Processing method of fuel valve hole of marine diesel engine cylinder cover

A technology of marine diesel engine and processing method, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of long processing time, high processing difficulty, large cutting resistance, etc. The effect of solving positioning difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] A kind of processing method of fuel valve hole of cylinder head of marine diesel engine of the present invention adopts common processing machine tool to process, comprises the following steps:

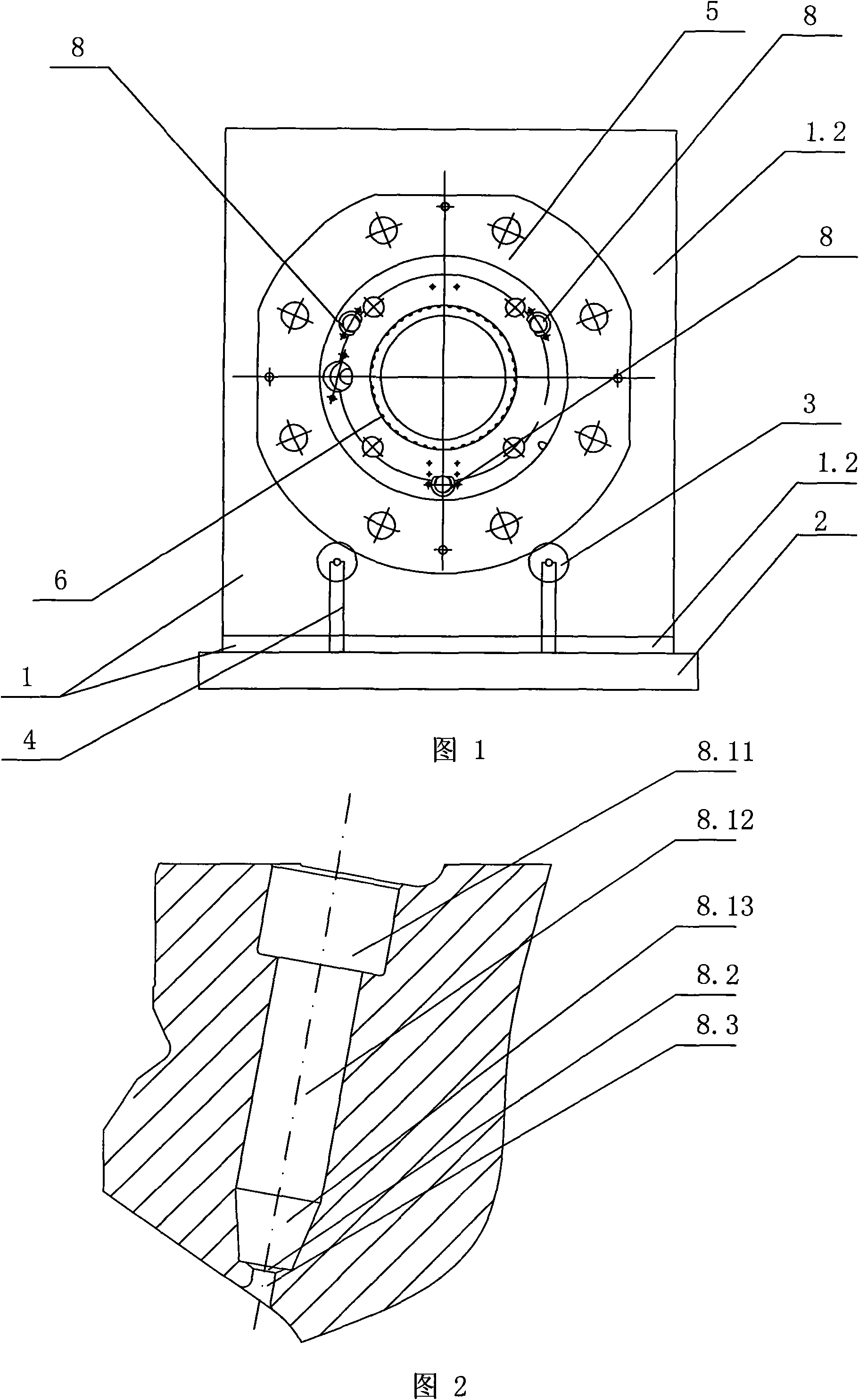

[0032] (1) if figure 1 As shown, the right-angle bending plate is a common auxiliary part in machining; the horizontal plate 1.1 of the right-angle bending plate 1 is fixed on the workbench 2, and the verticality of the right-angle bending plate 1 is corrected, and the two rolling bearings 3 pass through Two columns 4 are fixed on the workbench 2, and the axes of the two rolling bearings 3 are parallel to the axis of the cylinder head 5 of the diesel engine. The cylinder head 5 of the diesel engine is vertically erected on the rolling bearings 3, and the end surface of the cylinder head is perpendicular to the horizontal plane. Position and fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com