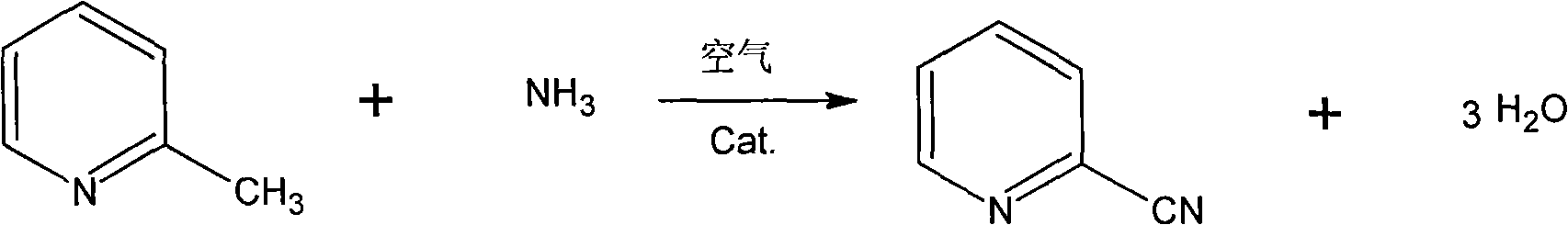

Synthesis method of 2-cyanopyridine

A technology of cyanopyridine and synthesis method, which is applied in the field of synthesis of 2-cyanopyridine, can solve the problem of low conversion rate of 2-picoline, and achieve the effect of easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The raw material 2-picoline and ammonia are vaporized and preheated to 180-330°C, then enter the mixer and mix with air evenly, and then distribute through the distributor on the upper part of the fixed bed reactor and then enter the fixed bed reactor filled with catalyst, controlled The reaction temperature is between 300-450°C, the pressure at the top of the reactor is controlled at 0.020-0.070KPa, the reaction temperature is controlled by molten salt, the reaction gas after the reaction is absorbed by water, and the 2-cyanopyridine content reaches 2-8% , and then extract and rectify to obtain the finished product 2-cyanopyridine. The molar ratio of the amount of raw materials is: 2-picoline: NH 3 : air=1:3-8:12-18. Described catalyzer is the 2-cyanopyridine ammoxidation catalyst that is carrier with silicon dioxide, and the composition of catalyzer is as follows:

[0023] A a B b C c Cr 10 o x

[0024] Wherein A=Na (or K or Ti or several combinations in Na, K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com