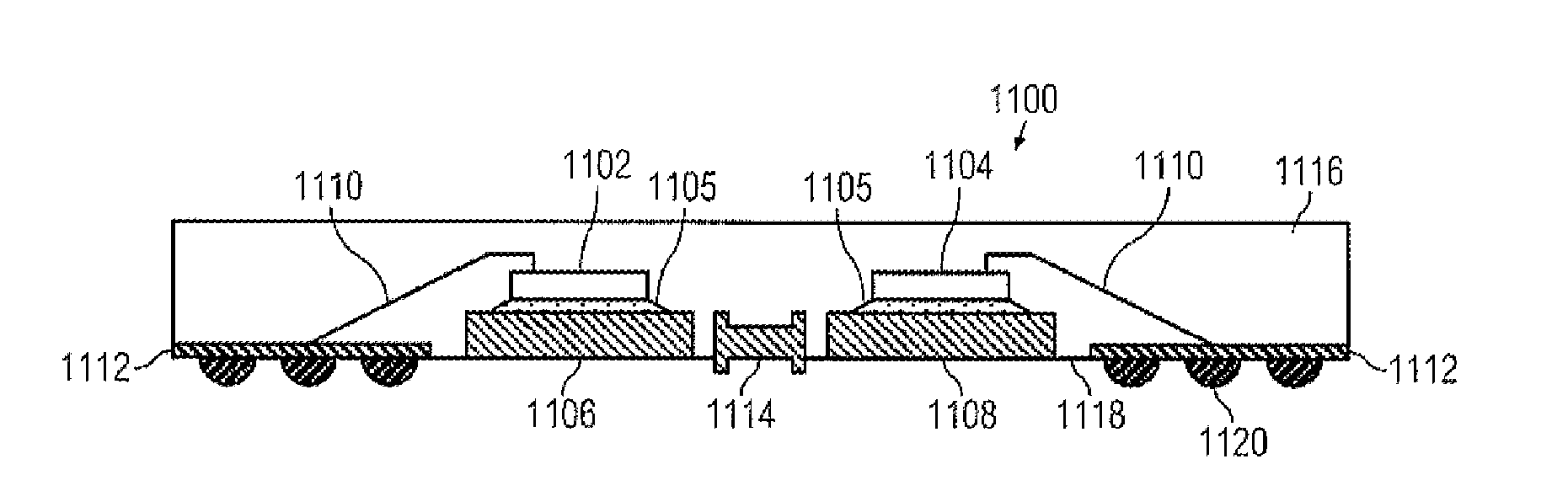

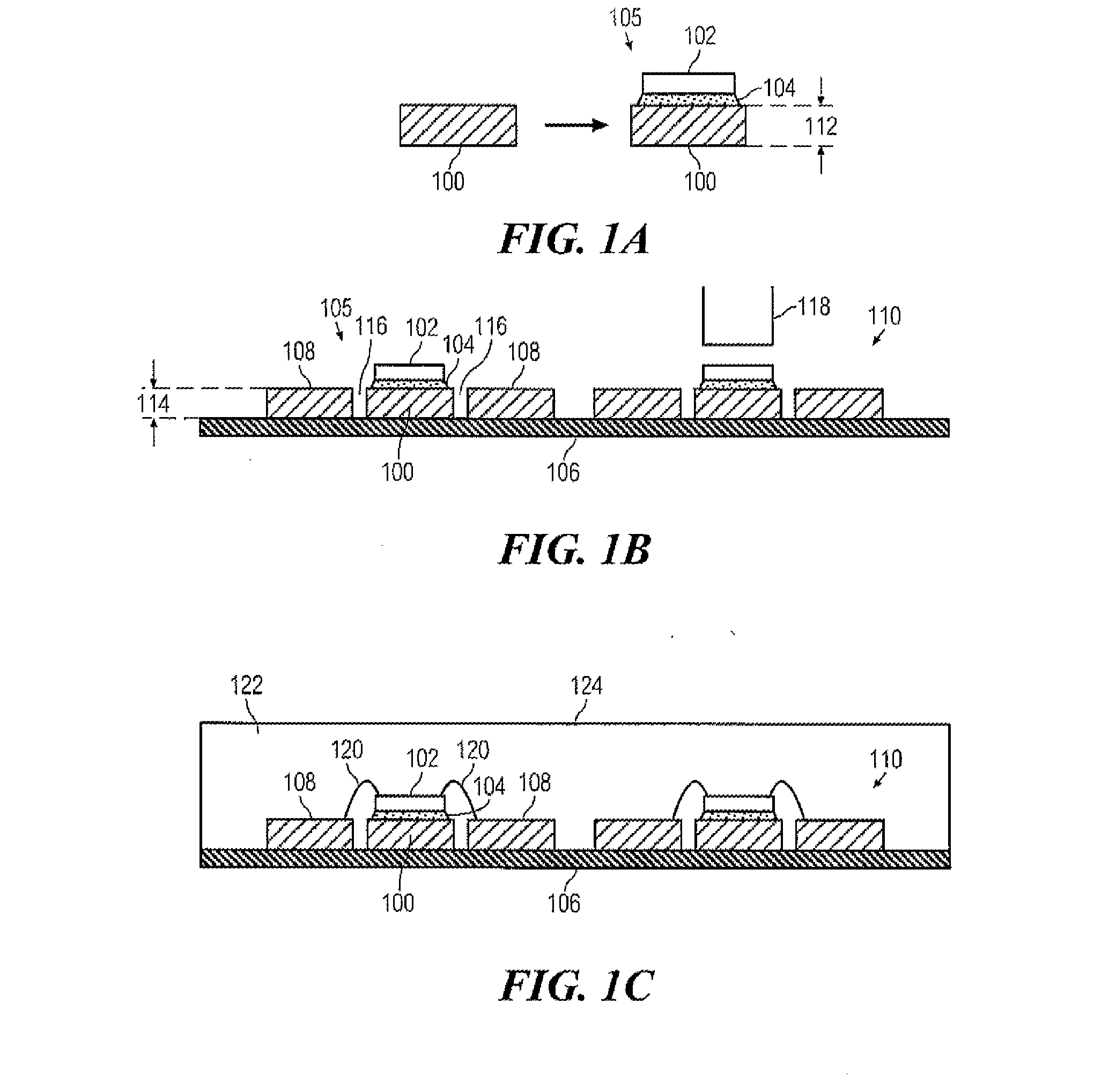

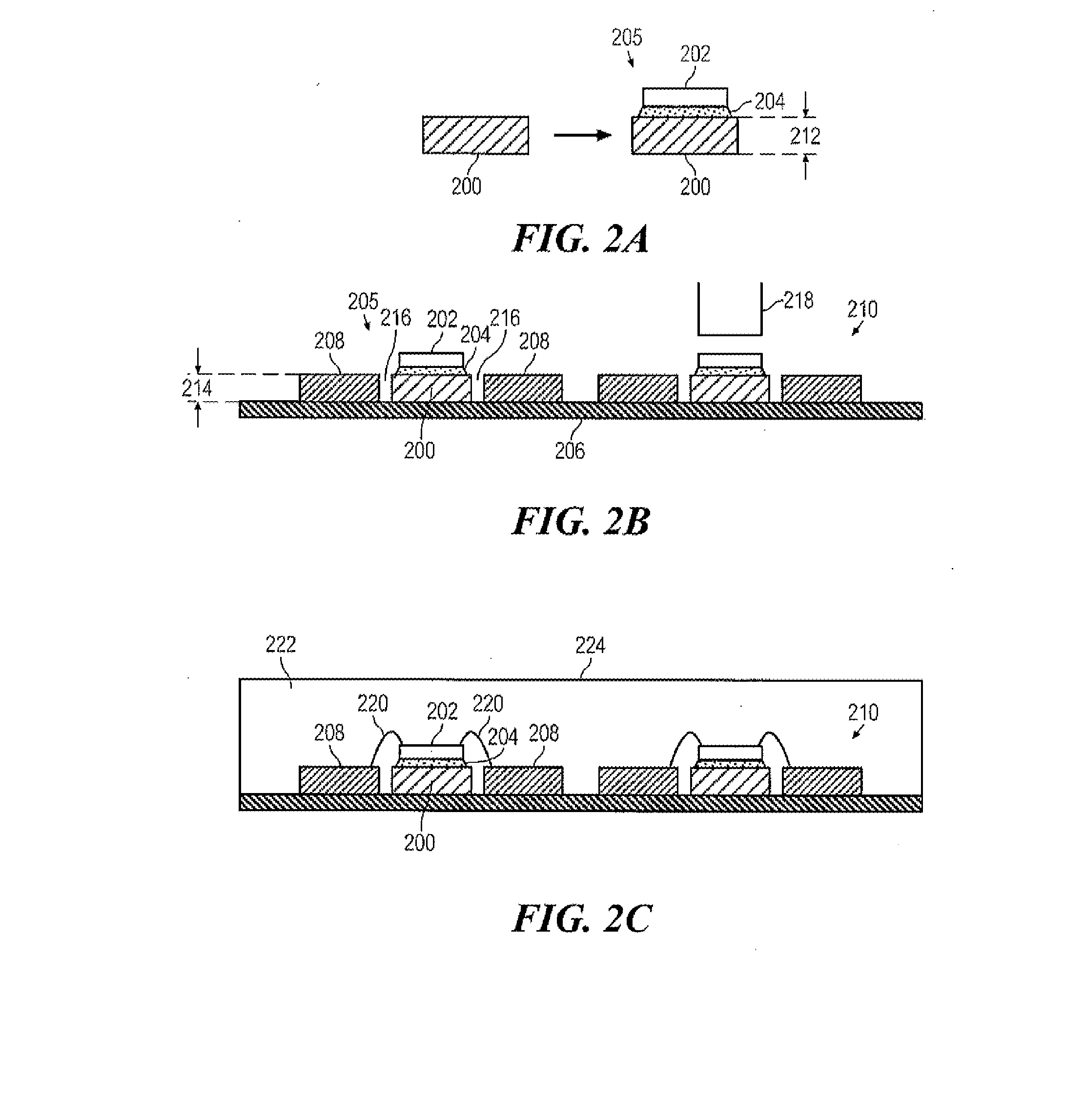

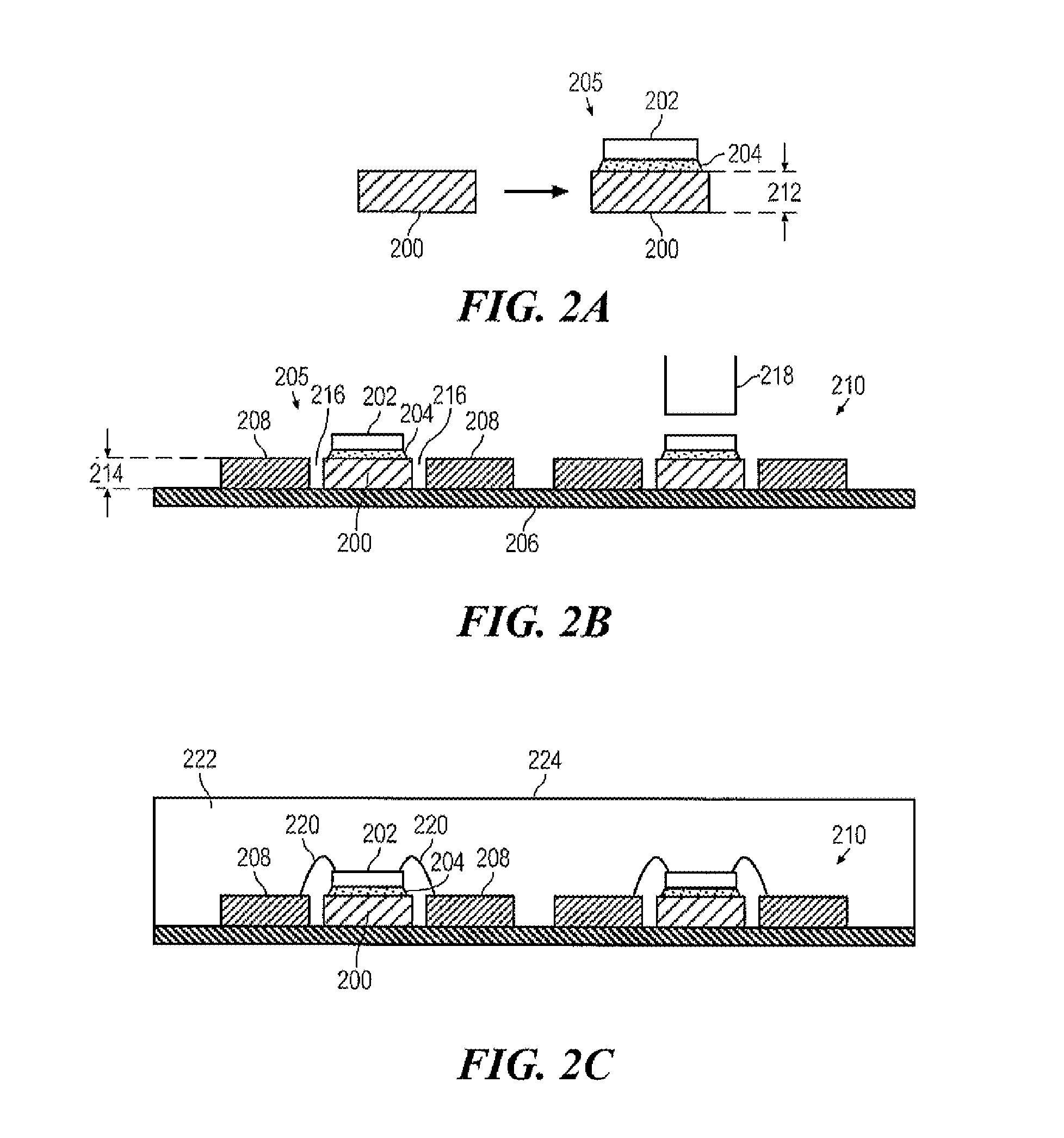

Semiconductor devices and methods of assembling same

InactiveUS20130056861A1Reduce difficultySignificant technical benefitsSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor

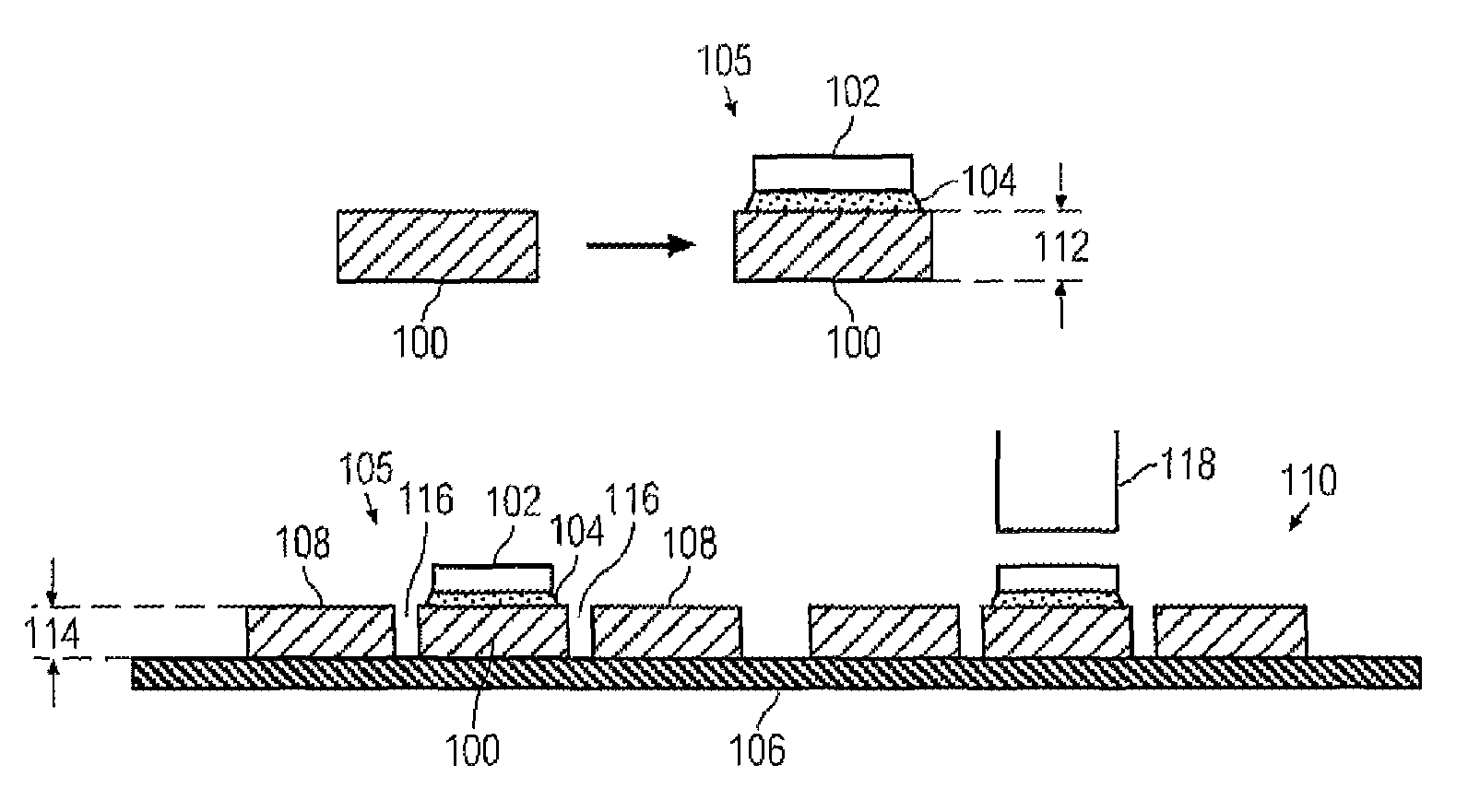

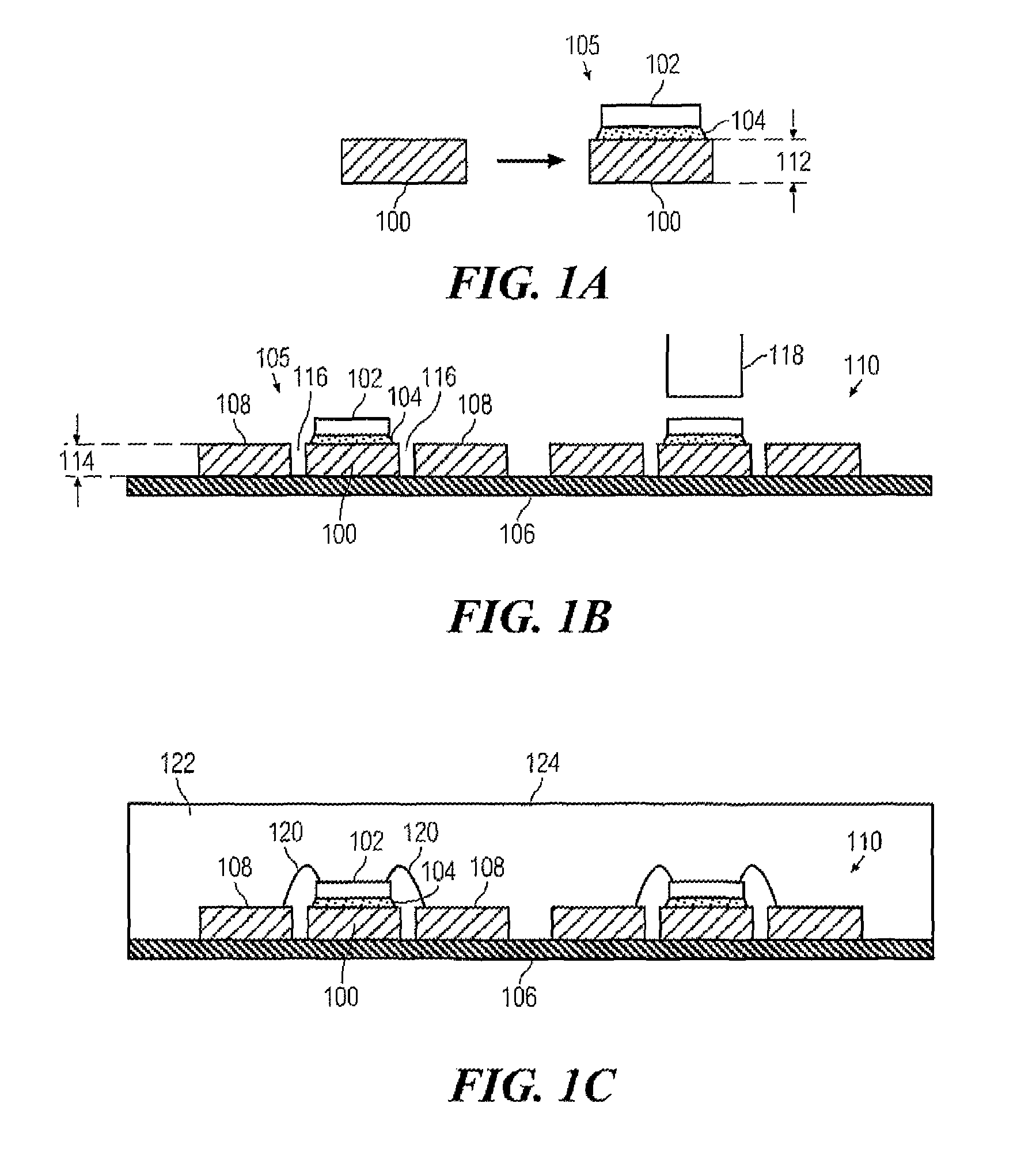

A method of forming a semiconductor device includes affixing a die to a heat sink to form a die and heat sink assembly and then placing the die and heat sink assembly on a support element. A semiconductor device includes a die and heat sink assembly disposed on a support element. The die and heat sink assembly is pre-assembled prior to being disposed on the support element.

