Use of high-frequency power supply in electrostatic fabric filter

A high-frequency power supply and composite technology, which is applied in the direction of combined devices, chemical instruments and methods, and the separation of dispersed particles, can solve the problems of low electric field efficiency and power factor

Inactive Publication Date: 2009-12-23

FUJIAN LONGKING

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the power supply for the electric bag composite dust collector is a commercial frequency power supply, which is suitable for the flue gas working condition of medium specific resistance and helps to improve the dust removal efficiency under specific conditions, but its electric field efficiency and power factor are low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

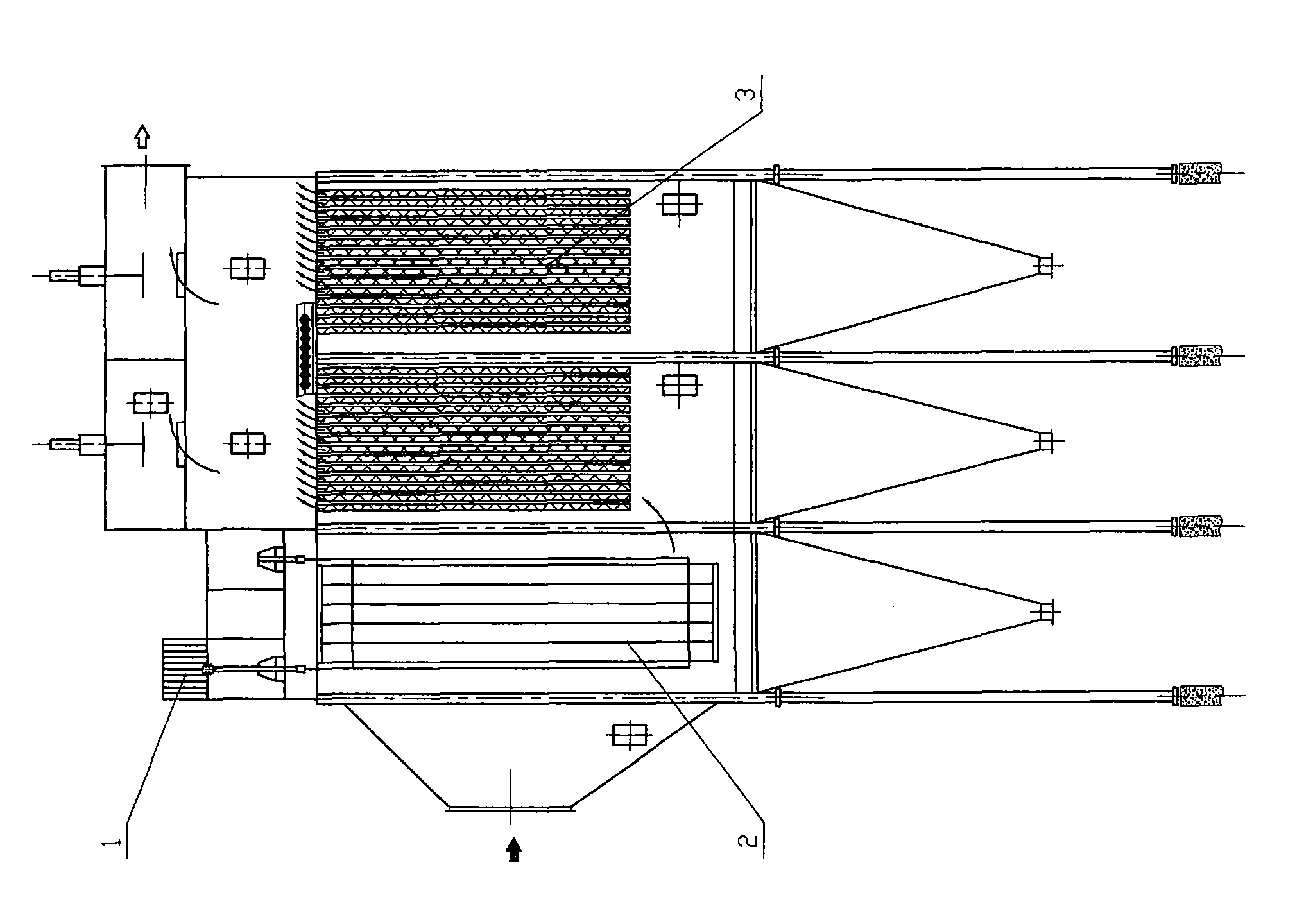

[0014] An electric bag compound dust collector using high frequency power supply, the electric field section is 135m 2 , The same pole distance is 400mm, ZT24 type anode plate is used, the cathode is acupuncture wire, and the rapping method is top electromagnetic rapping. The test result is that the inlet concentration is 30.1g / Nm 3 , the outlet concentration is 9mg / Nm 3 ; Dust removal efficiency is 99.97%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses the use of a high-frequency power supply in an electrostatic fabric filter for solving the problems of low dust collection efficiency and the like of the power-frequency power supply of the prior electrostatic fabric filter. The electric field dust charge strengthening effect of the high-frequency power supply is used to provide adequate electric field charge, allow dust on the surface of a filter bag to distribute and attach orderly and loosely, and ensure high gap rate. Thus, dust collection efficiency is improved greatly and the high-frequency power supply is an ideal rich-energy power supply for the electrostatic fabric filter.

