Mine tray for prejudging magnitude of anchoring force on basis of surface deformation and monitoring method

A technology of surface deformation and anchoring force, applied in mining equipment, mining equipment, earth-moving drilling, etc., can solve the problems of bolt breaking and popping out, nut falling out and ejection, unrealistic and other problems, achieving good popularization and demonstration. The effect of high stability, obvious technical benefits, and simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing.

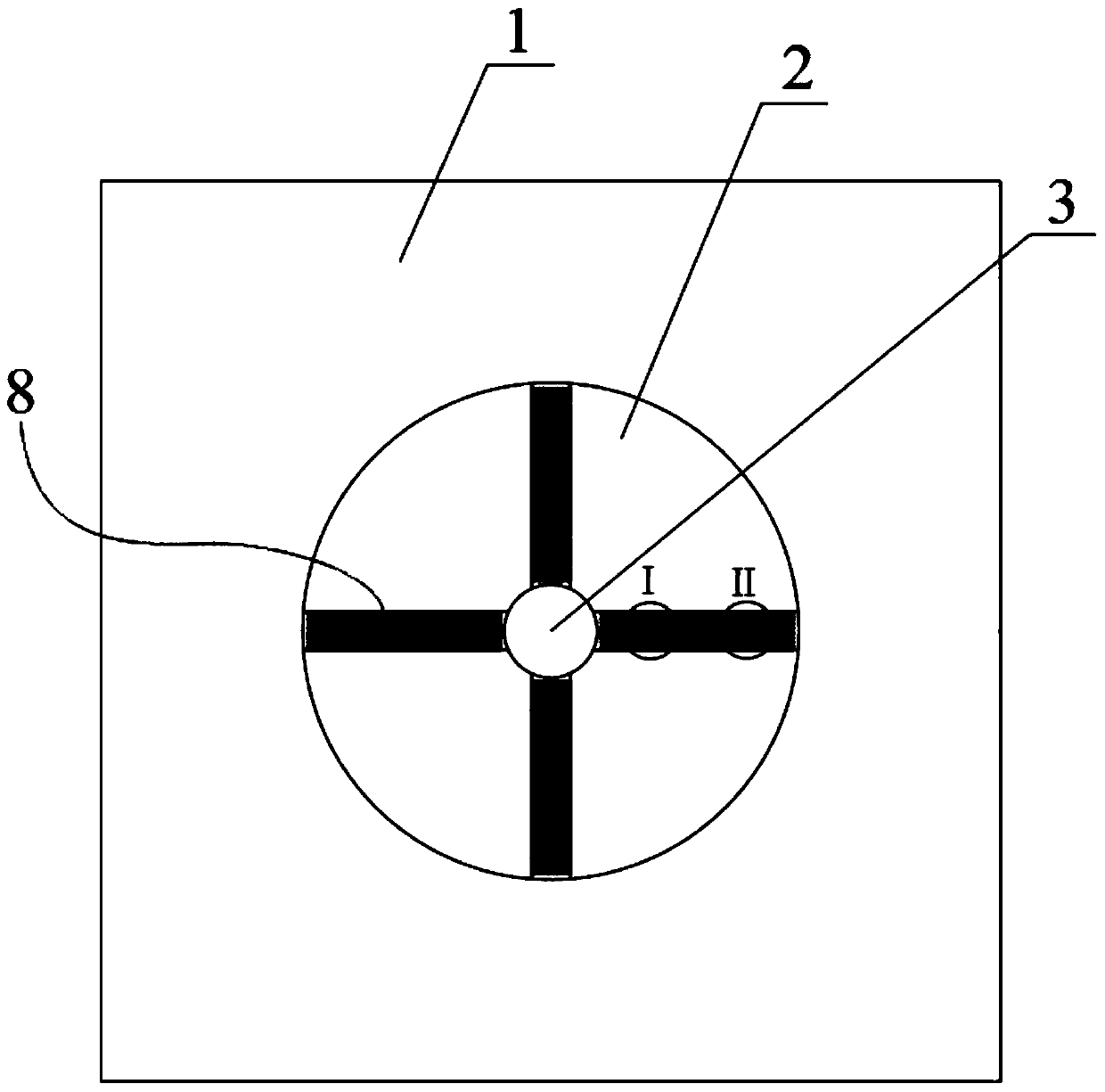

[0042] Such as Figure 1 to Figure 15 As shown, a mine pallet that predicts the anchoring force based on surface deformation includes a pallet body and a deformation identification unit; the pallet body includes a spherical crown-shaped part 2 in the middle and a flat part 1;

