Track car drive system, and track car using the system

A technology for rail vehicles and drive systems, which is used in engine-driven traction, railway vehicles, vehicle components, etc. to reduce vibration, improve ride feel, and reduce noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

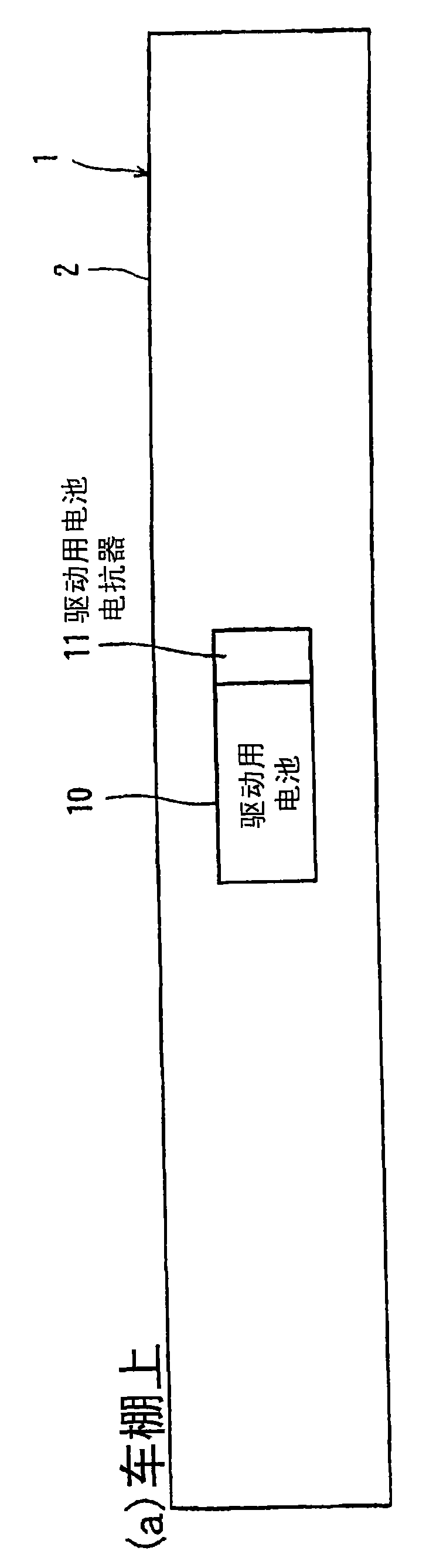

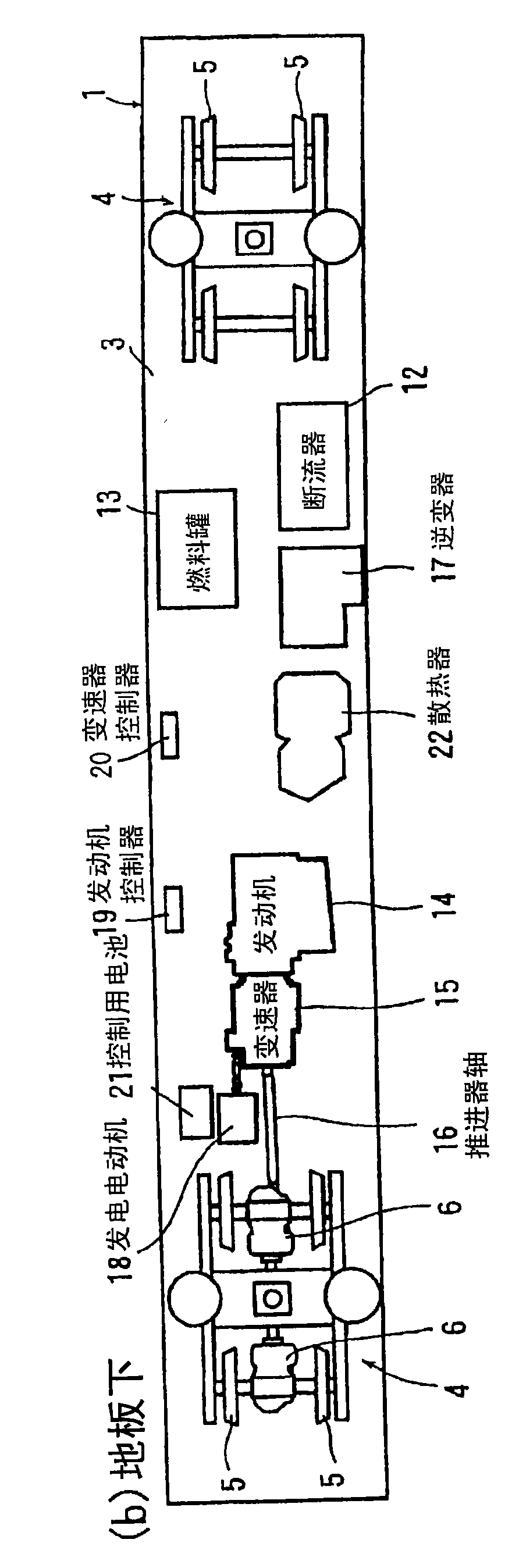

[0035] Figure 1A and Figure 1B It is a schematic diagram showing an example of a rail vehicle to which the rail vehicle drive system of the present invention is applied, especially a rail vehicle, Figure 1A is the top view on the carport, Figure 1B It is the figure which looked at the bottom with the plane along the bottom under the floor. Such