Automatic rope distributing and discharging device of winch

An automatic rowing and winch technology, applied in the direction of hoisting device, clockwork mechanism, etc., can solve the problems of limited winch space, slow descending speed, loose and messy rowing rope, etc., to achieve strong practicability and applicability, and convenient disassembly The effect of replacing and avoiding potential accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

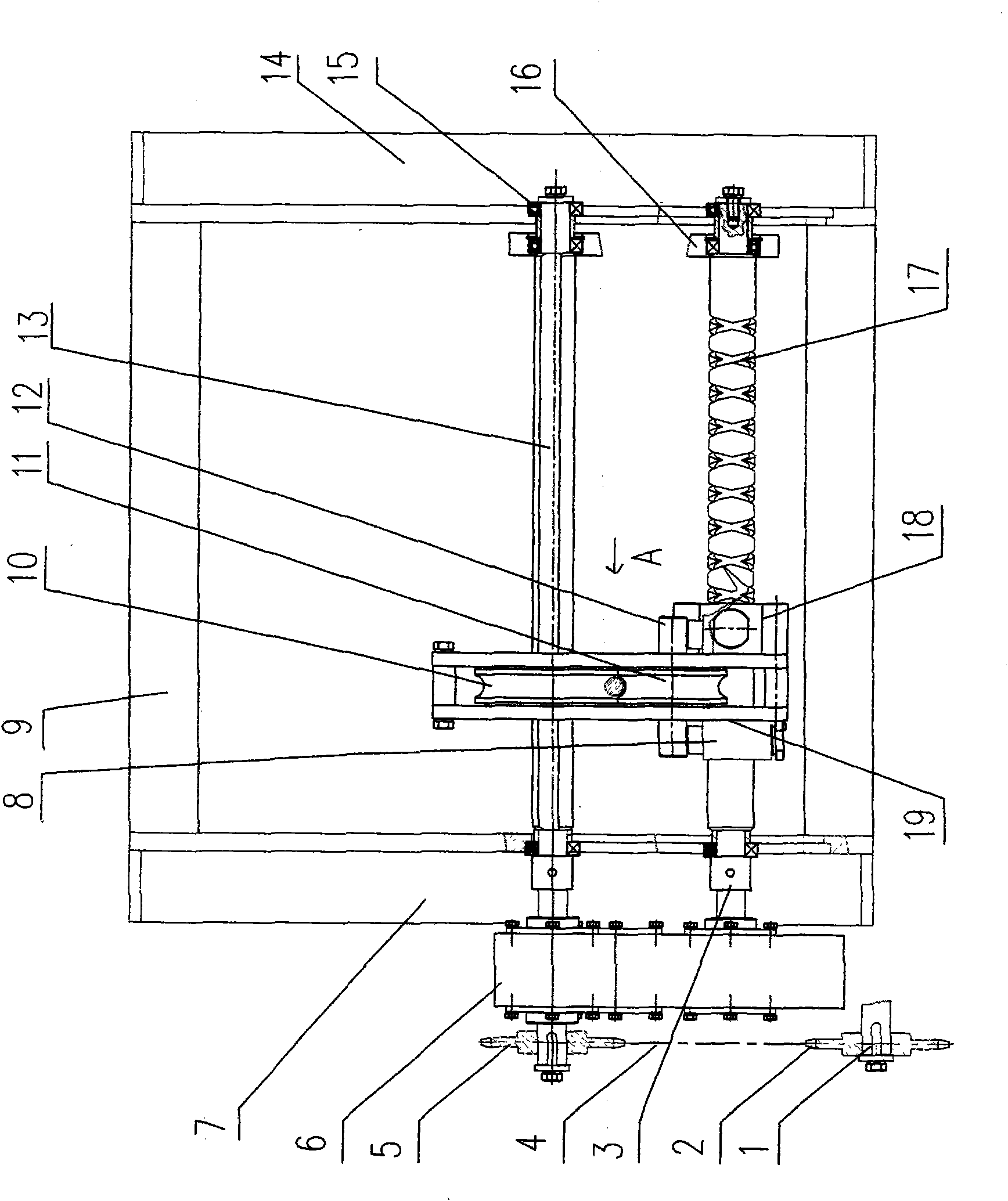

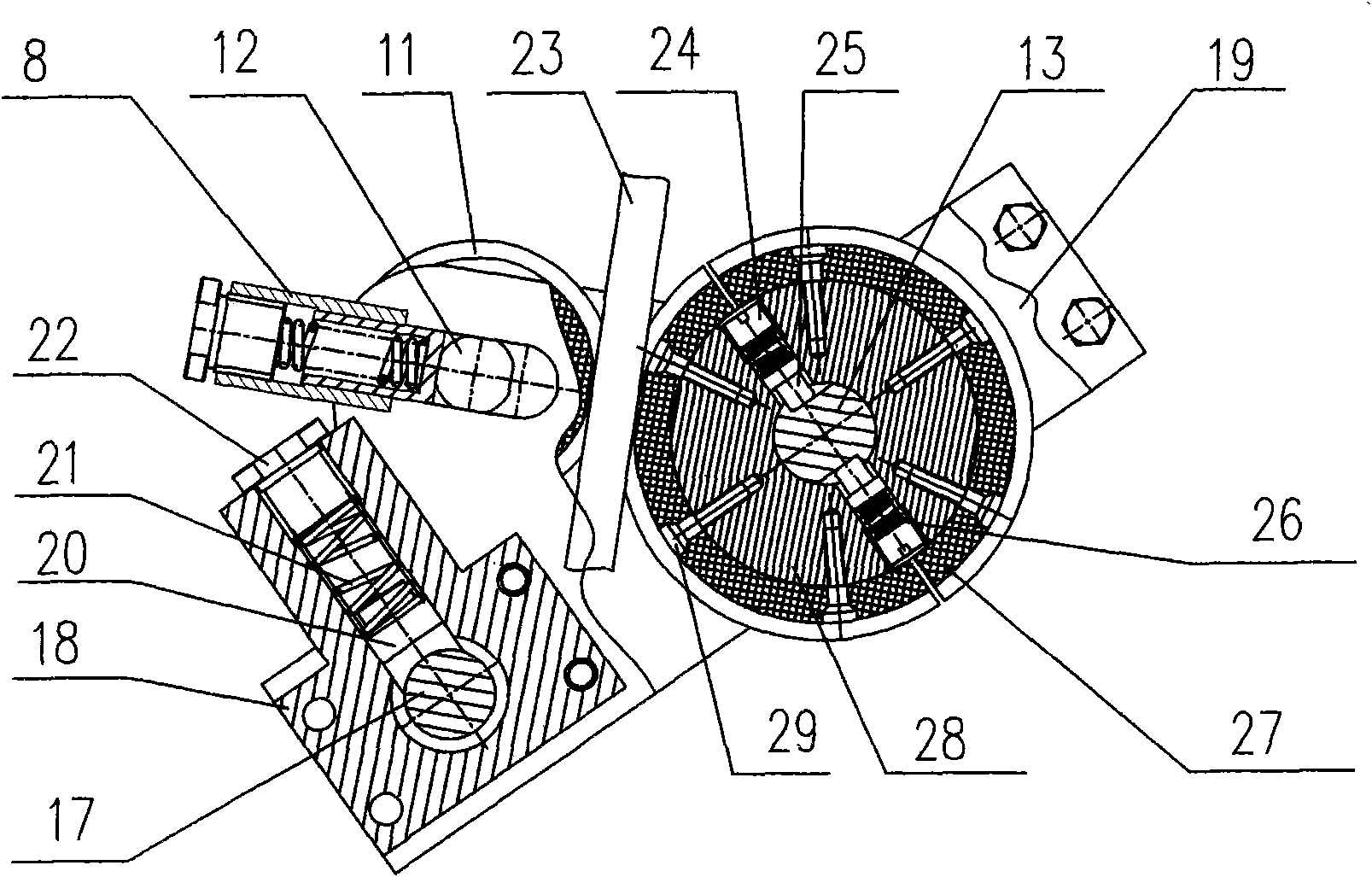

[0013] From figure 1 As can be seen from the structural schematic view of the automatic rowing and rope-out device of the winch of the present invention, the present invention includes a gear box 6 and a rope-out mechanism, and the rope-out mechanism includes a two-way lead screw 17, a ratchet shaft 13, a rope pulley 10, a pressure pulley Sheave 11 and slide block 18, two-way lead screw 17 and ratchet shaft 13 are installed in parallel on left support plate 7 and right support plate 14, and speed distribution box 6 is arranged on the transmission shaft of two-way lead screw 17 and ratchet shaft 13 one ends superior. The present invention is placed on the top or the side of the winch in use, and is fixed on the base of the winch by four columns linking to each other with the left and right support plates 7,14.

