Method of manufacturing semiconductur device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as uneven nitride film length, decreased uniformity of memory cells, and reduced reliability of semiconductor devices, etc., to achieve Effects of Preventing Changes in Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, reference will be made in detail to preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

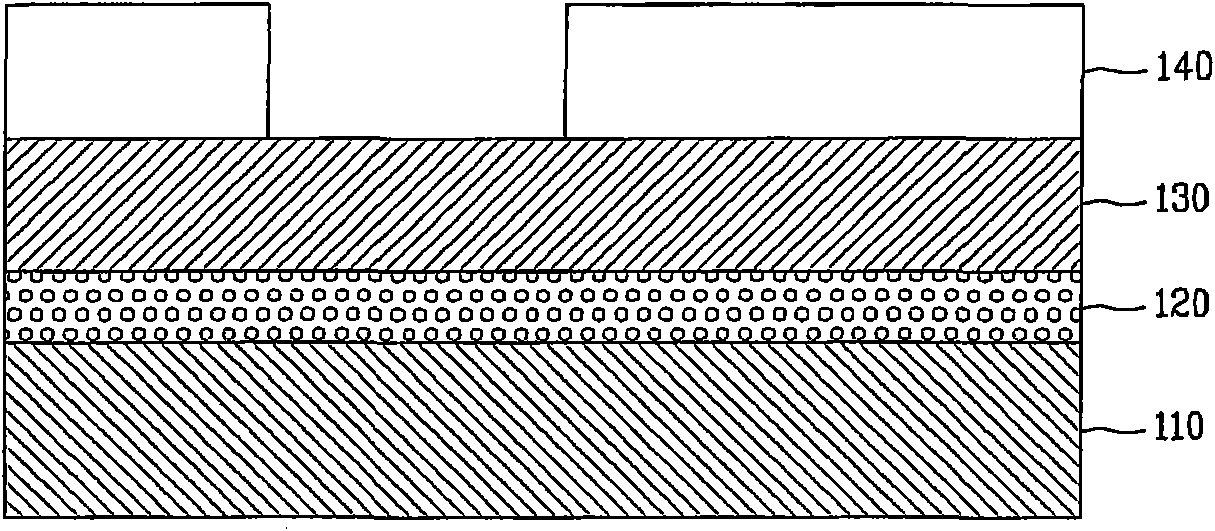

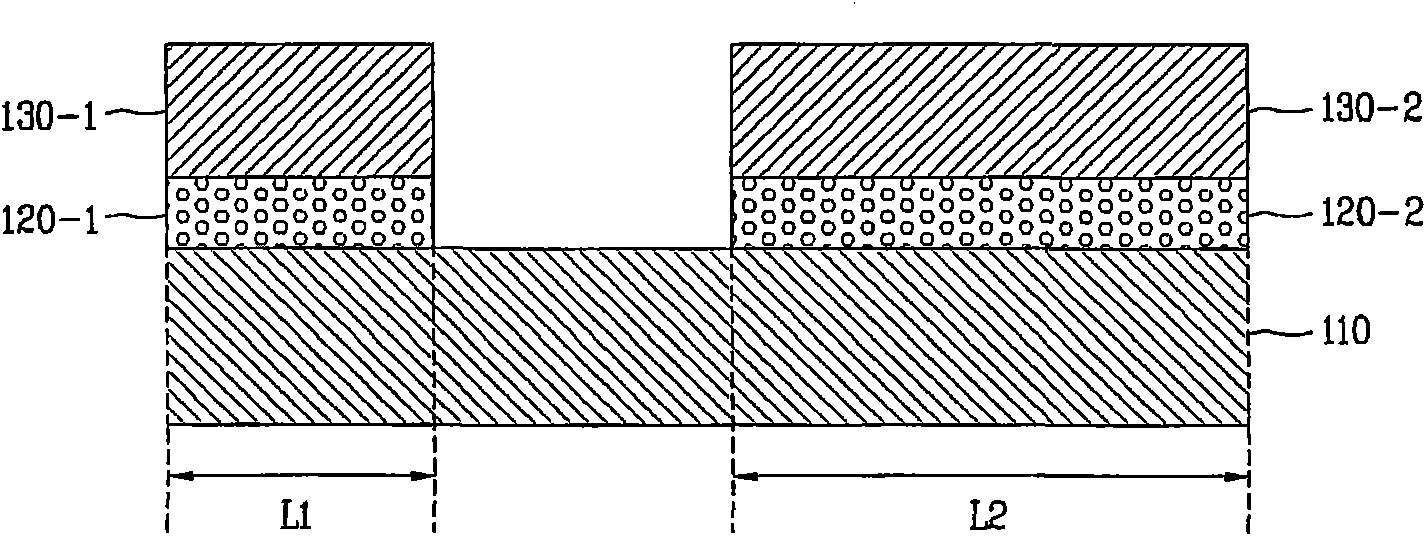

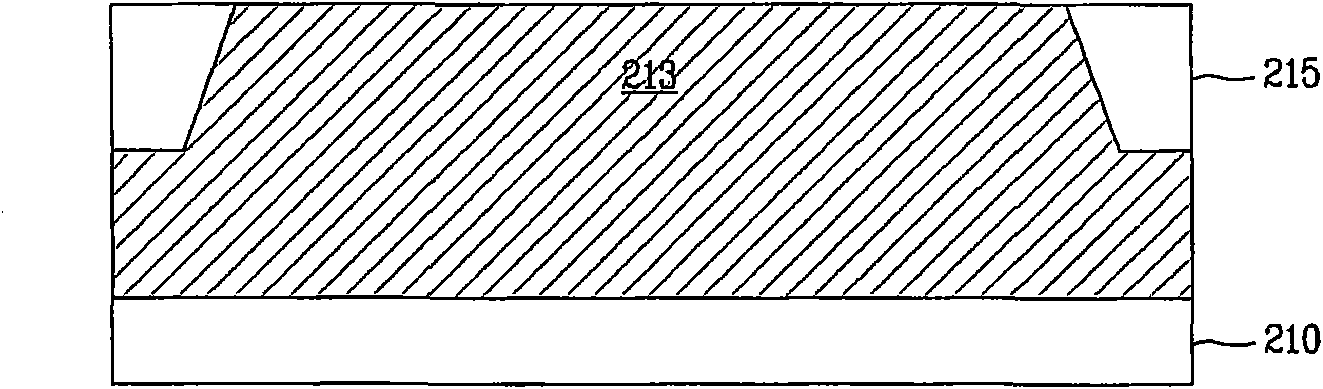

[0022] Figure 2A to Figure 2M is a longitudinal sectional view showing a method of manufacturing a semiconductor device according to an embodiment of the present invention.

[0023] First, if Figure 2A As shown, an active region 213 and a device isolation region 215 are formed on a semiconductor substrate (eg, a p-type substrate) 210 . The active region 213 can be a p-type well or an n-type well.

[0024] For example, an epitaxial layer is grown on the semiconductor substrate 210, and then lightly doped with a p-type impurity, namely boron. Thereafter, a mask for forming the active region 213 is formed on the semiconductor substrate 210 using photolithography, and by using the mask (not shown) ions of an n-type impurity such as phosphorus implanted into the epitaxial layer to form an n-type well. In ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com