Gas-liquid force increasing mechanism

A gas-liquid boosting and gas-liquid technology, applied in mechanical equipment, fluid pressure converters, etc., can solve the problems of stamping products such as quality problems, unstable pressure, large resistance changes, etc., to achieve stable and reliable products, quality assurance, even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

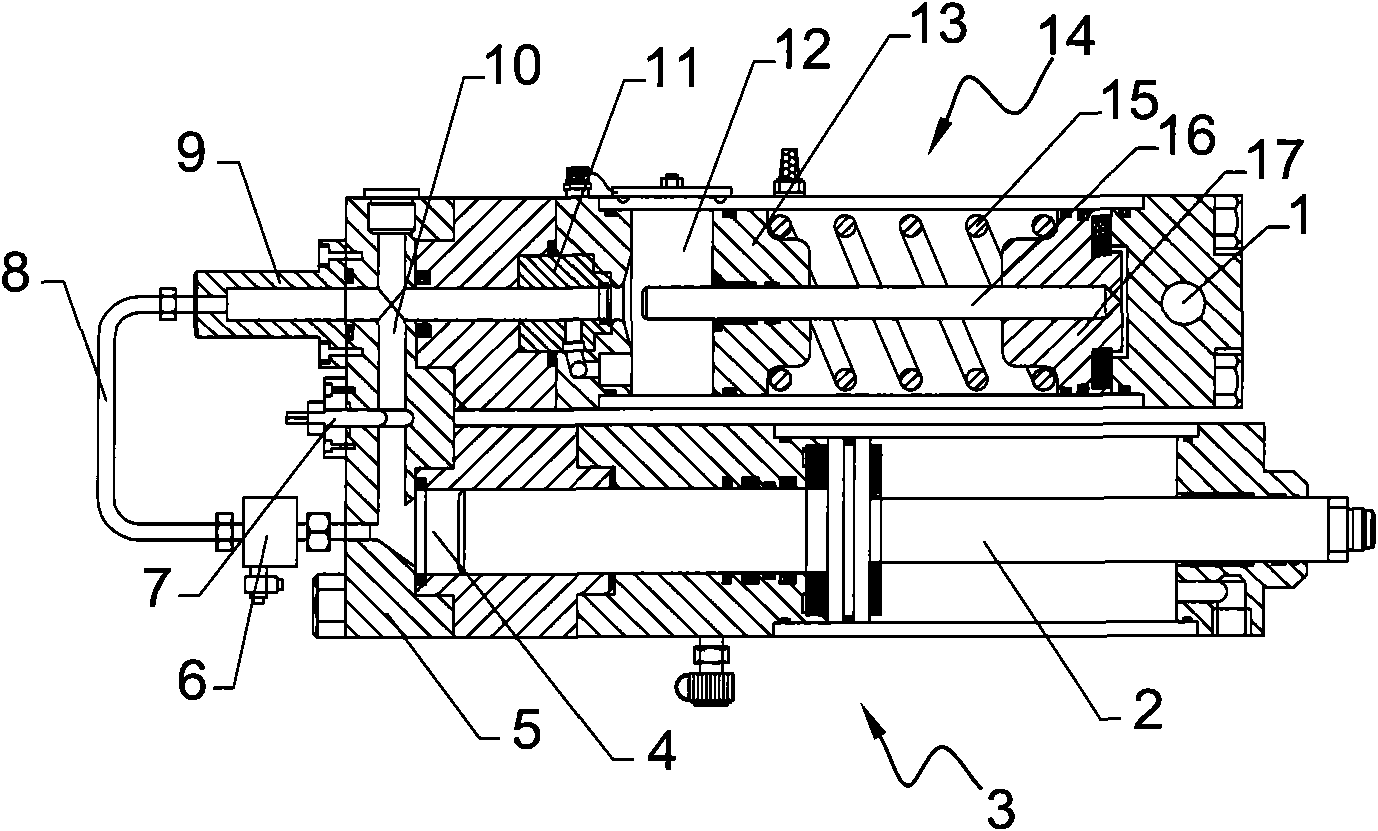

[0027] See attached figure 1 And attached Figure 4 , a gas-liquid booster mechanism, which includes a working pressure cylinder 3 and a gas-liquid booster 14 fixedly arranged on the working pressure cylinder 3 for applying thrust to the working pressure cylinder 3, the gas-liquid booster 14 and the working The pressure cylinder 3 is integrally fixed. The working pressure cylinder 3 has a first oil storage chamber 4, an output chamber, and a working piston rod 2 located between the first oil storage chamber 4 and the output chamber. The pressure in the output chamber is constant, and the working piston rod 2 outputs punching force; gas-liquid The booster 14 has a second oil storage chamber 12, an air storage chamber, and a booster piston rod 16 between the second oil storage chamber 12 and the air storage chamber. The air storage chamber has an air inlet 1, and the air inlet The hole 1 is connected with the high-pressure air source, and one end of the booster piston rod 16 i...