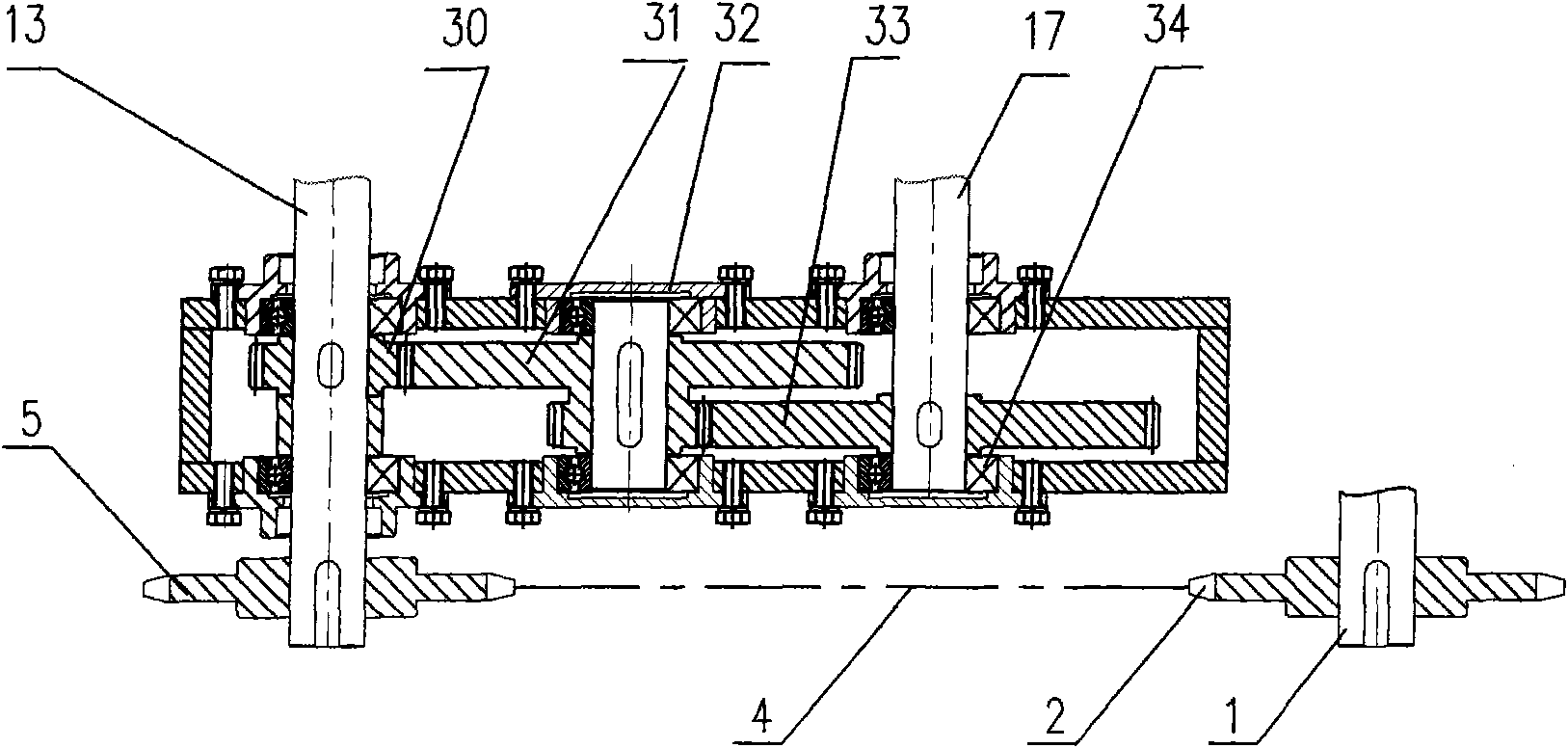

[0014] From image 3 It can be seen from the schematic diagram of the structure of the gearbox part that the power is obtained from the appropriate position of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com