Technique of preparing blue pills and device thereof

A preparation process and amalgam technology, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of inconsistency in particle size of mercury pellets, reduce production costs, unique and simple production process, and advanced technology significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

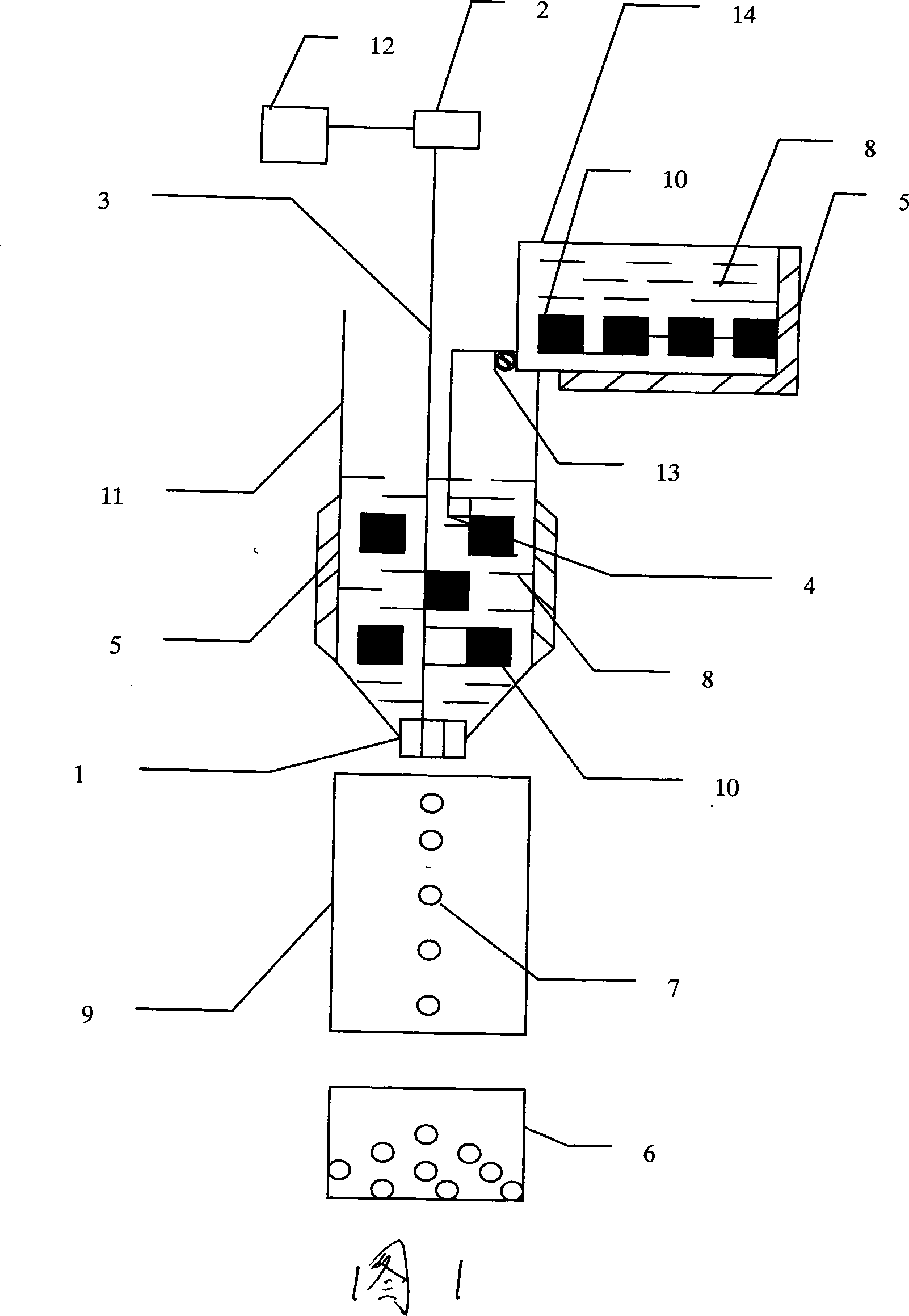

[0017] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as shown in Figure 1, device of the present invention is made of tower body 11, electric heating mantle 5, vibrator 2, signal generator 12, nozzle 1, liquid level sensor 4 , cooler 9, collector 6 and alloy feeder 14, the electric heating jacket 5 wraps the tower body 11, the nozzle 1 is fixed at the lower end of the cone part of the tower body 11, and the exciter 2 fixed above the tower body 11 The horn 3 is inserted into the tower body 11, the lower end of the horn 3 is connected to the nozzle 1, the cooler 9 and the collector 6 are placed under the nozzle 1 in turn, the liquid level sensor 4 is set in the tower body 11, and the signal is generated The signal output of the device 12 is connected to the exciter 2, and the signal of the liquid level sensor 4 is connected to the electric regulating valve 13 on the molten alloy liquid feeder 14.

[0018] The method of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com