On-line detection and real-time control devices for tension of yarn

A technology of real-time control and yarn tension, applied in the direction of mechanical pressure/force control, transportation and packaging, non-electric variable control, etc., can solve the problems of human error, increase of labor cost, inability to realize online monitoring of yarn tension and real-time automatic Adjustment and other issues to achieve the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

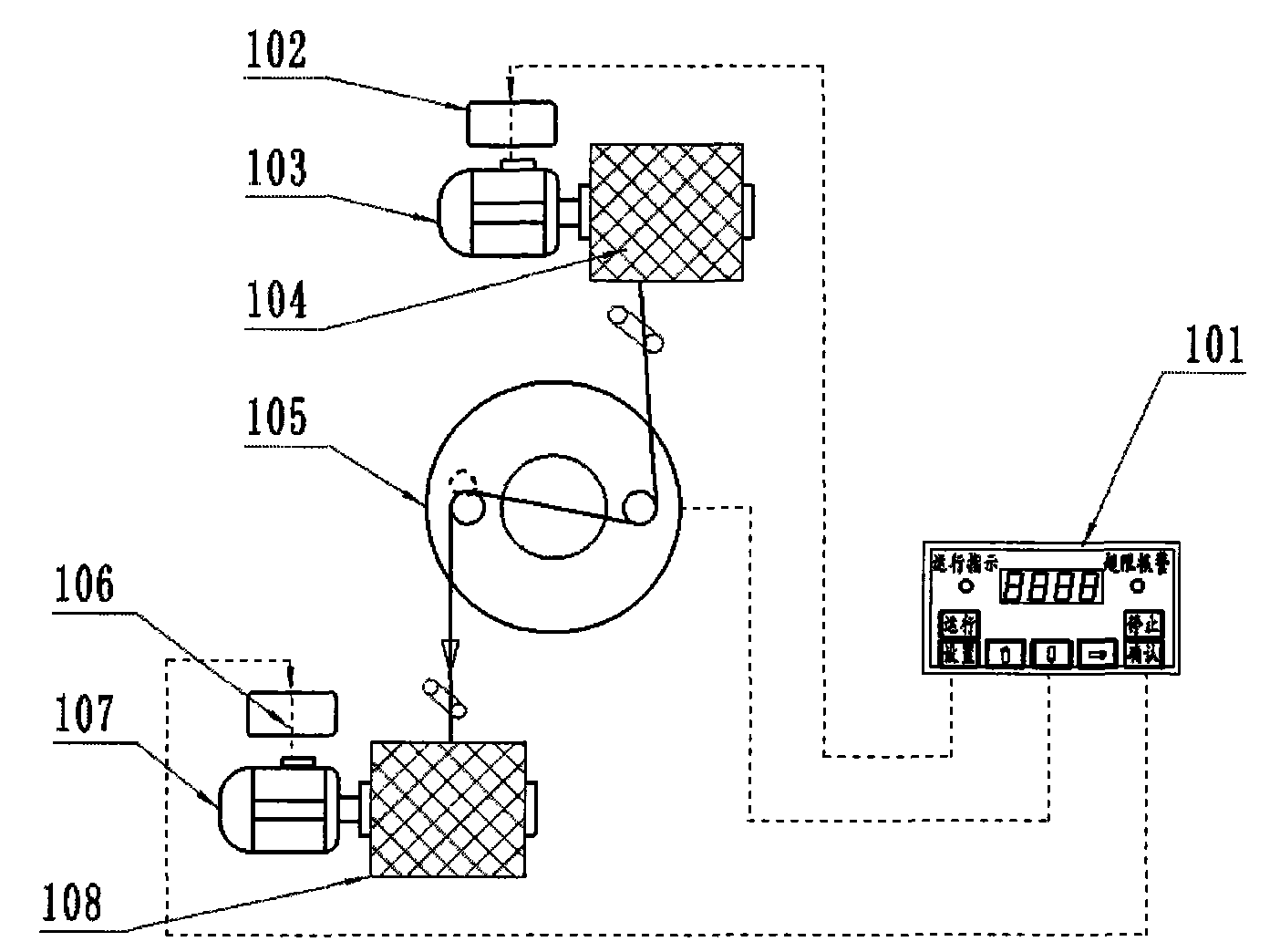

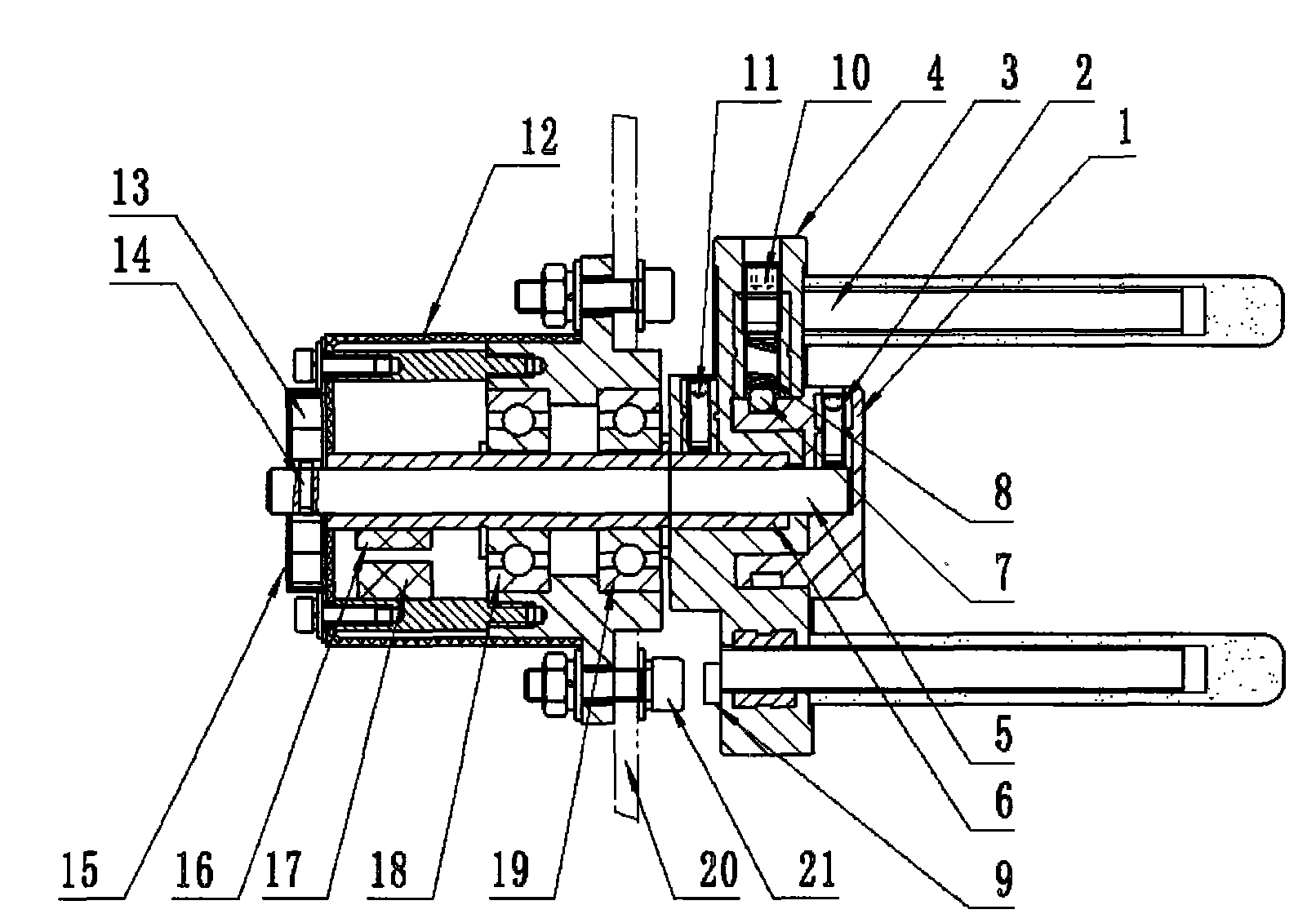