Owner:NXP USA INC

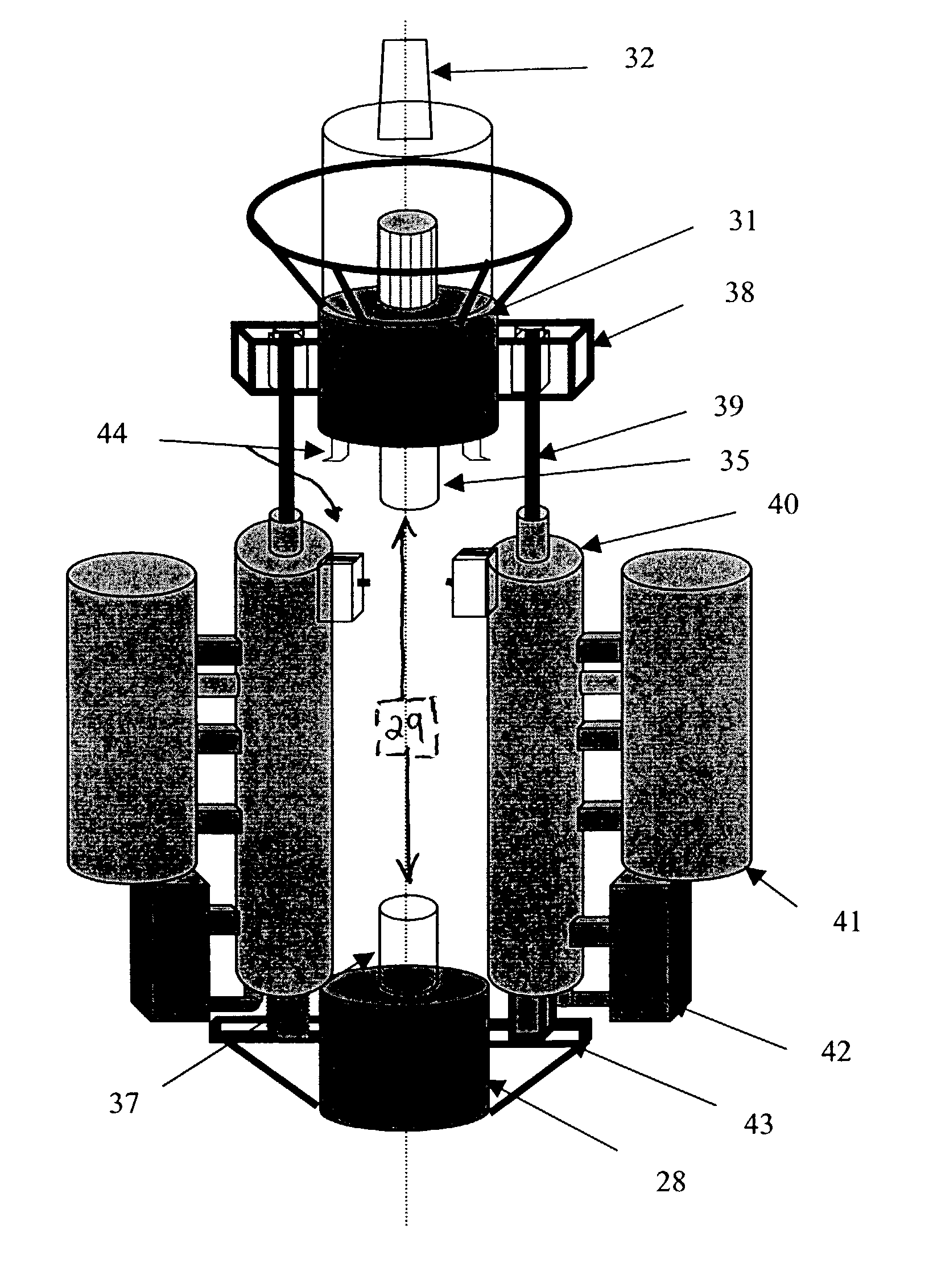

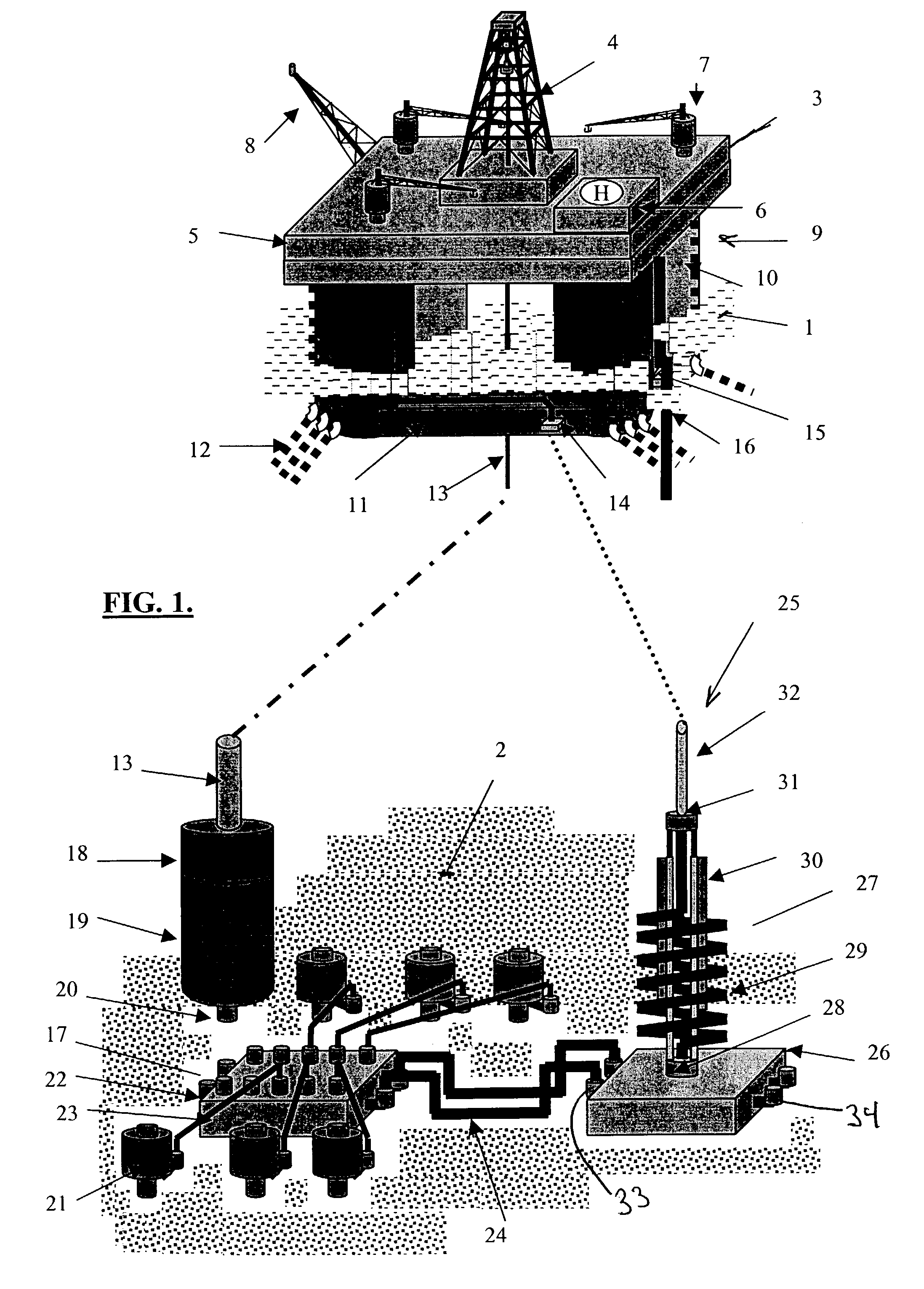

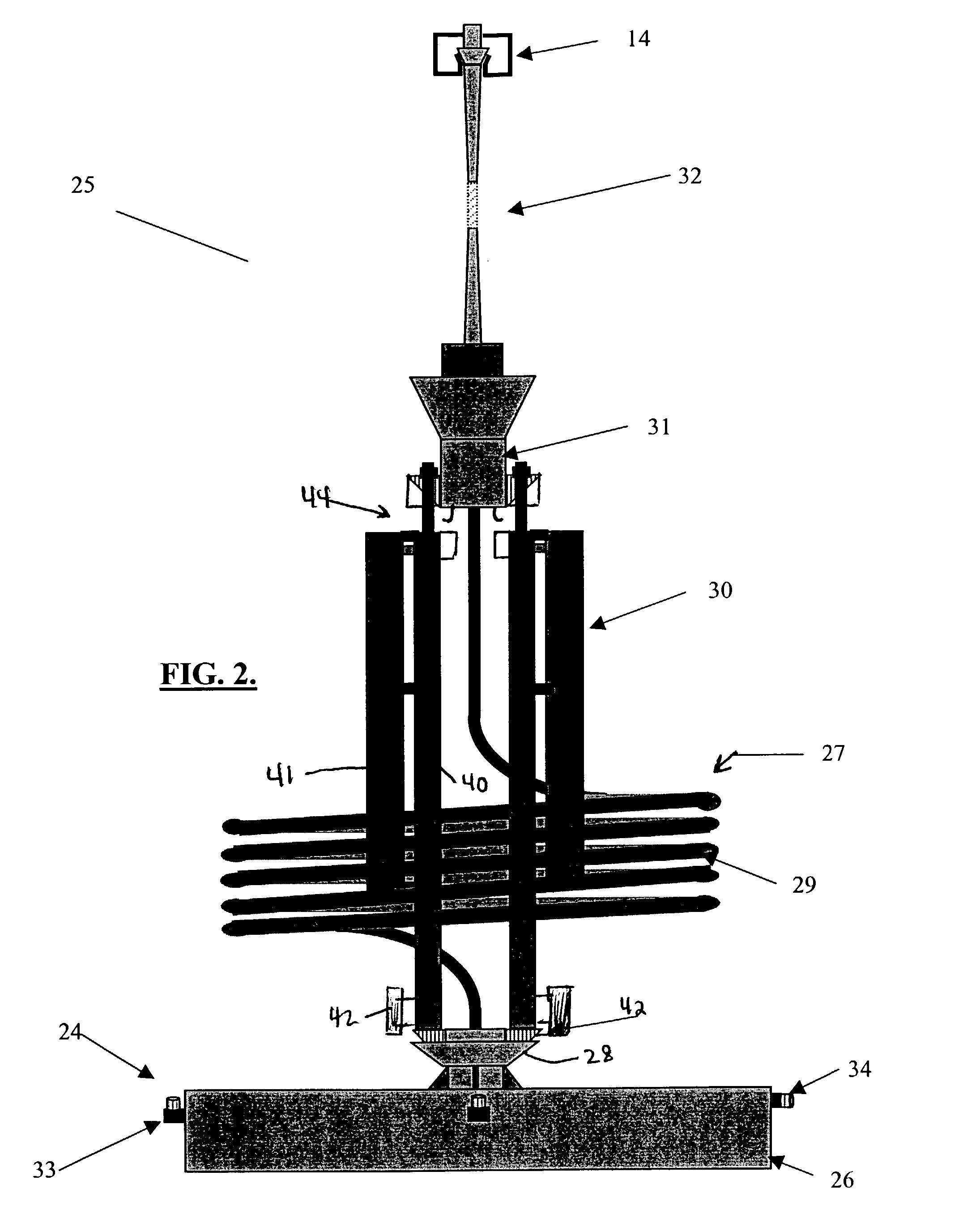

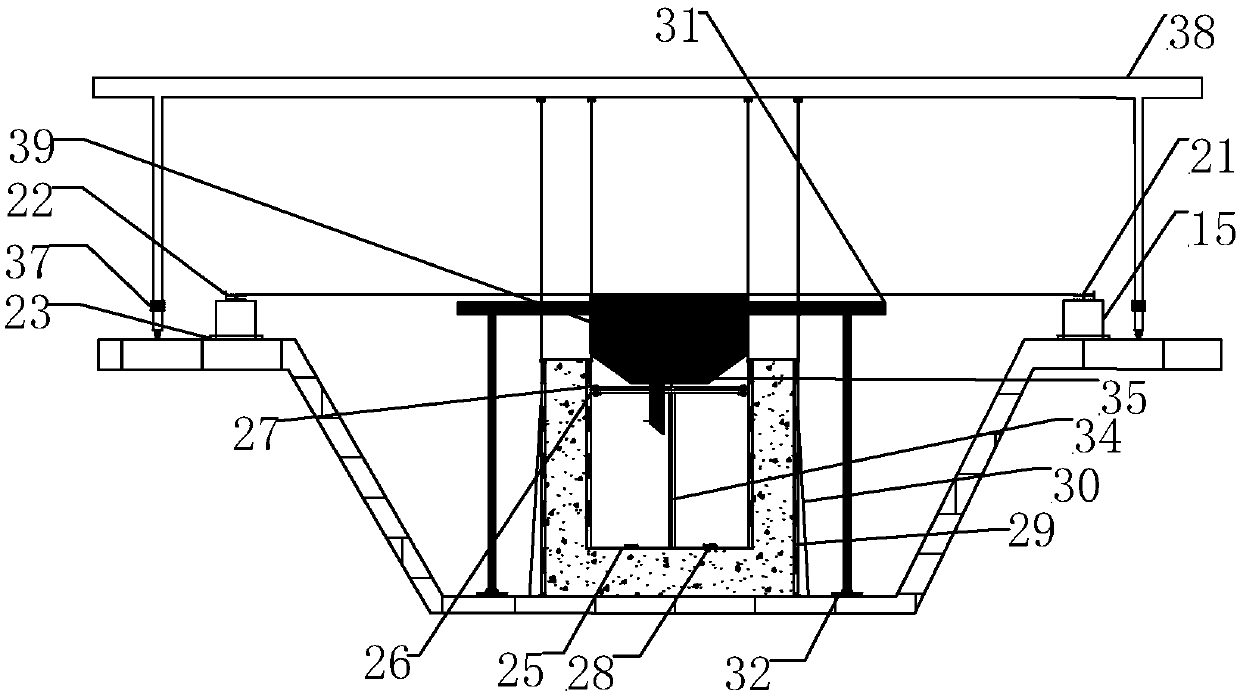

Marine bottomed tensioned riser and method

InactiveUS7104329B2Eliminate needBetter resolve uncertainties about the models and their required assumptionsDrilling rodsFluid removalOil productionPetroleum

A new marine oil production riser system for use in deepwater applications is disclosed. An efficient means for accommodating movements of the host facility, while maintaining riser top tension within the limits for long-term riser performance. Long riser stroke lengths can be accommodated without requiring complex interfacing with the topsides. The riser assembly comprises: a generally extendable substantially non-vertical section having an upper end adapted to be in flow communication with a generally vertical marine riser carried by a facility floating on the surface of a body of water, and having a lower end adapted to be in flow communication with a fluid source on the seafloor; and tensioning means, mechanically connecting the upper end of the marine riser with the lower end of the marine riser, for biasing said ends towards each other. The tensioning means comprises: a cylinder having one end open to sea pressure, having an opposite end sealed from sea pressure, and connected to one end of the marine riser; a piston within the cylinder disposed for movement within the cylinder; and a piston rod passing through the opposite end of the cylinder and having one end connected to the other end of the marine riser.

