Fire pump discharge pressure full-automatic balancing system

A balance system, fully automatic technology, applied in the direction of pump control, machine/engine, liquid variable capacity machinery, etc., can solve problems such as long balance time, ineffectiveness, and reduced water outlet pressure, and achieve short balance time and balance pressure Numerically accurate, easy-to-install effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below according to the embodiments and the accompanying drawings.

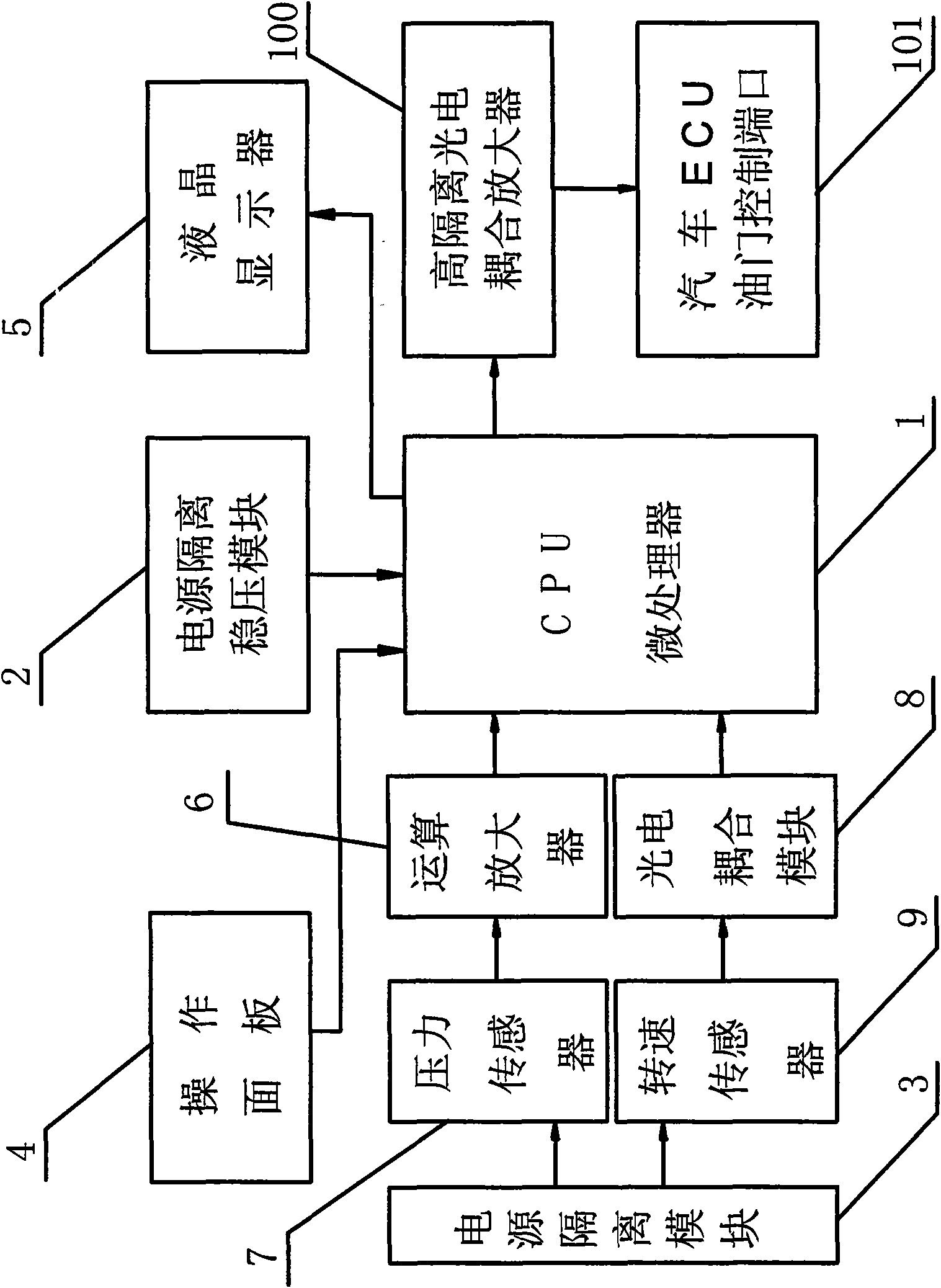

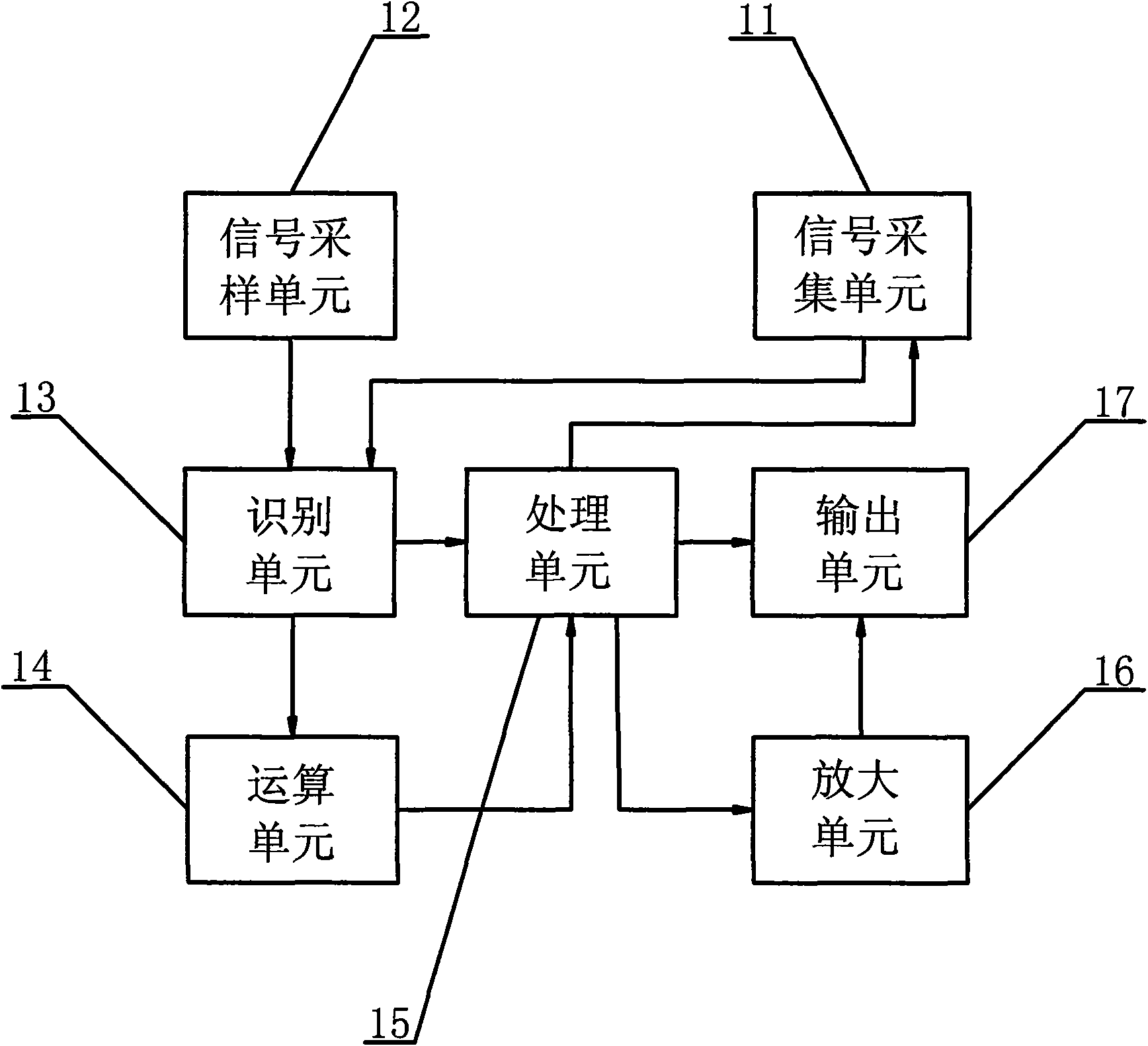

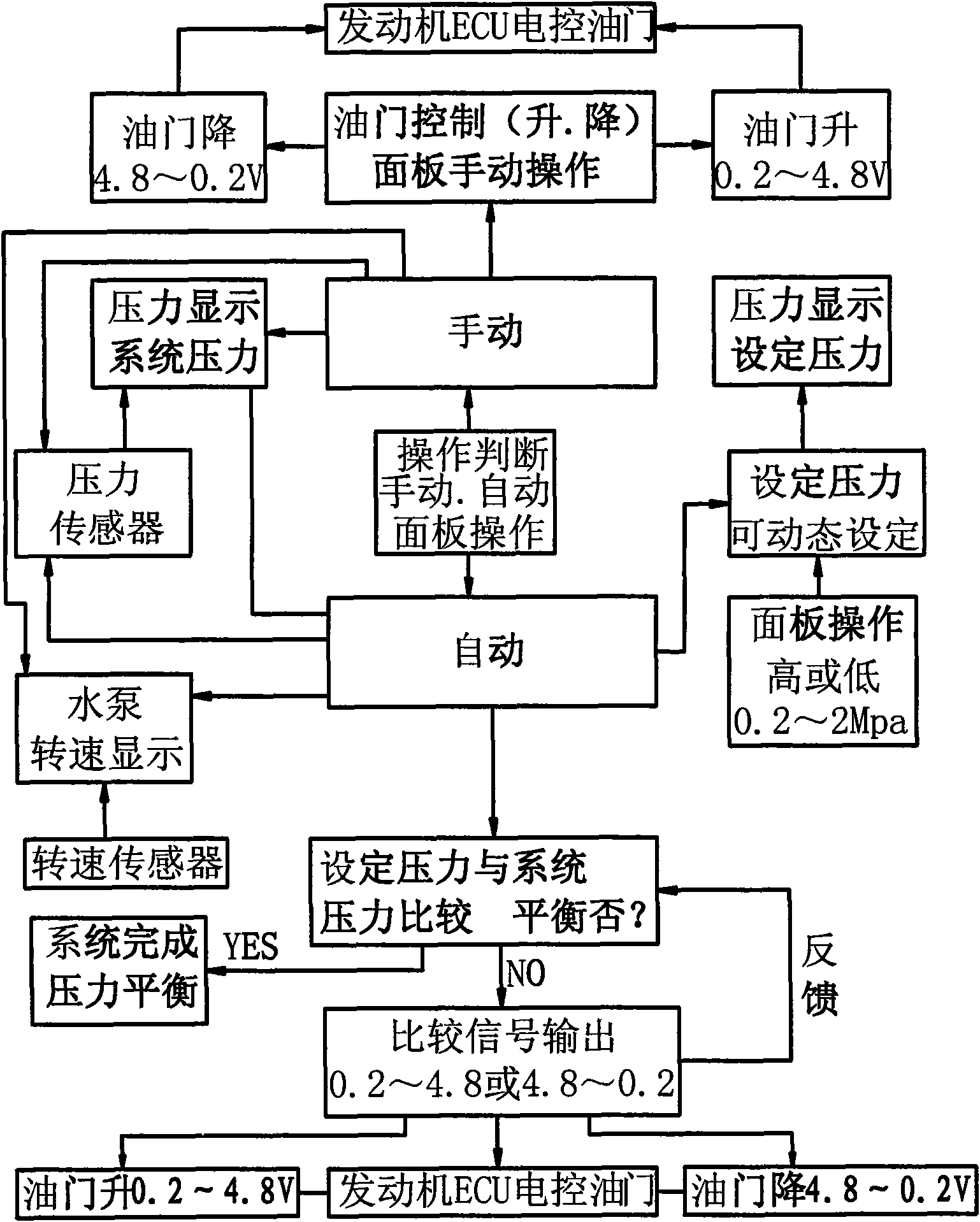

[0018] Such as Figures 1 to 5 As shown, a fire pump outlet pressure automatic balancing system includes a CPU microprocessor 1, a power isolation voltage stabilization module 2, a power isolation module 3, an operation panel 4, and a liquid crystal display 5; the liquid crystal display 5, the operation panel 4 1. The power isolation and voltage stabilization module 2 is respectively connected to the CPU microprocessor 1;

[0019] It also includes a pressure sensor 7 that is connected to the CPU microprocessor through an operational amplifier 6; a rotational speed sensor 9 that is connected to the CPU microprocessor 1 through a photoelectric coupling module 8; the power isolation module 3 is connected to the pressure sensor respectively. Sensor 7, rotational speed sensor 9; Described CPU microprocessor 1 inserts an automobile ECU throttle contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com