Construction machinery

A technology for construction machinery and engines, applied in the direction of exhaust devices, etc., can solve the problems of poor assembly workability, inability to install, and difficult to install shields, and achieve the effect of improving assembly workability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

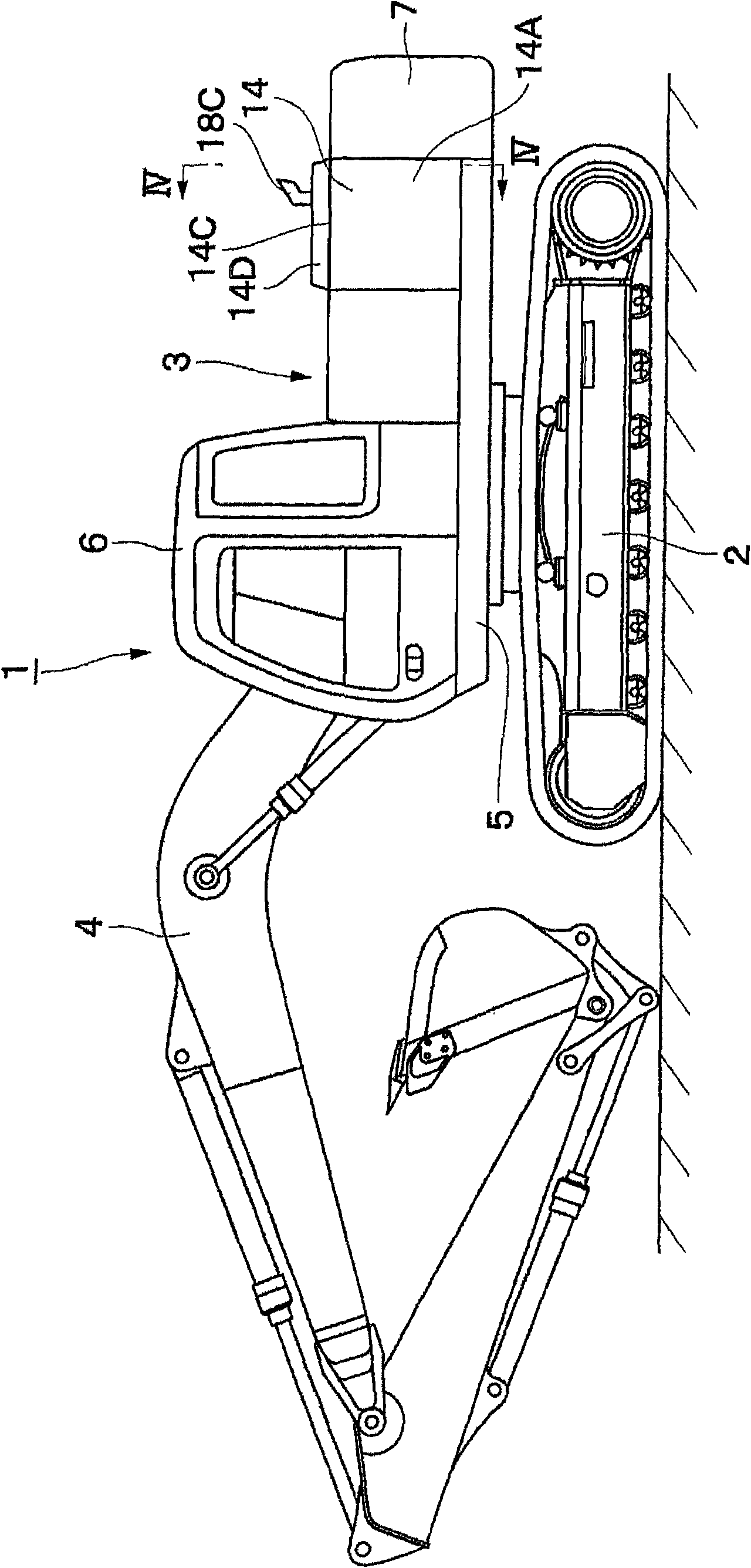

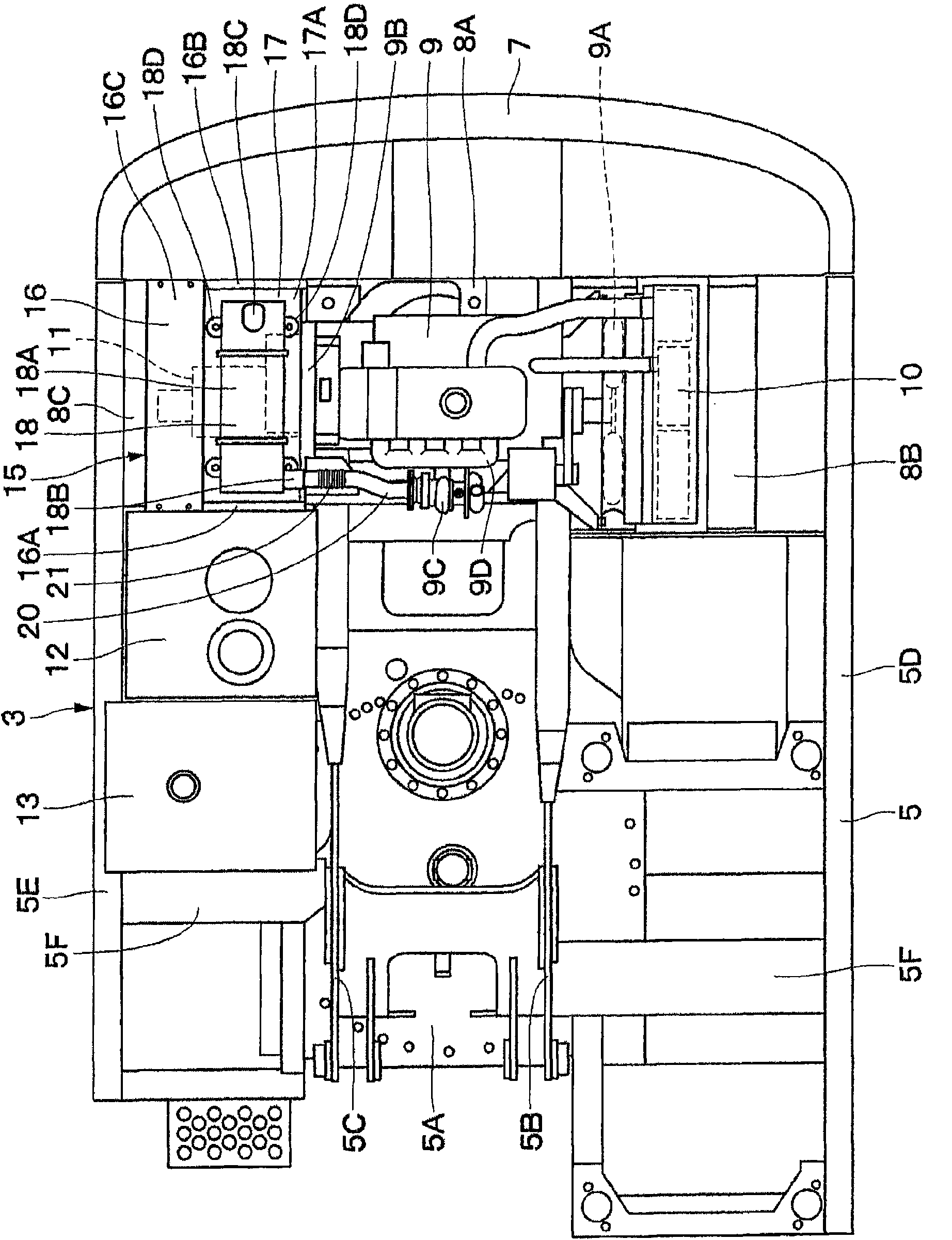

[0042] Hereinafter, as a construction machine according to an embodiment of the present invention, a crawler hydraulic excavator is taken as an example, according to Figure 1 to Figure 12 It demonstrates in detail.