Owner:BP CORP NORTH AMERICA INC

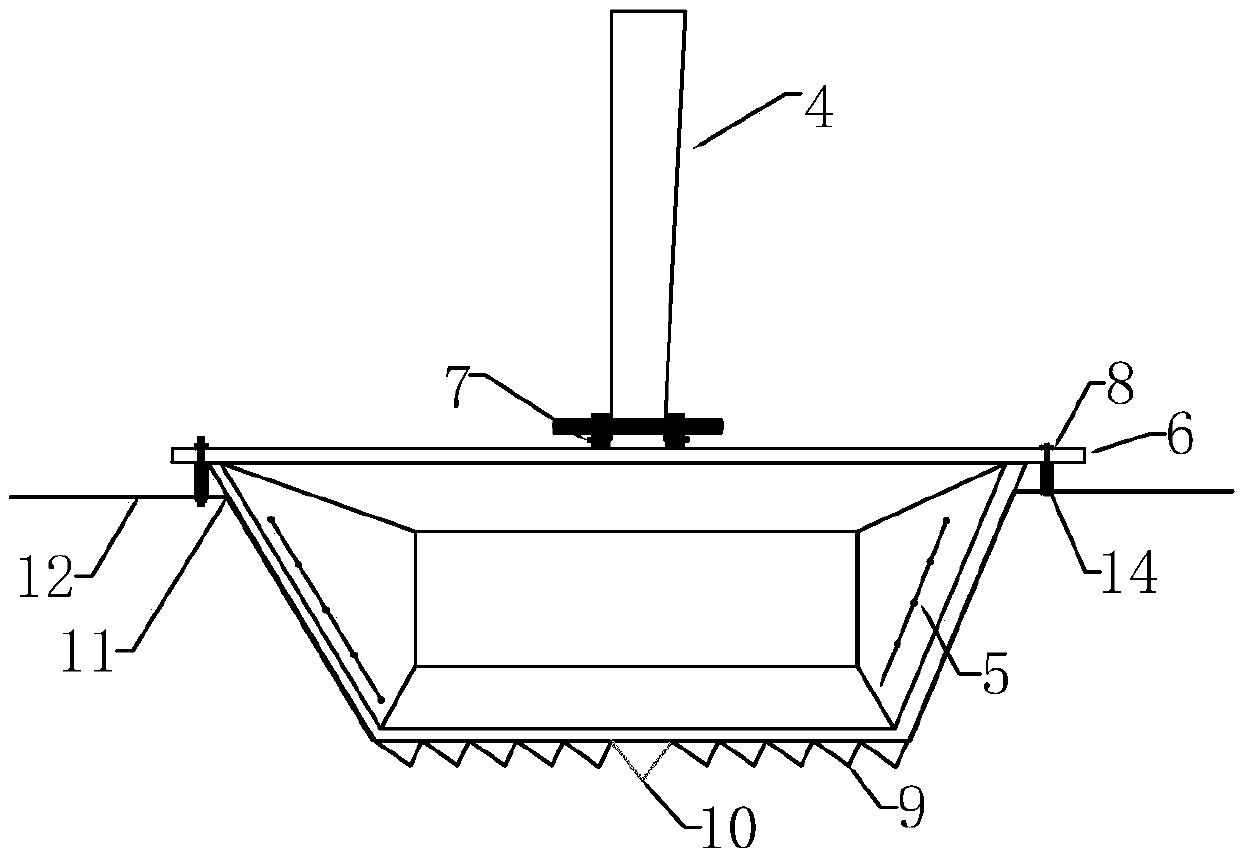

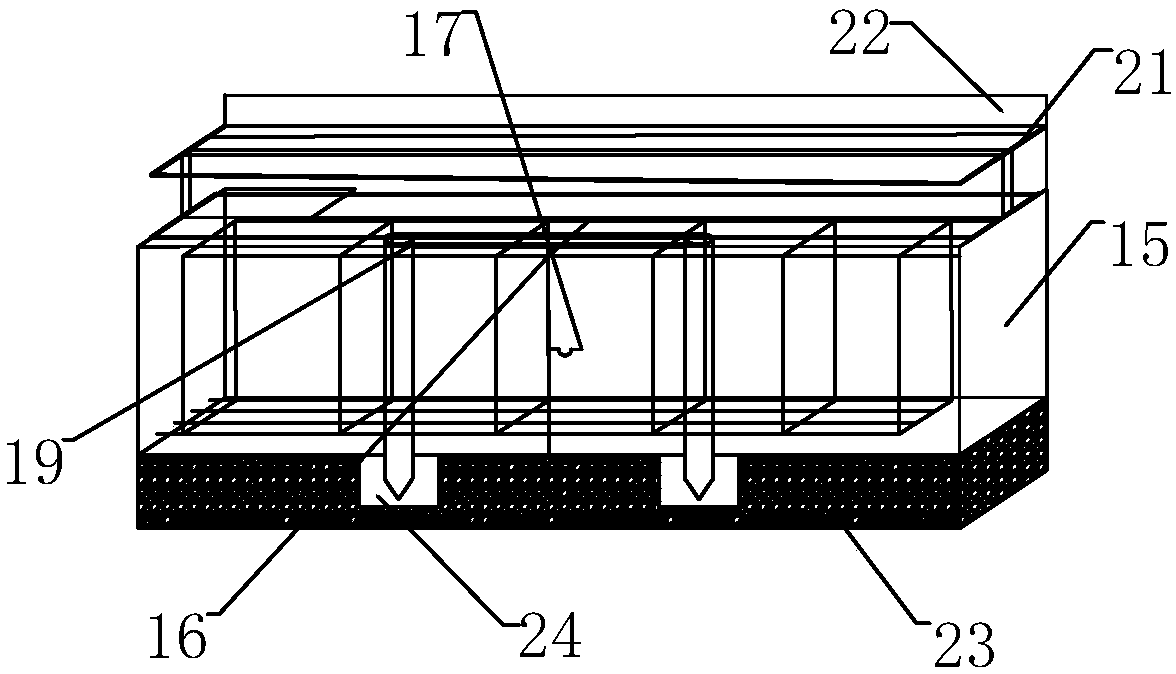

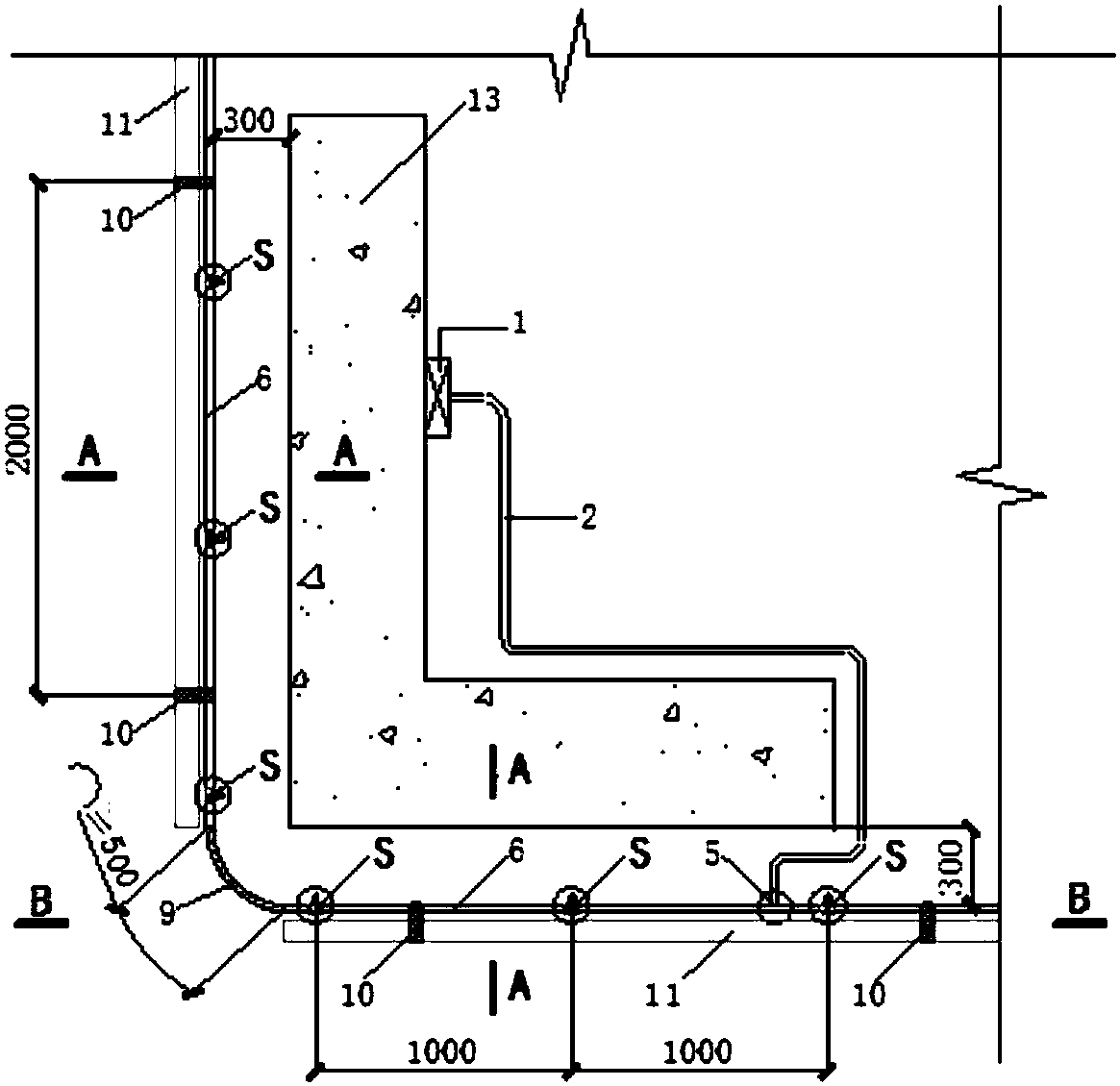

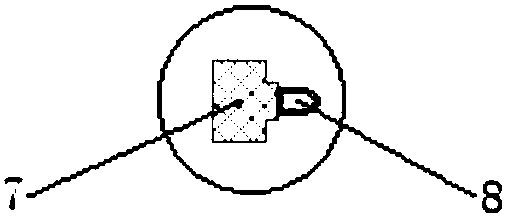

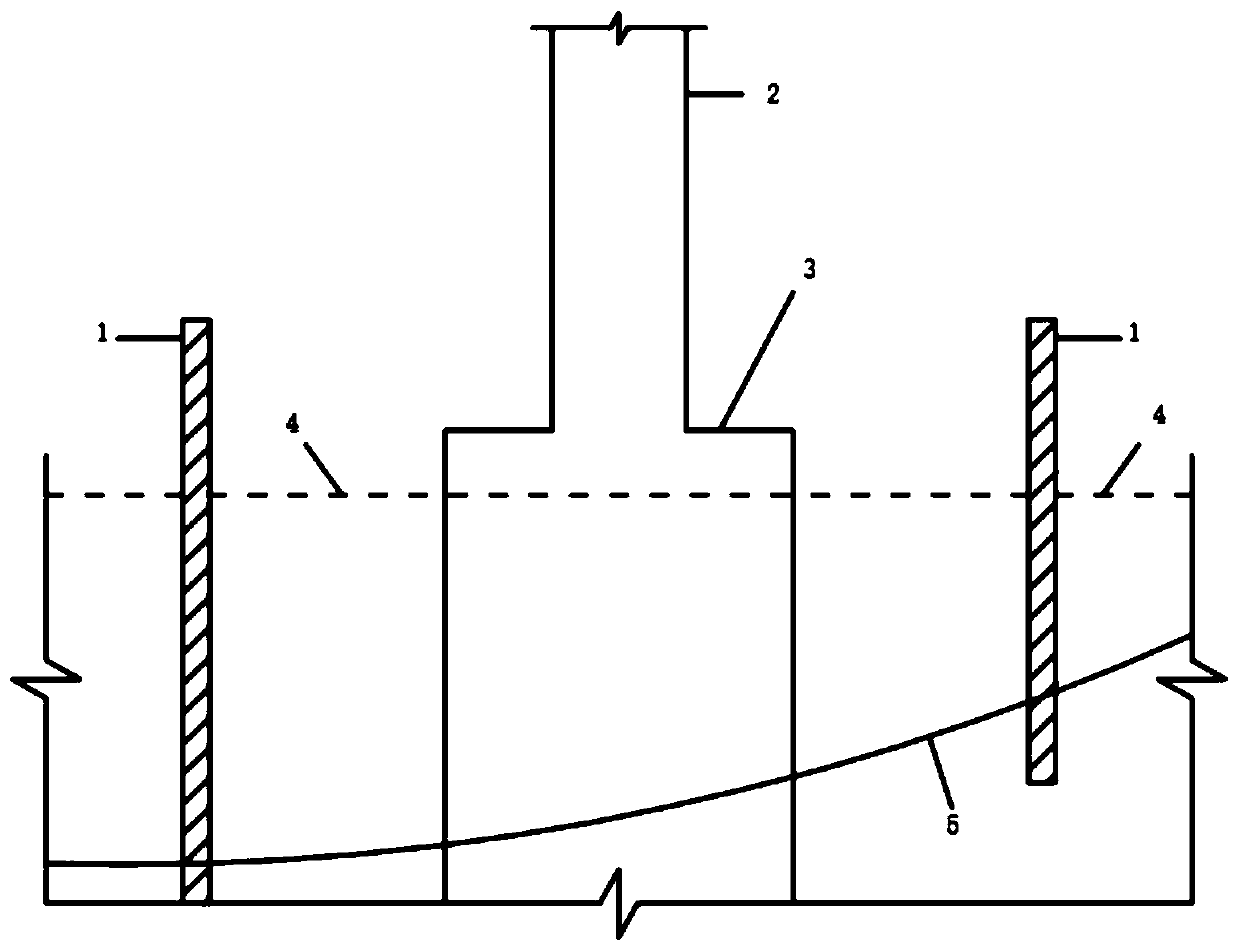

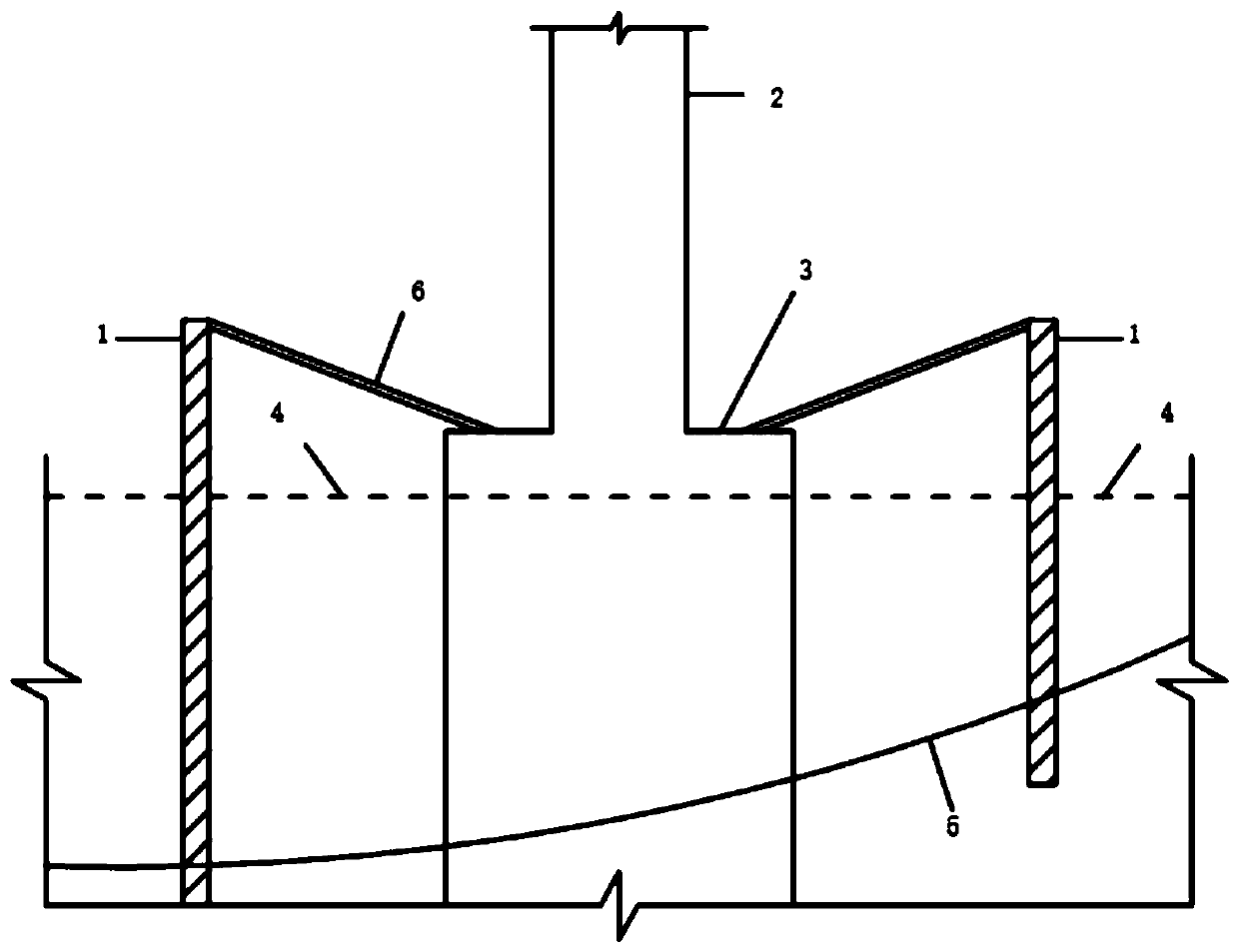

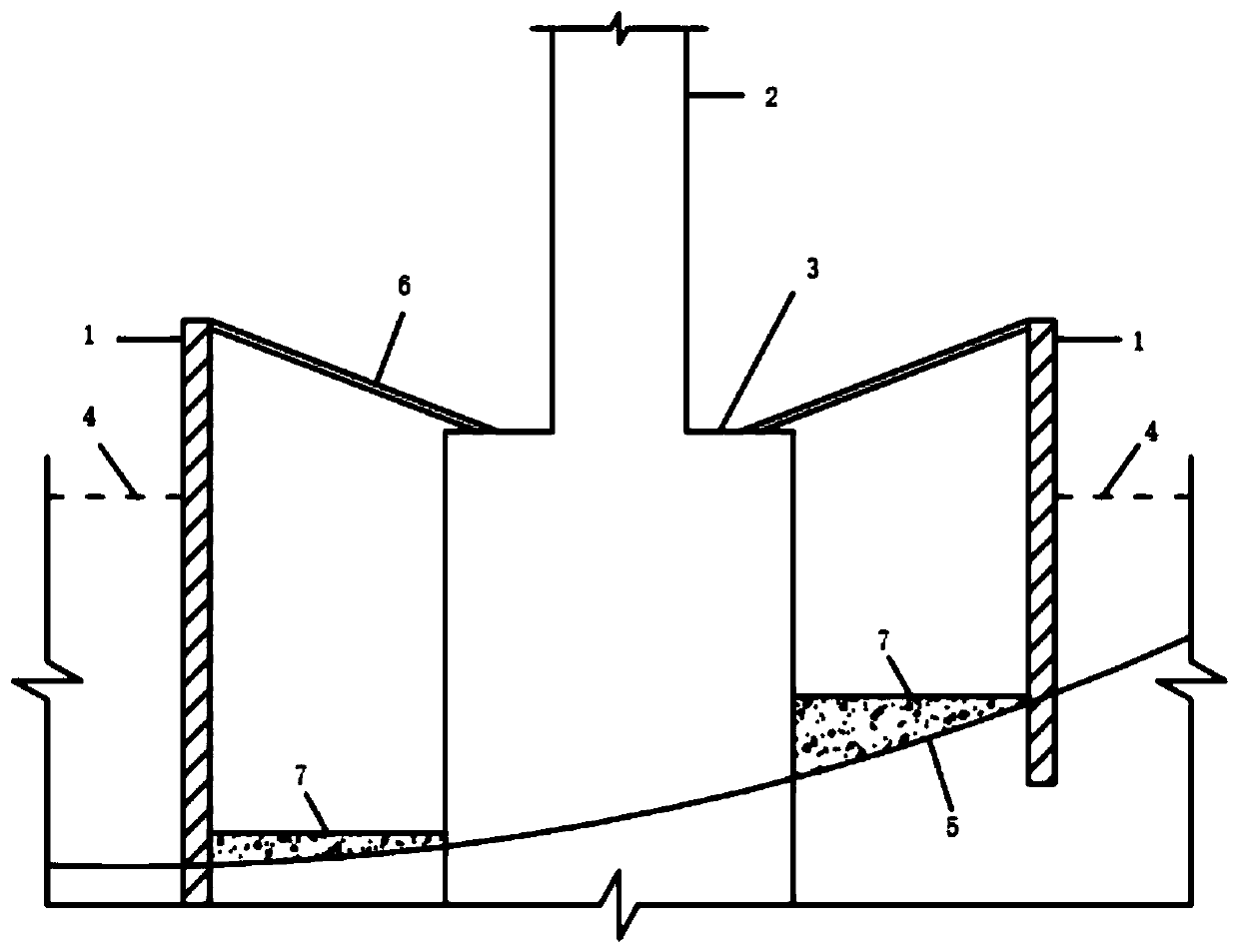

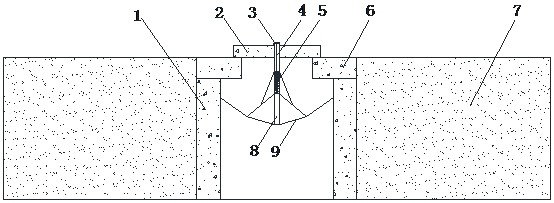

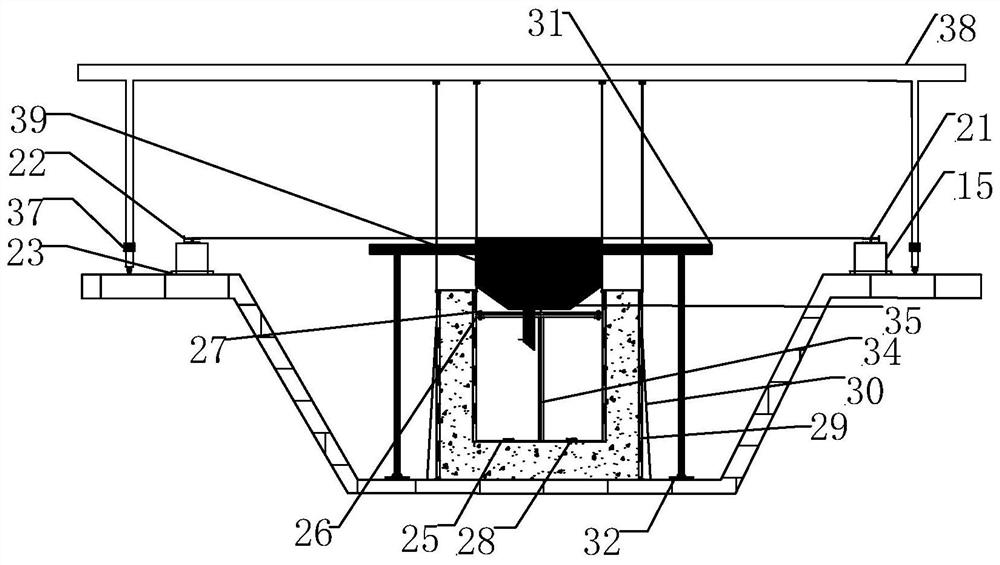

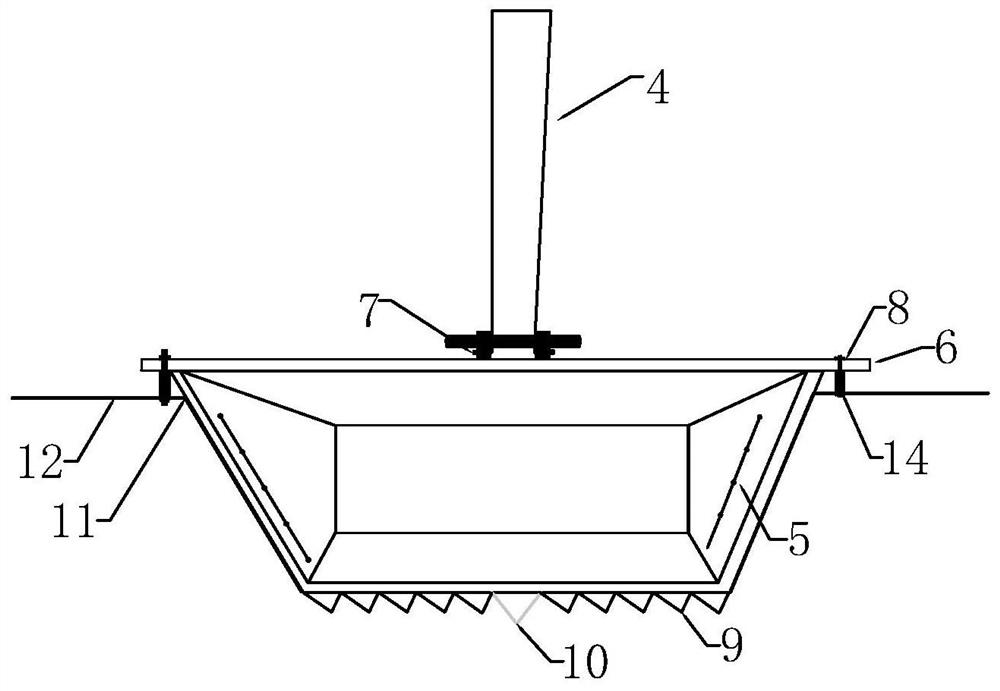

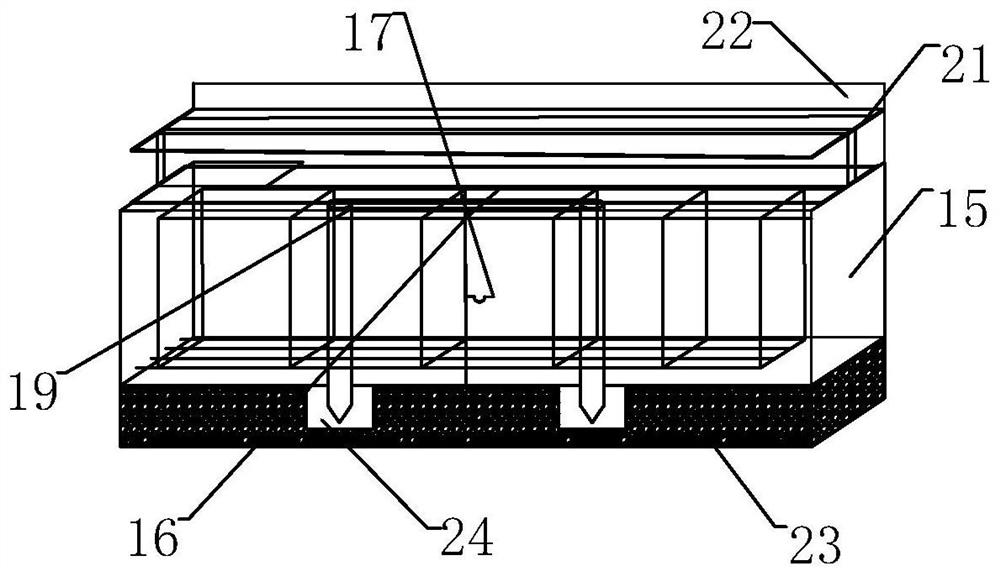

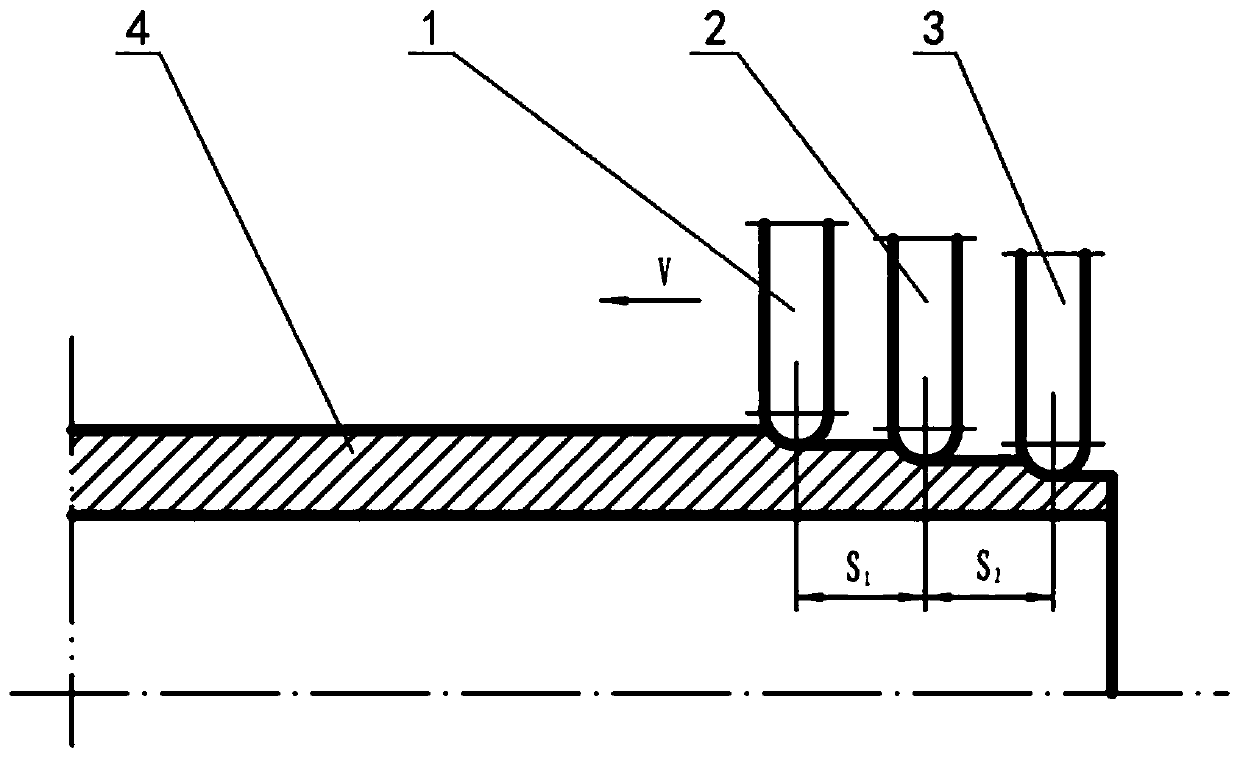

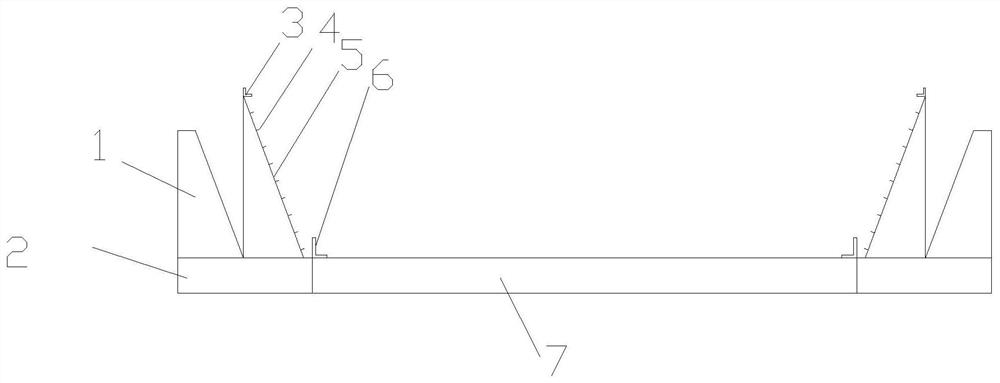

Integrally-formed drainage ditch and construction method thereof

The invention discloses an integrally-formed drainage ditch, which comprises a drainage ditch body, a shaped digging bucket, a shaped slope scraper, sliding mold rails, a shaped side mold and a bottomscraping cross beam frame, wherein the sliding mold rails are assembled on two sides of the drainage ditch body; the shaped side mold is arranged in the drainage ditch body; the bottom scraping crossbeam frame is arranged at the bottom of the drainage ditch body; the shaped side mold can be fixedly arranged on the bottom scraping cross beam frame; the bottom scraping cross beam frame is connected with a sliding cross beam gantry and is dragged and slid by the sliding cross beam gantry; and the shaped side mold is connected with a side mold gantry and is dragged and slid by the side mold gantry. The drainage ditch simplifies the construction steps, saves the construction time, reduces the construction cost, is easy to excavate and form, has low operation difficulty, so that the safety inthe construction process can be effectively ensured; and the drainage ditch has beautiful appearance and good quality. The second object of the invention is the construction method of the integrally-formed drainage ditch, the method is applied to the integrally-formed drainage ditch, and further has the advantages of high safety, high convenience and the like.

Owner:HANGZHOU JIANGRUN TECH LIMITED

Climbing mold system attachment type intelligent spraying maintenance device and maintenance method thereof

PendingCN108276024ASolve spray maintenance problemsQuality improvementBuilding material handlingWater resourcesEngineering

The invention discloses a climbing mold system attachment type intelligent spraying maintenance device and a maintenance method thereof. The spraying maintenance device comprises a water supply pipeline and a spraying assembly; the spraying assembly comprises a plurality of water conveying pipelines and spraying heads; the water conveying pipelines are jointed sequentially around the structural exterior wall; the spraying heads are arranged on the water conveying pipelines; the spraying assembly is fixedly arranged on a climbing mold frame steel beam of a climbing mold system; one end of the water supply pipeline is connected with a water supply point and the other end of the water supply pipeline is in run-through connection with the water conveying pipelines; and when the climbing mold system lifts to a station, the spraying assembly sprays the to-be-maintained structural exterior wall. The climbing mold system attachment type intelligent spraying maintenance device has the advantages of saving water resource, saving cost and improving concrete quality.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

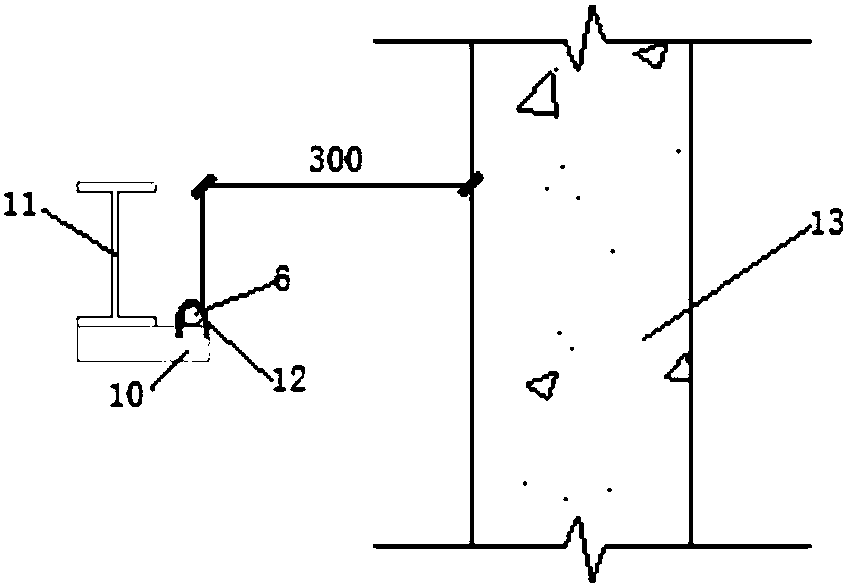

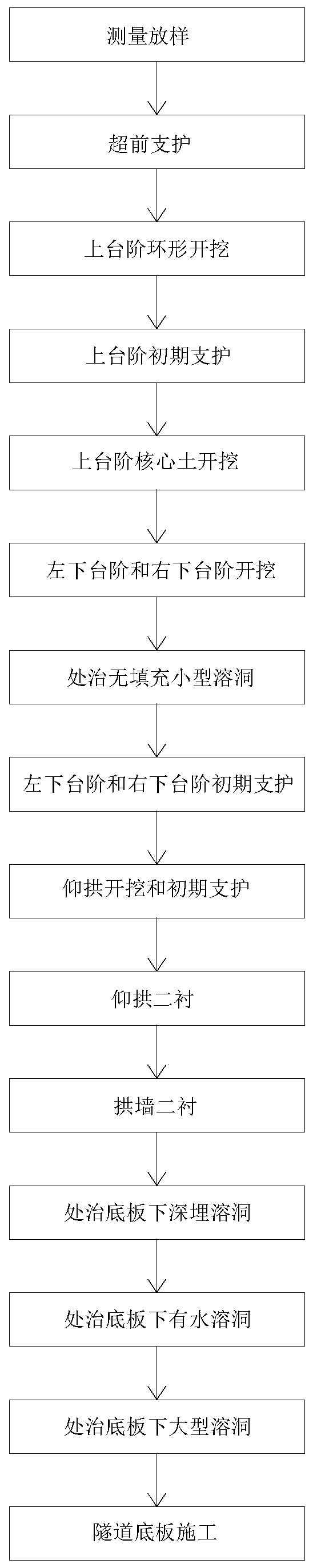

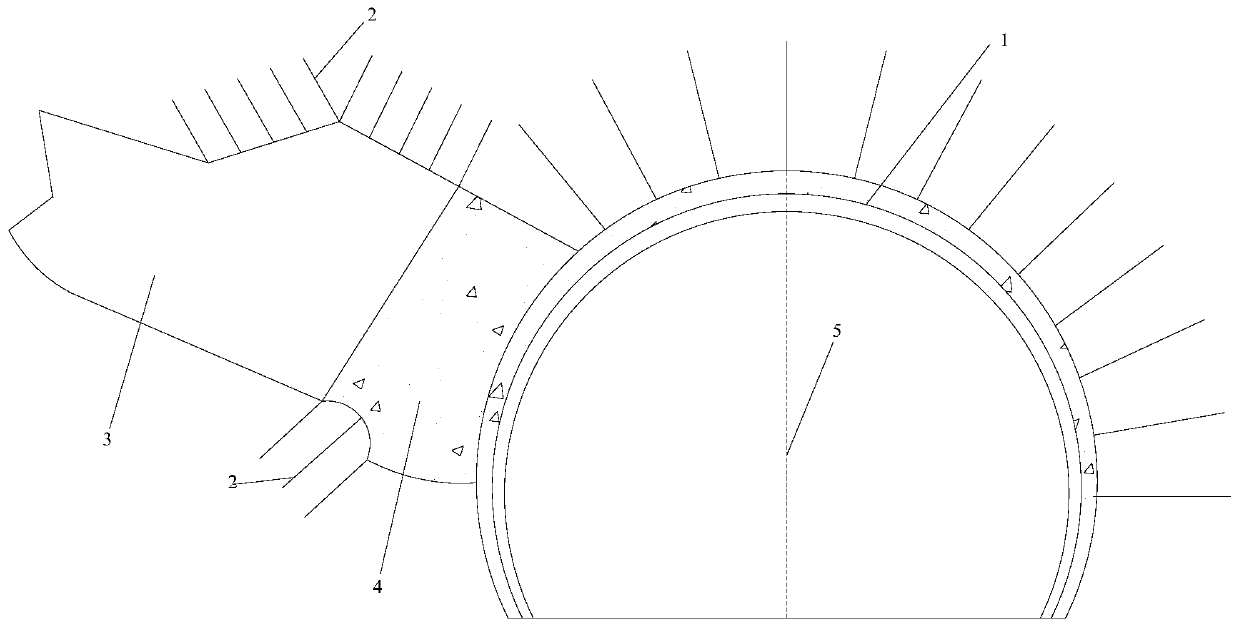

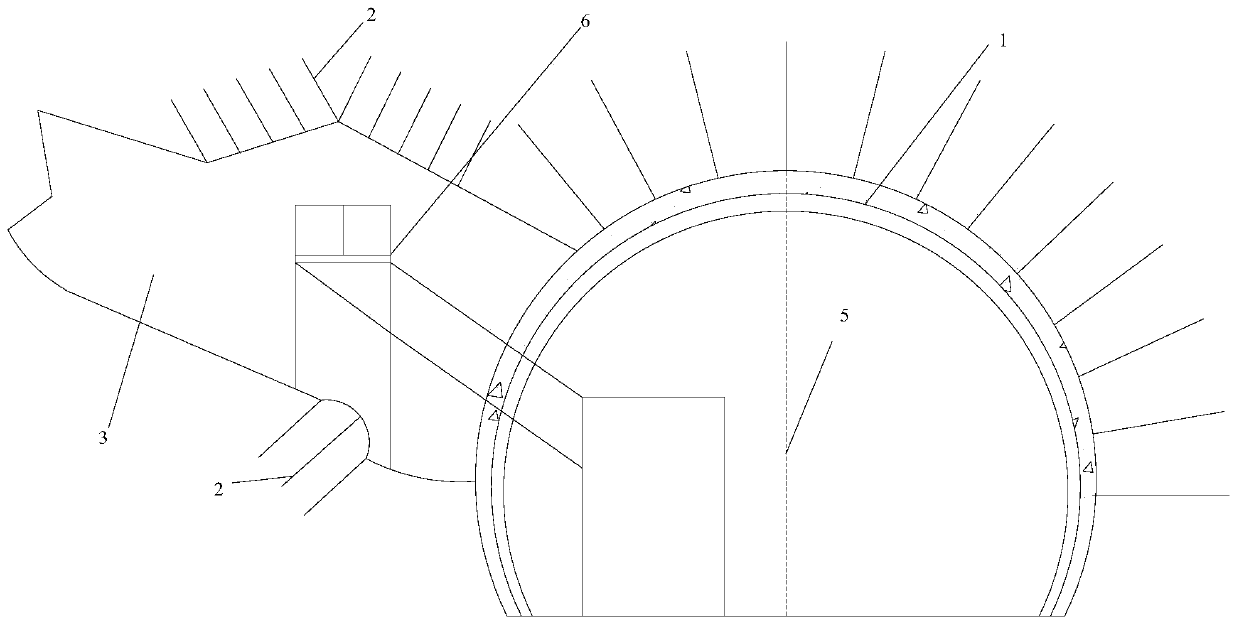

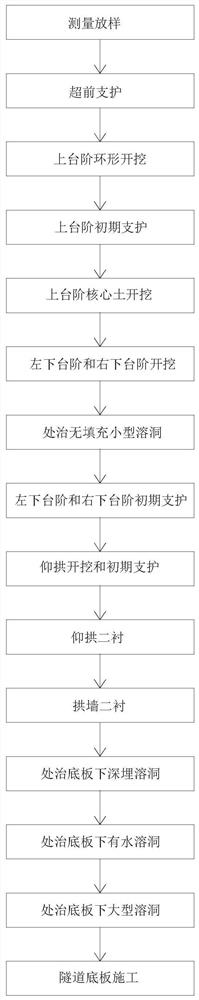

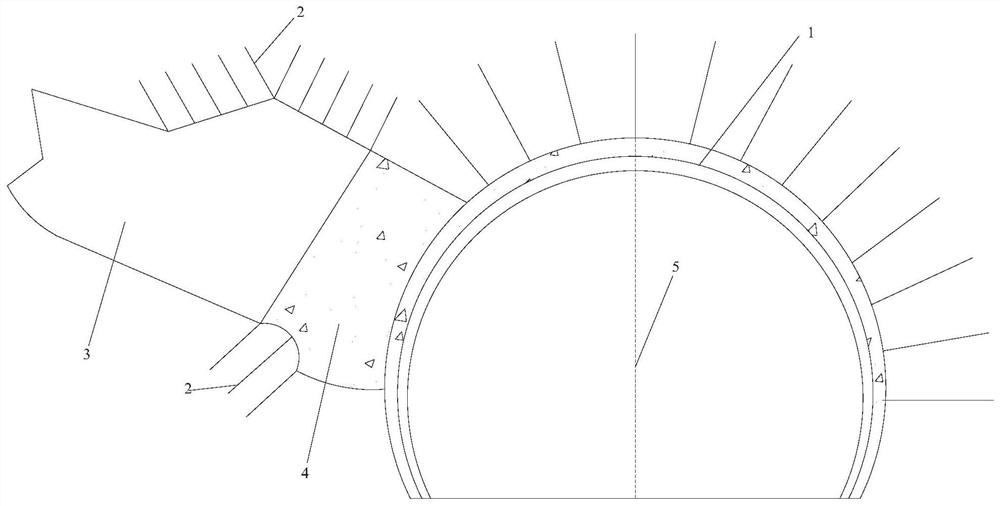

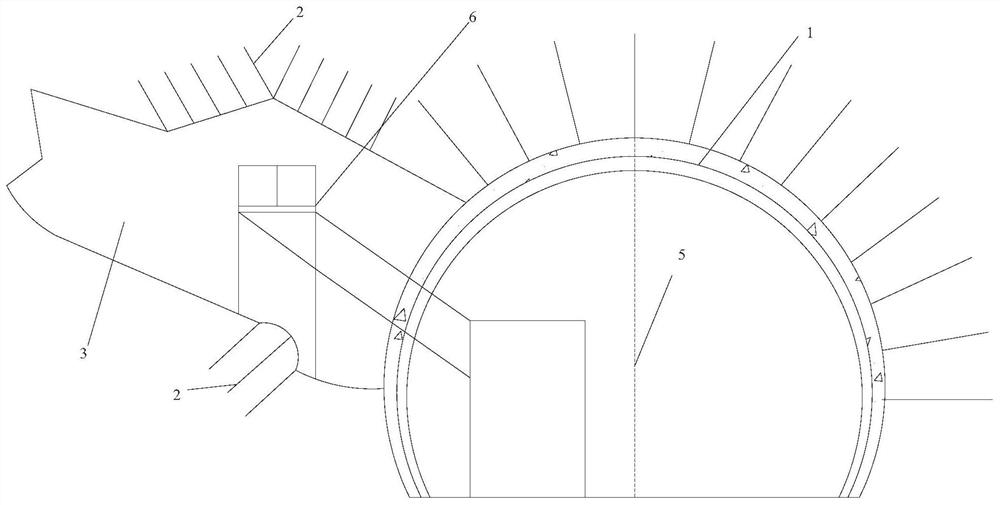

Construction method of tunnel in karst section of soft surrounding rock

ActiveCN111119904AReduce construction stepsShorten construction timeUnderground chambersDrainageKarstCave

The invention relates to a construction method of a tunnel in a karst section of soft surrounding rock. The construction method of the tunnel in the karst section of soft surrounding rock comprises the steps of 1, measuring and lofting; 2, carrying out forepoling; 3, starting to annularly excavate upper steps; 4, carrying out early support on the upper steps; 5, starting to excavate core soil of the upper steps; 6, starting to excavate left lower steps and right lower steps simultaneously; 7, adopting a tunnel through non-filling small-sized karst cave treatment structure to treat a non-filling small-sized karst cave; 8, carrying out early support on the left lower steps and on the right lower steps at the same time; 9, starting to excavate an inverted arch and carrying out early support on the inverted arch; 10, carrying out second lining on the inverted arch and on an arch wall; 11, adopting an under tunnel floor deep-buried karst cave treatment structure to treat a deep-buried karstcave; 12, adopting an under tunnel floor water karst cave treatment structure to treat a water karst cave; 13, adopting an under tunnel floor large karst cave treatment structure to treat a large karst cave; and 14, carrying out construction on a tunnel floor. The construction method of the tunnel in the karst section of soft surrounding rock has the beneficial effects that a dismantling-free template used in the construction method does not need to be dismantled after concrete is poured, the number of construction steps is reduced, and construction time is shortened.

