A clear pulp production process for realizing complete comprehensive utilization and removing three wastes

A process method and clean production technology, applied in textiles and papermaking, pulping liquid regeneration, papermaking and other directions, can solve the problems of increasing production costs, three pollution emissions, waste of plant resources, etc., to save land, eliminate Three wastes discharge, the effect of increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

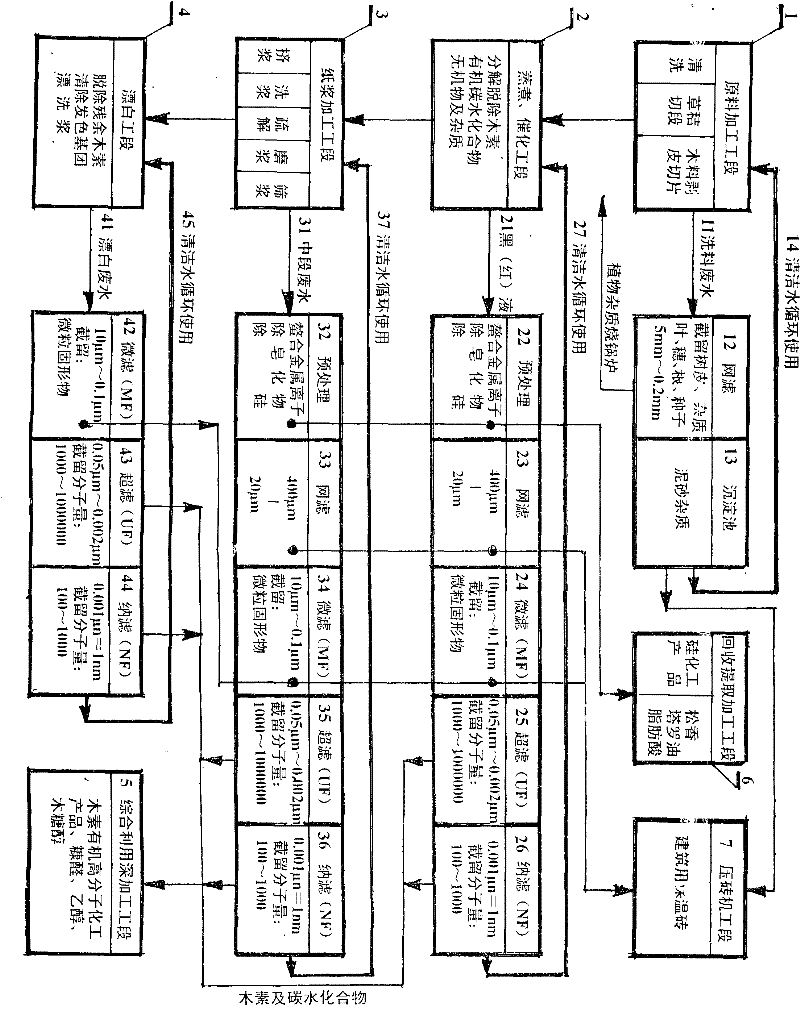

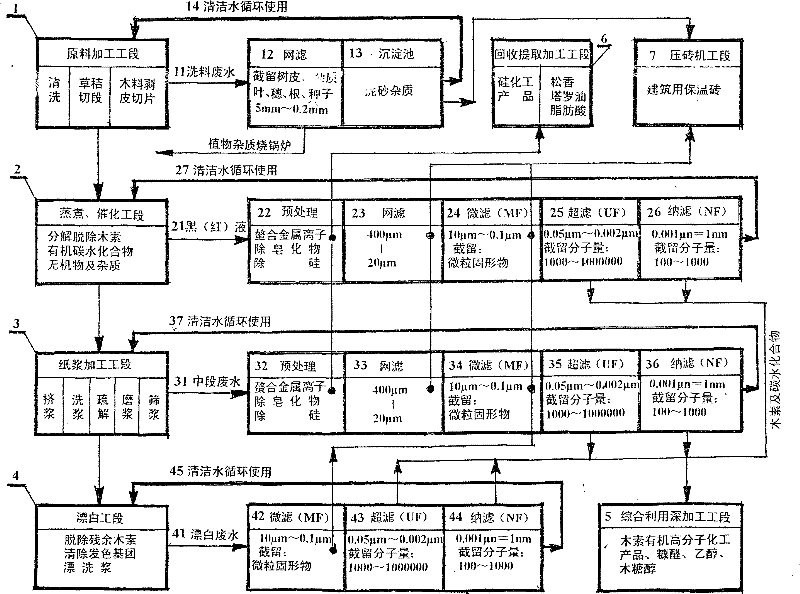

[0052] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, features and effects of the clean pulp production process for realizing 100% comprehensive utilization and eliminating the three wastes proposed by the present invention are described in detail below.

[0053] see figure 1 As shown, the present invention realizes 100% comprehensive utilization and eliminates the three wastes of paper pulp clean production process which includes four production sections 1, 2, 3, 4 and three comprehensive utilization sections 5, 6, 7 that generate waste water: (1) In the raw material processing section 1, the discharged washing wastewater 11 is treated by the screen filter 12 and the sedimentation tank 13 to become clean water 14, and then the clean water 14 is returned to the raw material processing section 1 for recycling. (2) Cooking and catalytic workshop section 2, the black (red) liquid 21 that is discharged becomes clean wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com