Method, system and semiconductor processing equipment for reducing particle deposition in cavity

A semiconductor and chamber technology, applied in the field of microelectronics, can solve the problems affecting the process performance and service life of semiconductor processing equipment, corrosion of the inner wall of the vacuum lock chamber, etc., and achieve the effect of reducing deposition and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

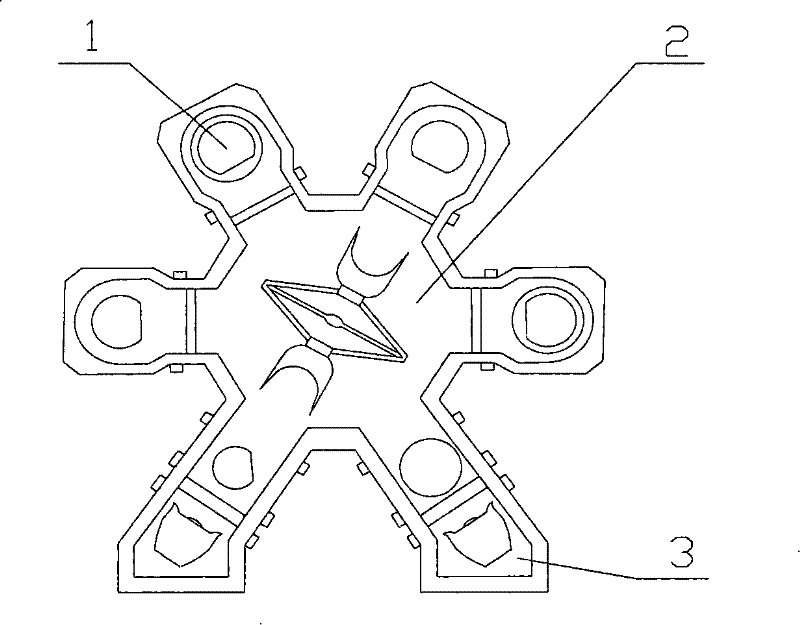

[0037]The core of the present invention is: introducing into the chamber a gas (such as N 2 etc.), and by means of the natural convection of the air in the chamber, the particles adhering to the inner wall of the chamber are swept off, so that the inner wall of the chamber is prevented from being attacked by the above-mentioned particle corrosion and the like.

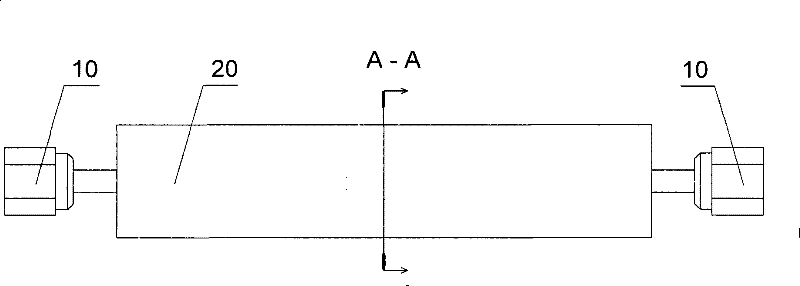

[0038] In order to make those skilled in the art better understand the technical solutions of the present invention, the following steps are used to pass through the chamber, such as N 2 The method and system for reducing the deposition of particles in the chamber and the semiconductor processing equipment using the method and / or system provided by the present invention are described in detail.

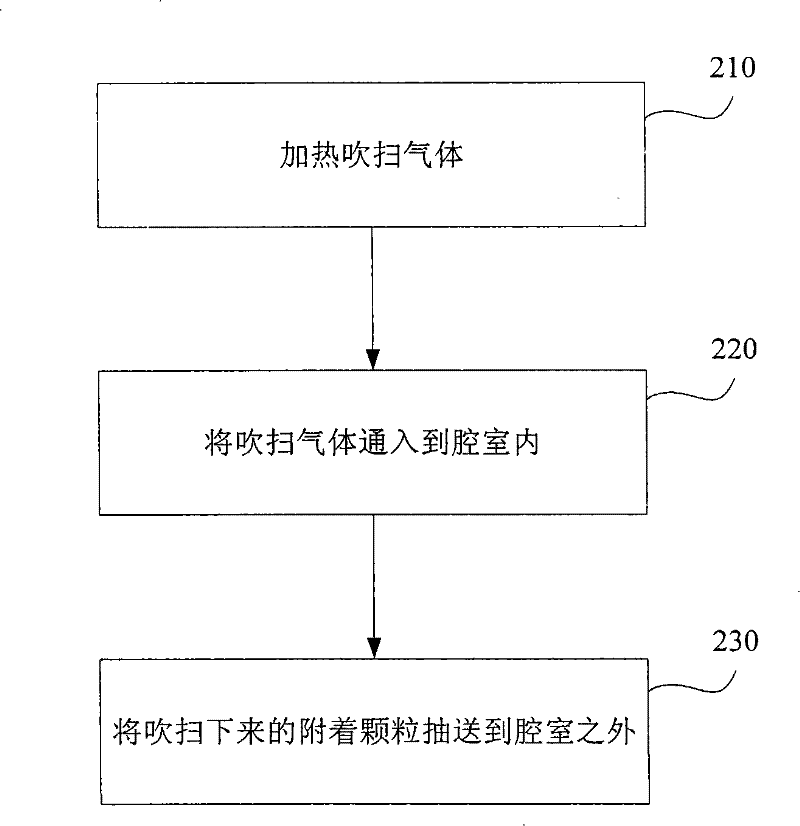

[0039] In the method for reducing the deposition of particles in the chamber provided by the present invention, firstly, the N to enter the chamber is 2 Heating, and ensure that the temperature after entering the chamber is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com