Suspension piston engine

A piston engine and engine technology, applied to internal combustion piston engines, engine components, combustion engines, etc., can solve the problems of low utilization value, melting of cylinder liner, low-quality waste heat, etc., and achieve low cost, improved thermal efficiency, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

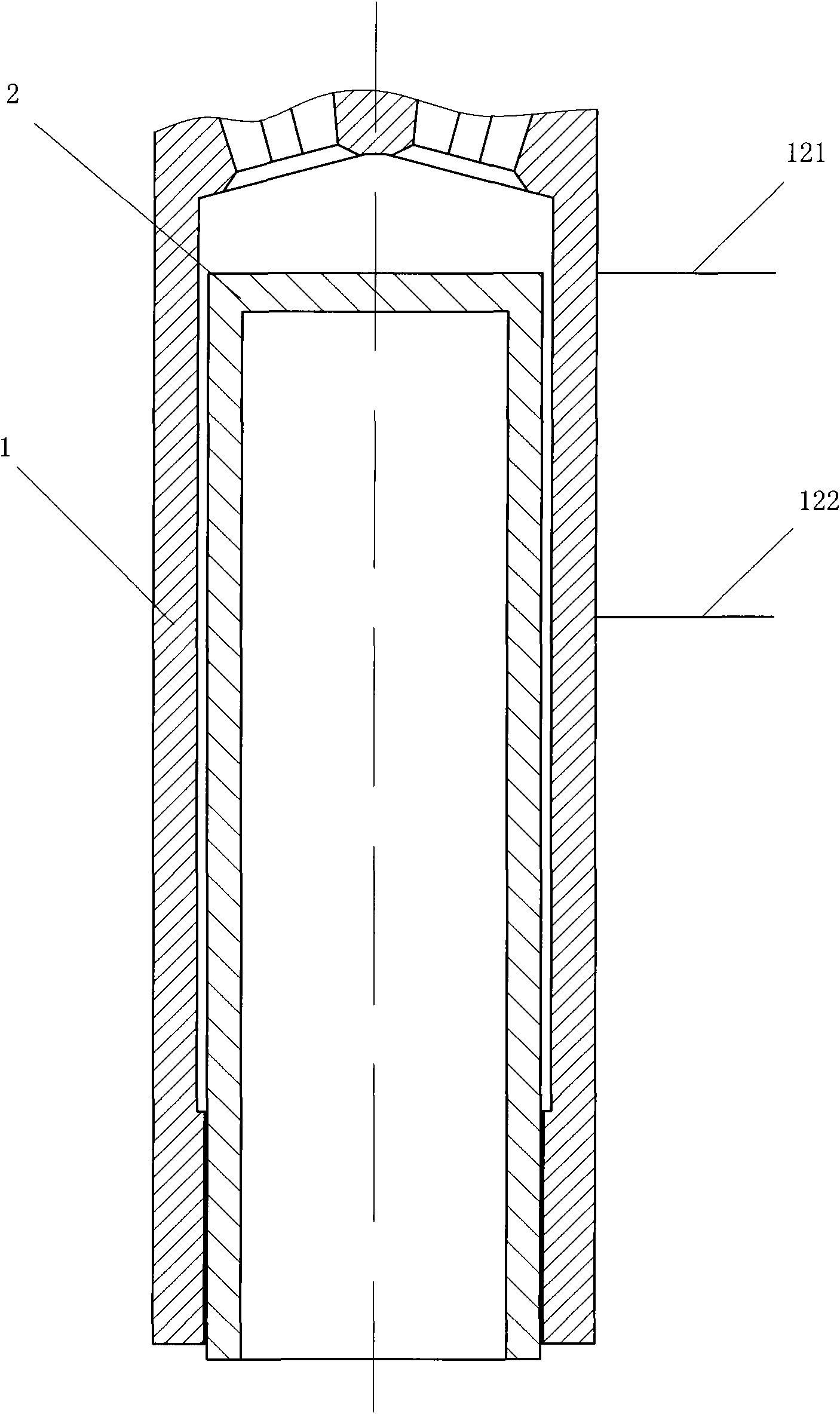

[0049] like figure 1 The suspended piston engine shown includes a cylinder 1 and a piston 2, the piston 2 is wholly or partly arranged in the cylinder 1, and the piston 2 is between the top dead center 121 and the bottom dead center 122 of the cylinder 1. Non-contact suspension setting or quasi-suspension setting with the cylinder 1 within the whole stroke range or part of the stroke range.