Owner:ZHEJIANG UNIV CITY COLLEGE

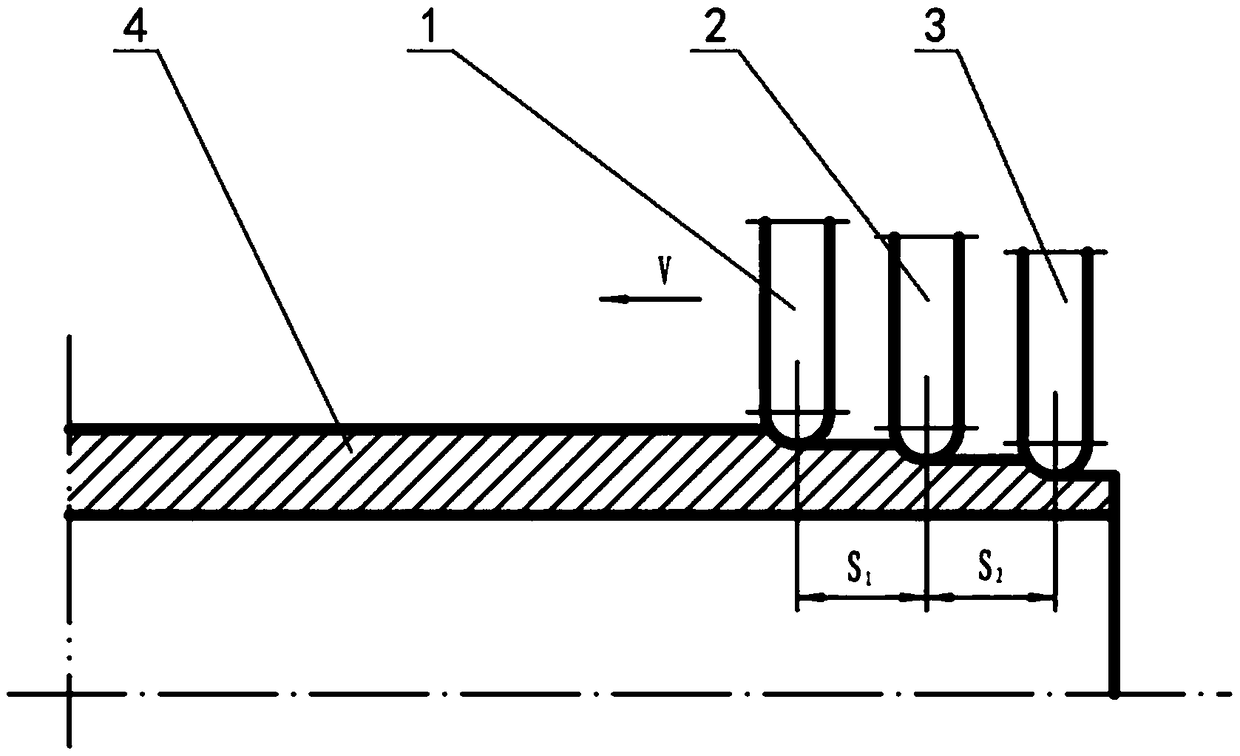

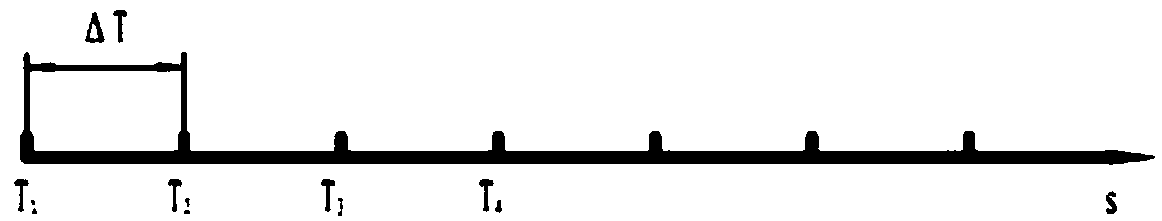

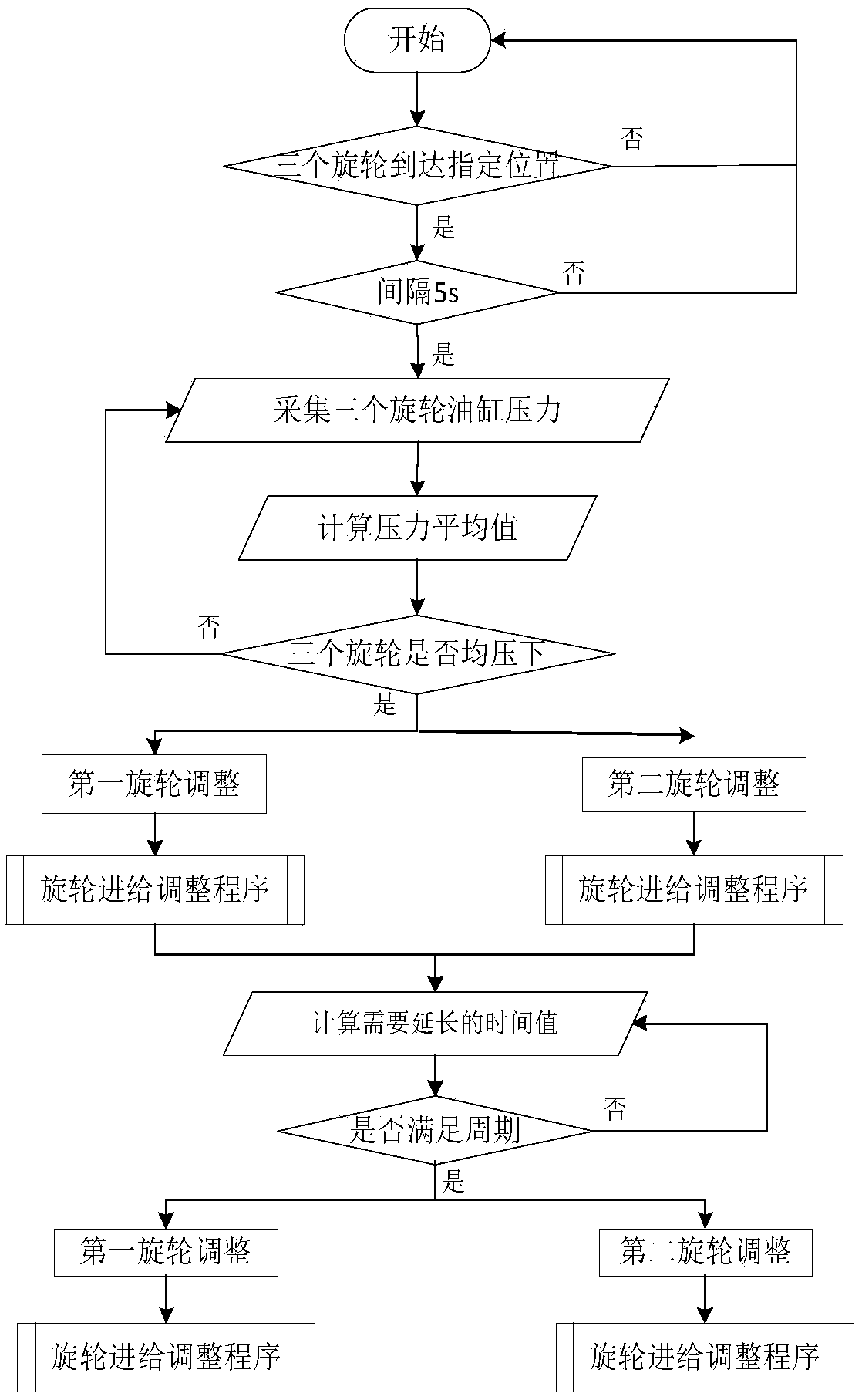

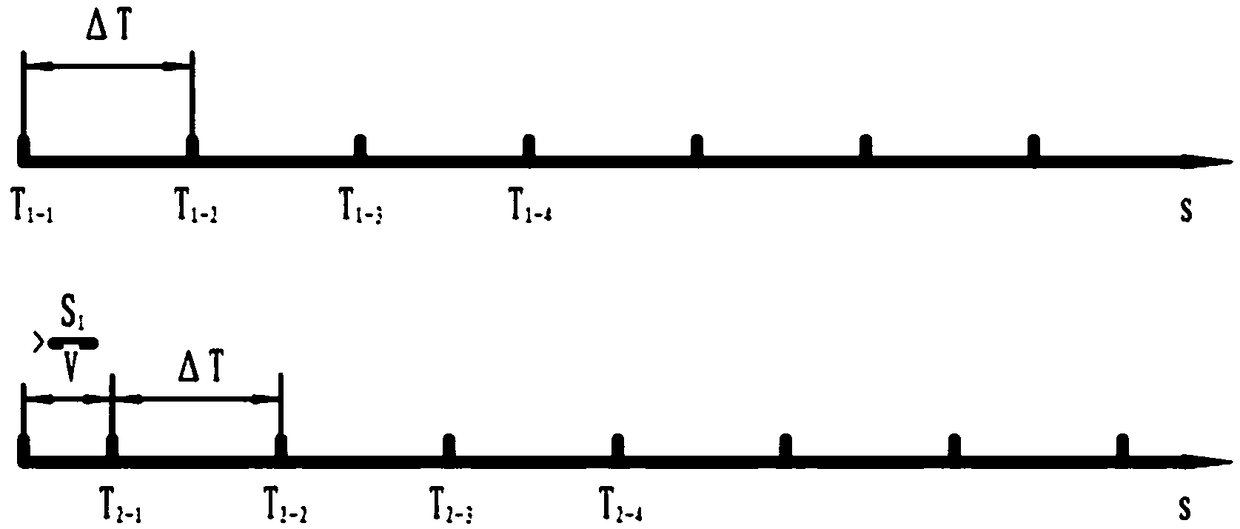

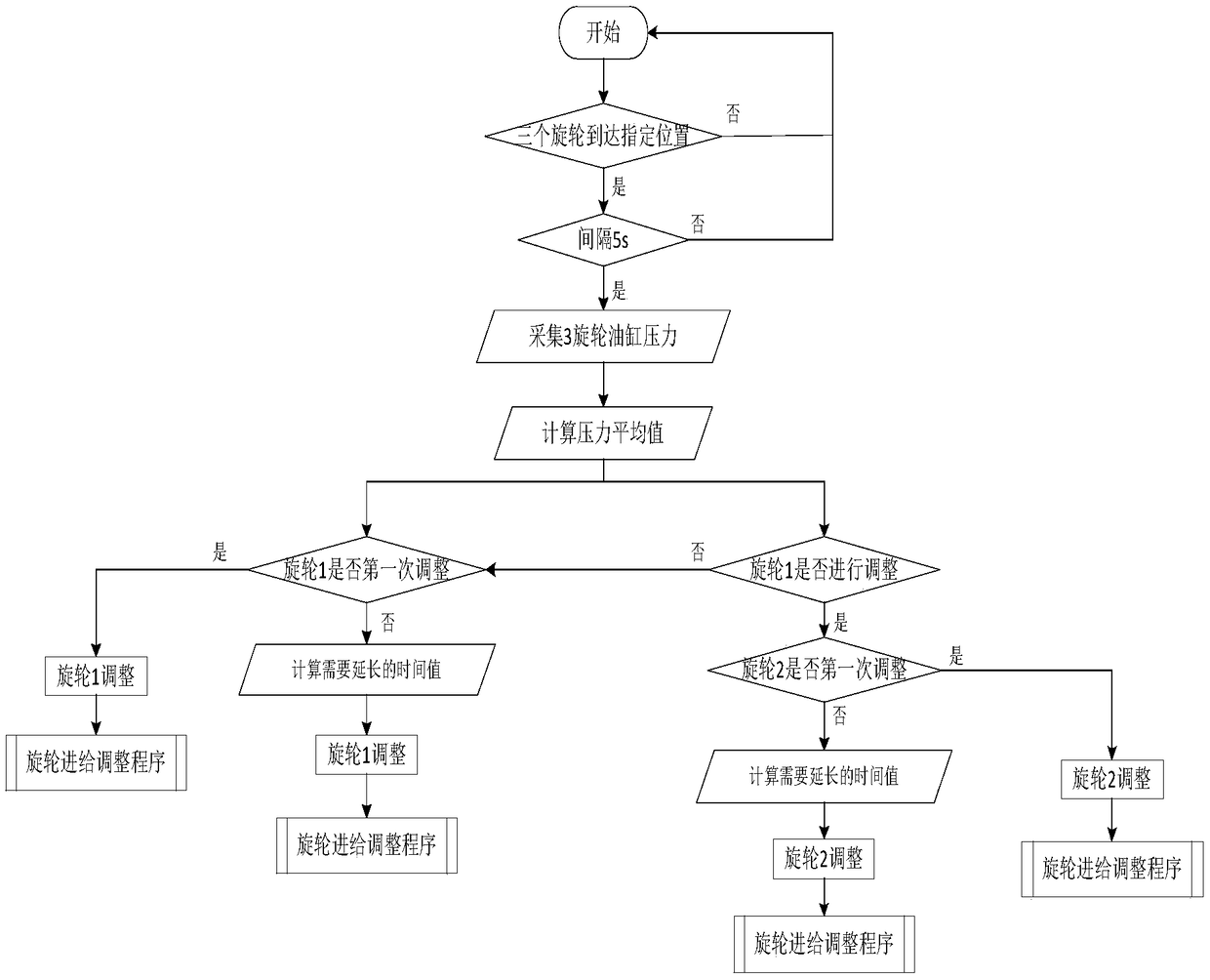

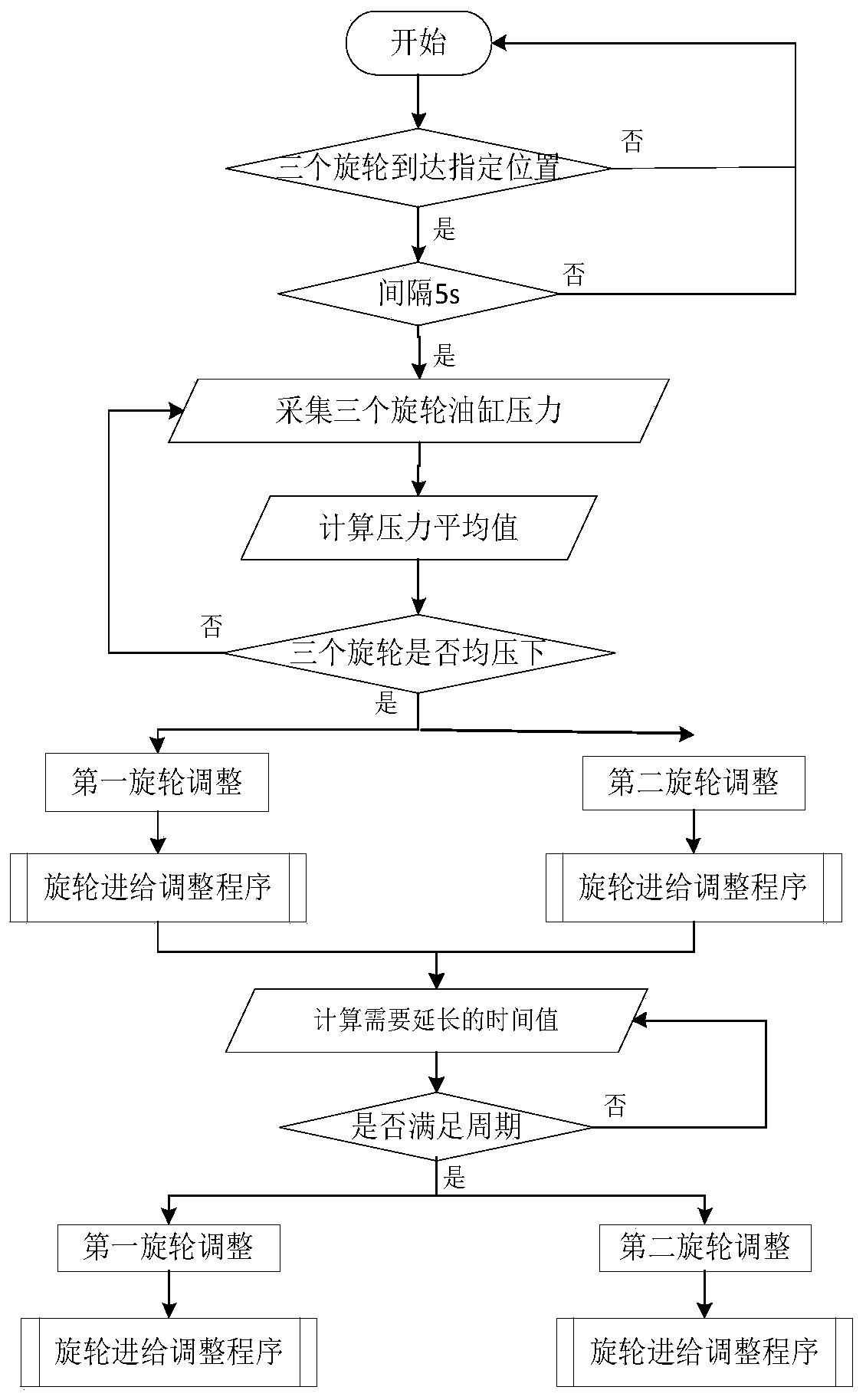

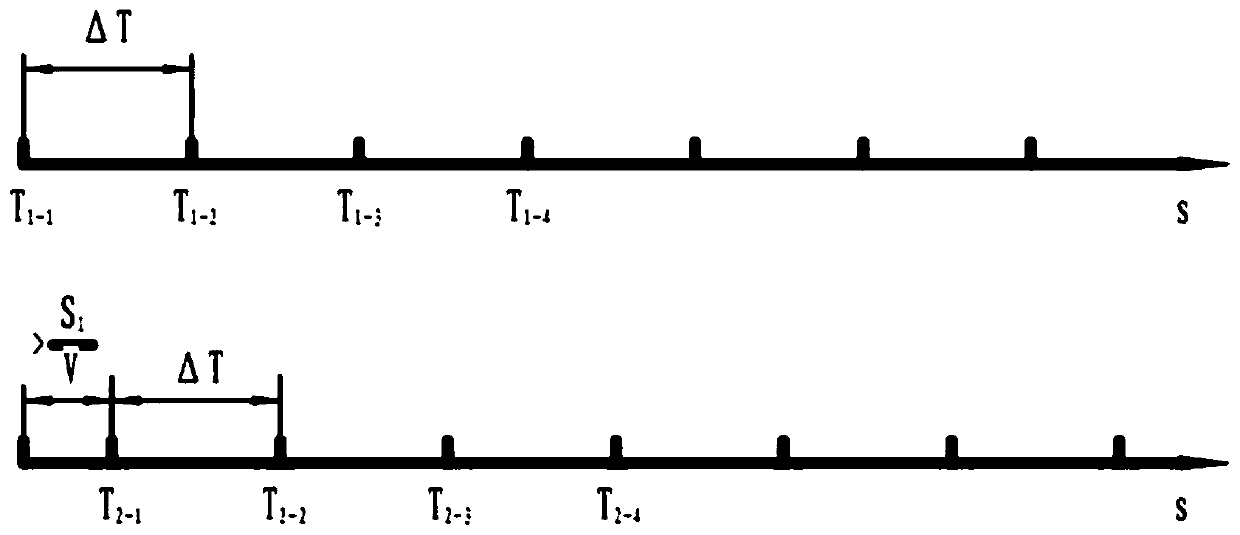

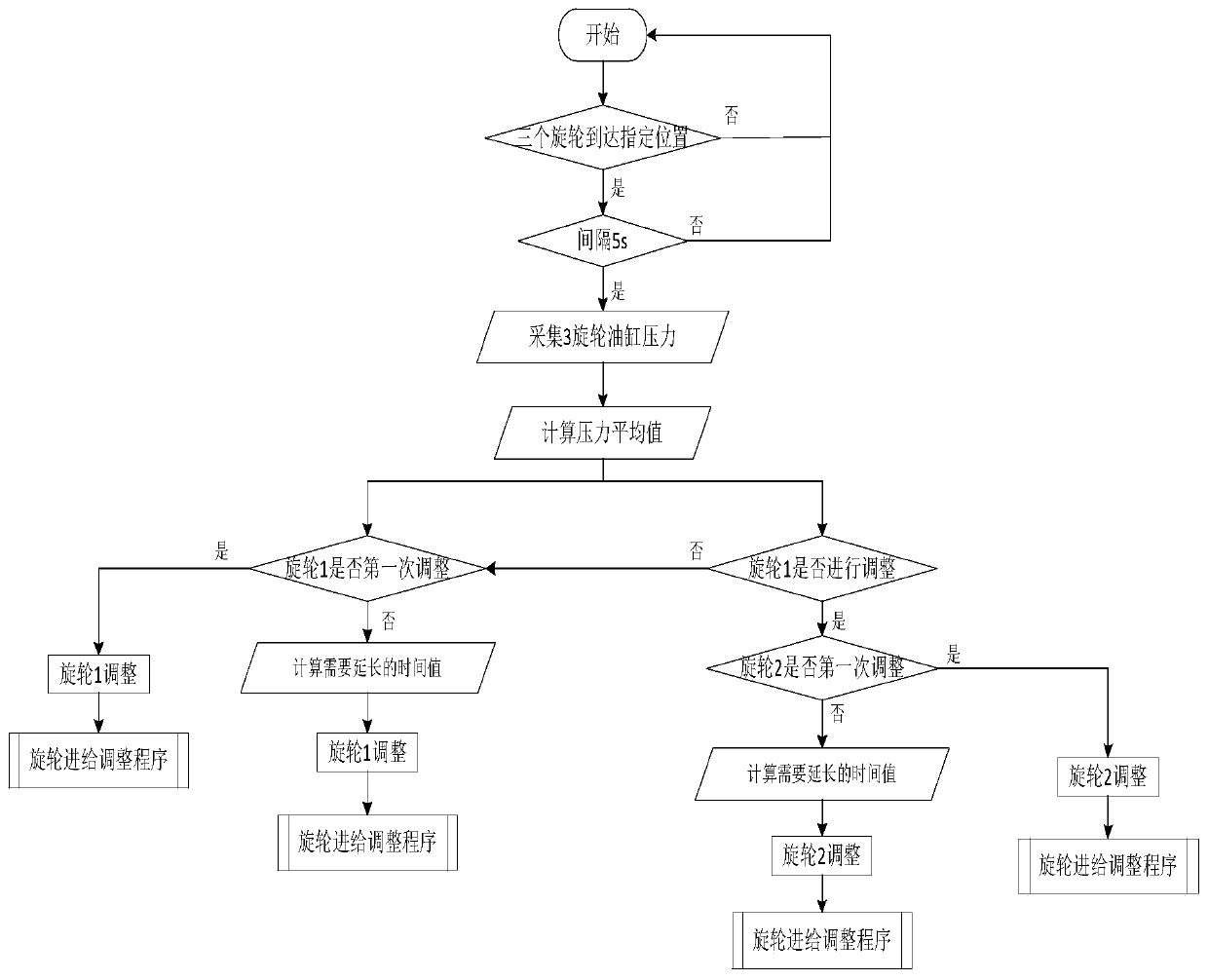

Method for force balance control over three transverse spinning rollers of spinning machine

The invention provides a method for force balance control over three transverse spinning rollers of a spinning machine. The method for force balance control over the three transverse spinning rollersof the spinning machine comprises the steps that the initial pressing positions of the spinning wheels and the offset distance between the spinning wheels are arranged; the initial pressing reductionrectifying moments and pressing reduction rectifying sampling periods are determined respectively; after the spinning wheels are in place, the pressure data of the spinning wheels are collected; trackof a third spinning wheel is determined, and the standard pressure value of the spinning wheels is determined; and in the initial pressing reduction rectifying moment of a first spinning wheel, according to the pressure data and the standard pressure value of the first spinning wheel collected, first time rectification is conducted on the pressing reduction of the first spinning wheel, and then rectification is conducted on the pressing reduction of the first spinning wheel in each pressing reduction rectifying sampling period. By means of the method for force balance control over the three transverse spinning rollers of the spinning machine, the method for controlling transverse force balance of the three spinning wheels in the spinning machining process can be solved; the sizes of spinning pressure of the first spinning wheel and the second spinning wheel are actively adjusted successively; the radial displacement variable of the three spinning wheels is calculated and adjusted automatically through a numerical control system; and the purpose of transverse force balance control over the three spinning wheels is gradually achieved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

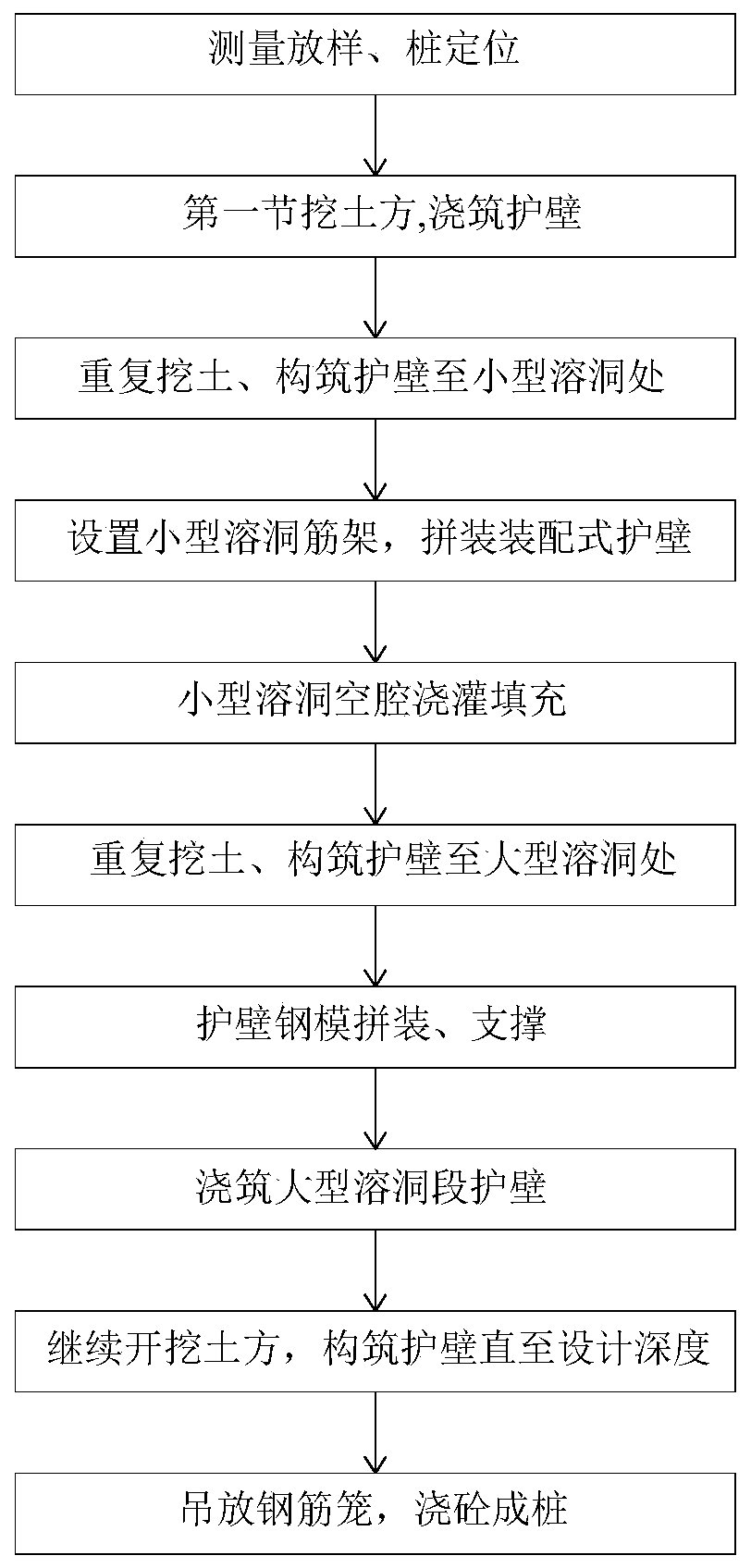

Construction method of karst geological cast-in-place piles

InactiveCN110952534AImprove construction efficiencyShorten the construction periodBulkheads/pilesKarstRebar

The invention relates to a construction method of karst geological cast-in-place piles. The construction method comprises the following steps: (1) performing survey and setting out, and positioning piles; (2) carrying out a first section of earth excavation, and pouring retaining walls; (3) repeatedly excavating earth, and constructing the retaining walls to small karst caves; (4) arranging smallkarst cave reinforcement frames, and assembling fabricated retaining walls; (5) pouring and filling cavities of the small karst caves; (6) repeatedly excavating earth, and constructing retaining wallsto large karst caves; (7) assembling and supporting retaining wall steel moulds; (8) pouring large karst cave section retaining walls; (9) continuously excavating earth, and constructing the retaining walls till the design depth is reached; and (10) hoisting and placing reinforcement cages, and pouring concrete to form the piles. The construction method has the advantages that assembled precast slabs in the construction method are prefabricated in a factory and transported to a site for assembly, so that the construction efficiency is greatly improved, a construction period is shortened, andthe technical benefit is remarkable. The built-in reinforcement frames and cavity pouring and filling structures in the karst caves according to the construction method can improve the overall stability of the karst caves, so that the stability of pile foundations at the karst caves is improved.

