Method for synthesizing (E)-2-hexenoic acid

A synthesis method, a technology of hexenoic acid, applied in chemical instruments and methods, preparation of carboxylic acids by ozone oxidation, organic compounds/hydrides/coordination complex catalysts, etc., can solve the use of toxic solvents, harsh reaction conditions, and side reactions. Serious problems, to achieve the effect of less side reactions, easy availability of raw materials and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 10 milliliters of water, 5.0 millimoles of diethyl malonate, 5.0 millimoles of n-butyraldehyde and 0.15 millimoles of catalyst TBAB were added to the reaction flask equipped with a reflux condenser and agitator, and the reaction mixture was stirred at 25° C. for 12 hours. Afterwards, the temperature was raised to 60°C, and the stirring was continued for 6.0 hours, then the temperature was raised to 90°C, and the stirring was continued for 2 hours, then a 10% sodium hydroxide solution was added, stirred and refluxed for 0.5 hours, and then 10% hydrochloric acid was added to acidify , stirred and refluxed for 0.5 hour, stopped the reaction, distilled under reduced pressure, and dried in vacuum to obtain 0.485 g of (E)-2-hexenoic acid with a yield of 85%.

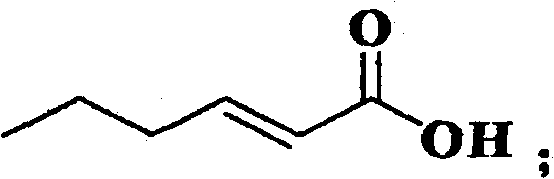

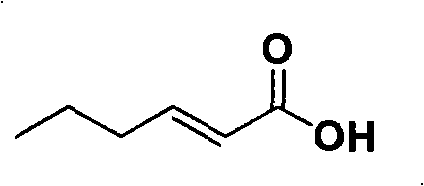

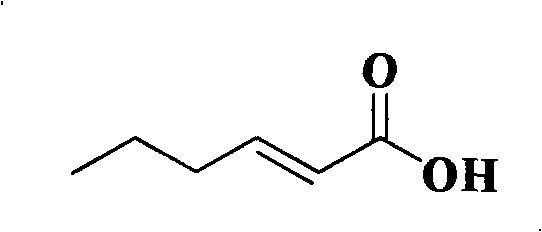

[0021] The reaction equation is as follows:

[0022]

[0023] Data characterization of hexenoic acid:

[0024] Mp: 125~127℃ / 2.66KPa

[0025] 1 H NMR (500MHz, CDCl 3 , 25°C) δ=0.87(3H), 1.41(2H), 2.14(2H), 5.76(2H...

Embodiment 2

[0030] The consumption of n-butyraldehyde is 0.48 mmol, and other operating conditions are all the same as in Example 1, and the yield of (E)-2-hexenoic acid is 82%, 124~125°C / 2.66KPa.

Embodiment 3

[0032] Except that the consumption of n-butyraldehyde was 0.52 mmol, other operating conditions were the same as in Example 1, and the yield of (E)-2-hexenoic acid was 80%, 125~126°C / 2.66KPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com