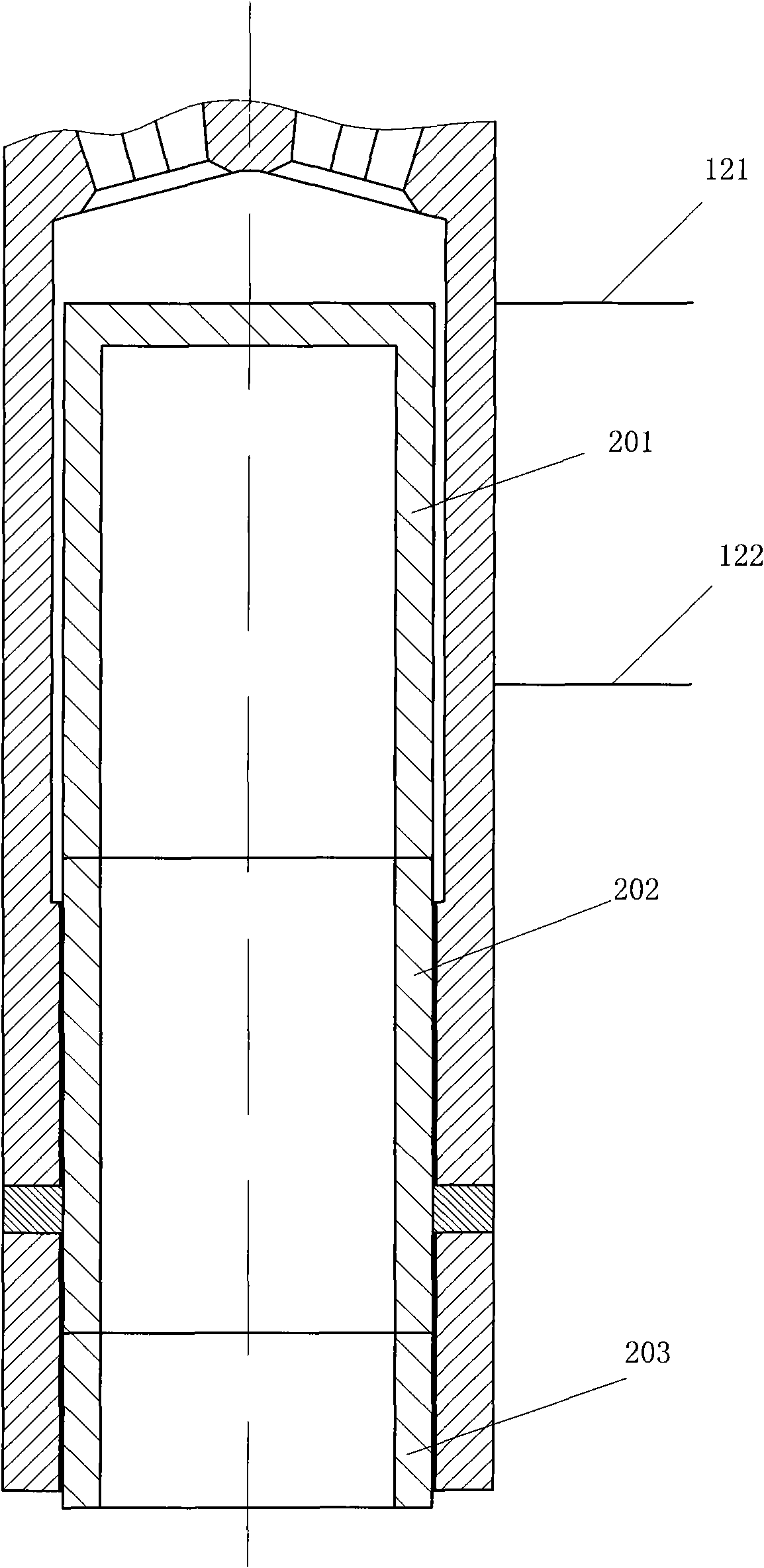

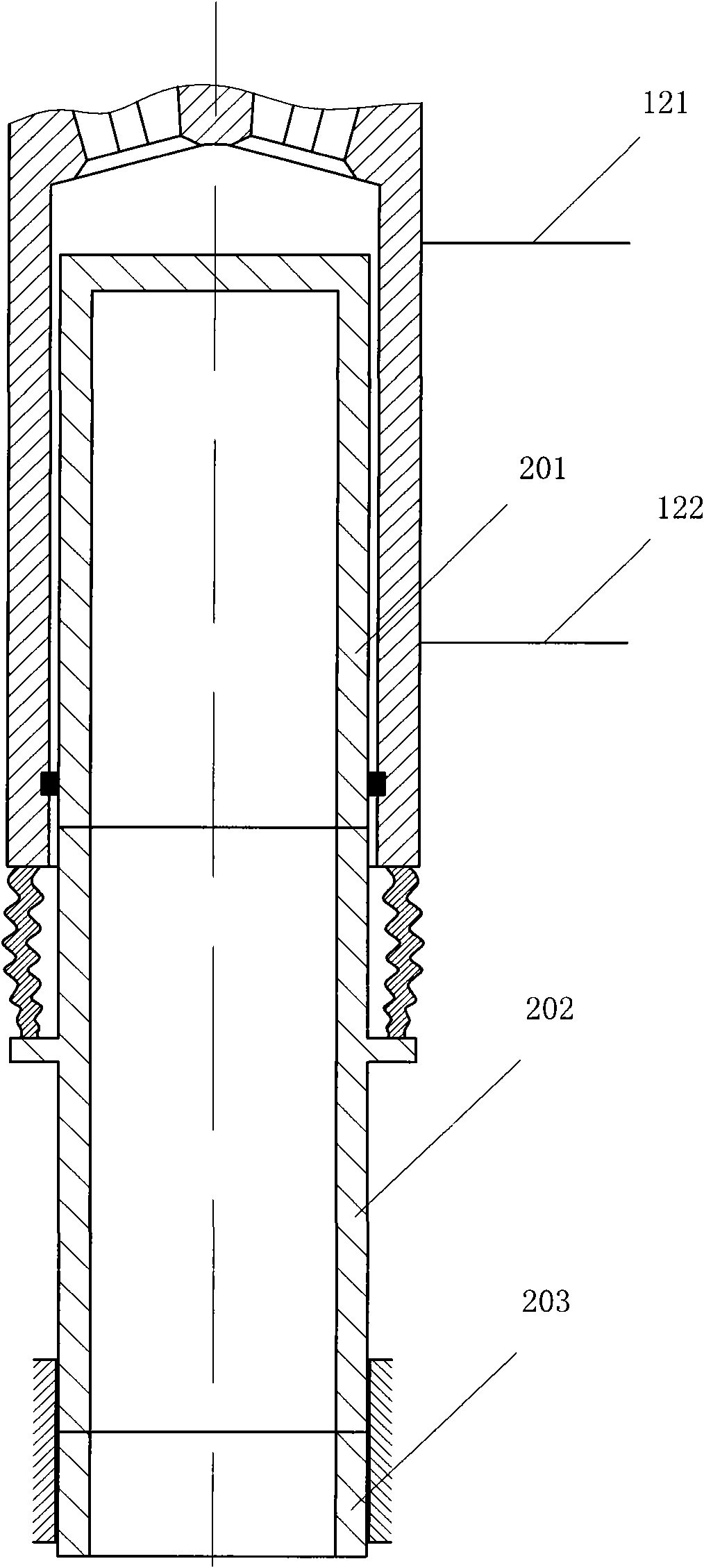

[0050] like figure 2 and image 3 In the suspension piston engine shown, the piston 2 is composed of a piston suspension section 201, a piston sealing section 202 and a piston power section 203, the piston suspension section 201 is connected with the piston sealing section 202, and the piston sealing section 202 is connected with the piston sealing section 202. The piston power section 203 is connected, the length of the piston suspension section 201 is greater than or equal to the distance between the top dead center 121 and the bottom dead center 122, and the piston 2 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com