Owner:ZHEJIANG UNIV CITY COLLEGE

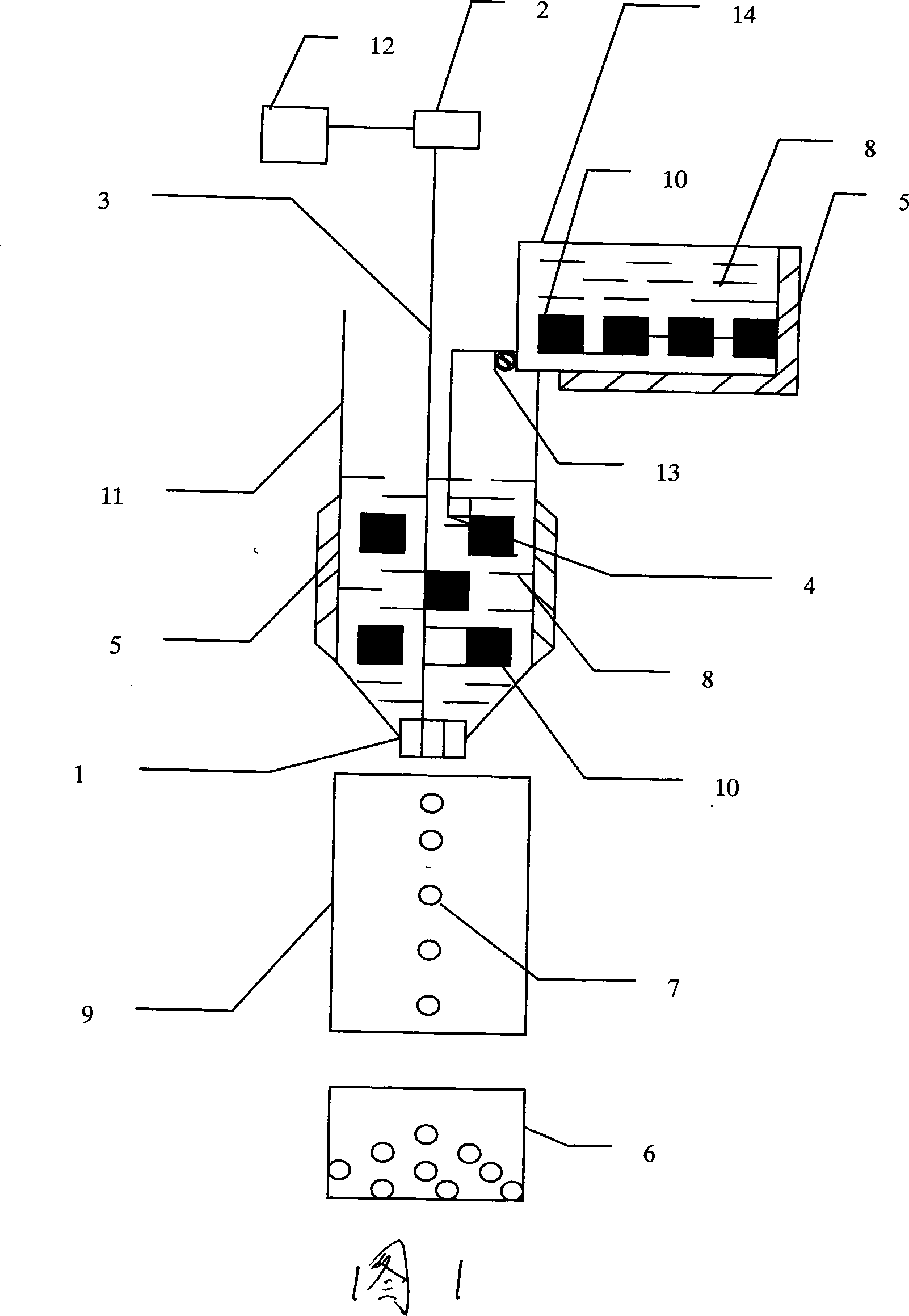

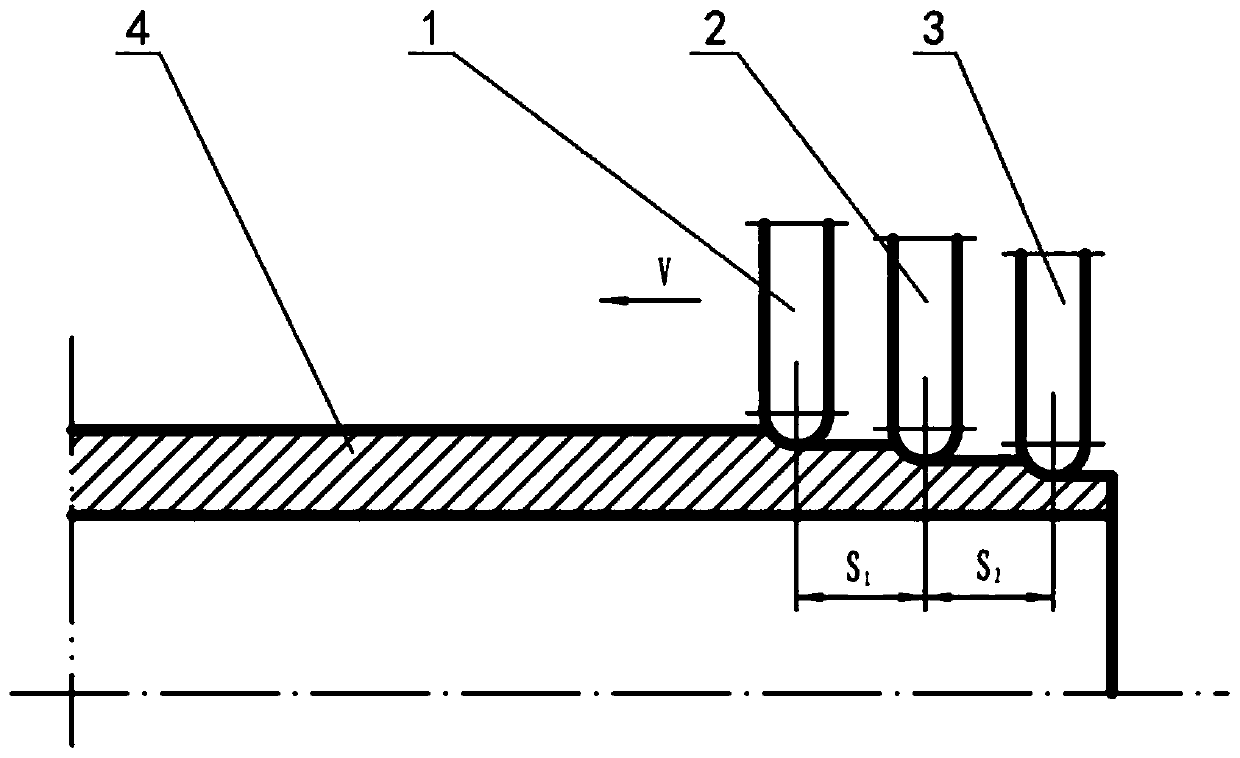

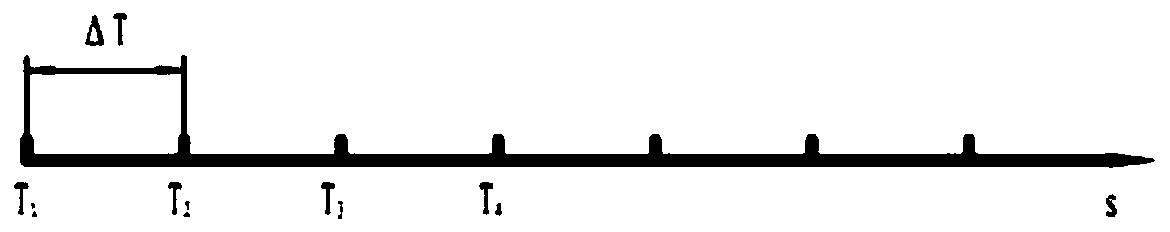

Technique of preparing blue pills and device thereof

InactiveCN101176921AUniformityKnow uniformityTube/lamp vessel fillingGas discharge lamp detailsAlloyLength wave

The invention relates to a manufacturing technique and a device for the pilulae hydrargyri, belonging to the technical field of pilulae hydrargyri manufacturing, which mainly comprises a tower body, an electrical heating jacket, an exciter, a signal generator and a nozzle. The invention is characterized in that: by changing the height of the fused alloy liquid and controlling the velocity and vibration of the fused liquid passing through the nozzle, the vibration wavelength Lambada can be got, which is required for forming the uniformed pilulae hydrargyris under a certain alloy liquid flow velocity based on the manufacturing technique; the mercury drops are cooled for producing the pilulae hydrargyris; and the uniformity of the pilulae hydrargyris can be obtained through measuring the diameters of the pilulae hydrargyris. The invention has the advantages of novel, unique and simple manufacturing technique, capability of obtaining the pilulae hydrargyris with ideal size, great reduction for production cost, increase of the one-time finished product qualified rate of the produced pilulae hydrargyris from 30% or so to 85 to 90%, and obvious technical benefit.

Owner:扬州市邗江天和电子厂

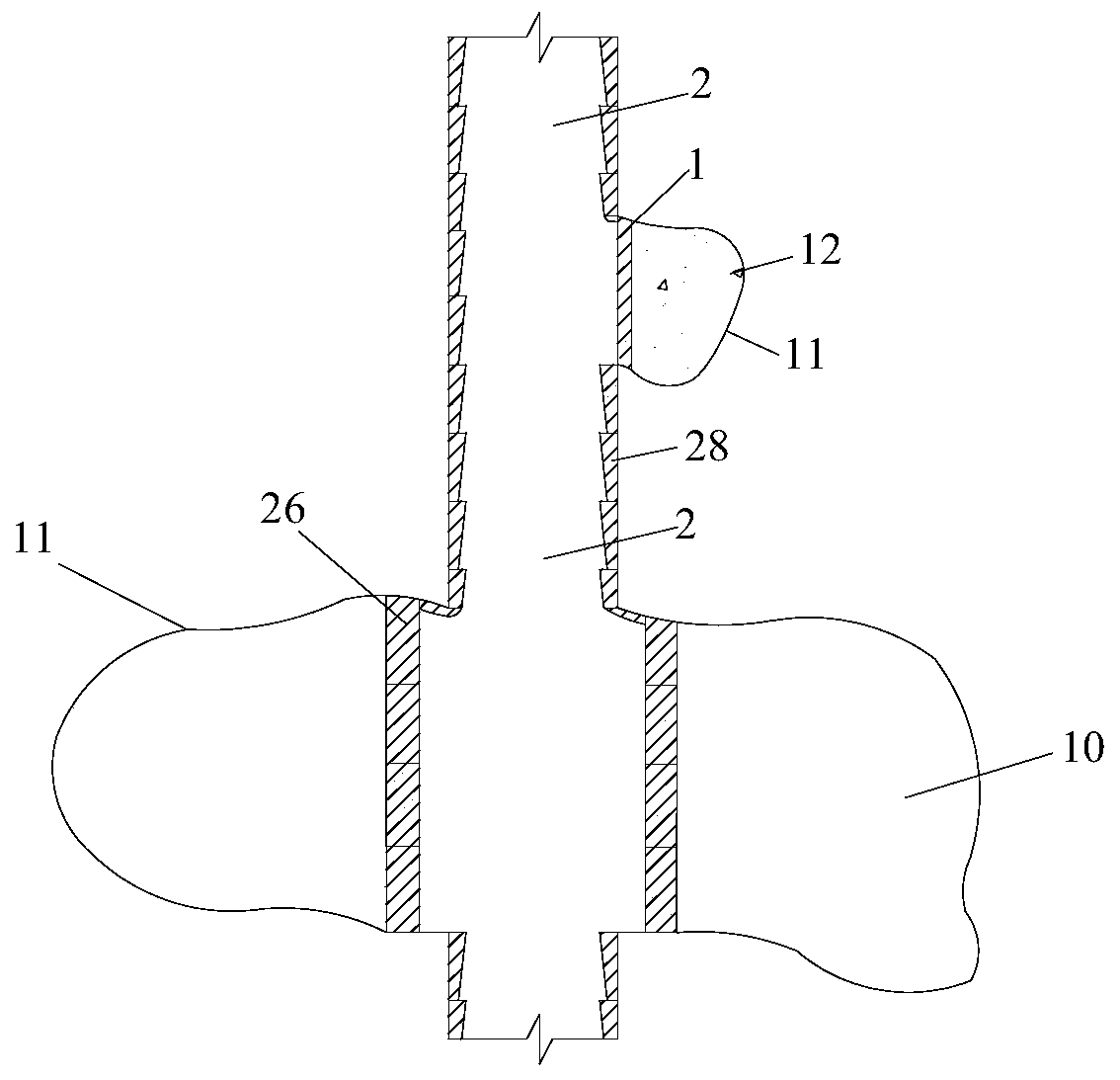

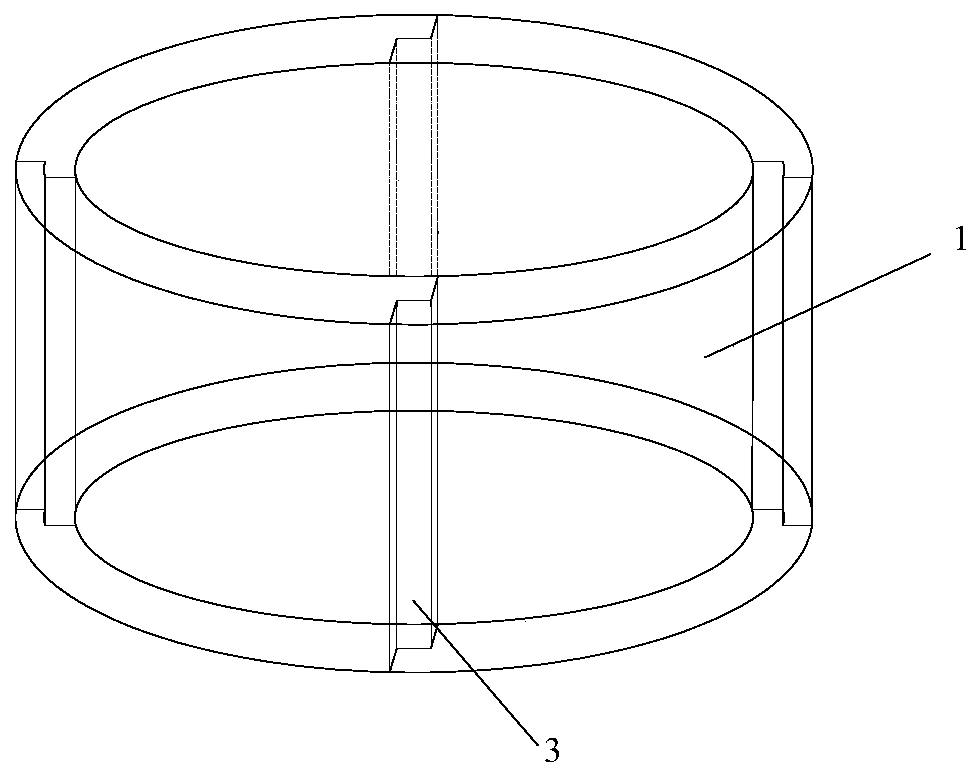

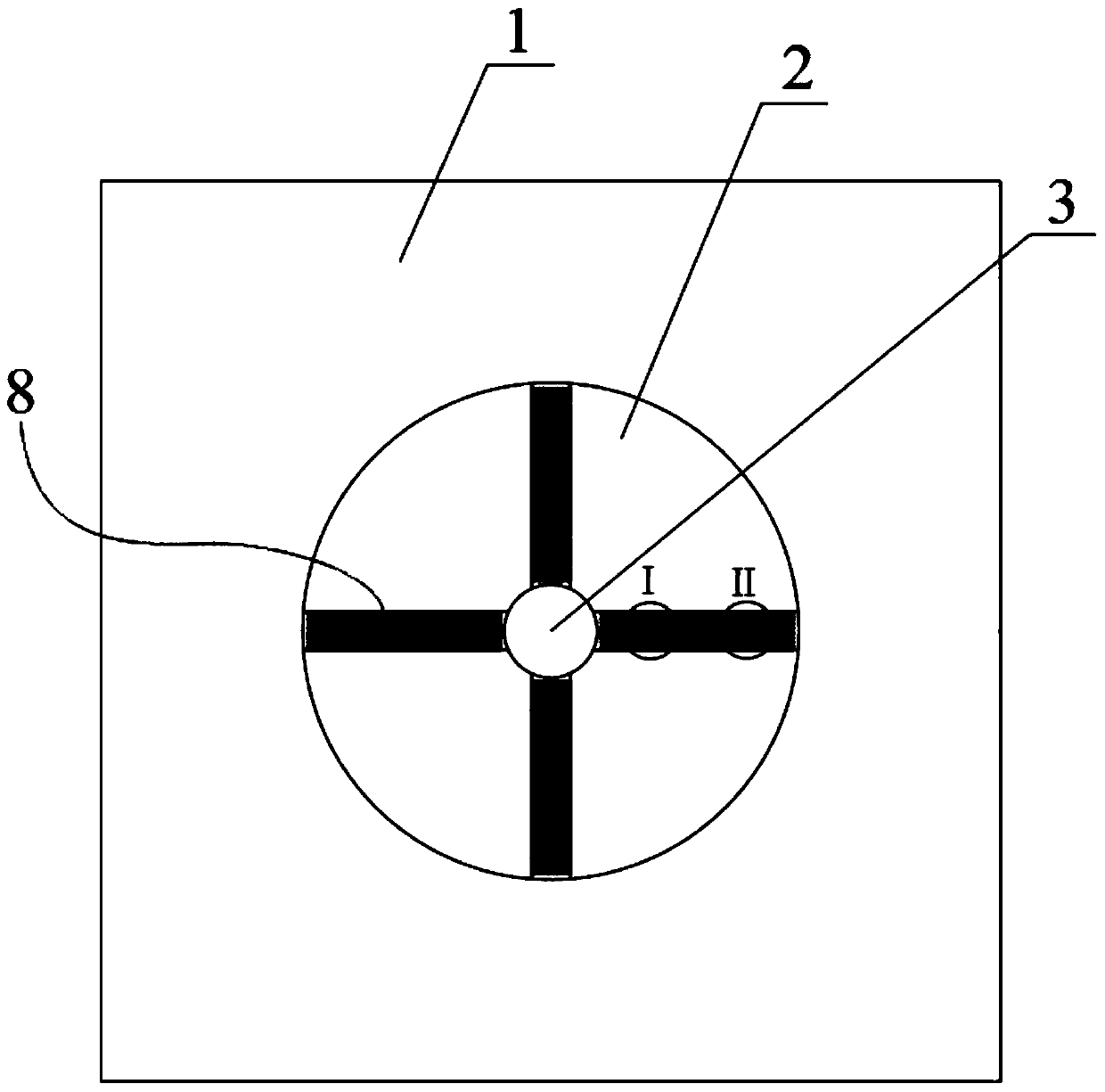

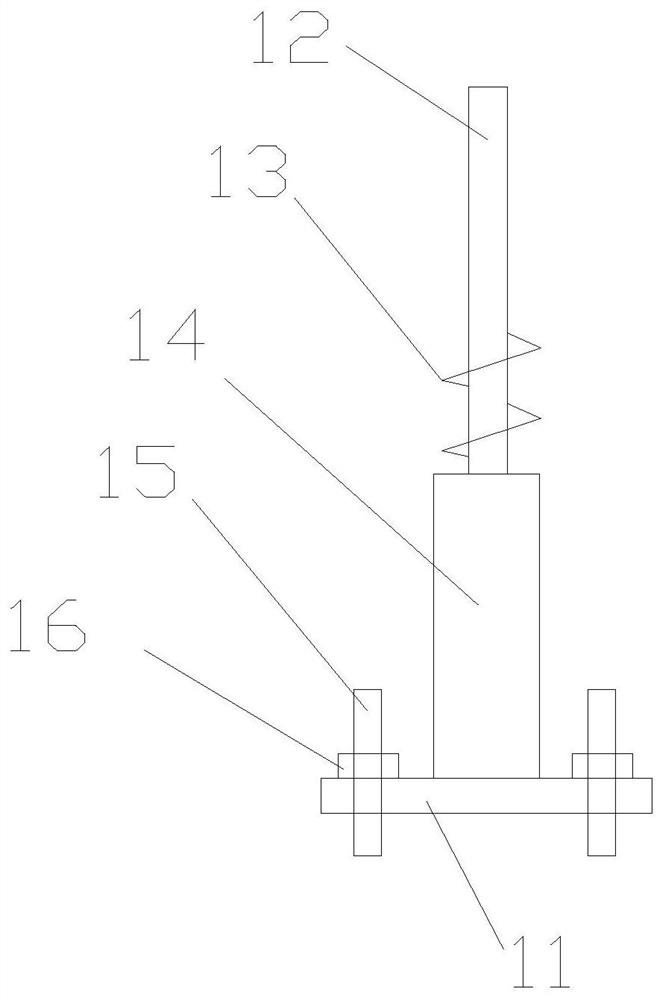

Mine tray for prejudging magnitude of anchoring force on basis of surface deformation and monitoring method

InactiveCN110905567AReduce labor intensityEasy to implement reinforcement measuresMining devicesAnchoring boltsEngineeringStructural engineering

The invention provides a mine tray for prejudging the magnitude of anchoring force on the basis of surface deformation and a monitoring method. According to the mine tray, a tray body comprises a spherical-crown-shaped part and a flat plate part; a deformation recognizing unit comprises four strip-shaped plastic thin pieces which form a cross shape and are attached to the surface of the spherical-crown-shaped part, one end of each strip-shaped plastic thin piece starts from the edge of an anchor rod hole, and the other end of each strip-shaped plastic thin piece extends to the edge of the spherical-crown-shaped part; each strip-shaped plastic thin piece is composed of a green section, an orange section and a red section, the surface of each strip-shaped plastic thin piece is coated with areflecting film material and covered with a fin unit, and the fin unit is composed of multiple rows of rectangular small plastic pieces distributed in the length direction of the strip-shaped plasticthin piece. The method includes the steps of calibrating the mine tray through a compression testing machine, installing mine trays produced in the same batch as the calibrated mine tray on site, andestimating the magnitude of the anchoring force. By means of the tray and the method, the stress conditions of a corresponding anchor rod or anchor cable can be conveniently and visually prejudged, and the labor intensity and monitoring cost of monitoring staff can be remarkably reduced.

Owner:CHINA UNIV OF MINING & TECH

Semiconductor devices and methods of assembling same

InactiveUS8735223B2Reduce difficultySignificant technical benefitsSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A method of forming a semiconductor device includes affixing a die to a heat sink to form a die and heat sink assembly and then placing the die and heat sink assembly on a support element. A semiconductor device includes a die and heat sink assembly disposed on a support element. The die and heat sink assembly is pre-assembled prior to being disposed on the support element.

