Trimmer for trimming polishing pad

A dressing device and polishing pad technology, which is applied to surface polishing machine tools, grinding devices, grinding/polishing equipment, etc., can solve the problems of heavy cantilever load and affecting the running stability of the swing motor, and achieve weight reduction, compact structure, The effect of smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention provides a dressing device for dressing the polishing surface of a polishing pad, and the present invention will be further described below through the description of drawings and specific embodiments.

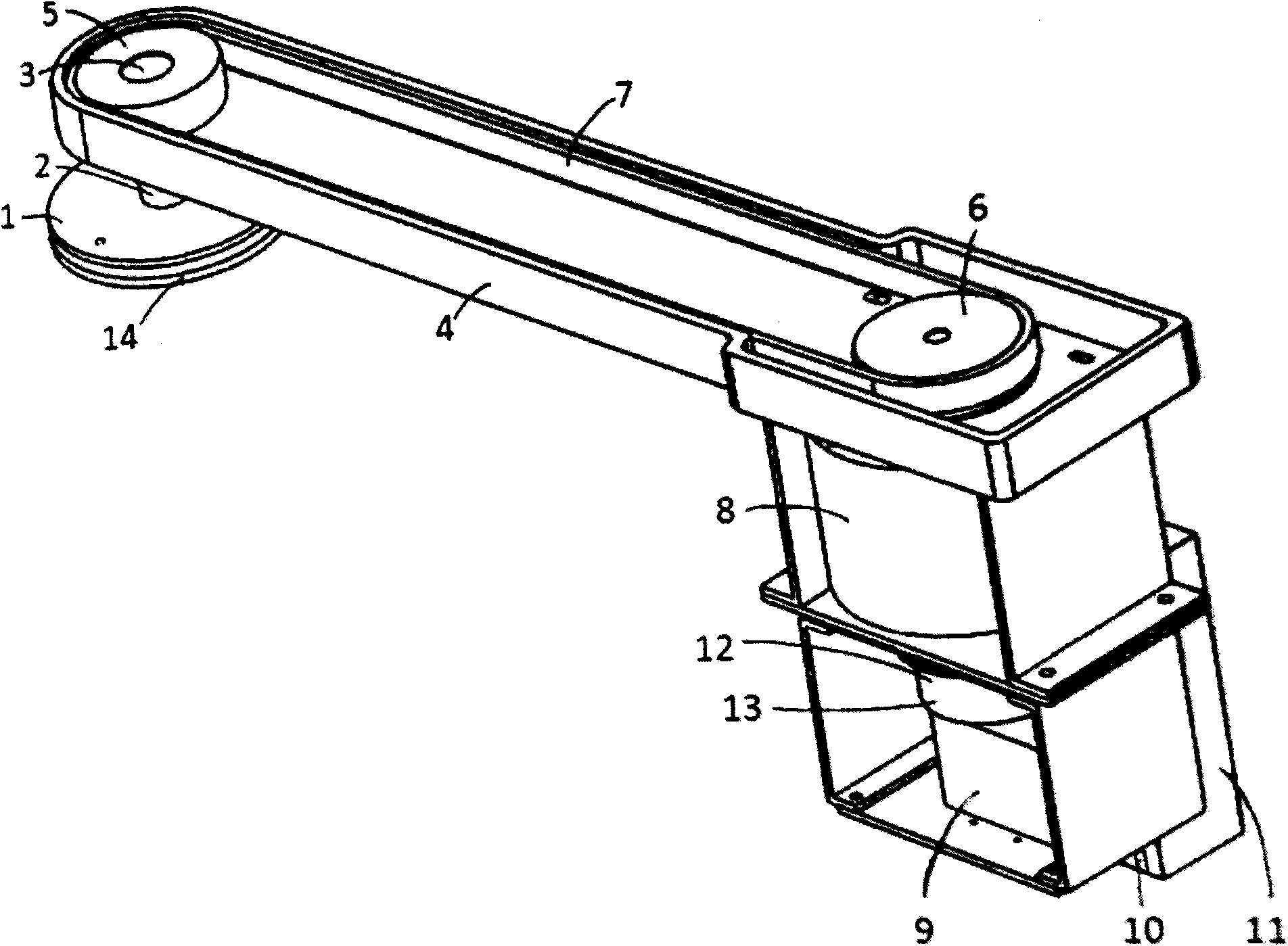

[0015] figure 1 It is a structural schematic diagram of the present invention. The output end of the rotation motor 8 is connected with the second synchronous pulley 6, and drives the first synchronous pulley 5 to rotate through the synchronous belt 7. The center of the first synchronous pulley 5 is successively installed with the rotatable part 3, the universal joint 2 and the final execution Part 1, the final executive part 1 is driven to rotate by the rotation motor 8 through the synchronous belt 7, and the universal joint 2 transmits torque and down force while realizing the self-adaptation of the dressing disc 14 to ensure that the dressing disc 14 is parallel to the polishing pad. The rotation motor 8 directly drives the synchronous belt pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com