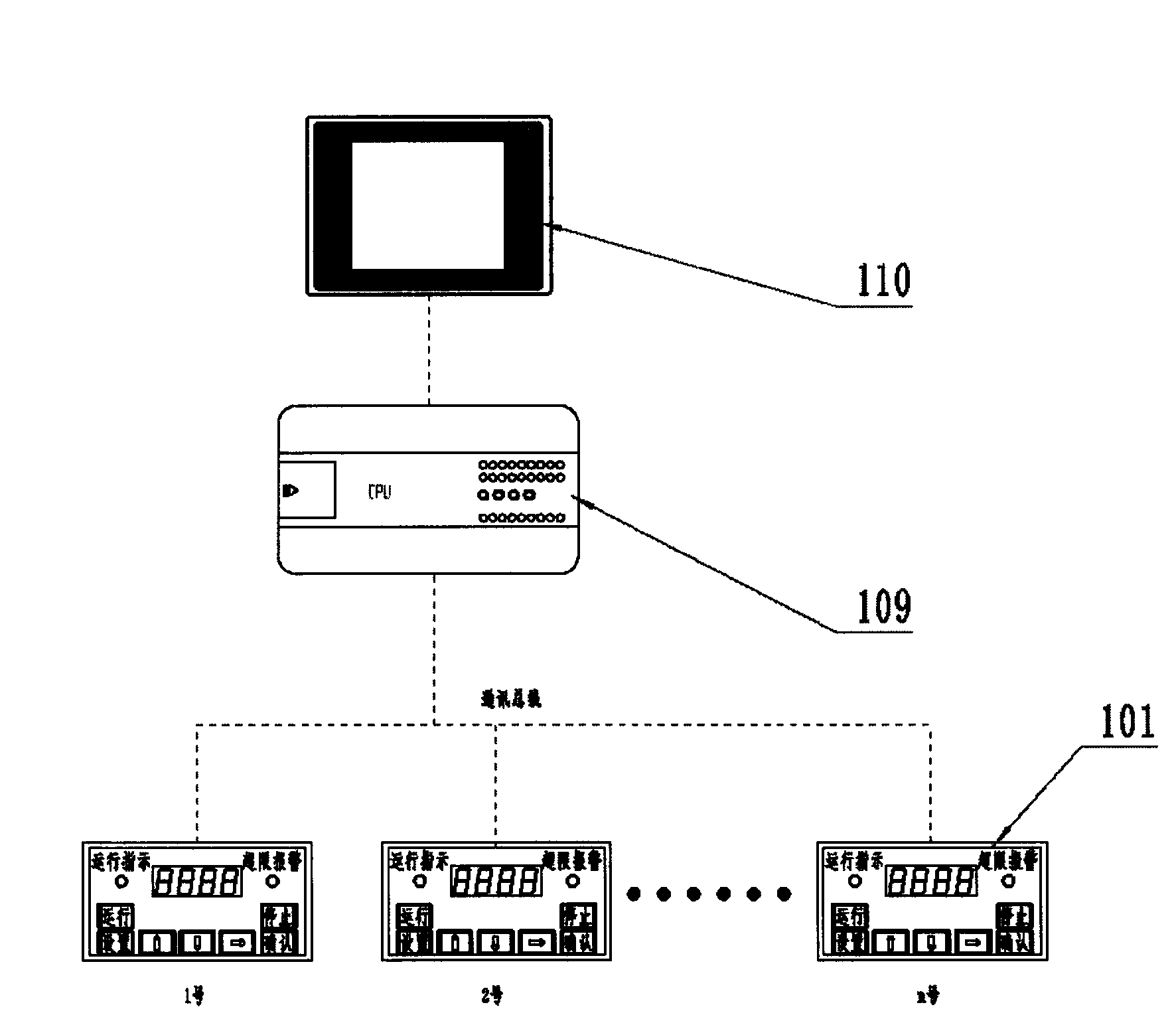

[0015] refer to figure 1 , which consists of a yarn tension on-line detection device 105 and a real-time control device. There is a rotating disk under the action of a coil spring and equipped with two swing arms for hanging the yarn and an angle sensor to form a yarn tension online detection device 105; the output signal of the angle sensor is connected to the central controller 101, and the central control The output signal of the device 101 is connected to the motor controllers 102 and 106, and the motor controllers 102 and 106 are respectively connected to the unwinding motor 103 and the winding motor 107 of the yarn, and the motor controllers 102, 106 and the central controller 101 constitute real-time control device. Central controller 101, motor controller 102, unwinding motor 103, spindle 104, yarn tension on-line detection device 105, motor controller 106, winding motor 107, spindle 108 and other parts constitute a tension closed-loop control system to realize yarn t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com