Epoxy resin composition, prepreg, laminates and printed wiring boards

A technology of epoxy resin and composition, applied in synthetic resin layered products, printed circuits, printed circuits, etc., to achieve the effects of improving dimensional stability, reducing thermal expansion coefficient, and inhibiting the development of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

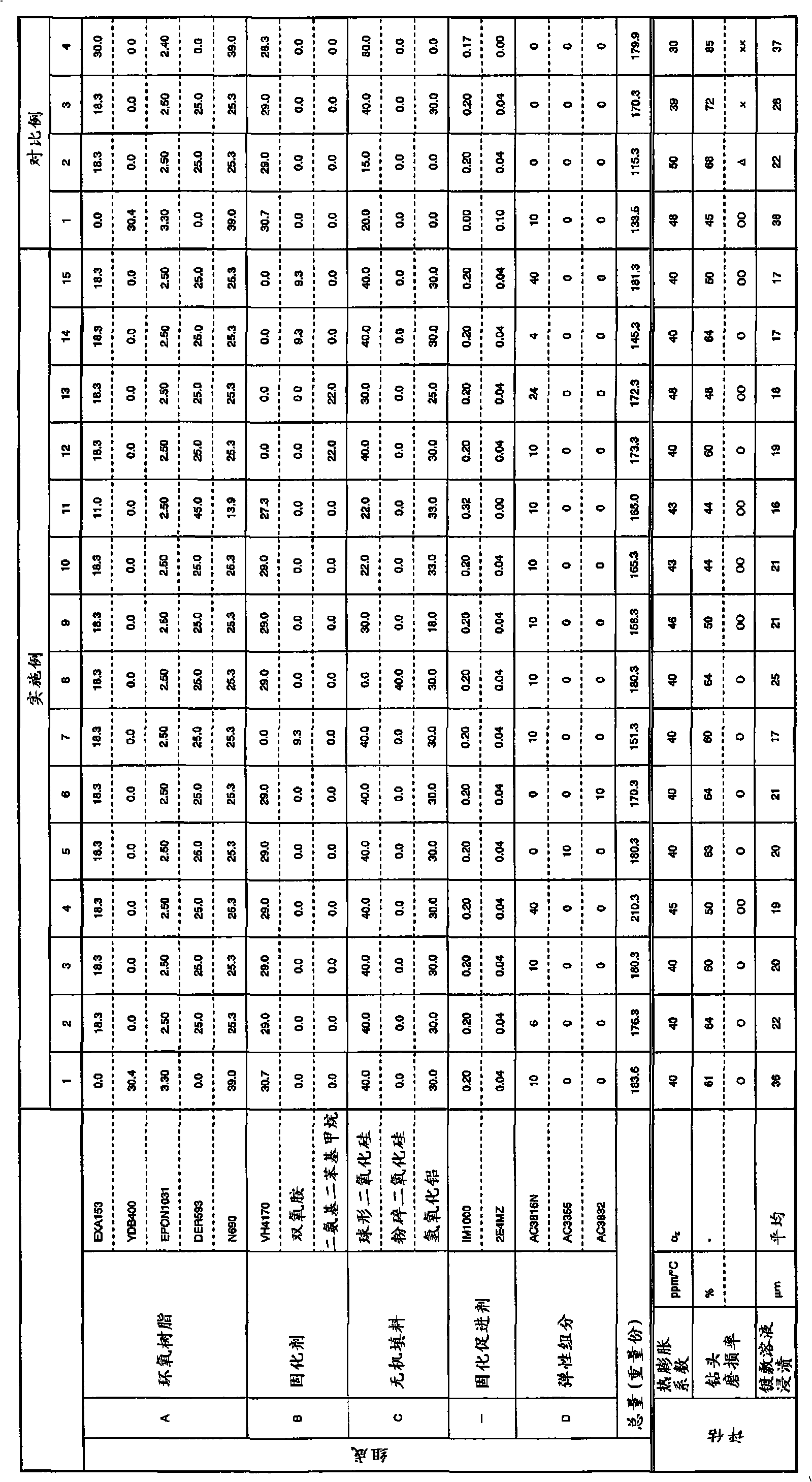

[0079] [1] The present inventors produced laminated boards to be evaluated in the following manufacturing process.

[0080] (1) Components

[0081] Resin varnishes having composition ratios (parts by weight) shown in Table 1 were prepared. The abbreviations of the components in Table 1 are given as follows.

[0082]

[0083] EXA153: EPICLON epoxy resin obtained from DIC Corporation

[0084] YDB400: brominated bisphenol A epoxy resin obtained from Tohto Kasei Co., Ltd.

[0085] EPON1031: epoxy resin obtained from HEXION Specialty Chemicals

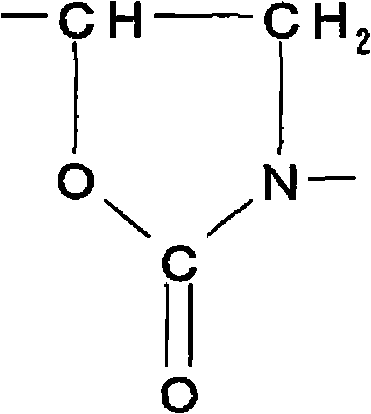

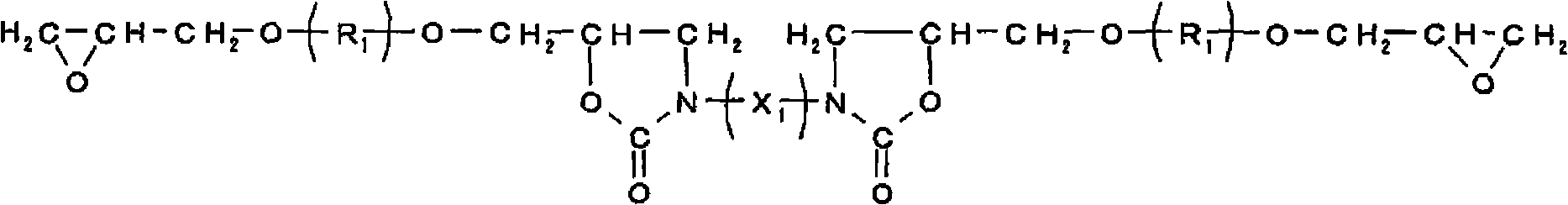

[0086] DER593: an epoxy resin obtained from Dow Chemical Company and containing nitrogen and bromine atoms (also containing oxazolidine rings) in its molecule; The molecular average is about 2 epoxy groups.

[0087] N690: cresol-novolac epoxy resin obtained from DIC Corporation and containing no nitrogen and bromine atoms in its molecule; epoxy equivalent of 190-240 g / equivalent, bromine content of 0% by weight, average of 6-4 per mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com