Device for detecting compositions of coal on conveying belt in real time

A real-time detection and conveyor belt technology, applied in the field of automatic detection technology and nuclear detection, can solve the problems of model error increase and inappropriateness, and achieve the effect of improving resource utilization and energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

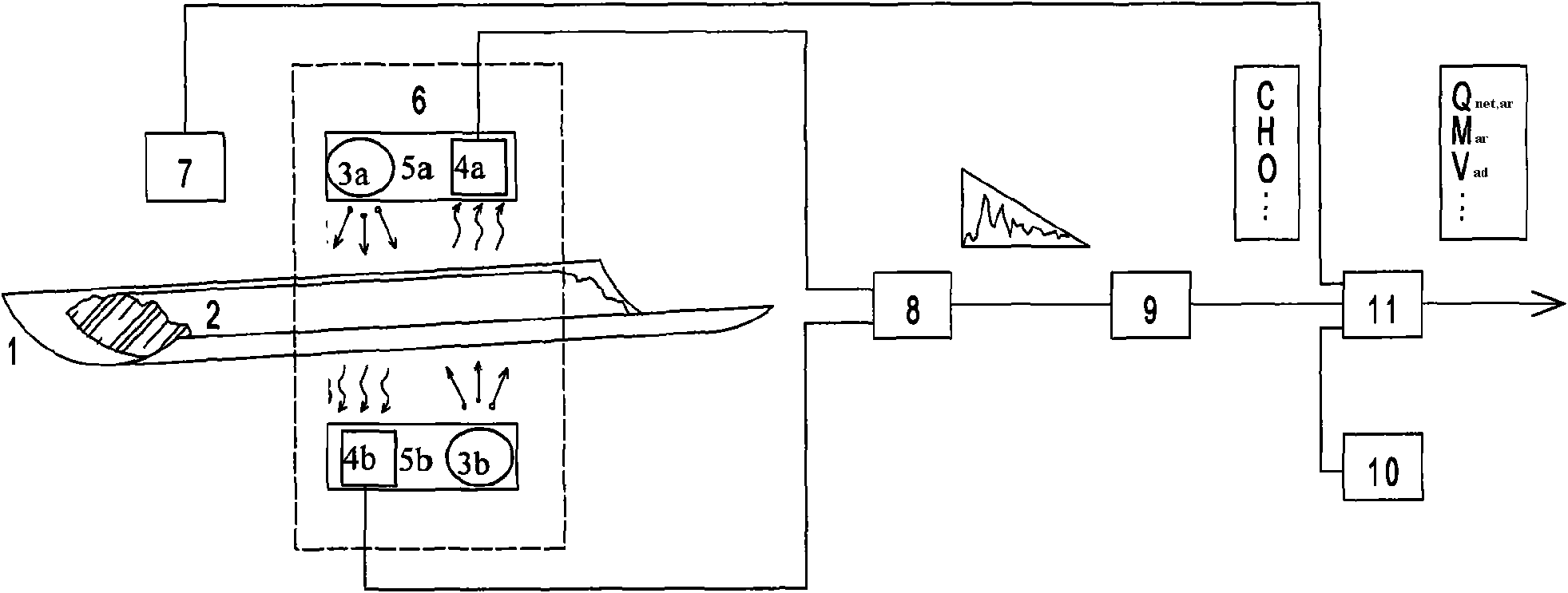

[0022] Such as figure 1 As shown, the coal component real-time detection device on the conveyor belt according to the present invention is directly installed on the industrial site, and is not in contact with the coal 2 to be tested on the conveyor belt 1 . The detection sensor includes the upper and lower neutron sources 3a, 3b and the upper and lower gamma ray detectors 4a, 4b that excite the signal, which are installed symmetrically above and below the conveyor belt in a misaligned position to form a high-precision transmission-scattering compound Type detection system, that is: the connection line between the upper neutron source 3a above the conveyor belt and the lower gamma ray detector 4b below the conveyor belt, the upper gamma ray detector 4a above the conveyor belt and the lower neutron source 3a below the conveyor belt The connection lines of source 3b are all perpendicular to the conveyor belt. The upper neutron source 3a above the conveyor belt and the upper gamm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com