Owner:NXP USA INC

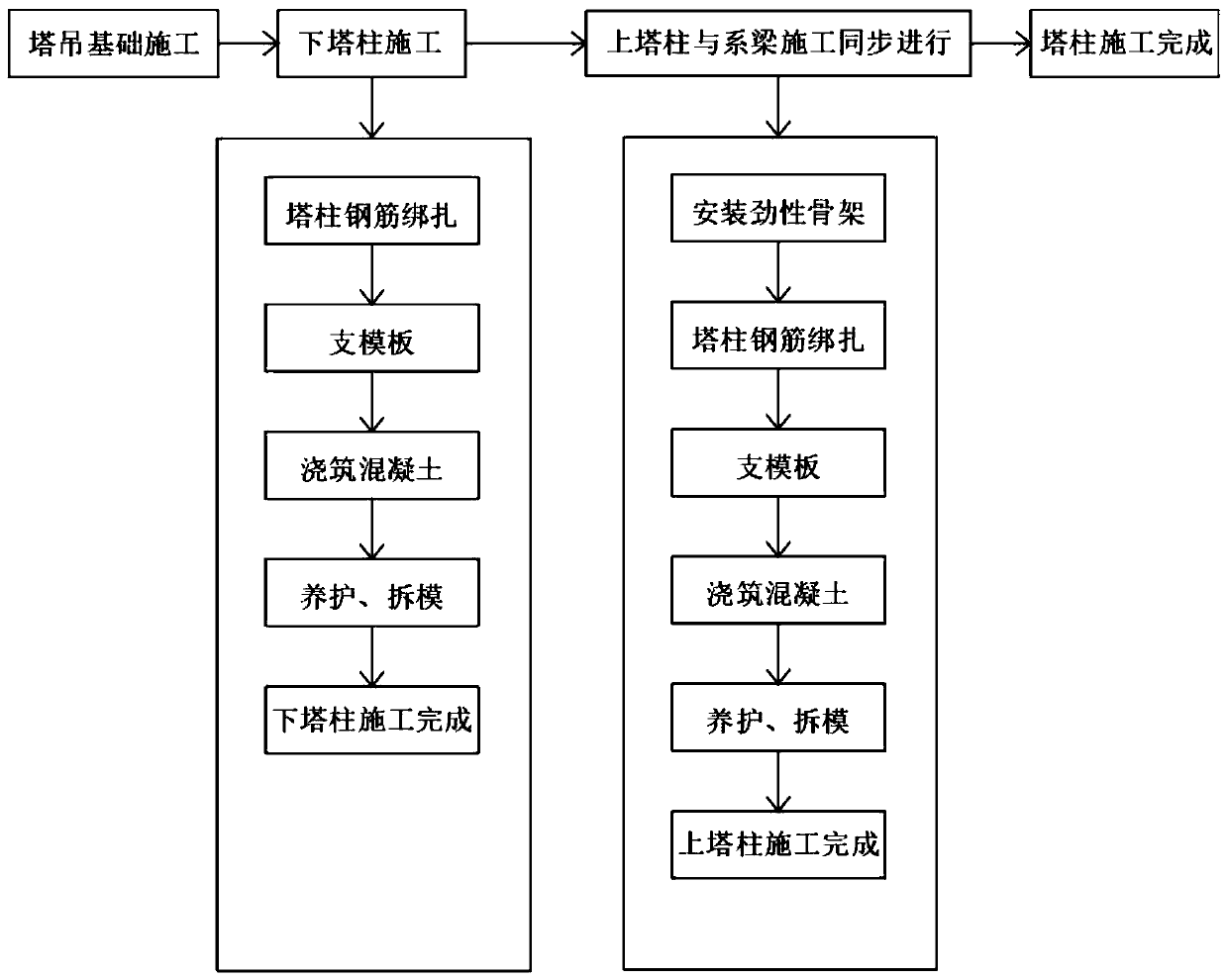

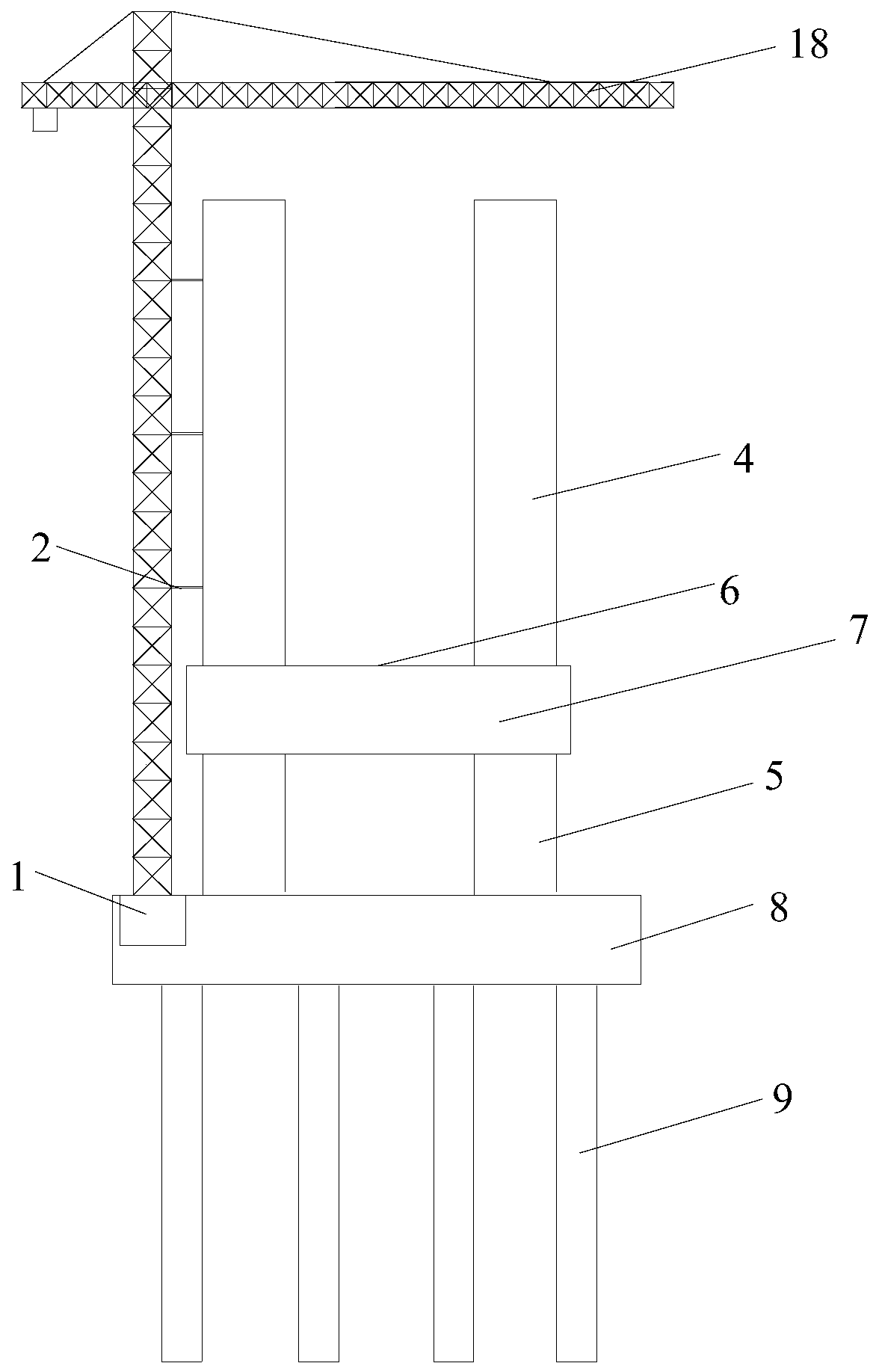

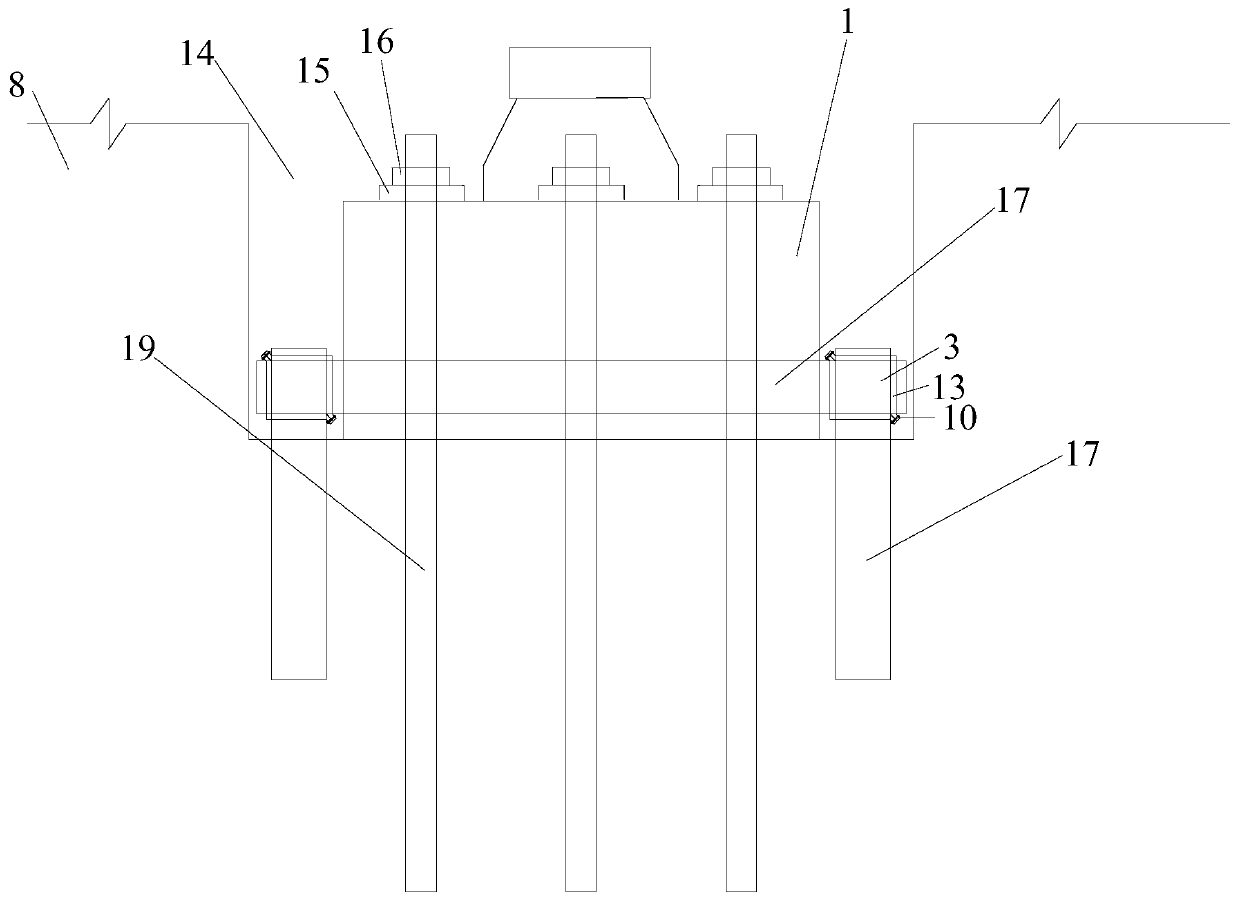

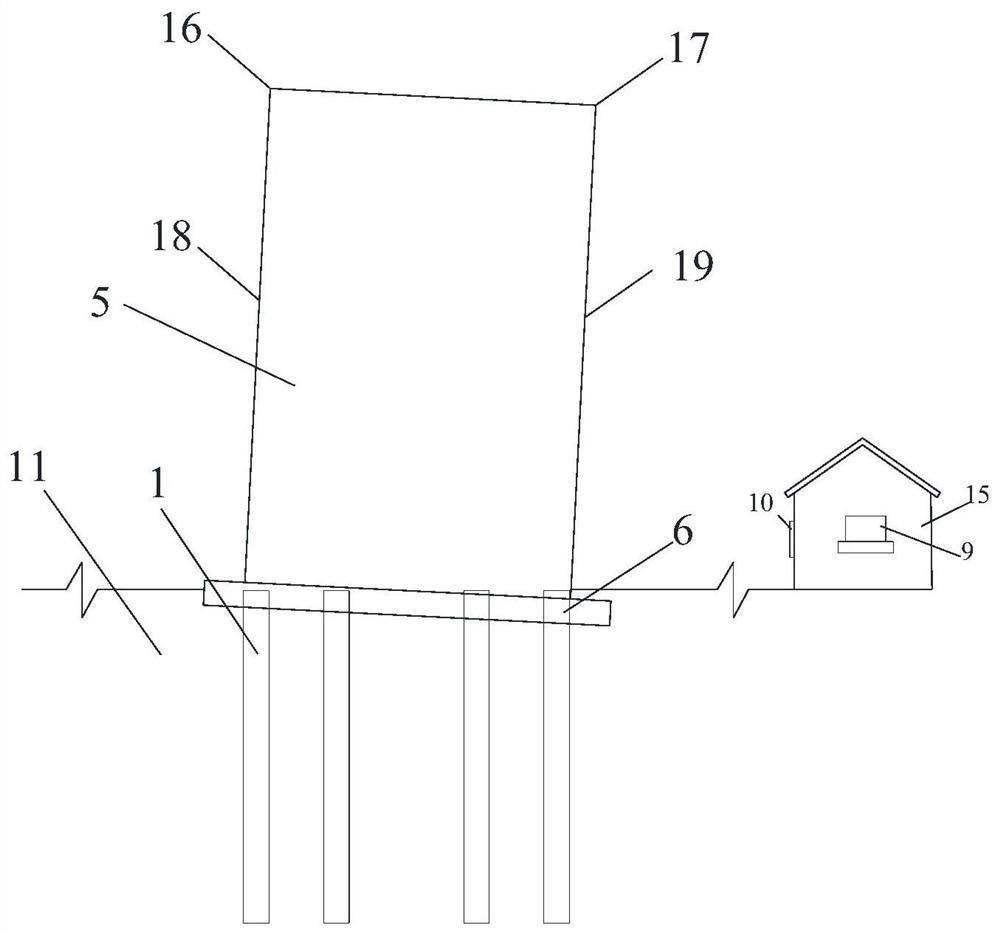

Cast-in-place tower of cable-stayed bridge and construction method of cast-in-place tower

ActiveCN110184915AEasy constructionSignificant technical benefitsCable-stayed bridgeBridge structural detailsSupporting systemFalsework

The invention relates to a cast-in-place tower of a cable-stayed bridge. The cast-in-place tower of the cable-stayed bridge comprises an upper tower straining beam supporting mold system, an upper tower supporting mold system, a lower tower supporting mold system and a cast-in-place tower construction tower crane system, wherein the upper tower straining beam supporting mold system comprises a supporting mold system construction platform, a longitudinal straining beam supporting system and a hanging type concrete pouring platform, the upper tower supporting mold system comprises a fast speed sliding type transferring system, a template fixing adjusting system and a stiff skeleton positioning and connecting device, the lower tower supporting mold system comprises a scaffold system integraltype hoop pile cap fixing system, a template fixing adjusting system fixed to a scaffold and a lower tower template system, and the cast-in-place tower construction tower crane system comprises an integral pre-buried tower crane foundation, a tower attached type hoop device and a tower crane. The cast-in-place tower has the beneficial effects that the tower crane foundation adopts the prefabricated integral type pre-buried tower crane foundation, the prefabricated foundation is placed in a space reserved in a pile cap and is fixed, the construction is simple, and the technical benefit is remarkable.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

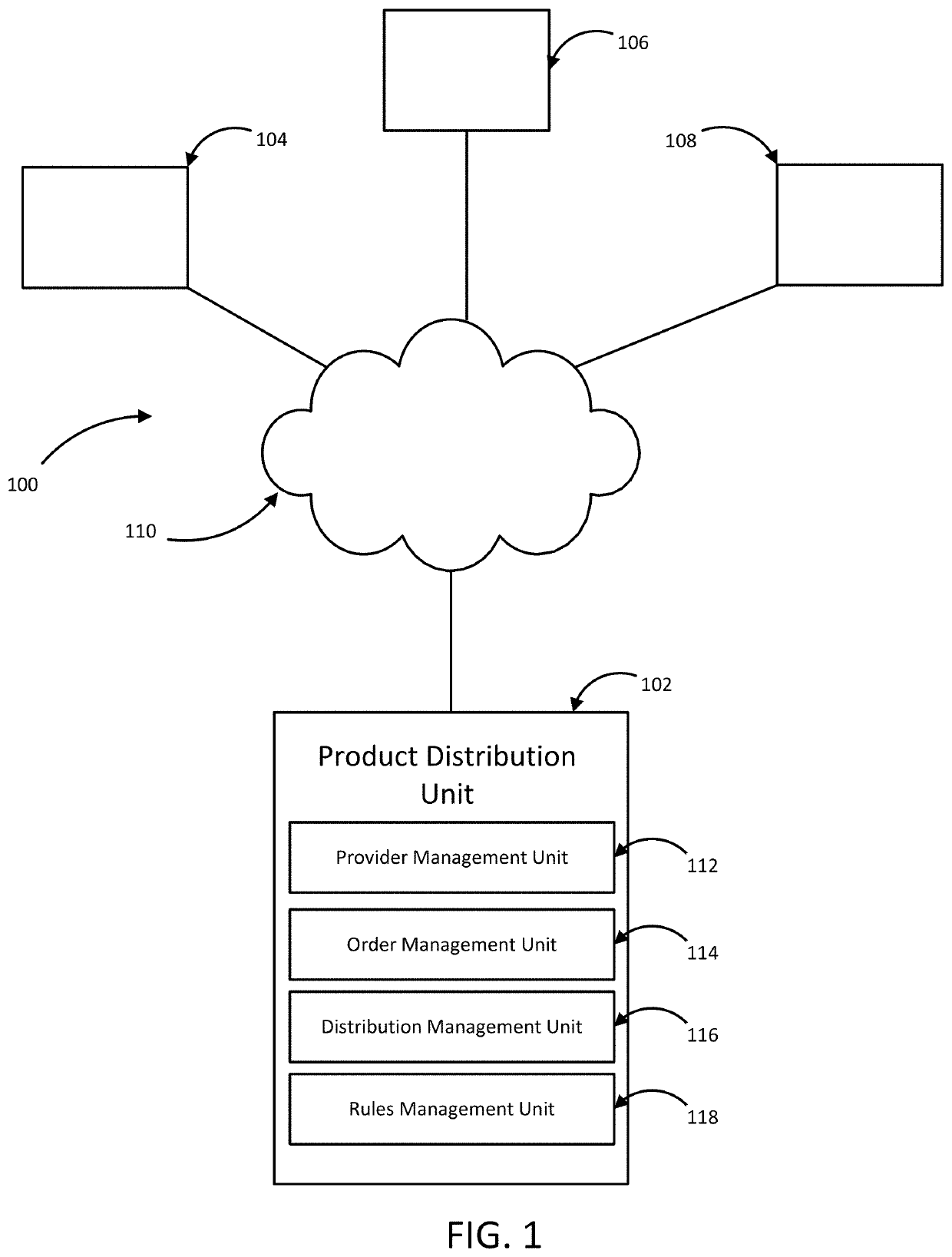

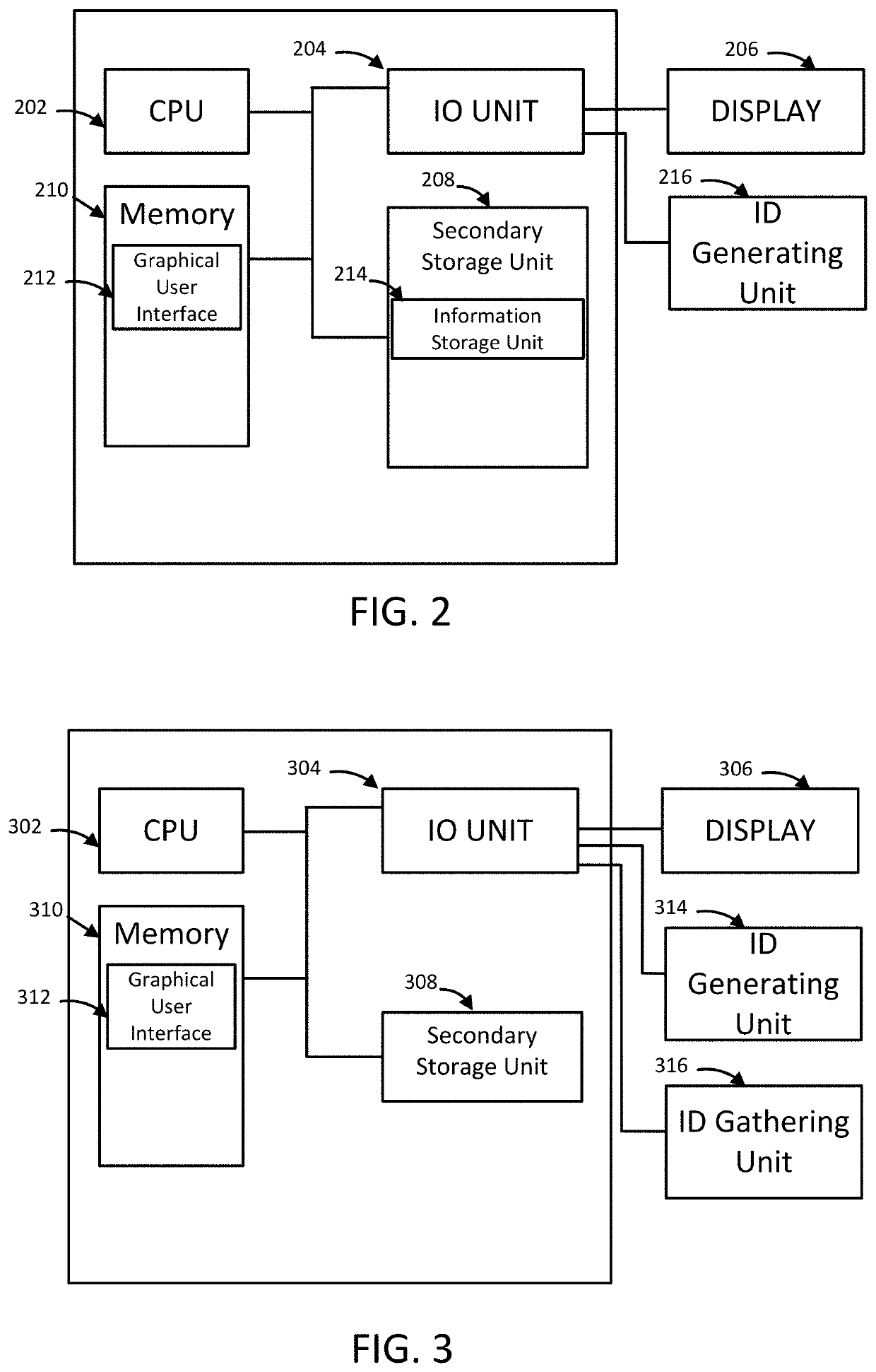

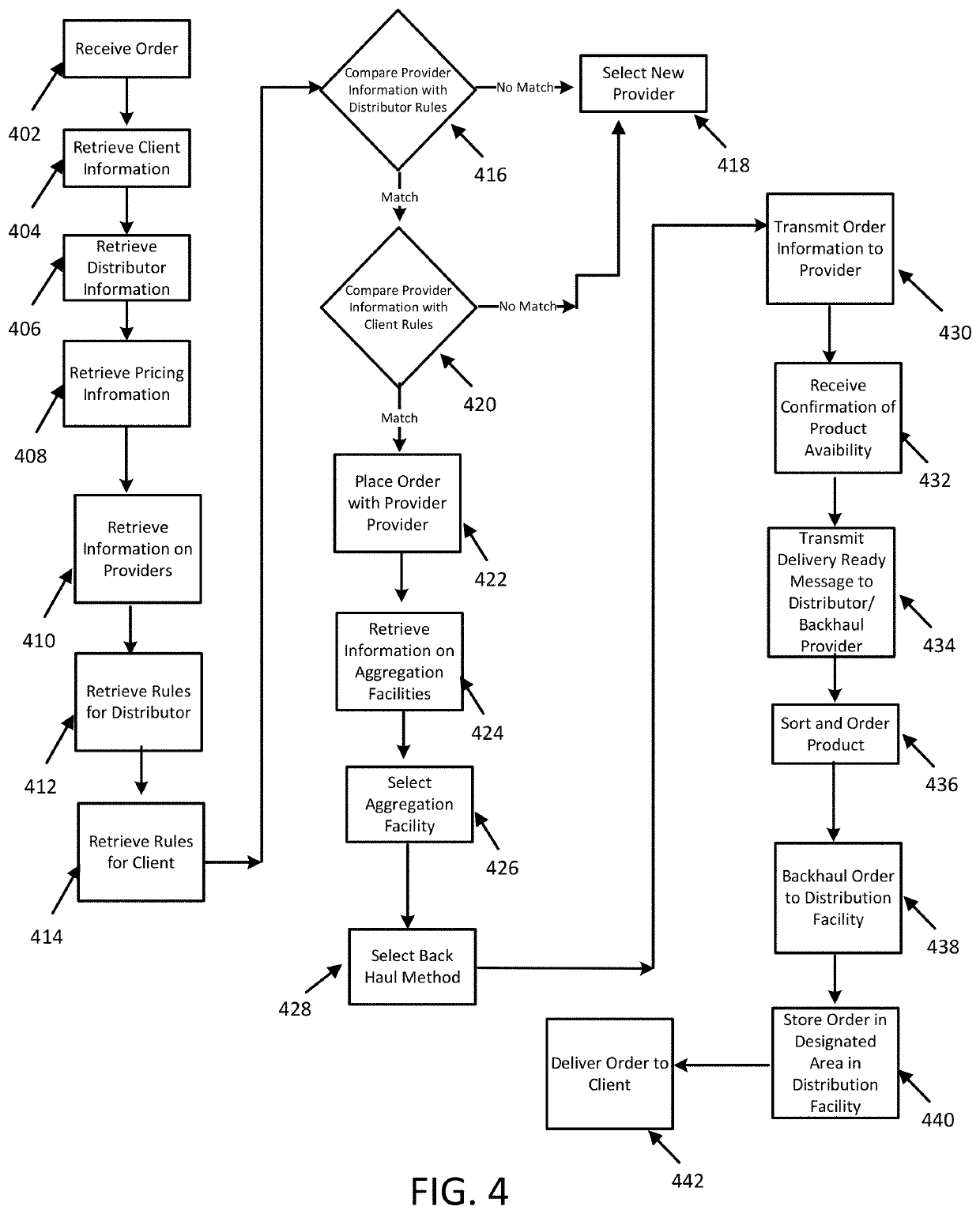

Distributed Computing System That Practically Applies Networked Computing Technology and Machine-Readable Indicia to Support Traceability of Products from Providers to Clients

PendingUS20220188763A1Accurately quickly reflectReduce network congestionLogisticsTerm memoryProduct traceability

A distributed computing system is disclosed that practically applies networked computing technology and machine-readable indicia to support traceability of products from providers to clients, the system comprising a plurality of distributed computers for connection over a network regarding a product identified by machine-readable indicia, for which a record is maintained in memory, and which is distributed through a supply chain that includes the provider, a transporting entity, an aggregation facility, a back haul provider, a distribution facility, and the client. The distributed computers include first, second, third, and fourth computers that cooperate with each other to support compliance with client rules and tracking of the order from the provider to the client through the participants in the supply chain via the machine-readable indicia and associations that are created in the memory to link the product with its passage through the supply chain.

Owner:FARM LOGIX

Transverse three-rotation wheel force balance control method for spinning machine

The invention provides a transverse three-rotation wheel force balance control method for a spinning machine. The transverse three-rotation wheel force balance control method comprises the steps thatthe initial pressing positions of rotation wheels and the dip separation quantity between the rotation wheels are set; the initial pressing quantity correction time and the pressing quantity correction sampling periods of the rotation wheels are determined; after the rotation wheels are in position, pressure data of the rotation wheels are collected; the trajectory of the third rotation wheel is determined, and the rotation wheel standard pressure value is determined; and at the initial pressing quantity correction time of the first rotation wheel, according to the collected pressure data of the first rotation wheel and the standard pressure value, the pressing quantity of the first rotation wheel is corrected for the first time, and then the pressing quantity of the first rotation wheel is corrected at each pressing quantity correction sampling period. The transverse three-rotation wheel force balance control method can achieve the aim of controlling the balance of transverse force ofthe three rotation wheels in the spinning processing procedure. According to the transverse three-rotation wheel force balance control method, the magnitude of the spinning force of the first rotation wheel and the second rotation wheel are actively adjusted in sequence, the radial displacement variable of the three rotation wheels is calculated by a numerical control system and automatically adjusted, and the purpose of the transverse force balance control of the three rotation wheels is achieved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

