Engraving machine

An engraving machine and machine technology, applied in decorative arts, processing models, etc., can solve the problems of inability to eliminate backlash, single function, low processing accuracy, etc., and achieve a large range of engraving angle adjustment, material saving, and high processing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail in conjunction with the above drawings.

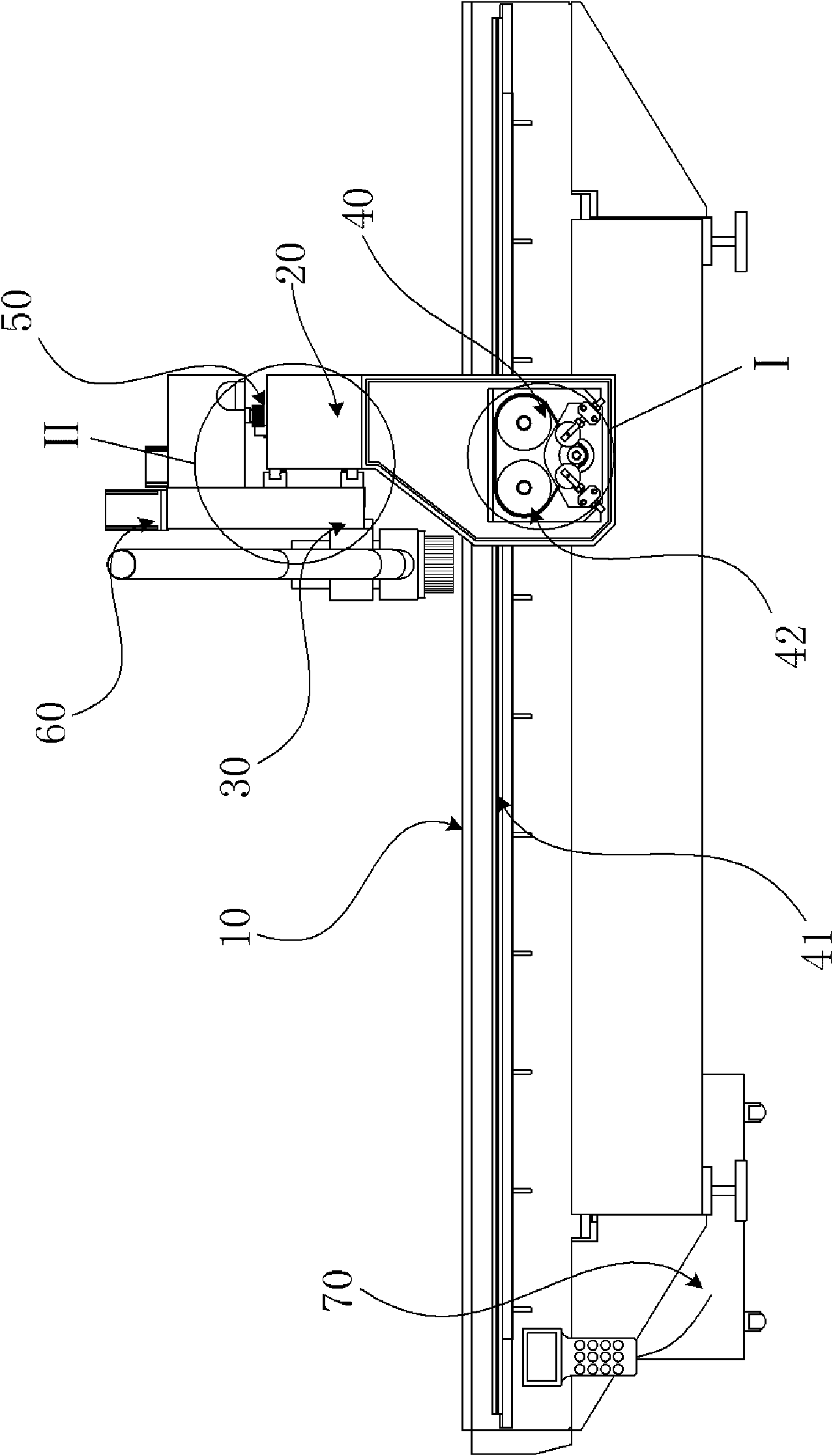

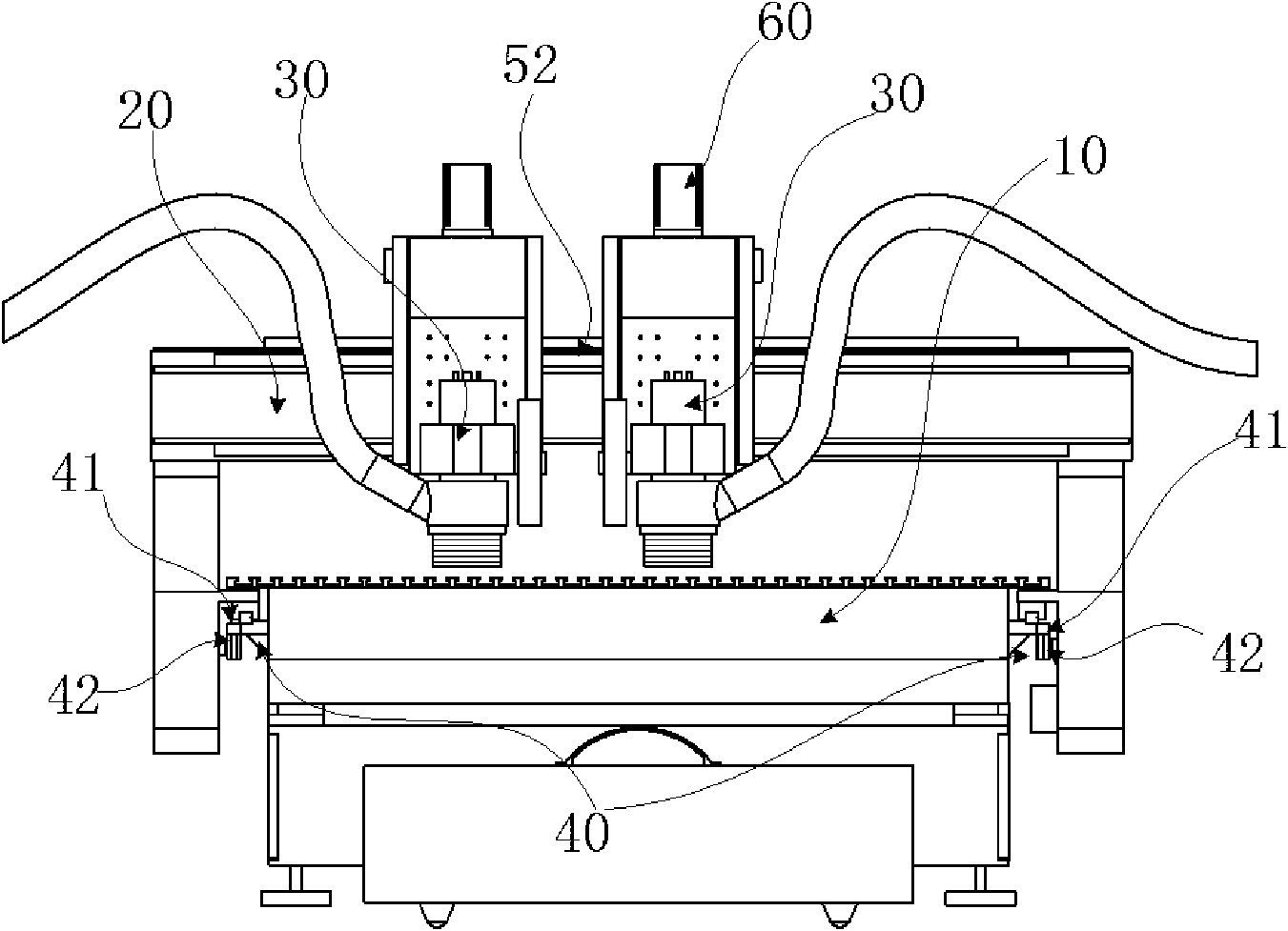

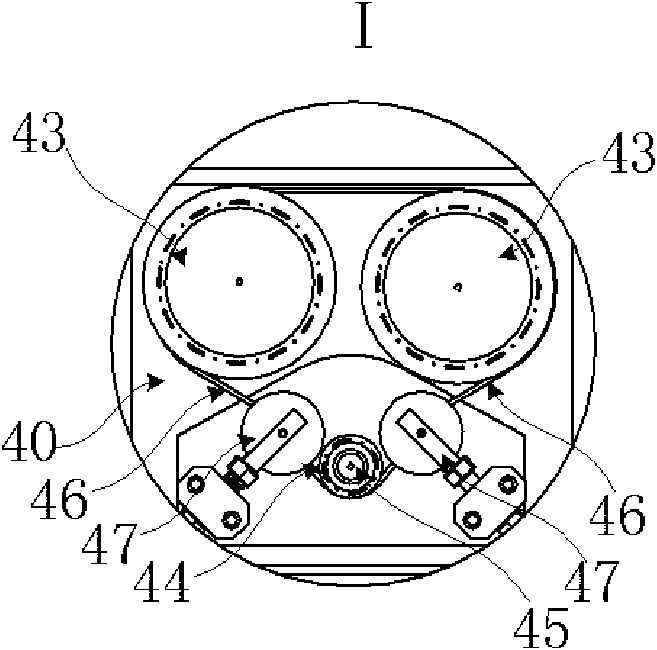

[0017] Depend on figure 1 with image 3 It can be seen from the figure that this engraving machine includes a machine table 10 for carrying and fixing objects to be engraved, a bracket 20 straddling the machine table 10, and the engraving machine also includes a Y-axis that controls the machine table 10 to move along the longitudinal direction of the machine table 10. Mechanism 40, the X-axis traveling mechanism 50 arranged on the support 20 and traveling horizontally along the machine table 10, and the Z-axis traveling mechanism 60 connected vertically on the X-axis traveling mechanism 50, the engraving machine main shaft 30 is connected on the Z-axis traveling mechanism 60 , the engraving machine further includes a control system 70 for controlling the Y-axis traveling mechanism 40, the X-axis traveling mechanism 50, the Z-axis traveling mechanism 60 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com