Embodiment 2

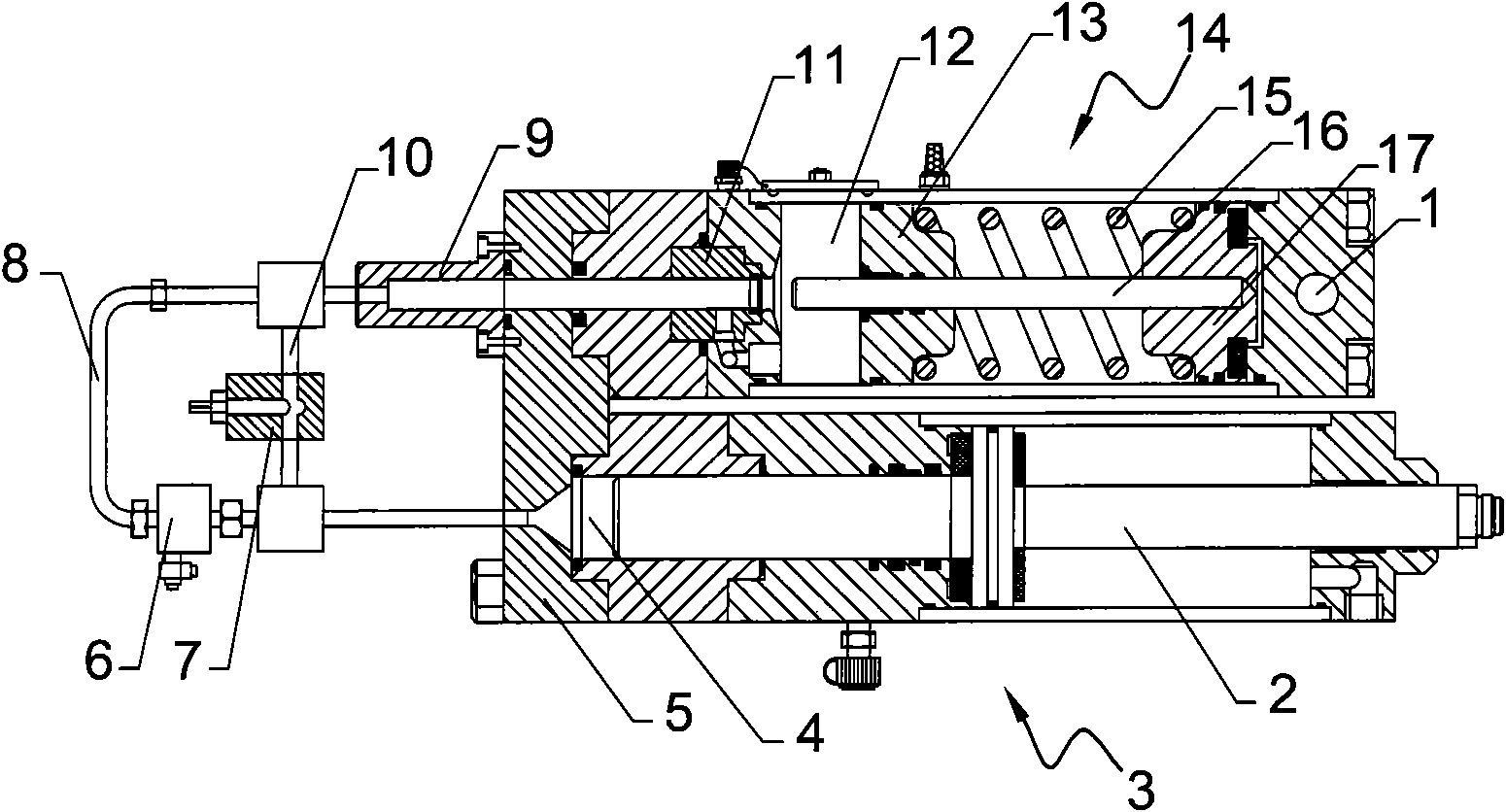

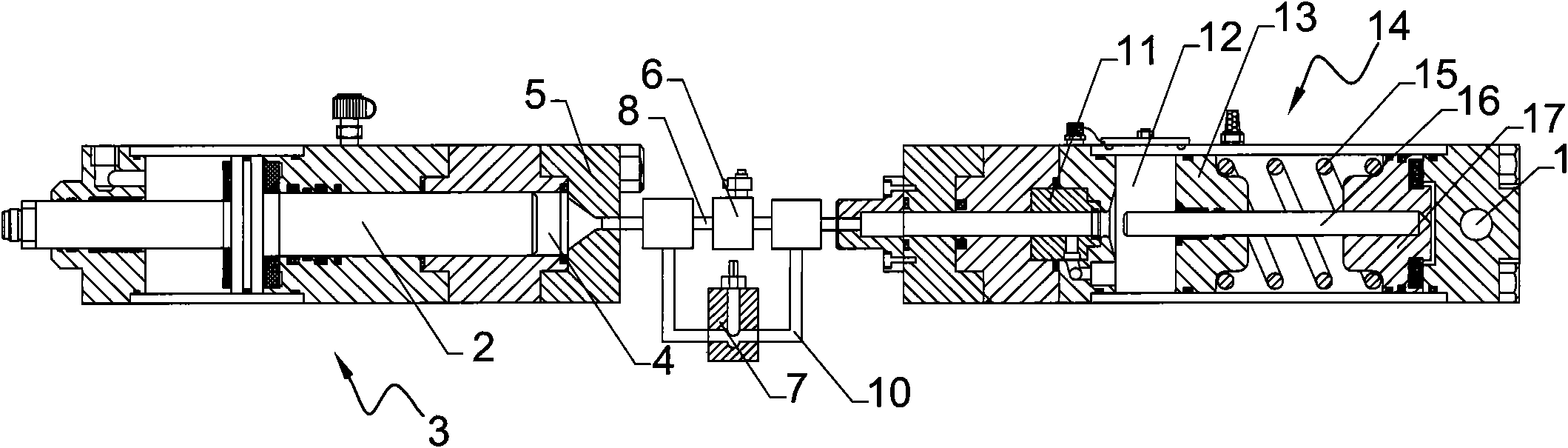

[0033] See attached figure 2 And attached Figure 8 , the difference between this embodiment and the first embodiment is that the first channel 10 and the second channel 8 are both pipe bodies arranged on the flange cover 5, at this time, the first channel 10 and the second channel 8 can be arranged on the flange cover 5, the advantage of this method is that the first channel 10 and the second channel 8 are located outside the cylinder, the throttle valve 7 and the electromagnetic reversing valve 6 are also located outside the cylinder, and any problem with any part can be solved. It is convenient to replace; those skilled in the art can also find out that this embodiment can also be an attached Figure 9 The constructions shown serve as equivalent transformations.

[0034] See attached image 3 As shown, since the first channel 10 and the second channel 8 are both externally placed, the gas-liquid booster mechanism can be set as a split type, so that it can be connected by ...

Embodiment 3

[0036] See attached Figure 10 And attached Figure 11 , is the main cross-sectional view of the flange cover 5 of the third embodiment. In this embodiment, the first channel 10 and the second channel 8 are set inside the flange cover 5. The mechanism design is tight, which can greatly reduce the gas-liquid boost body size.

[0037] From the above embodiments, it is not difficult to see that the present invention is a simple and practical structure, coherent operation, stable and reliable gas-hydraulic booster mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com