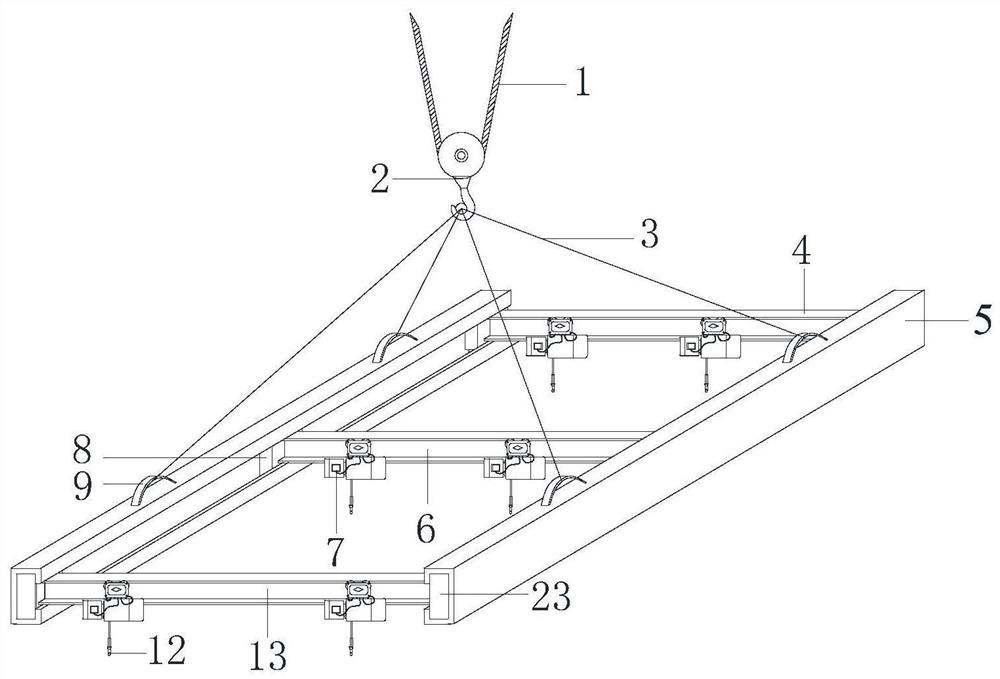

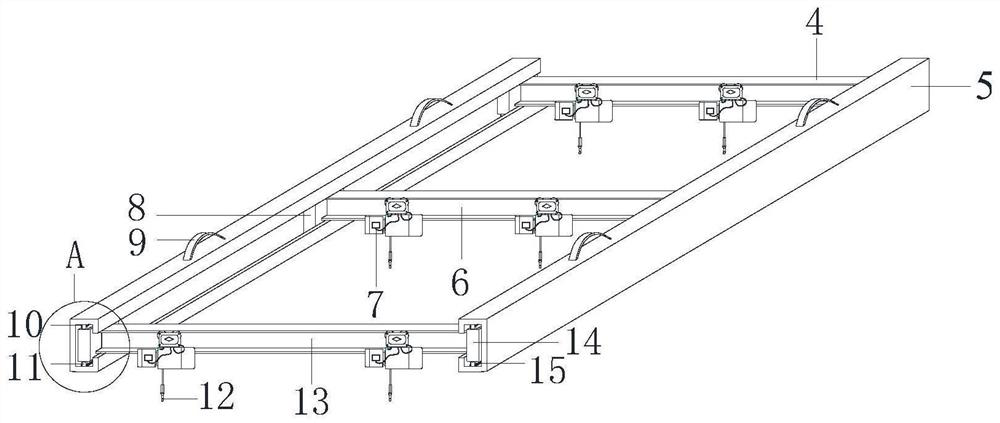

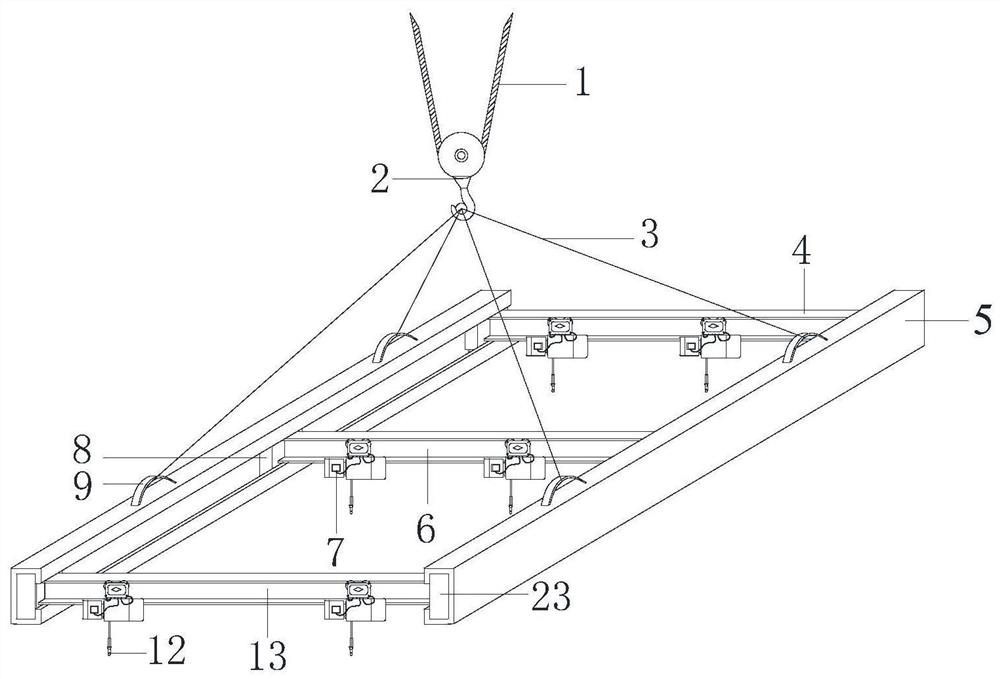

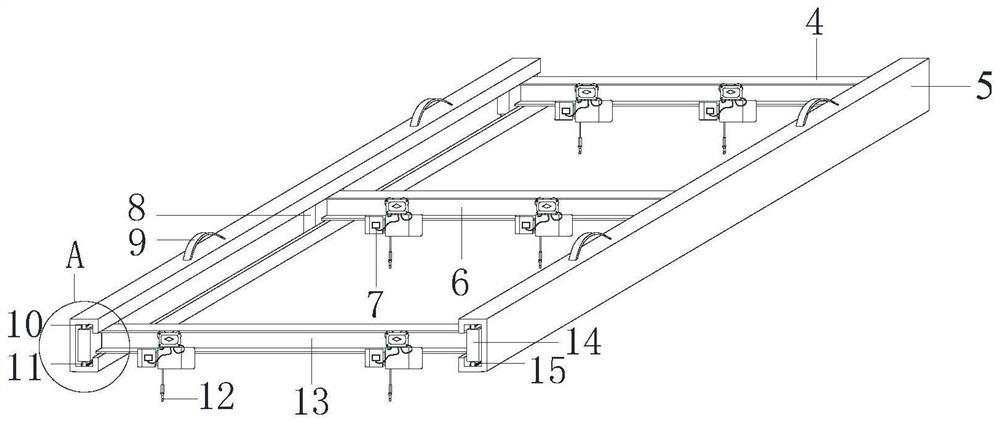

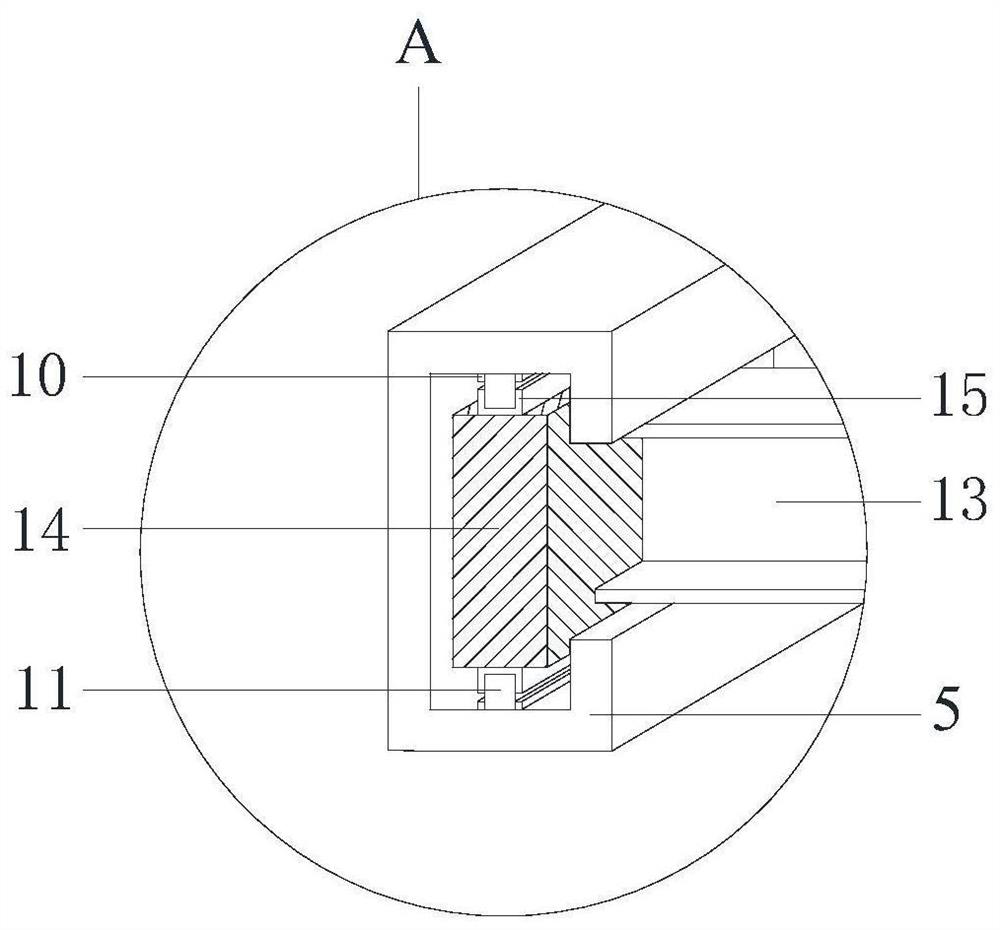

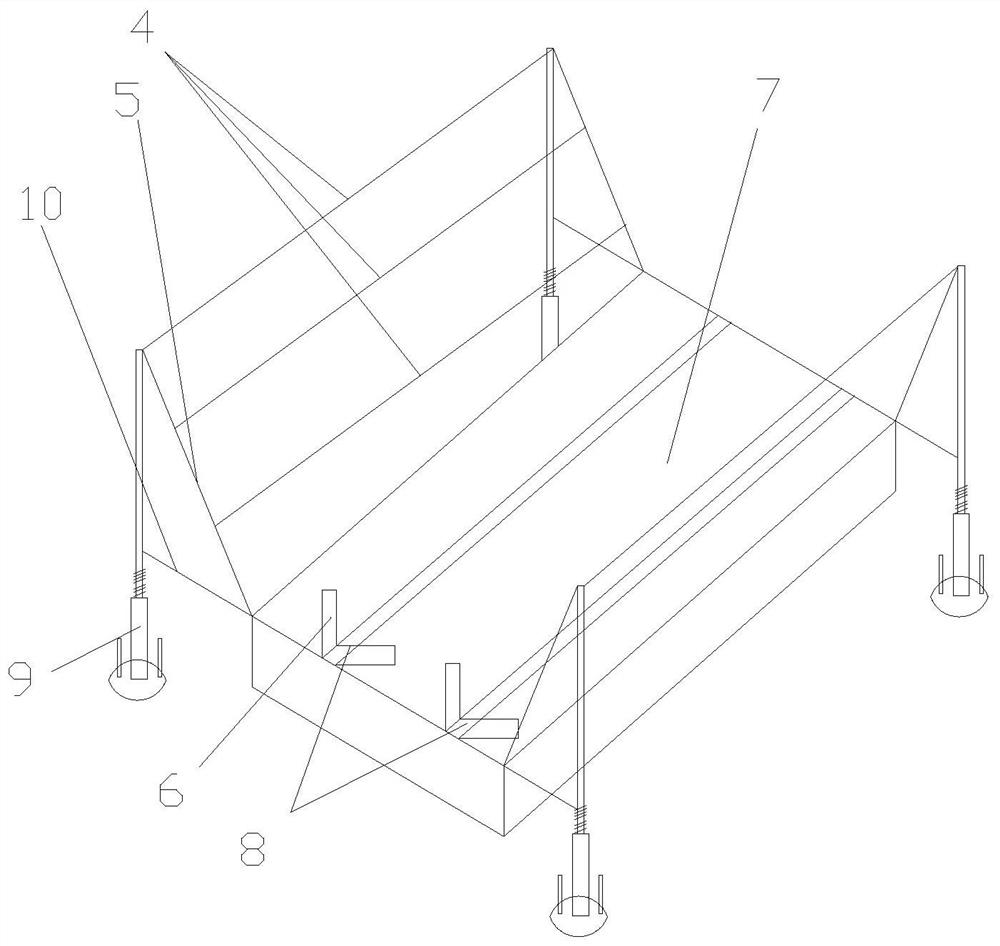

Shaping adjustable sling for hoisting prefabricated assembly type laminated plates and construction method thereof

ActiveCN111731986AHigh precisionImprove efficiencyBuilding material handlingLoad-engaging elementsFloor slabArchitectural engineering

The invention relates to a shaping adjustable sling for hoisting prefabricated assembly type laminated plates and a construction method thereof, belongs to the field of building engineering, is suitable for the construction of laminated floors in an assembly integral shear wall structure, and is also suitable for the hoisting construction of other assembly type members. The method comprises the construction steps of preparation before hoisting, acceptance of sling fittings, transportation and stacking of the laminated plates, adjustable sling assembly, lifting of the laminated plates, fallingin place of the laminated plates, height rechecking of the laminated plates, positions and height checking, hook picking, cast-in-place layer construction and the like, and has the effects of high hoisting precision, good stability, simplicity in manufacture and outstanding economic and technical benefits.

Owner:CONSTR & INSTALLATION ENG THE THIRD ENG GROUP OF CHINA RAILWAY +1

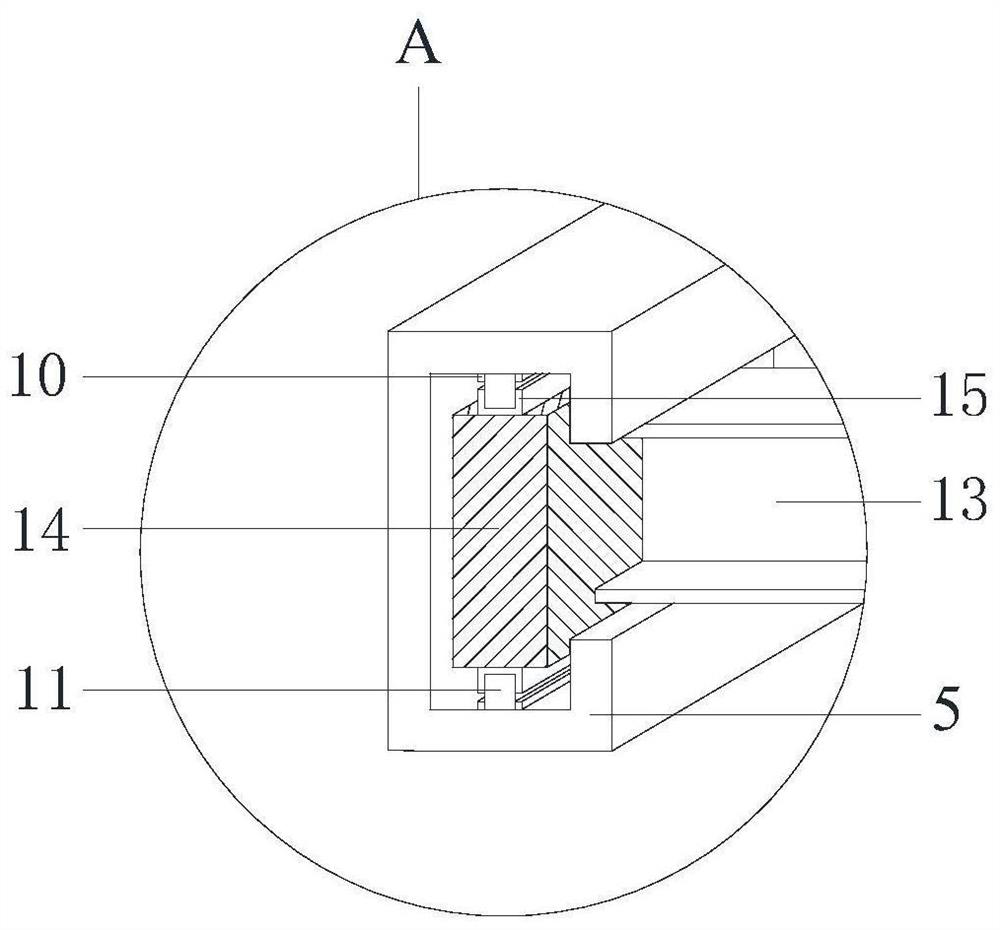

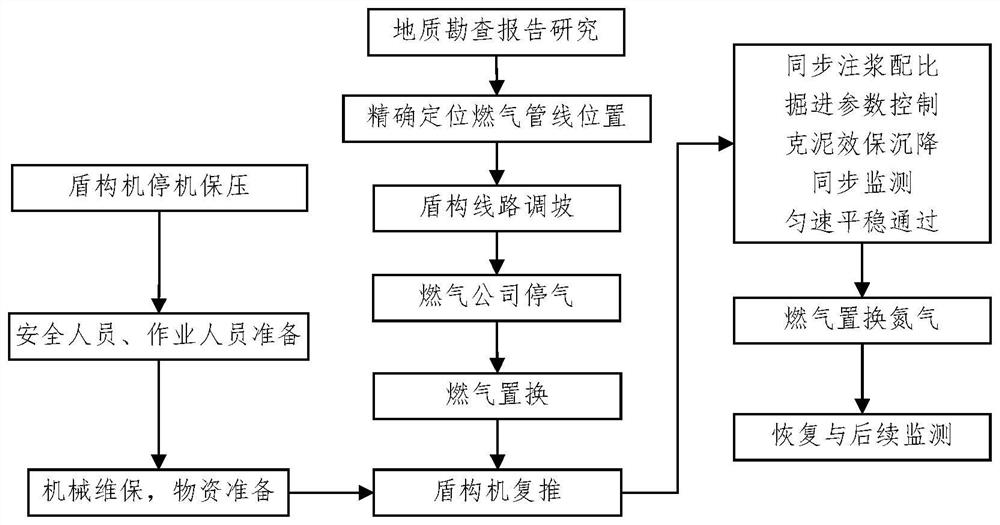

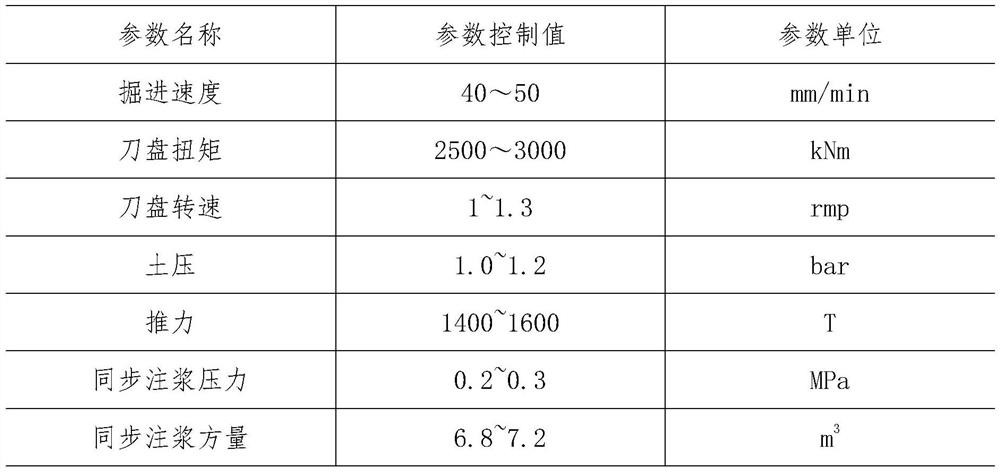

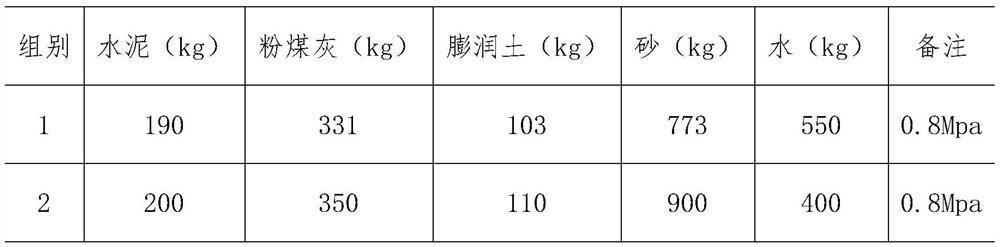

Construction method for penetrating through gas pipeline with pressure downwards at ultra-close distance by using shield tunneling machine

ActiveCN112983442AReduce riskGuaranteed validityUnderground chambersHydro energy generationGround subsidenceEngineering

The invention discloses a construction method for penetrating through a gas pipeline with pressure downwards at an ultra-close distance by using a shield tunneling machine, and relates to the technical field of shield tunneling machine construction methods. The construction method comprises the following steps of stopping the shield tunneling machine; accurately positioning the gas pipeline; performing three-dimensional modeling; adjusting the slope of the line, and calculating the nearest distance between the shield tunneling machine and the gas pipeline; replacing fuel gas; re-pushing the shield tunneling machine; grouting for the second time; and recovering the fuel gas. According to the construction method, nitrogen is adopted for replacing fuel gas for pressure maintaining, and the risk when the shield tunneling machine passes is reduced; the soil settlement at a shield body is guaranteed by adopting an anti-mud-effect construction method, and the soil pressure balance in the crossing process is guaranteed; a robot is used for pipeline detection, so that the position of an underground pipeline is conveniently and accurately detected; and the influence on the pipeline when the shield tunneling machine penetrates through the gas pipeline downwards is greatly reduced, the ground subsidence is reduced, the safety of the gas pipeline is guaranteed, the economic cost of pipeline diversion and the expense of long-time idleness of shutdown of the shield tunneling machine are eliminated, and great economic benefits are obtained.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

Water area bridge flexible anti-collision wall and construction method thereof

PendingCN110578320ASignificant technical benefitsLight weightClimate change adaptationBridge structural detailsCofferdamCoupling beam

The invention relates to a water area bridge flexible anti-collision wall which comprises a steel plate pile cofferdam, a pier bearing platform, a support, a concrete bottoming, expansion bolts, a light high-strength filler, anti-collision steel structures and anti-collision marks; the anti-collision steel structures, each of which is mainly formed by a single frame, a coupling beam and an anti-collision ring beam, are fixed at the periphery of the pier bearing platform; the single frames are fixed on the pier bearing platform through the expansion bolts respectively; the anti-collision ring beams are fixed on the outer side of the single frames respectively; and the adjacent single frames, each of which is formed by a connecting plate, a cross rod, a vertical rod, an intermediate inclinedrod and a bottom inclined rod, are connected through the corresponding coupling beam. The water area bridge flexible anti-collision wall has the beneficial effects that the water area bridge flexibleanti-collision wall is suitable for construction of anti-collision walls of pier bearing platforms in the rivers, lakes and sea and is formed by the steel plate pile cofferdam, the anti-collision steel structures and the light high-strength filler; and in addition, with arrangement of the steel plate pile cofferdam, a temporary support and auxiliary trestles are not required to be temporarily erected around a pier, an additional construction loading is not caused to bearing stress of the pier, and the technical benefit is obvious.

Owner:NINGBO UNIV

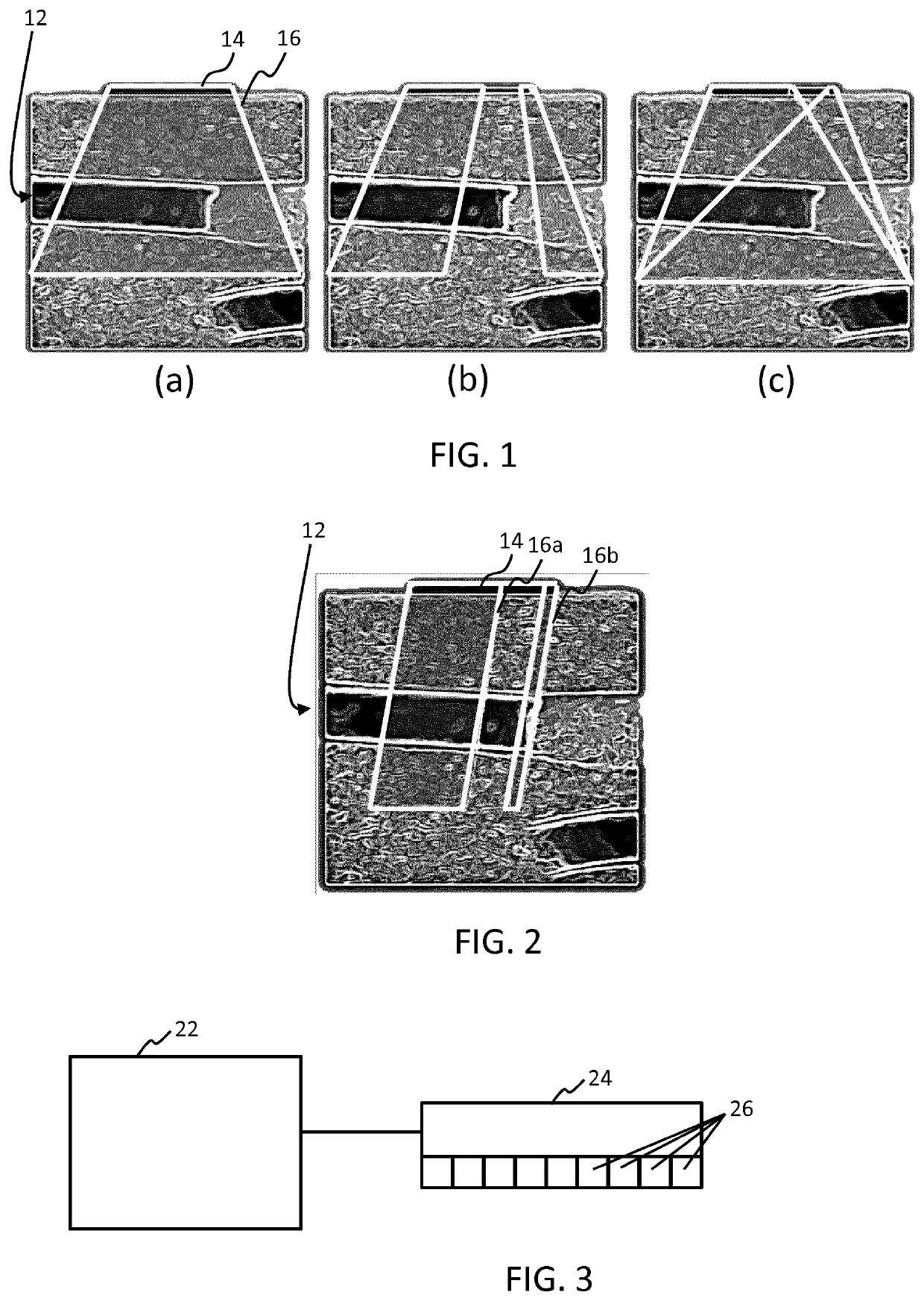

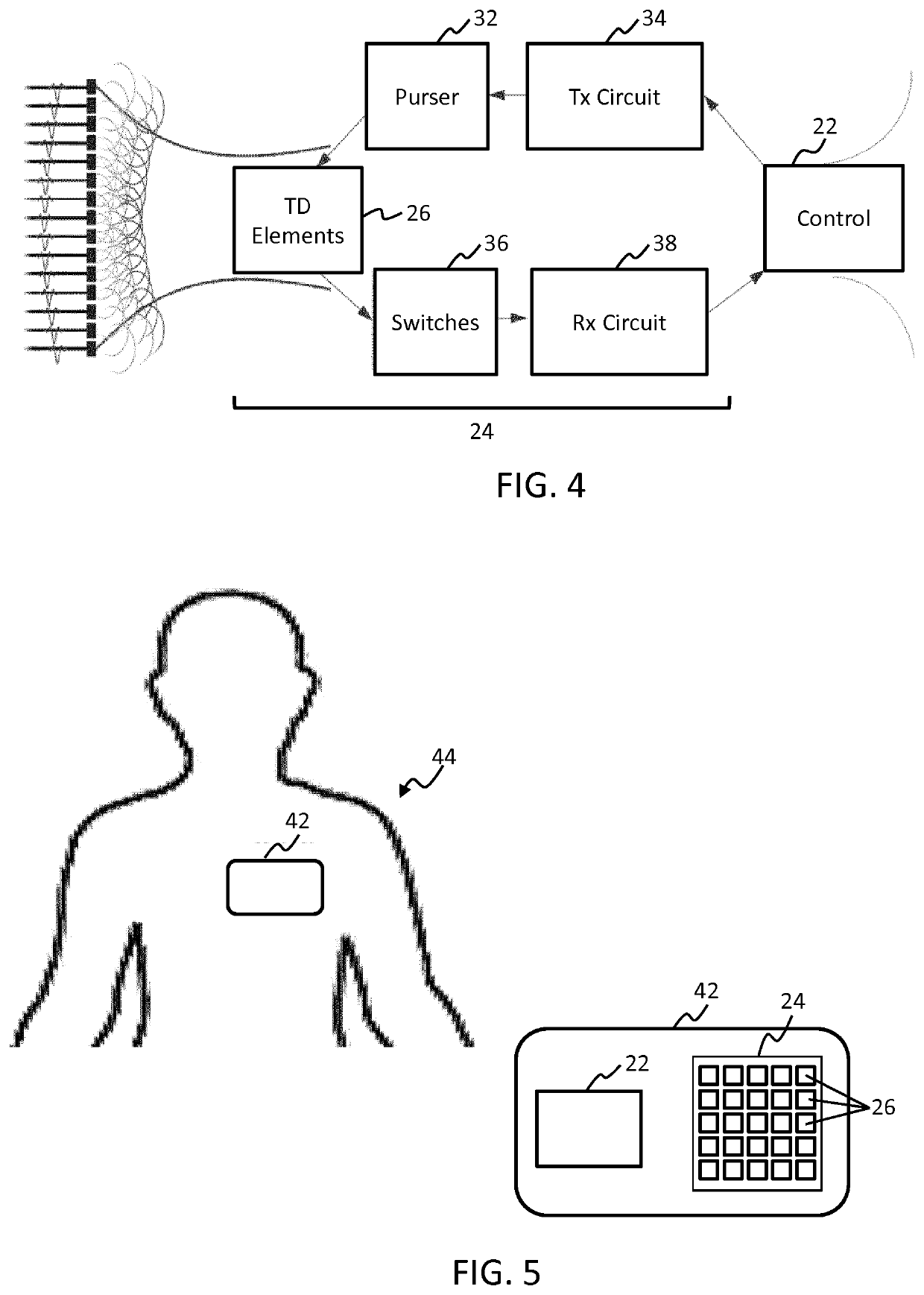

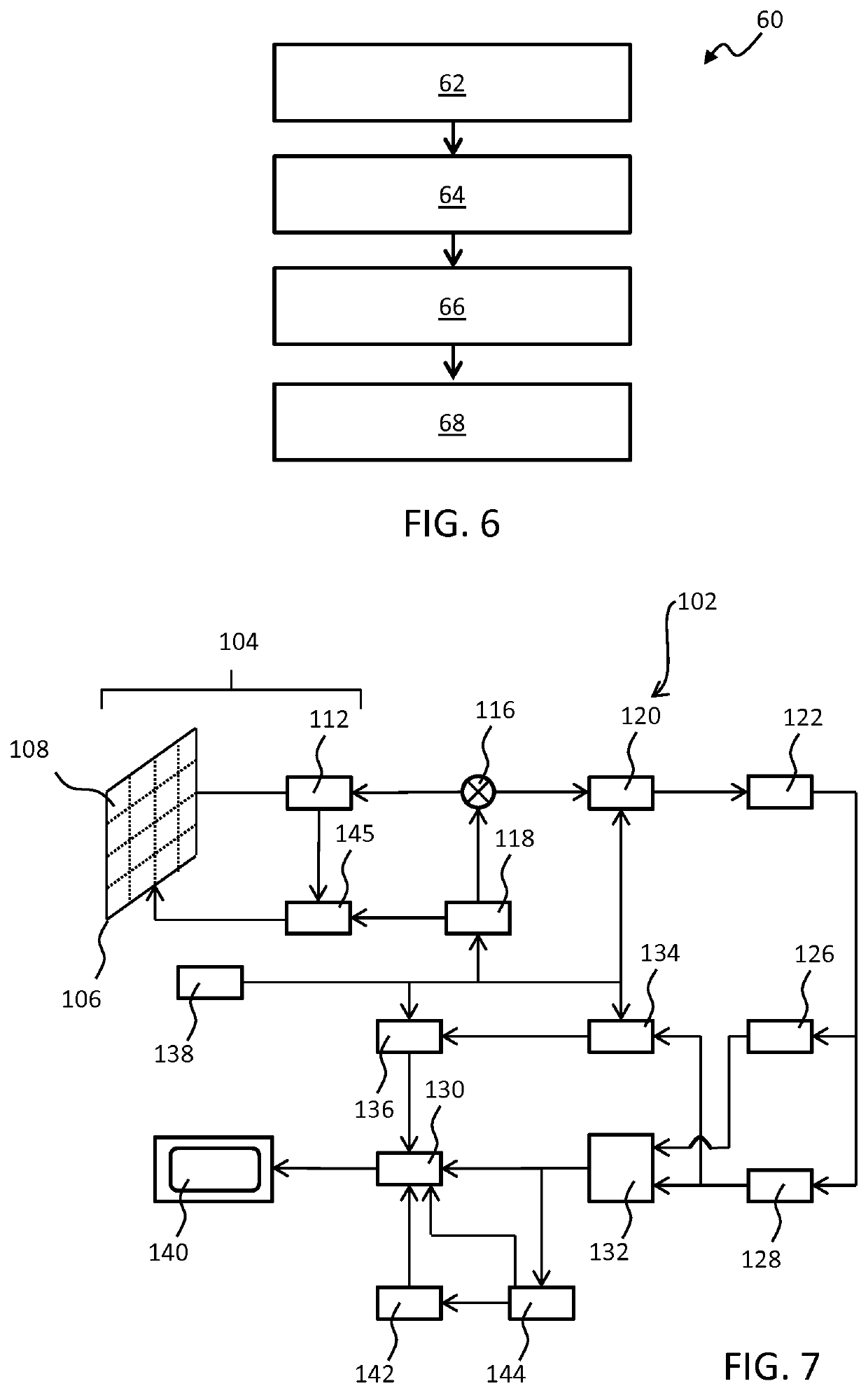

Ultrasound controller unit and method

PendingUS20210315546A1Minimize signalingMinimizing varianceMedical data miningHealth-index calculationTransducerControl ultrasound

An ultrasound controller unit (22) for controlling an ultrasound transducer unit (24) in acquiring ultrasound data for the purpose of deriving one or more physiological parameter measurements. The controller is adapted to control weighting coefficients applied to transmit and receive signals of each of a plurality of transducer elements (26) of the transducer unit. The controller is adapted to detect any artifact in received data affecting (e.g. obscuring) the output path of one or more of the transducers, and to identify the affected transducer elements. The weighting coefficients of the non-affected transducer elements are then adjusted so as to minimize an estimated noise component in the parameter measurement, if derived using only the non-affected transducer elements. Measurements of the one or more parameters are then derived by collecting data from the non-affected transducers only, these being configured with the optimized weighting coefficients.

