Rotationally locked tappet of a valve timing mechanism

A valve driving and anti-rotation technology, which is applied in the direction of valve devices, engine components, machines/engines, etc., can solve the problems of structural space constraints and high requirements for skirt materials that cannot be ruled out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

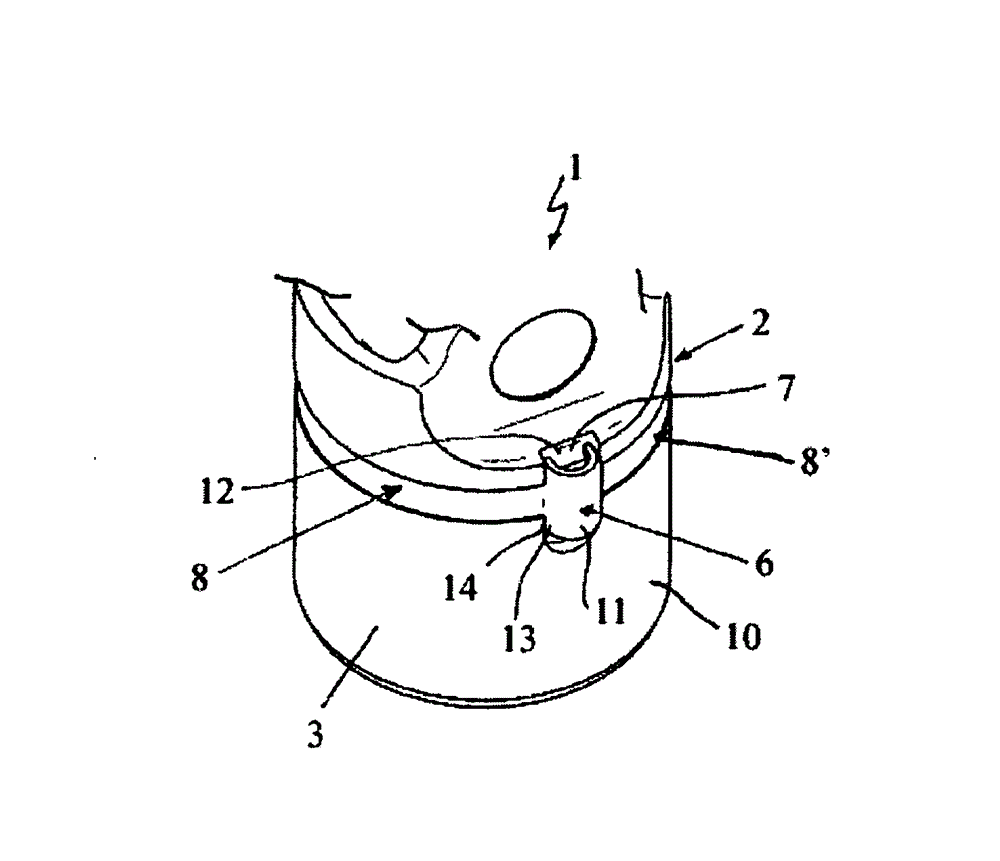

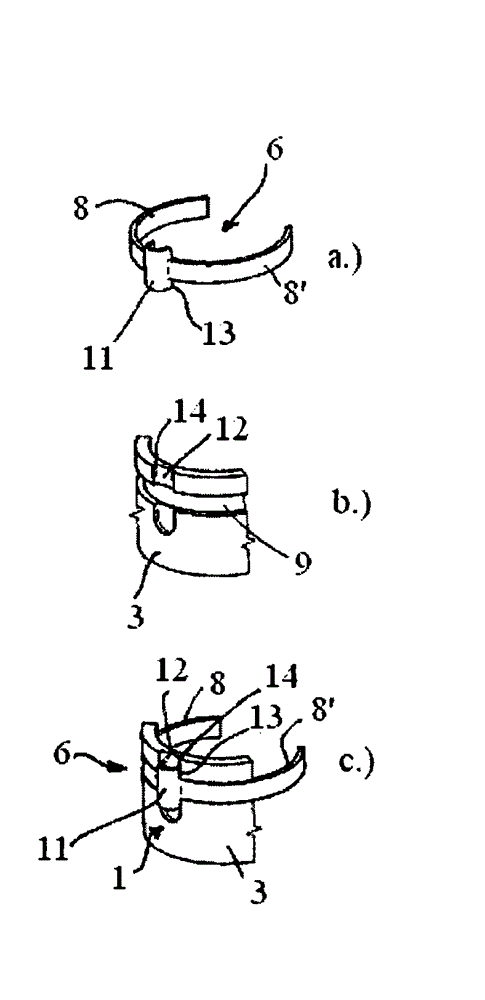

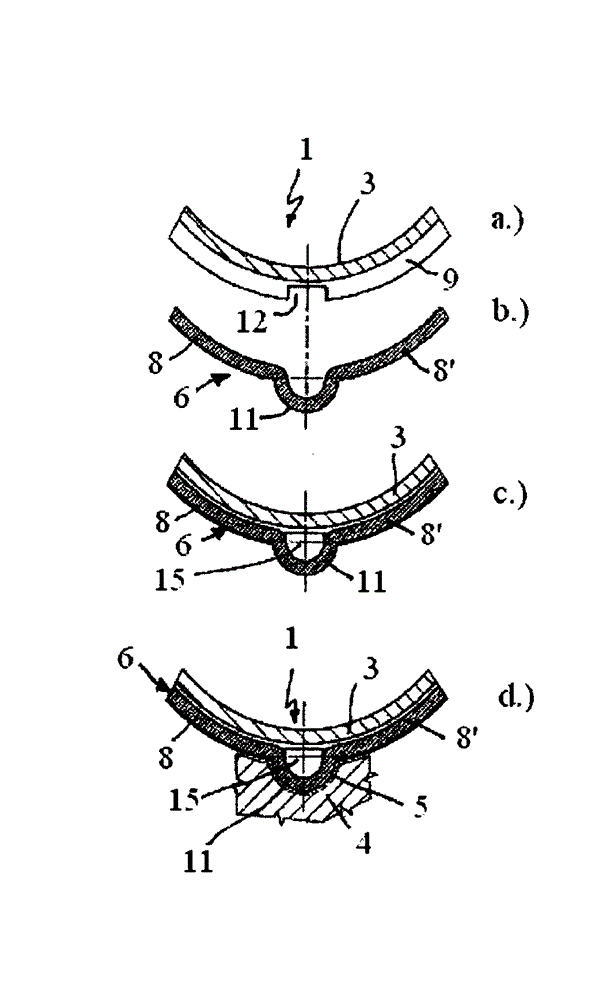

[0028] according to figure 1 , the anti-rotation positioning tappet 1 of the internal combustion engine valve drive has a base plate 2 and an apron 3, wherein the internal combustion engine is not shown. The anti-rotation locking tappet 1 is preferably designed as a piston tappet and is usually placed between a cam and a valve, which are not shown, eg between a control cam and a gas exchange valve. In this arrangement, the tappet 1 carries out an oscillating motion running back and forth in the receiving cylinder of the cylinder head 4, not shown (see image 3 d) A guide groove is provided in the cylinder head 4, wherein the guide groove protrudes radially outwards to engage the anti-rotation assembly 6 of the anti-rotation positioning tappet 1 . The anti-rotation assembly 6 is seated in a recess 7 of the skirt 3 of the tappet 1 .

[0029] according to figure 1 , the anti-rotation assembly 6 has two spring arms 8 , 8 ′ extending in the peripheral direction of the skirt 3 or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com