Heavy-load sliding friction testing machine

A technology of sliding friction and testing machine, which is applied in the direction of testing wear resistance, using mechanical devices, mechanical bearings, etc. It can solve the problems of small loading load, measurement error, single motion form, etc., and achieve various motion forms, convenient use, Consistent effect of test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

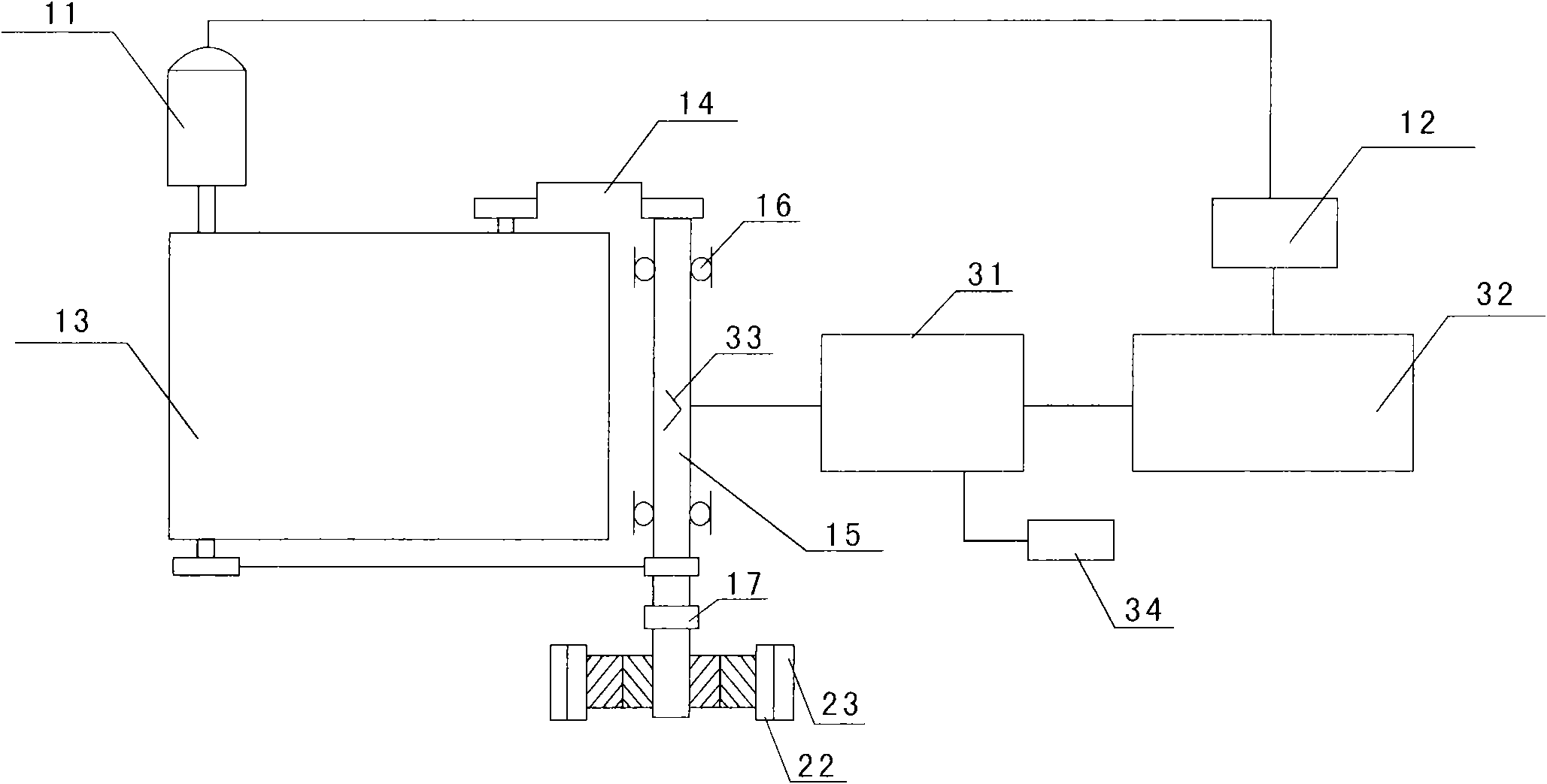

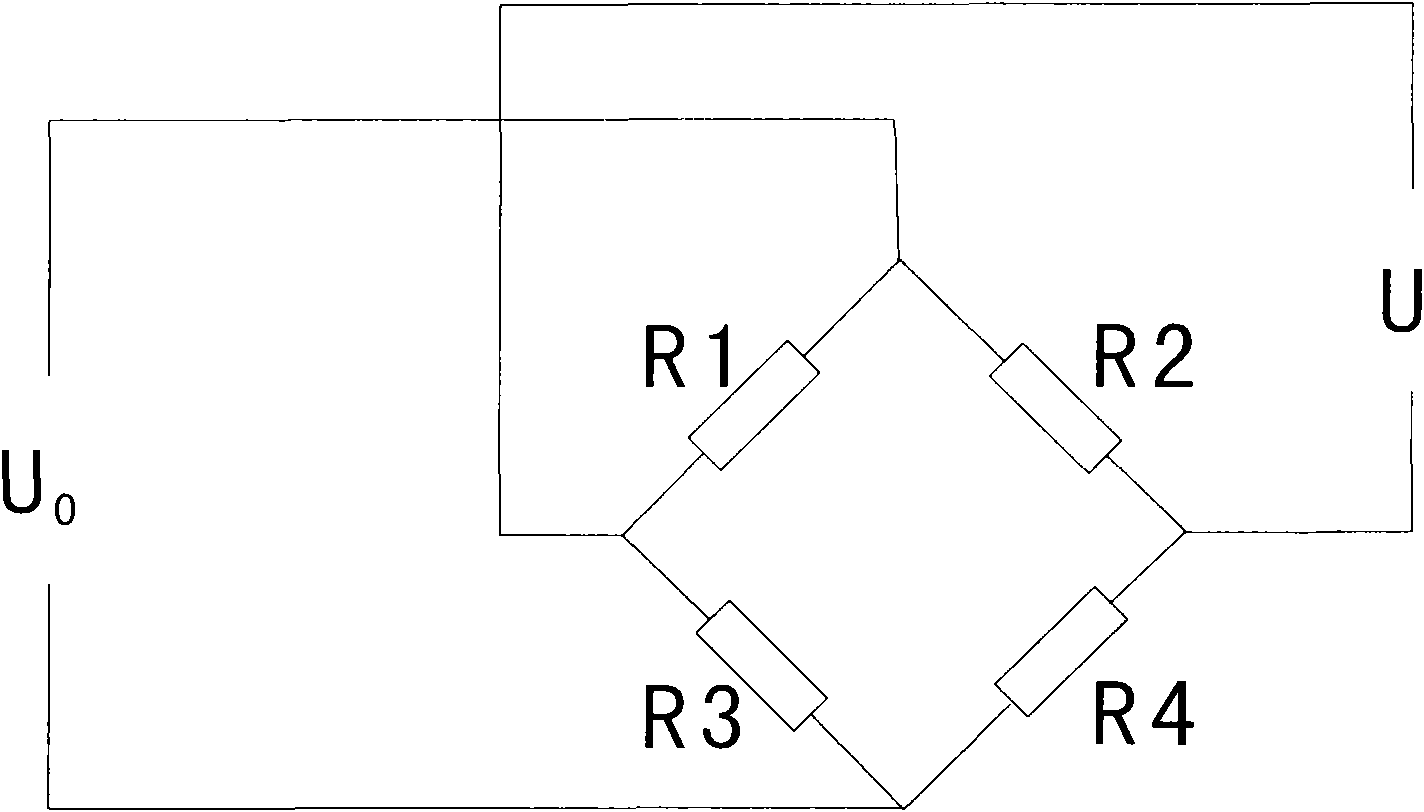

[0013] Such as figure 1 , 2 As shown, a heavy-duty sliding friction testing machine is mainly composed of a transmission system, a loading system and a data acquisition system; wherein the transmission system is composed of a motor 11, a frequency converter 12, a reducer 13, a sprocket transmission mechanism 14, a main shaft 15, and a main shaft bearing 16 and coupling 17; the loading system is composed of fixture 22 and press 23; the data acquisition system is composed of data acquisition card 31, computer 32, strain gauge 33 and oil pressure sensor 34.

[0014] When the testing machine is working, the motor 11 drives the sprocket transmission mechanism 14 through the output shaft of the reducer 13, so that the main shaft 15 drives the main shaft bearing 16 to rotate, thereby driving the inner ring of the bearing test piece to rotate, and the press 23 is pressurized by the clamp 22 On the outer ring of the bearing test piece, a friction moment is generated, because the whole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com