Owner:KONINKLJIJKE PHILIPS NV

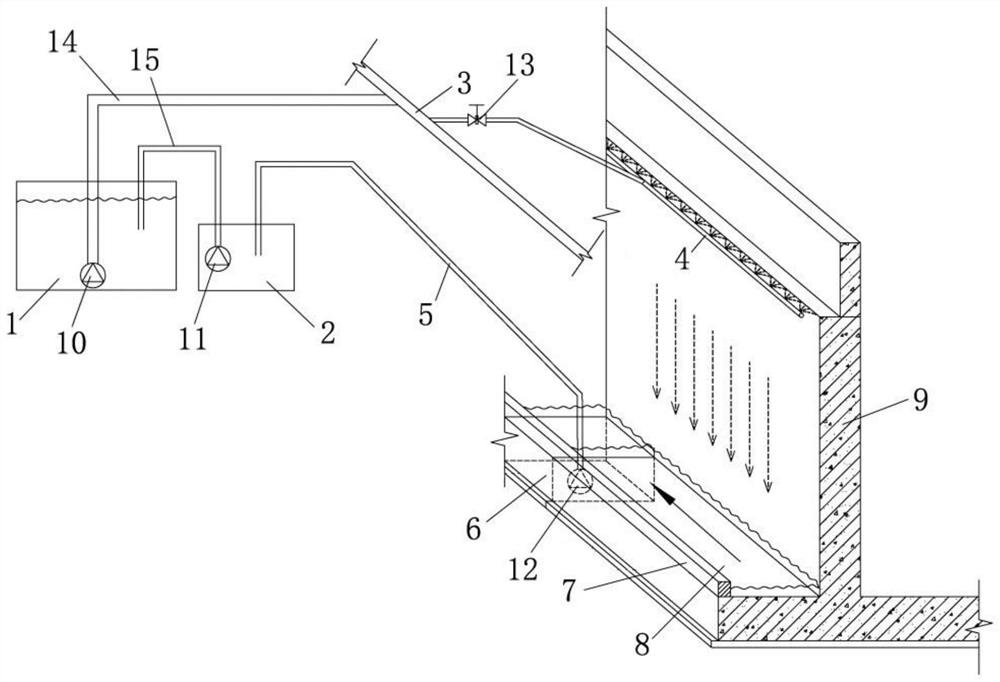

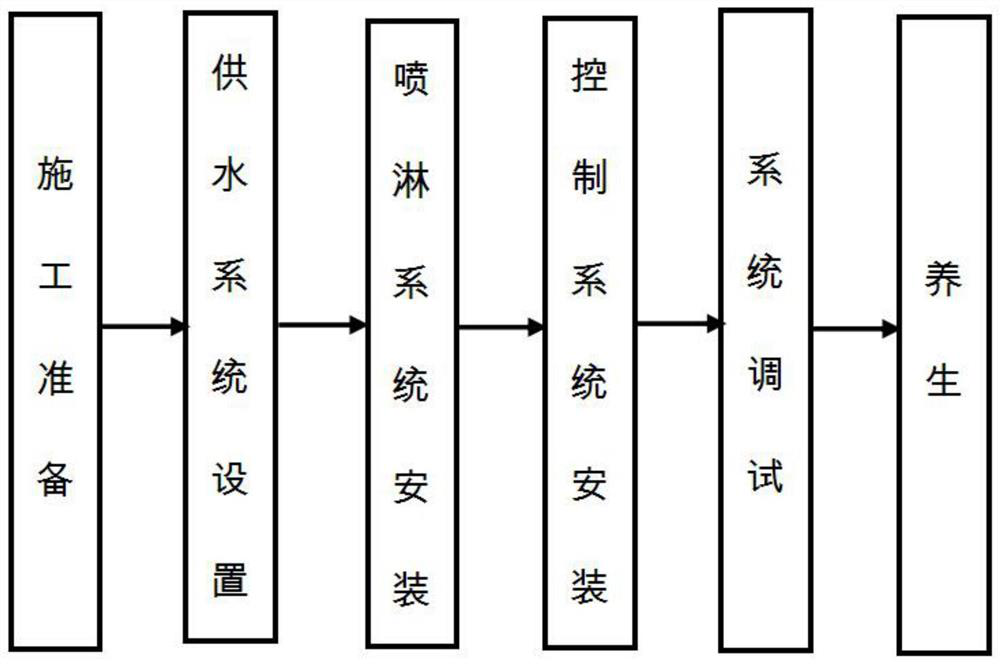

Basement shear wall automatic spraying maintenance system and construction method

PendingCN114033195AImprove maintenance effectRealize fully automatic controlFatty/oily/floating substances removal devicesSewerage structuresArchitectural engineeringIntelligent control system

The invention discloses a basement shear wall automatic spraying maintenance system and a construction method, the basement shear wall automatic spraying maintenance system is composed of a water supply system, a spraying system and an intelligent control system, the water supply system is composed of a sump, a reservoir and a sedimentation tank; the spraying system adopts a movable structure; the intelligent control system controls the total duration and waiting time of spraying circulation of the spraying system through the power switch. According to the technical scheme, the automatic spraying system is easy to install and maintain and easy to operate, the labor productivity is greatly improved, the structure in the concrete curing period is always kept in a wet state, the early strength of the concrete rises rapidly under the good curing condition, the concrete has obvious effects of improving the early strength of the concrete and preventing the concrete from generating shrinkage cracks.

Owner:贵州建工集团第四建筑工程有限责任公司

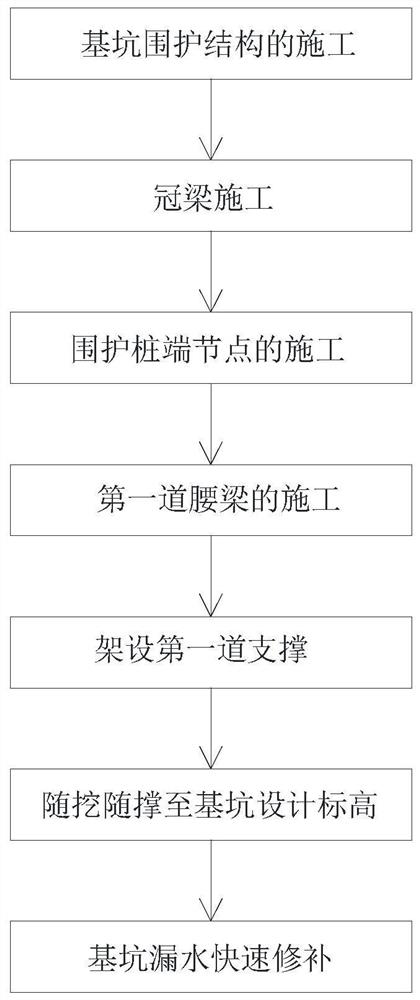

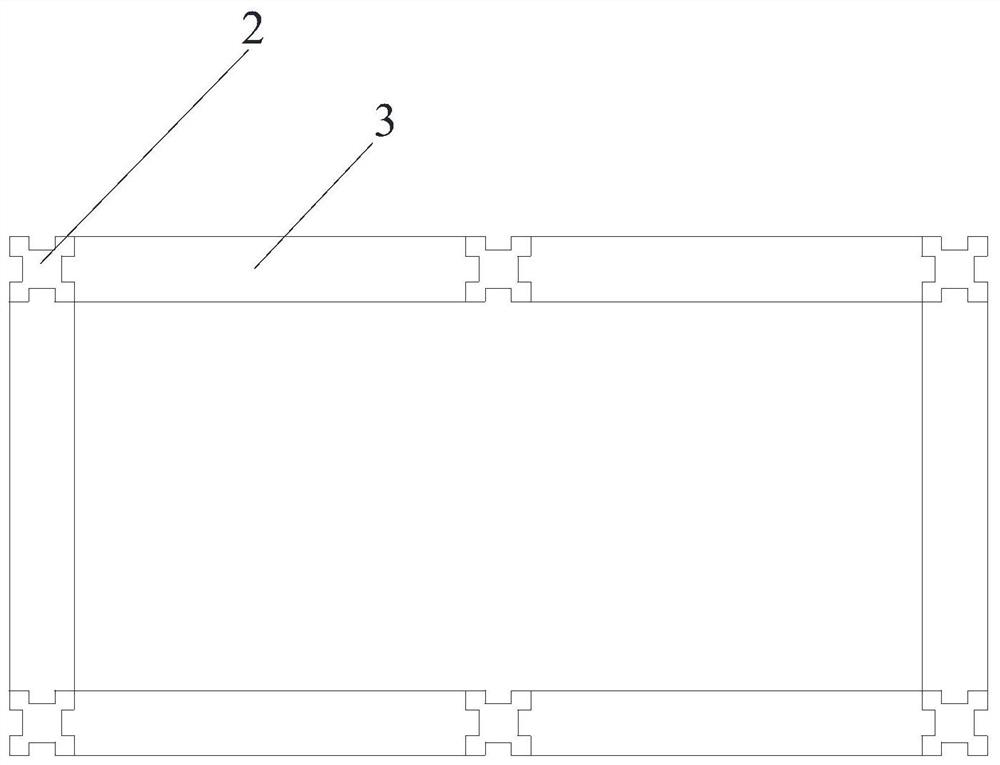

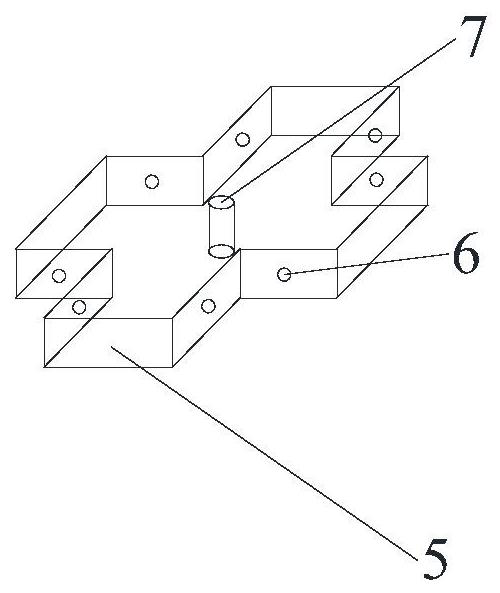

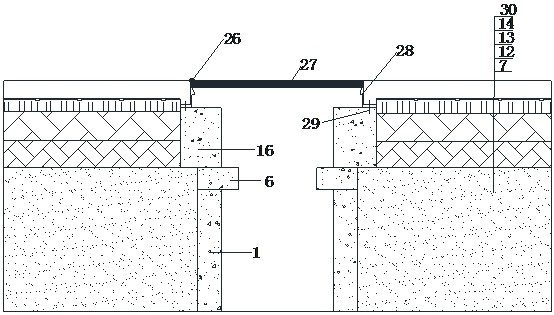

Construction method of foundation pit enclosure support system

ActiveCN110258576BShorten the construction periodImprove construction progressExcavationsSupporting systemPre stress

The invention relates to a construction method of a foundation pit enclosure support system, comprising: step 1, construction of the foundation pit enclosure structure; step 2, construction of crown beams; step 3, construction of enclosure pile end nodes; step 4, first step Waist beam construction; step 5, erecting the first support; step 6, digging and supporting to the design elevation of the foundation pit; step 7, rapid repair of foundation pit leakage. The beneficial effects of the present invention are: the prefabricated prefabricated reinforced concrete enclosure structure adopted in the present invention only needs to assemble the structure on site, which shortens the construction period and speeds up the construction progress compared with the traditional enclosure structure that needs to be cast-in-place. It has good technical and economic benefits; in the invention, the enclosure structure and the prestressed cover beam are strengthened and connected, which can make the upper part of the enclosure structure connected as a whole, greatly improve the stability of the upper part of the enclosure structure, and have remarkable technical benefits.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

Asphalt Pavement Inspection Well Masher Construction Method

ActiveCN108360570BOvercome deficienciesImprove construction efficiencyArtificial islandsUnderwater structuresArchitectural engineeringStructural engineering

The invention discloses a well raising construction method for an asphalt pavement inspection well acted to an asphalt pavement. The asphalt pavement comprises a pavement and a roadbed. The method comprises the following steps: setting a prefabricated well; preventing deviation of a temporary well lid; paving an intermediate layer; passing through a well raising space; putting an adjustable hanging mold system; preparing a well raising ring; mounting a steel well seat; and mounting the well lid. According to the well raising construction method for the asphalt pavement inspection well disclosed by the invention, a deviation-preventing technology of the temporary well lid is matched with the adjustable hanging mold technology, so that defects of conventional well raising construction methods are avoided, the construction efficiency is improved, and the method has relatively good economic and technological benefits.

Owner:ZHONGDA CONSTR

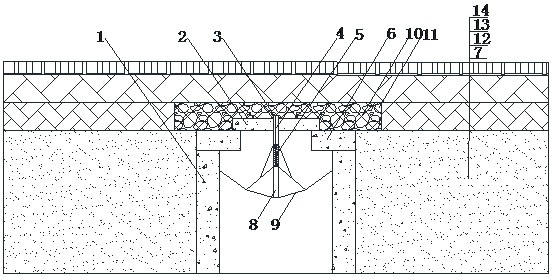

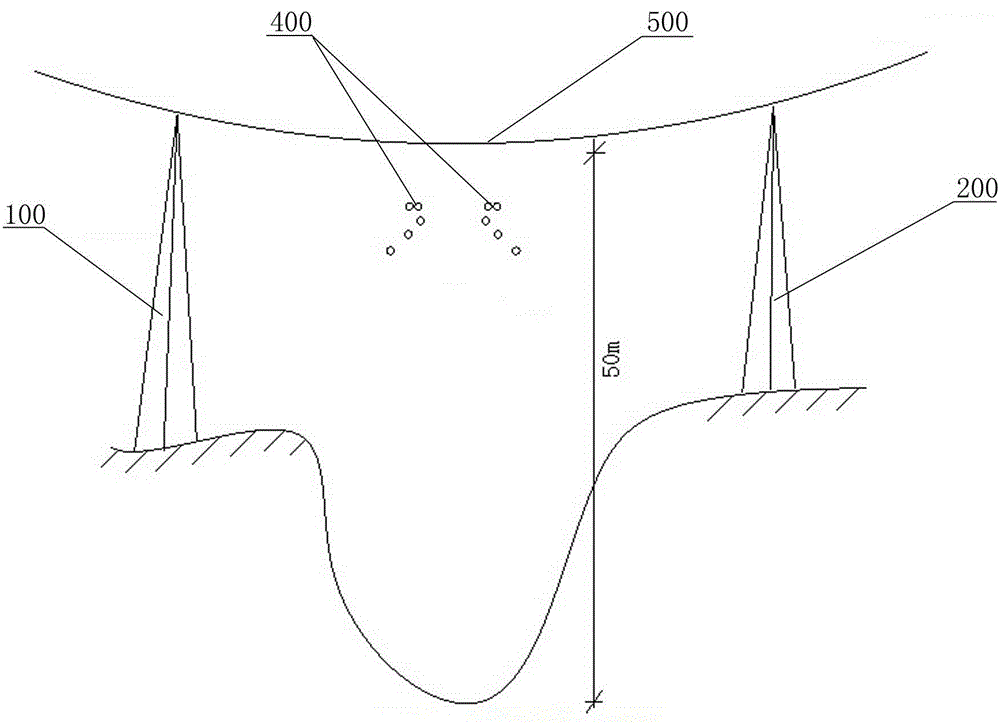

Wiring method across live high-voltage lines in mountainous terrain

ActiveCN103311844BImprove erection efficiencyErection process safetyApparatus for overhead lines/cablesArchitectural engineeringMountainous terrain

The invention relates to a method for erecting high-voltage lines, in particular to a method for erecting mountainous-terrain cross charged high-voltage lines, which solves the problem that the current method for erecting the cross high-voltage lines cannot realize crossing under the condition of mountainous terrain. The method for erecting the mountainous-terrain cross charged high-voltage lines comprises the following steps: (1) setting up timber scaffolds and hanging pulleys: setting up a first timber scaffold of which the height is not lower than the height of a second new tower close to the second new tower, and hanging a first pulley at the cross arm of the second new tower; and setting up a second timber scaffold of which the height is at least 2 m higher than the height of a crossed tower near the crossed tower closest to a crossed charged high-voltage line, and hanging a second pulley at the top of the crossed tower. The bottom of the second pulley and the crossed charged high-voltage line on the crossed tower meet the safety distance 2.5m. The method has the advantages of reasonable design, low crossing project construction cost and high construction speed, meets the construction schedule requirement, and has a construction environment with higher safety.

Owner:山西太行建设开发有限公司

Tunnel Construction Method in Karst Section of Weak Surrounding Rock

ActiveCN111119904BReduce construction stepsShorten construction timeUnderground chambersDrainageKarstCave

The invention relates to a construction method of a tunnel in a karst section of soft surrounding rock. The construction method of the tunnel in the karst section of soft surrounding rock comprises the steps of 1, measuring and lofting; 2, carrying out forepoling; 3, starting to annularly excavate upper steps; 4, carrying out early support on the upper steps; 5, starting to excavate core soil of the upper steps; 6, starting to excavate left lower steps and right lower steps simultaneously; 7, adopting a tunnel through non-filling small-sized karst cave treatment structure to treat a non-filling small-sized karst cave; 8, carrying out early support on the left lower steps and on the right lower steps at the same time; 9, starting to excavate an inverted arch and carrying out early support on the inverted arch; 10, carrying out second lining on the inverted arch and on an arch wall; 11, adopting an under tunnel floor deep-buried karst cave treatment structure to treat a deep-buried karstcave; 12, adopting an under tunnel floor water karst cave treatment structure to treat a water karst cave; 13, adopting an under tunnel floor large karst cave treatment structure to treat a large karst cave; and 14, carrying out construction on a tunnel floor. The construction method of the tunnel in the karst section of soft surrounding rock has the beneficial effects that a dismantling-free template used in the construction method does not need to be dismantled after concrete is poured, the number of construction steps is reduced, and construction time is shortened.

Owner:ZHEJIANG UNIV CITY COLLEGE

Prefabricated and assembled composite panel hoisting stereotyped adjustable spreader and its construction method

ActiveCN111731986BHigh precisionImprove efficiencyBuilding material handlingLoad-engaging elementsFloor slabArchitectural engineering

The invention relates to a stereotyped adjustable spreader for hoisting prefabricated assembled laminated slabs and a construction method thereof, which belongs to the field of building construction engineering and is applicable to the construction of laminated floor slabs in assembled integral shear wall structures, and is also applicable to other assembled slabs. Component hoisting construction; including preparation before hoisting, inspection and acceptance of spreader accessories, transportation and stacking of laminated slabs, assembly of adjustable spreaders, lifting of laminated slabs, placement of laminated slabs, review of the elevation of laminated slabs, position, calibration of elevations, unhooking, on-site Construction steps such as pouring layer construction have the effects of high hoisting precision, good stability, simple production, and outstanding economic and technical benefits.

Owner:CONSTR & INSTALLATION ENG THE THIRD ENG GROUP OF CHINA RAILWAY +1

A force balance control method for horizontal three-rotor wheels of spinning machine

The invention provides a method for force balance control over three transverse spinning rollers of a spinning machine. The method for force balance control over the three transverse spinning rollersof the spinning machine comprises the steps that the initial pressing positions of the spinning wheels and the offset distance between the spinning wheels are arranged; the initial pressing reductionrectifying moments and pressing reduction rectifying sampling periods are determined respectively; after the spinning wheels are in place, the pressure data of the spinning wheels are collected; trackof a third spinning wheel is determined, and the standard pressure value of the spinning wheels is determined; and in the initial pressing reduction rectifying moment of a first spinning wheel, according to the pressure data and the standard pressure value of the first spinning wheel collected, first time rectification is conducted on the pressing reduction of the first spinning wheel, and then rectification is conducted on the pressing reduction of the first spinning wheel in each pressing reduction rectifying sampling period. By means of the method for force balance control over the three transverse spinning rollers of the spinning machine, the method for controlling transverse force balance of the three spinning wheels in the spinning machining process can be solved; the sizes of spinning pressure of the first spinning wheel and the second spinning wheel are actively adjusted successively; the radial displacement variable of the three spinning wheels is calculated and adjusted automatically through a numerical control system; and the purpose of transverse force balance control over the three spinning wheels is gradually achieved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

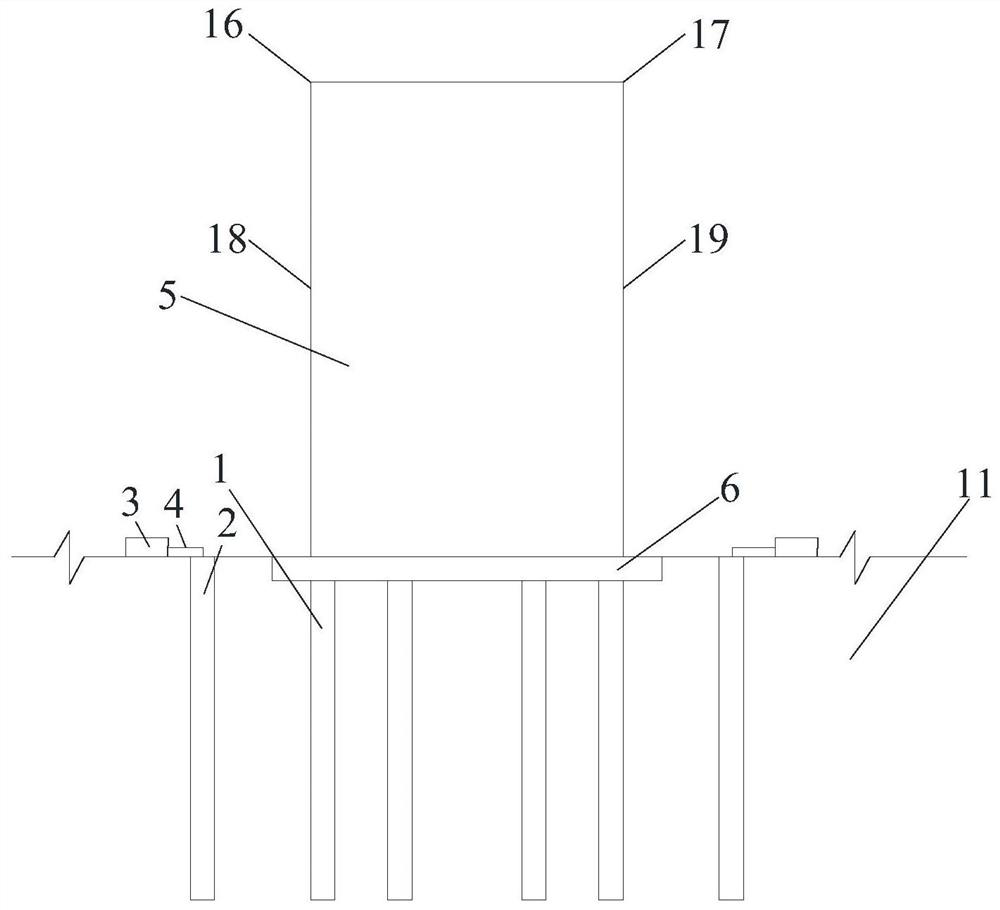

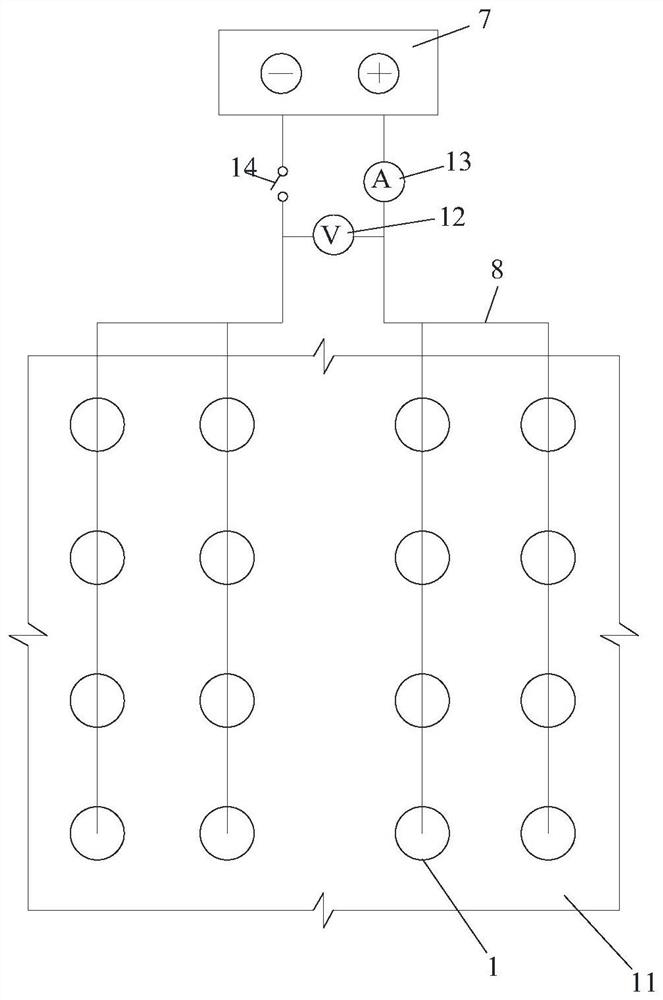

The rectification method of existing buildings based on electroosmotic technology

ActiveCN109898570BQuick rectificationEffective rectification and straighteningSoil preservationMonitoring siteElectroosmosis technique

Owner:NINGBO UNIV

Integral forming drainage ditch construction system and its construction method

ActiveCN109577453BFast formingShort timeSewer pipelinesArchitectural engineeringStructural engineering

The invention discloses an integrally formed drainage ditch, including a drainage ditch body, a shaped bucket, a shaped slope scraper, a sliding form track, a shaped side form and a bottom scraping beam frame, and the sliding form track is assembled on both sides of the drainage ditch body , the shaped side form is set in the drain body, the bottom scraping beam is erected at the bottom of the drain body, the shaped side form can be fixed on the bottom scraping beam frame, and the bottom scraping beam frame is connected to the sliding beam gantry frame and formed The sliding beam gantry pulls and slides, and the finalized side formwork is connected to the sideform gantry and is pulled and slipped by the sideform gantry. The drainage ditch simplifies construction steps, saves construction man-hours, reduces construction costs, is easy to excavate and form, and has low operation difficulty, can effectively ensure safety during construction, and the drainage ditch has beautiful appearance and good quality. The second object of the present invention is the construction method of integrally formed drainage ditch, which is applied to the above-mentioned integrally formed drainage ditch, which also has the advantages of high safety and high convenience.

Owner:HANGZHOU JIANGRUN TECH LIMITED

The force balance control method of the horizontal three-spin wheel of the spinning machine

The invention provides a transverse three-rotation wheel force balance control method for a spinning machine. The transverse three-rotation wheel force balance control method comprises the steps thatthe initial pressing positions of rotation wheels and the dip separation quantity between the rotation wheels are set; the initial pressing quantity correction time and the pressing quantity correction sampling periods of the rotation wheels are determined; after the rotation wheels are in position, pressure data of the rotation wheels are collected; the trajectory of the third rotation wheel is determined, and the rotation wheel standard pressure value is determined; and at the initial pressing quantity correction time of the first rotation wheel, according to the collected pressure data of the first rotation wheel and the standard pressure value, the pressing quantity of the first rotation wheel is corrected for the first time, and then the pressing quantity of the first rotation wheel is corrected at each pressing quantity correction sampling period. The transverse three-rotation wheel force balance control method can achieve the aim of controlling the balance of transverse force ofthe three rotation wheels in the spinning processing procedure. According to the transverse three-rotation wheel force balance control method, the magnitude of the spinning force of the first rotation wheel and the second rotation wheel are actively adjusted in sequence, the radial displacement variable of the three rotation wheels is calculated by a numerical control system and automatically adjusted, and the purpose of the transverse force balance control of the three rotation wheels is achieved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Cement Concrete Bridge Deck Pavement and Construction Method

ActiveCN110820559BAccurate installation and positioningImprove binding accuracyBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention provides a cement concrete bridge deck pavement and construction method. The cement concrete bridge deck pavement and construction method comprises: cement concrete bridge deck reinforcement cage in situ binding tire frame, cement concrete bridge deck tool type support formwork, cement concrete bridge deck Bridge deck track sliding type operation platform and cement concrete bridge deck track sliding type pouring device. The overall structure first uses the tire frame to bind the steel bars, and then uses the formwork tool to support the formwork. After the formwork is supported, the integrated operation platform is used to pour and level it. After the leveling is completed, the pouring device is used to chisel and maintain .

Owner:QINGDAO HAIDE ROAD & BRIDGE ENG

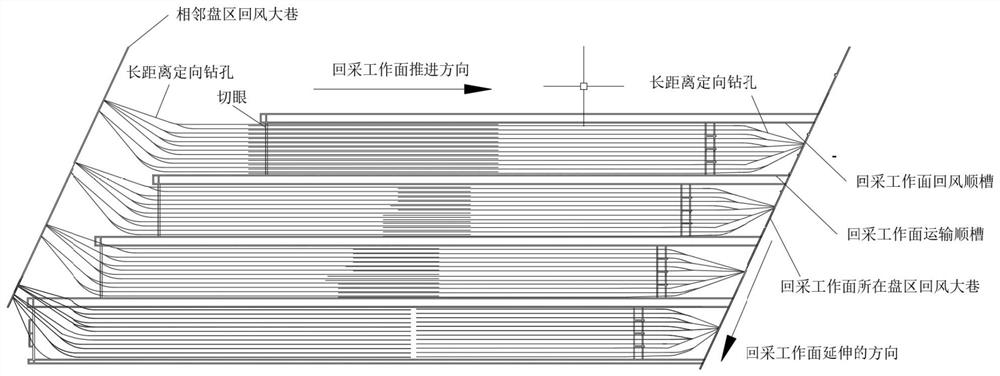

Method for intensifying coal seam gas extraction through two-way long-distance directional drilling overlapping

The invention relates to a method for intensifying coal seam gas extraction through two-way long-distance directional drilling overlapping, and belongs to the field of coal mine safety. A stope face is divided into an early-stage mining part, a middle-stage mining part and a later-stage mining part according to the mining replacement plan of the stope face and the coal seam gas occurrence condition; long-distance directional drilling holes are constructed in the coal body of the stope face from an air return main roadway of a panel where the stope face is located to the coal body of the stope face in the trend direction of the coal body of the stope face; long-distance directional drill holes are constructed in a coal body of the stope face from an air return main roadway of an adjacent panel, the two-way long-distance directional drill holes of an early-stage mining part have an overlapping area, one side of the overlapping area exceeds the cutting hole of the stope face in the advancing direction, and the other side of the overlapping area is located behind the cutting hole of the stope face; the two-way long-distance directional drill hole of the middle-stage mining part has an overlapping area, and the overlapping area is in a gas content enrichment area in the coal body; the two-way long-distance directional drill holes of the later mining part have no overlapping area.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com