Pistons for internal combustion engines

A technology of piston and piston crown, applied in the directions of piston rings, mechanical equipment, engine components, etc., can solve the problems of large piston height, large engine height, unpractical four-stroke engine, etc., and achieve the effect of saving manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

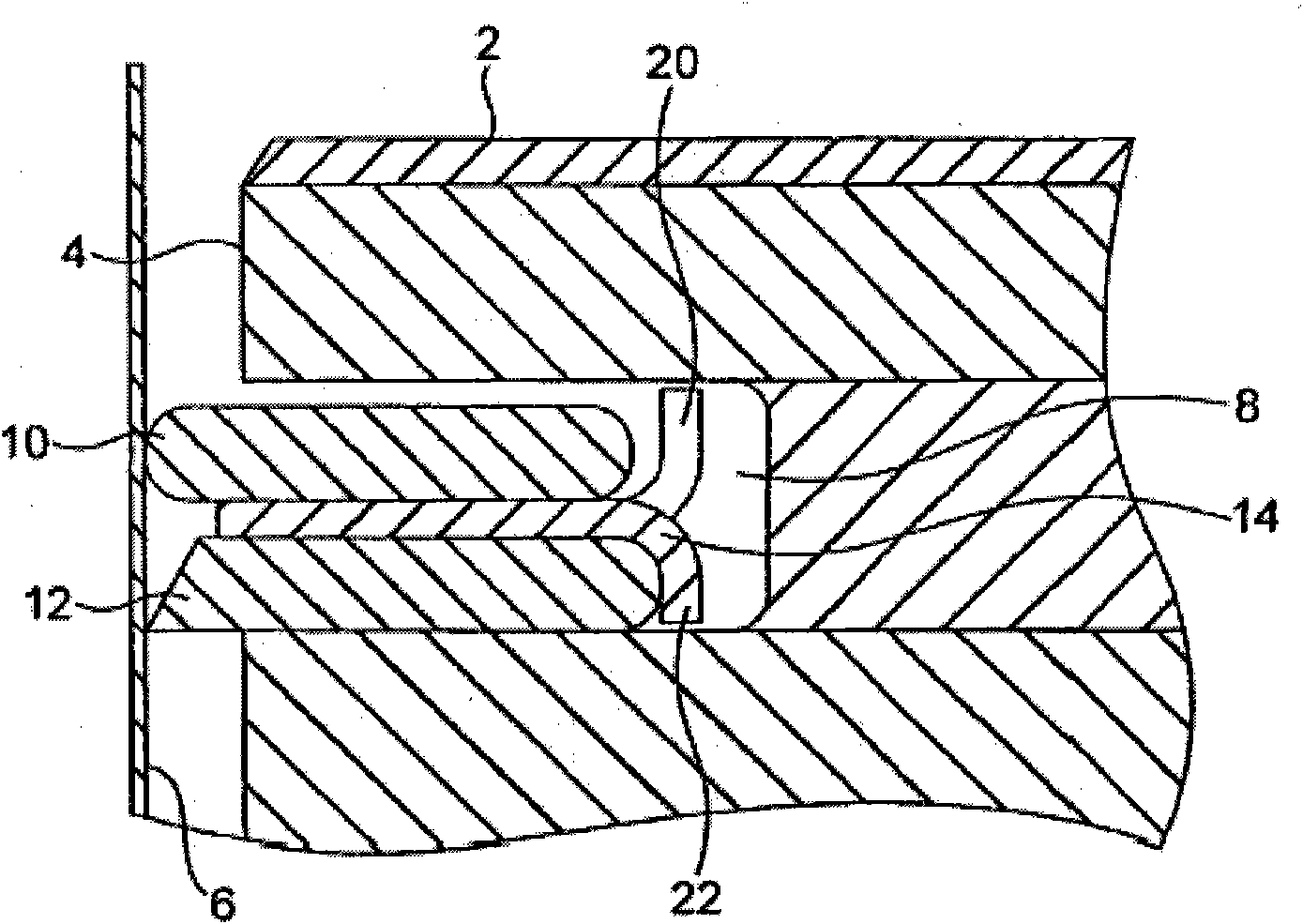

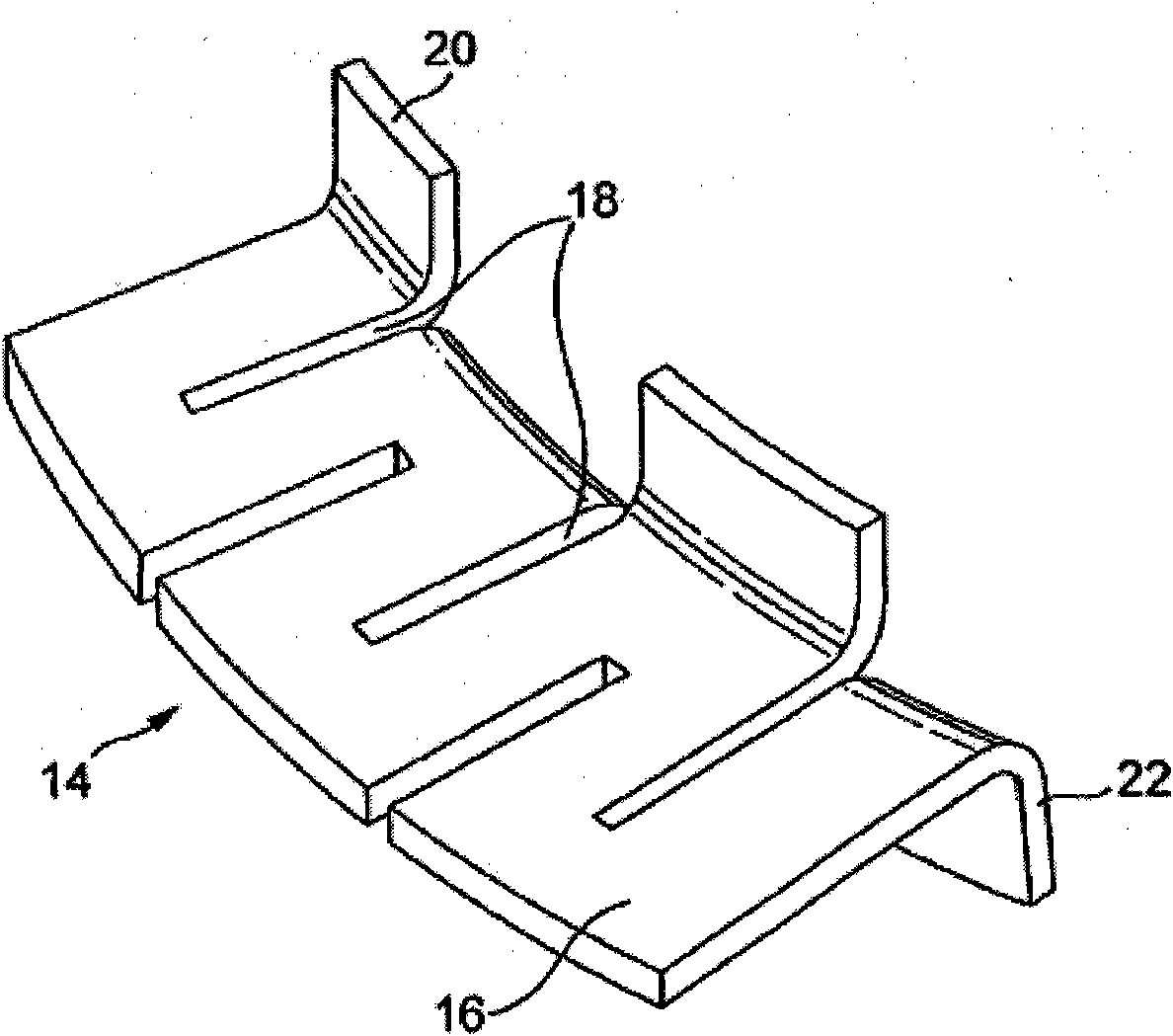

[0015] figure 1 The piston shown includes a top or upper surface 2 and a cylindrical side surface 4 . In use, the piston is reciprocally housed in a cylinder of a four-stroke petrol engine, only one wall 6 of which is shown. A piston ring groove 8 is formed on the cylindrical side surface 4, and the height of the piston ring groove 8 along the axial direction of the piston is usually 3mm to 4mm, such as 3.5mm, which is slightly greater than the height of the piston ring groove of a traditional gasoline automobile. But it is close to the height of the piston ring groove of a traditional diesel car. The groove 8 accommodates an annular compression ring 10 , an annular oil wiper ring 12 and an annular spring 14 . Each of these three parts forms a discontinuous ring (ie a split ring) and is made of spring steel to allow sufficient deformation to allow its introduction into the groove 8 . The split ring then returns under the influence of its own elasticity to its natural substa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com