Directly embedded high-power LED illumination module

A technology for LED modules and LED lighting, which is applied in lighting devices, lighting and heating equipment, and components of lighting devices to achieve compact structure, prolong service life, and improve thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

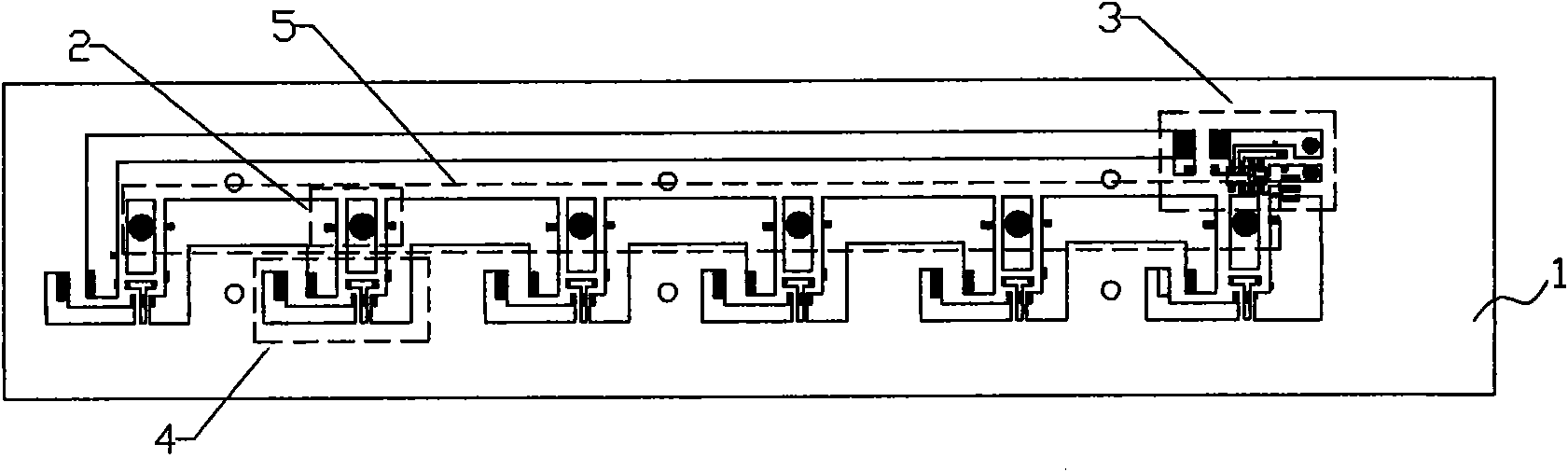

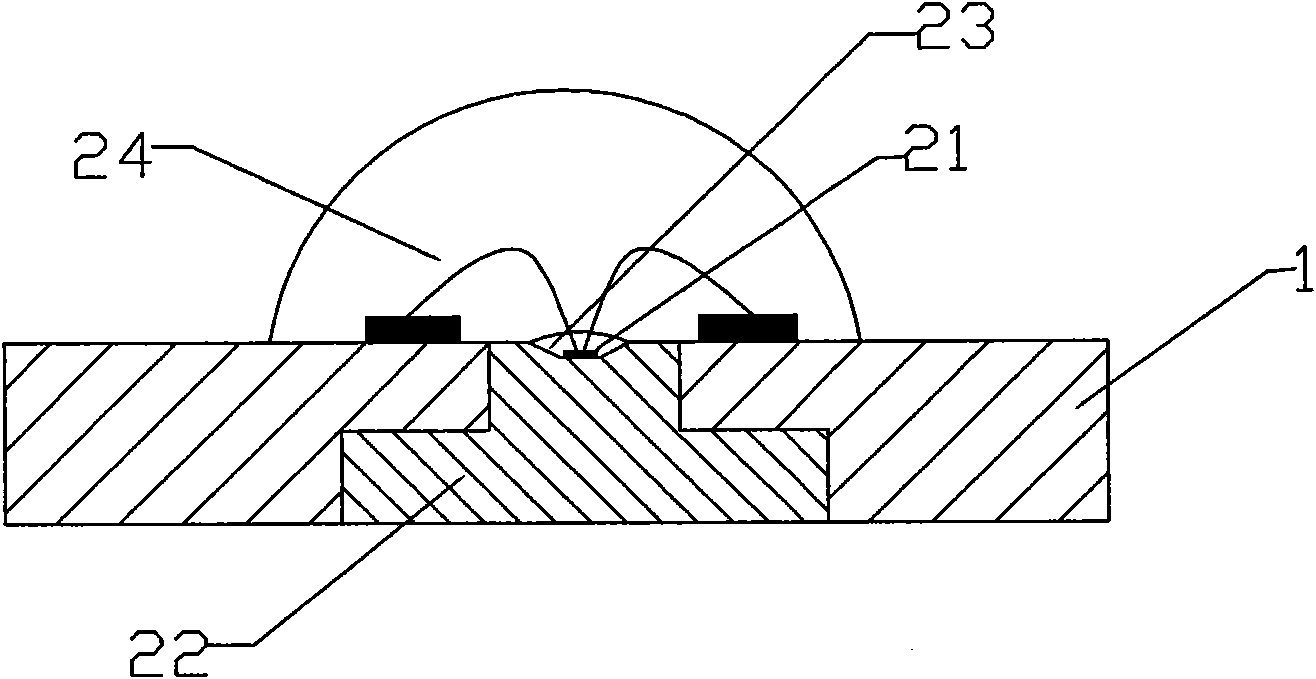

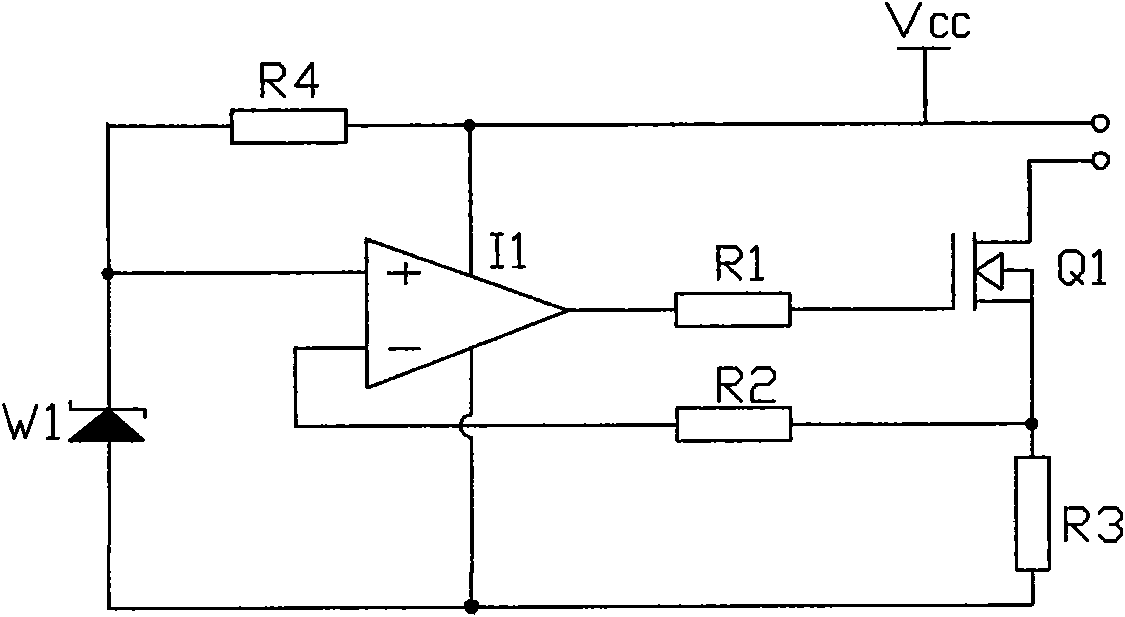

[0029] Such as figure 1 As shown, the direct-embedded high-power LED lighting package module of the present invention includes a PCB board 1, the lighting module includes an LED module 2 and a constant current drive module 3, and the LED module 2 is connected to the constant current drive module 3 and is directly embedded on the PCB. The surface of the board 1, in this embodiment, the number of LED modules 2 is 6, and each LED module 2 is connected in parallel with a redundant drive module 4, and the LED modules 2 are connected in series to form an LED module group 5, and the positive side of the LED module group 5 , and negative ends are respectively electrically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com