[0043] The deformation identification unit includes four strip-shaped plastic sheets 8, and the four strip-shaped plastic sheets 8 are adhered to the surface of the spherical crown part 2 in the shape of a cross, and one end of each strip-shaped plastic sheet 8 starts from the anchor rod hole 3 edge, and the other end extends to the edge of the spherical part 2;

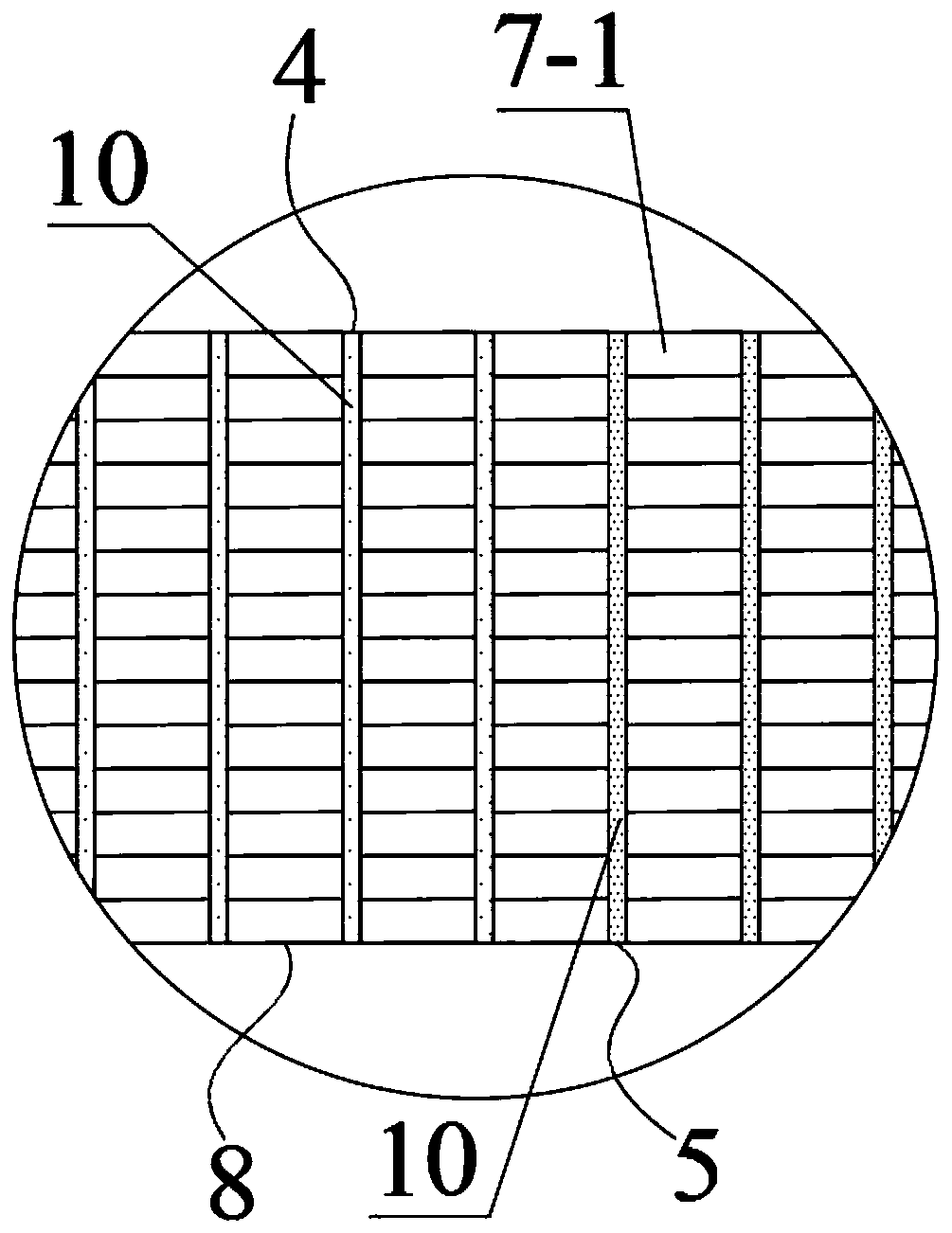

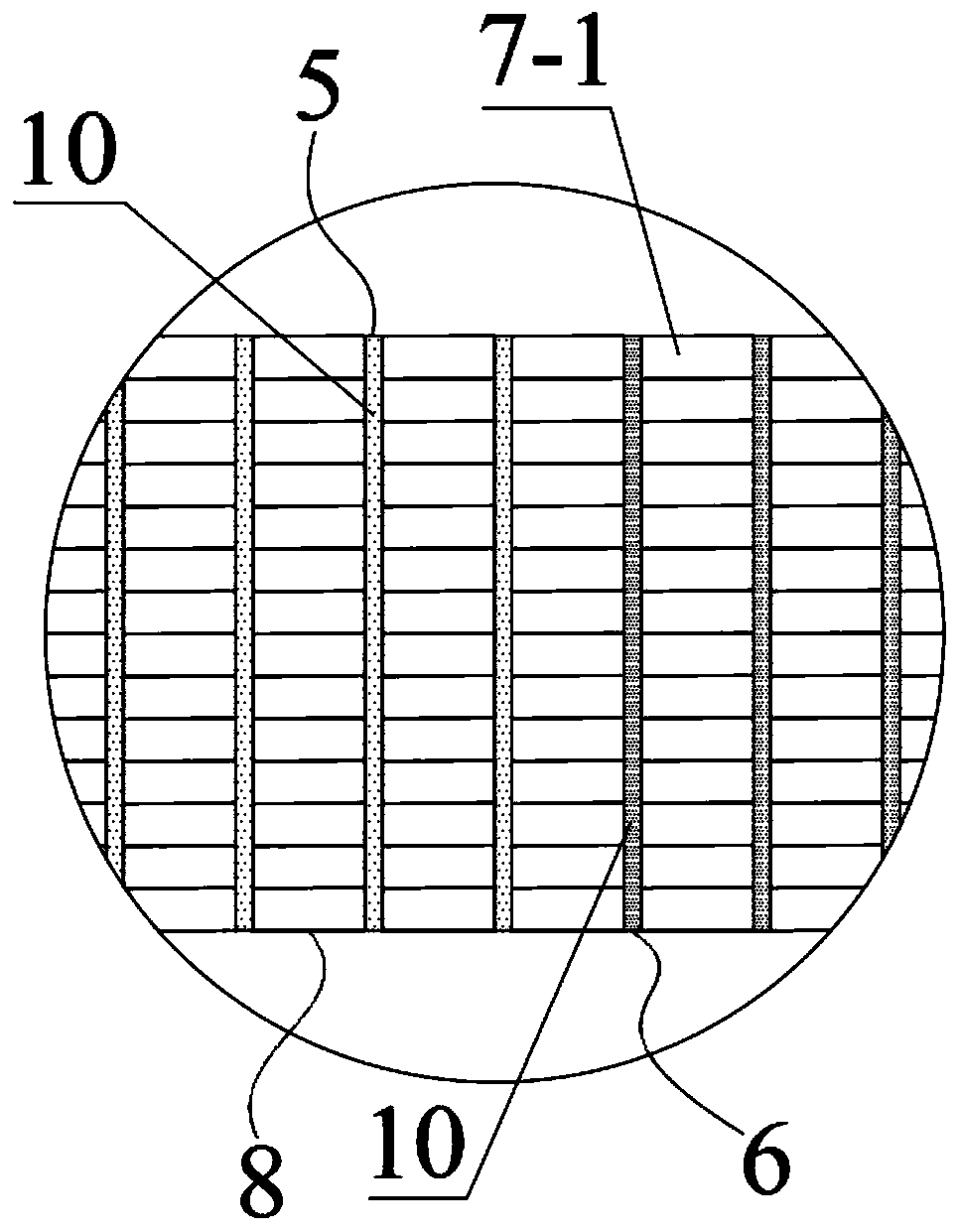

[0044] The structure of each strip-shaped plastic sheet 8 is the same, and it is all made up of the green segment 4 positioned at the inner side, the orange segment 5 positioned at the middle and the red segment 6 positioned at the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com