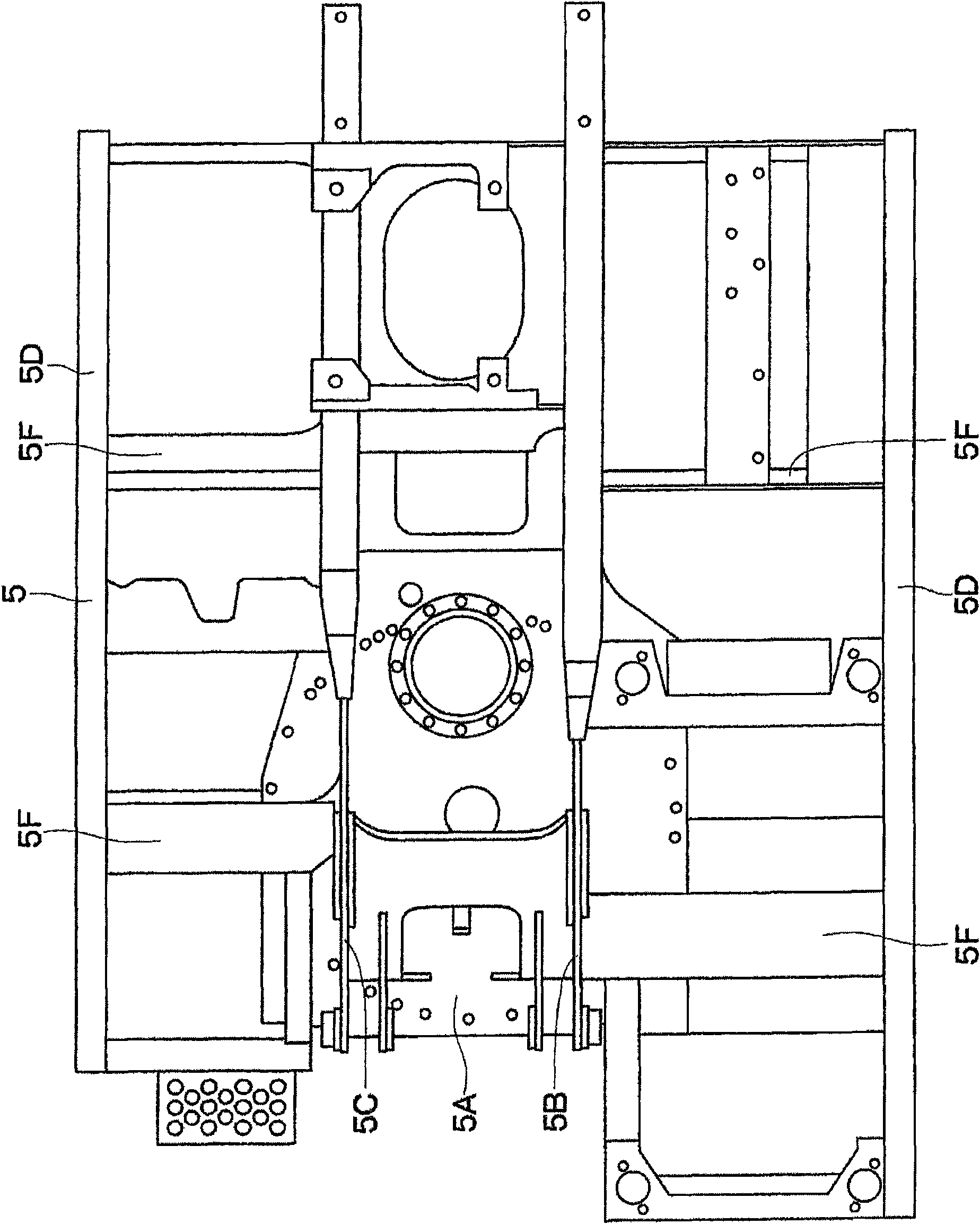

[0043] exist figure 1 Among them, reference numeral 1 is a crawler-type hydraulic excavator as a construction machine. The hydraulic excavator 1 roughly includes: a self-propelled undercarriage 2; An upper swing body 3 constituting a vehicle body; and a working device 4 provided on the front side of the upper swing body 3 so as to be movable in pitch and pitch, and for performing excavation work of earth and sand. In addition, the undercarriage 2 and the upper swing structure 3 are specific examples of the vehicle body of the present invention.

[0044] Here, the upper swing body 3 constituting the hydraulic excavator 1 will be described in detail. Reference numeral 5 is a revolving frame of the upper revolving body 3, and the revolving frame 5 is configured a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com