Description

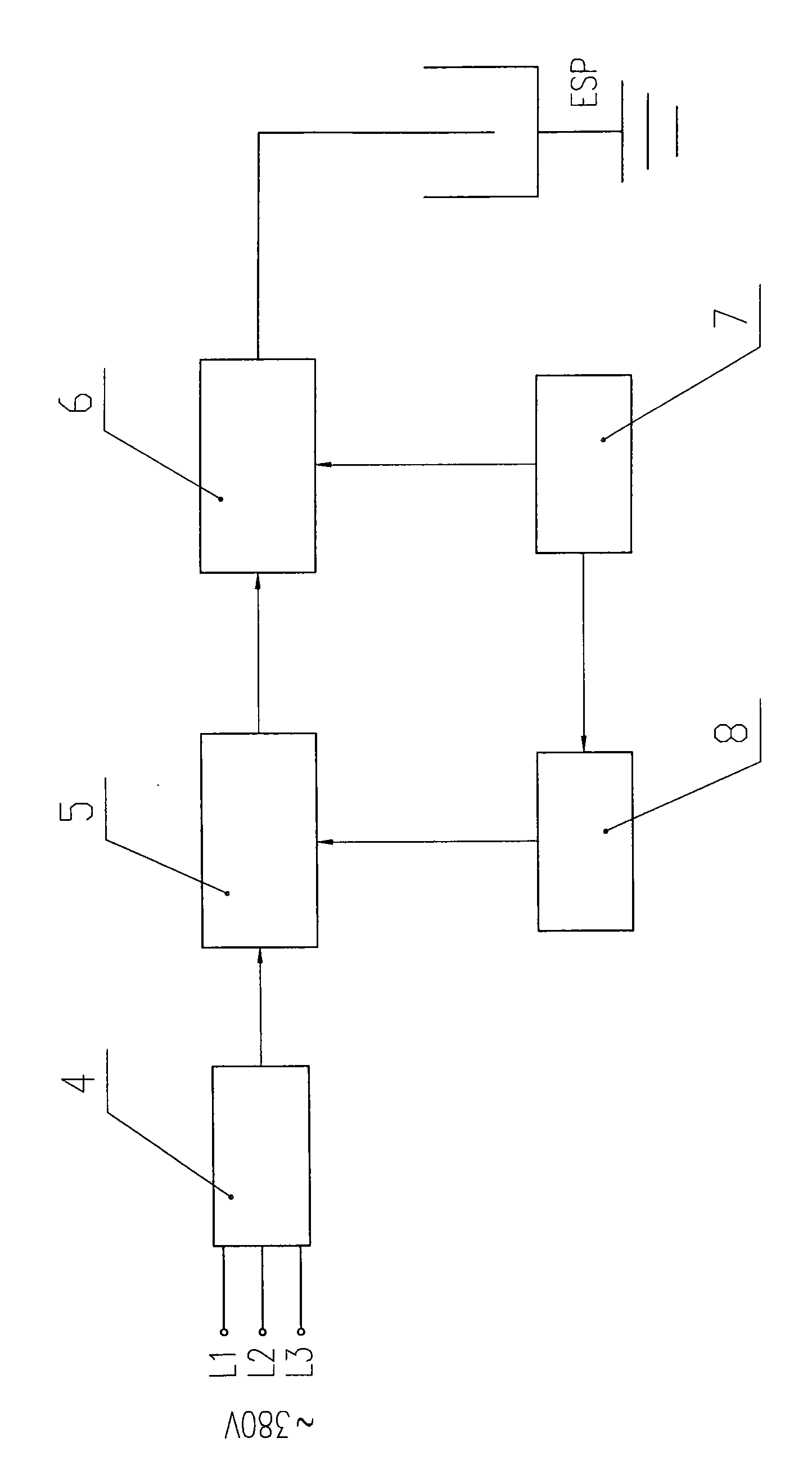

Technical field: [0001] The invention relates to the use of high-frequency power supply, in particular to the application in electric bag compound dust collector. Background technique: [0002] Such a high-frequency power supply is disclosed on the market. Its structural characteristics are: it is composed of a three-phase rectifier bridge, a full-bridge series-parallel resonant power converter, a main control system, a high-frequency and high-voltage silicon rectifier transformer, and a detection and feedback system. The three-phase rectifier The bridge is electrically connected to the full-bridge series-parallel resonant power converter, the full-bridge series-parallel resonant power converter is electrically connected to the main control system with a high-frequency high-voltage silicon rectifier transformer, and the high-frequency high-voltage silicon rectifier transformer is electrically connected to the detection and feedback system. The feedback system is electrically...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D50/00

Inventor 黄炜林宏修海明郑奎照陈颖

Owner FUJIAN LONGKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com