Assembly integrated precast concrete shear wall and construction method thereof

A prefabricated concrete and shear wall technology, applied in the direction of walls, building materials, building components, etc., can solve problems such as large cross-section, volume and weight, prefabrication, transportation, hoisting and installation difficulties, unsuitable for assembly construction methods, etc. To achieve the effects of construction quality assurance, easy construction quality assurance, and improvement of construction environment and conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

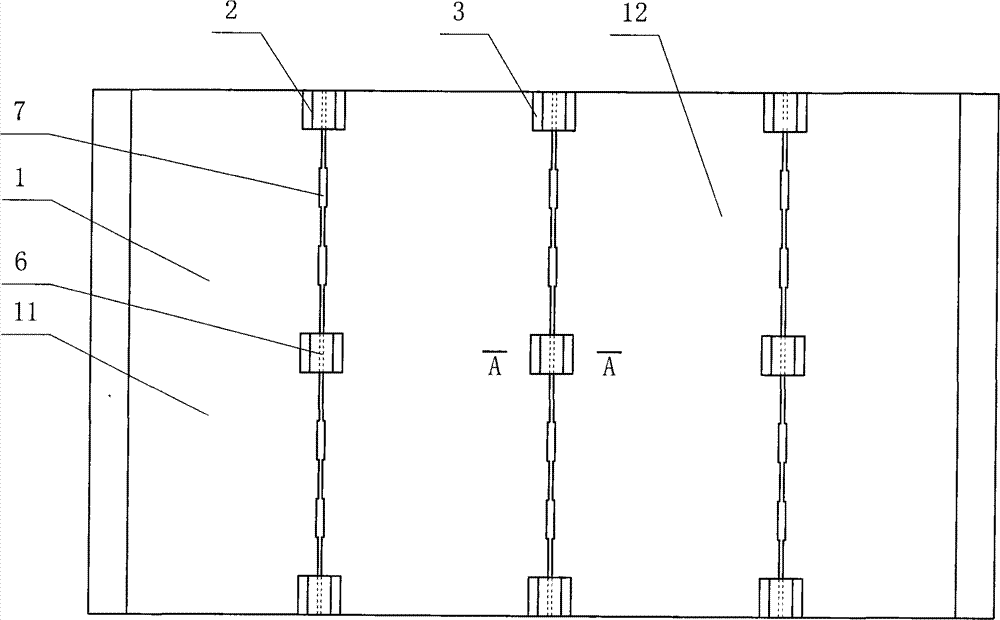

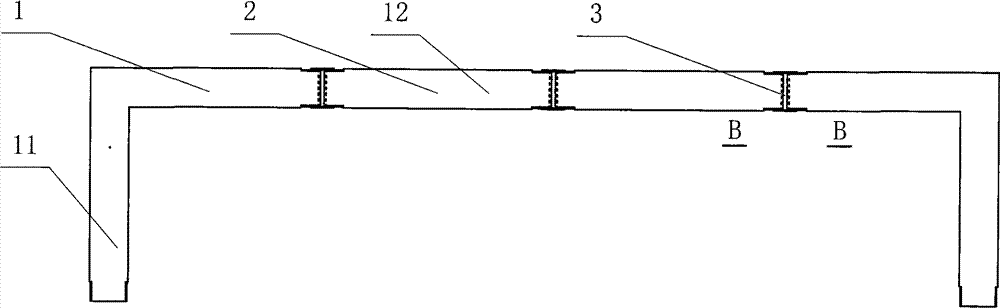

[0024] An assembled integral precast concrete shear wall comprises: a set of prefabricated concrete short-leg shear walls 1, the prefabricated concrete short-leg shear walls are connected by connectors 2, and have overall mechanical performance.

Embodiment 2

[0026] For the above-mentioned assembled integral precast concrete shear wall, the section shape of the precast concrete short-leg shear wall is in-line, or T-shaped, or L-shaped, or cross-shaped. The ratio of section height to thickness of wall pier is 5-8.

Embodiment 3

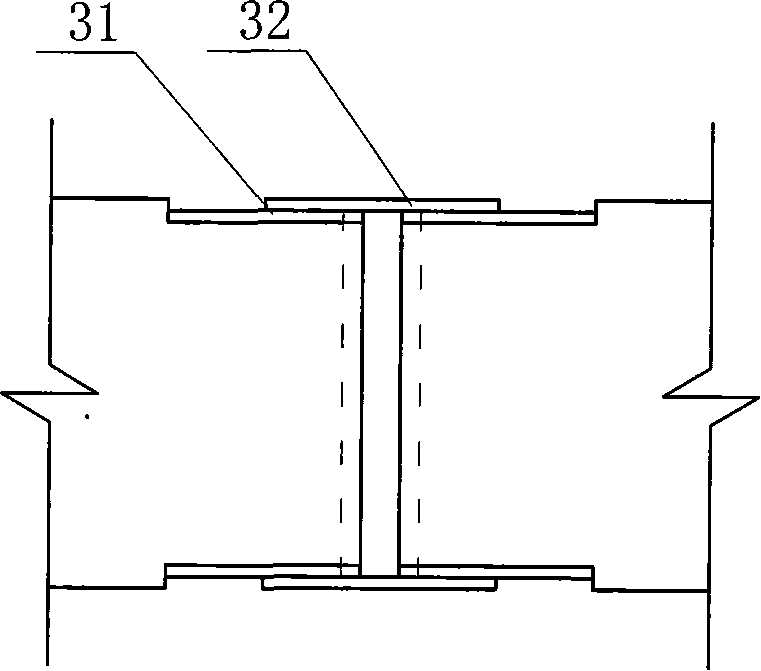

[0028] For the above assembled integral precast concrete shear wall, the connectors are interface shear connectors 3 or through the reserved steel bars 4 on both sides of the prefabricated concrete short limb shear wall, the vertical reserved post-casting strips are used. 5 connections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com