as Figure 1A As shown, a driving battery 10 and a driving battery reactor 11 are installed on the carport 2 of the rail vehicle 1 .

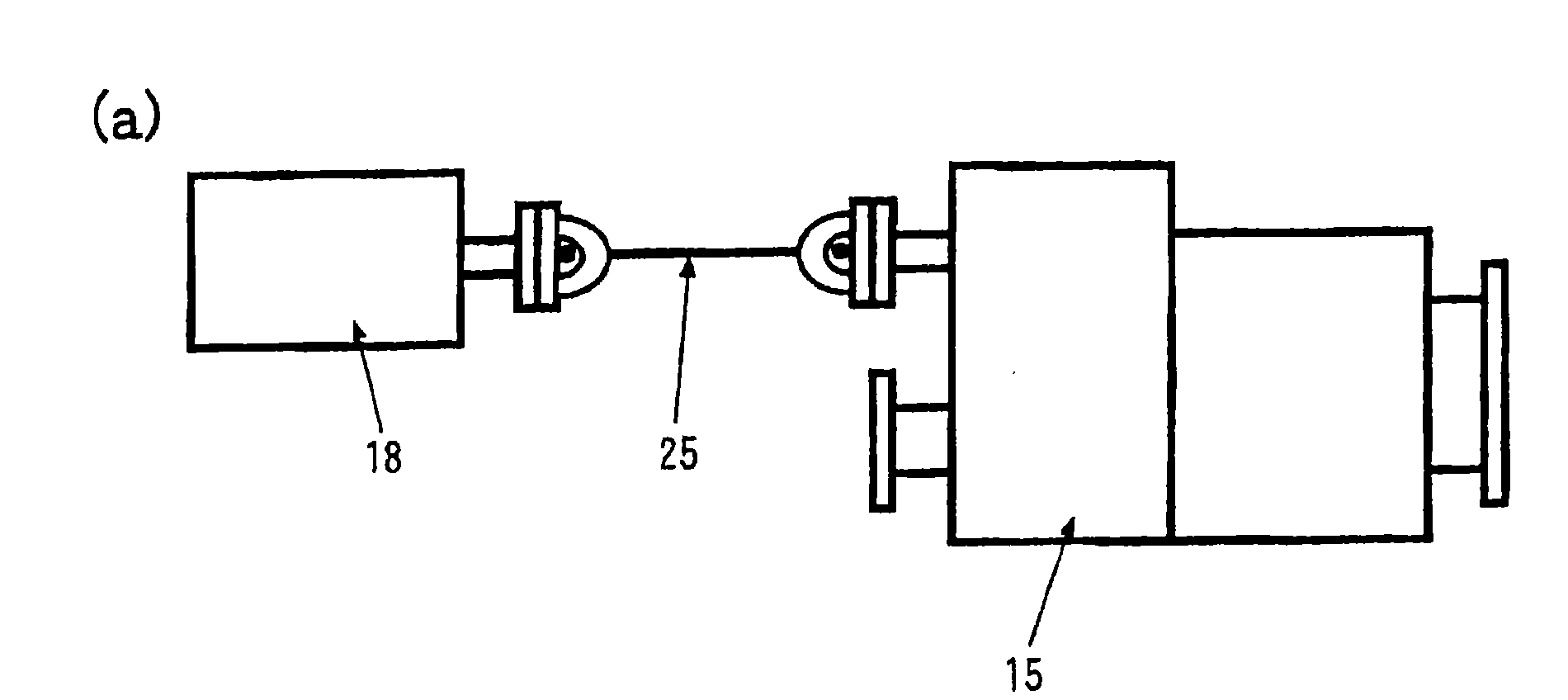

[0036] Such as Figure 1B Shown, configuration is equipped with and supports rail vehicle 1, and the chassis 4,4 that can travel on track (line) wheel 5 and speed reducer 6, under the floor 3 of rail vehicle 1, be provided with the following all in the mode of suspension: Various devices are disclosed. That is, a fuel tank 13 that stores fuel such as gasoline and is formed as a supply source, an engine 14 composed of an internal combustion engine such as a diesel engine driven by receiving fuel fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com