Hydraulic system

A hydraulic system and hydraulic technology, applied in the field of control valves, can solve problems such as high shaft power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

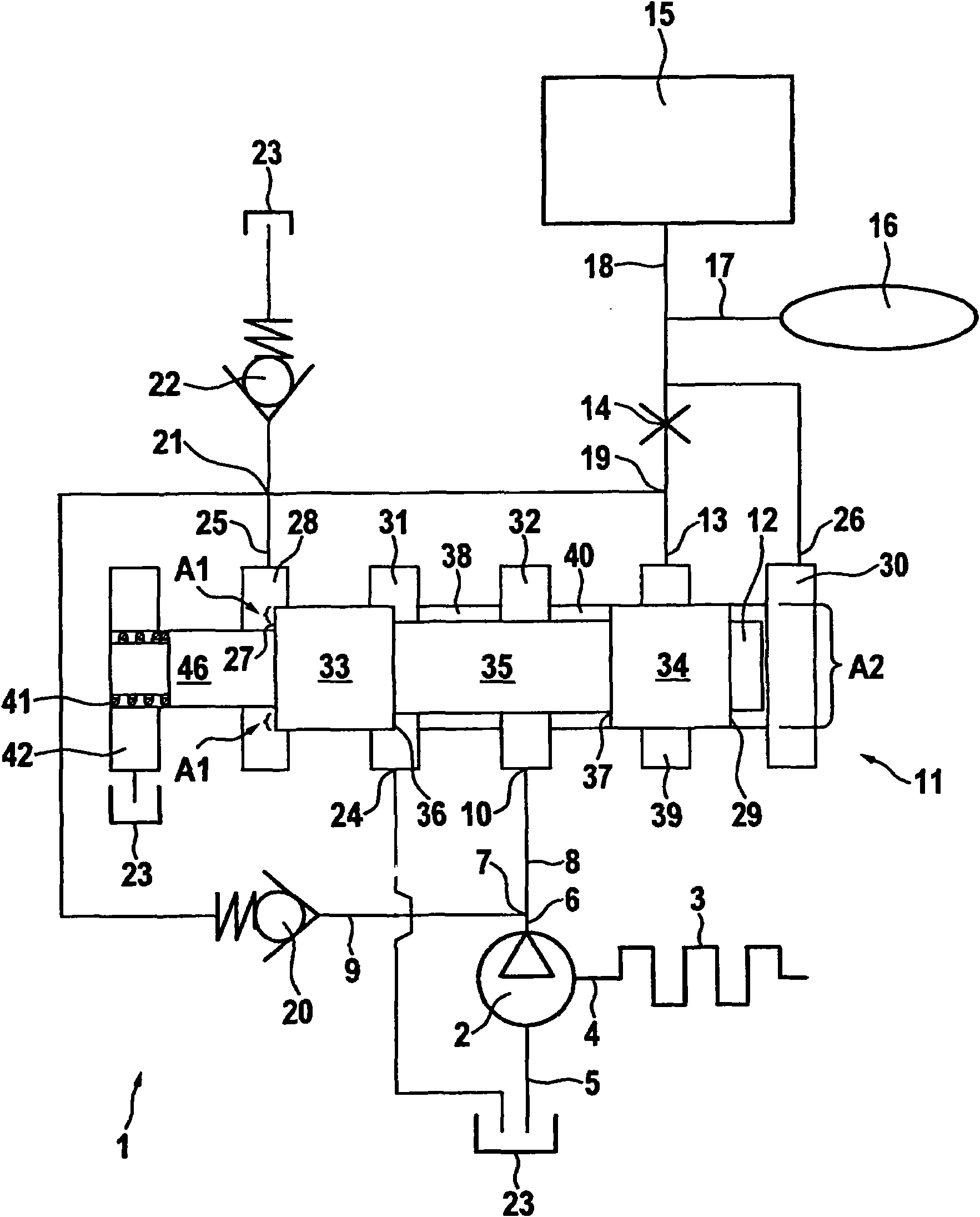

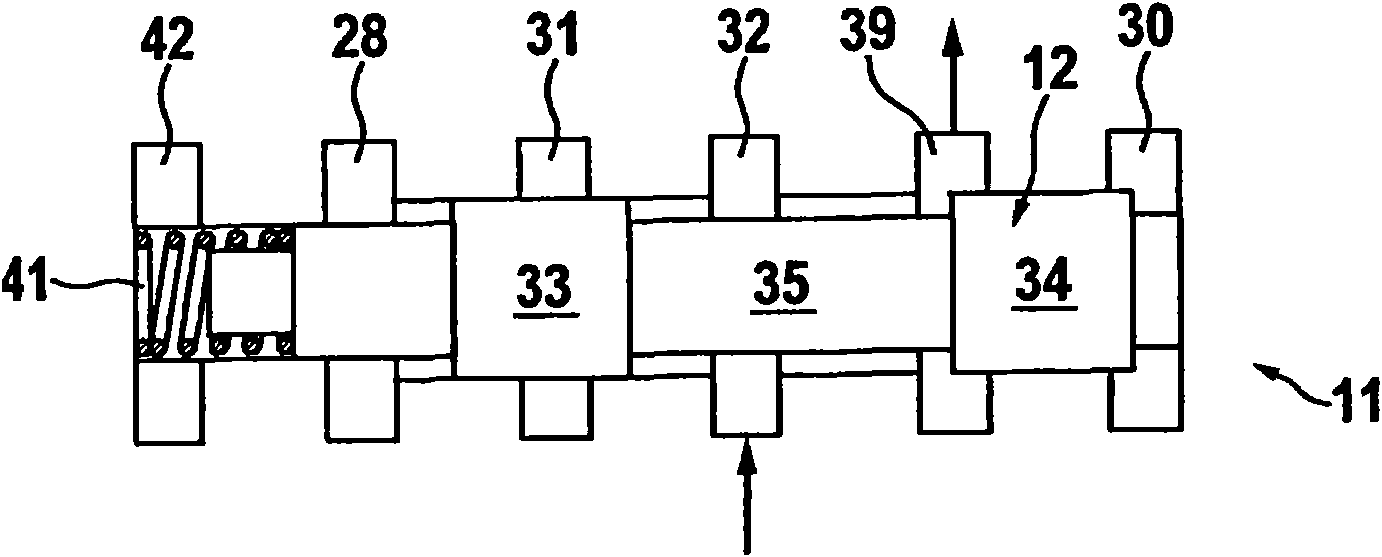

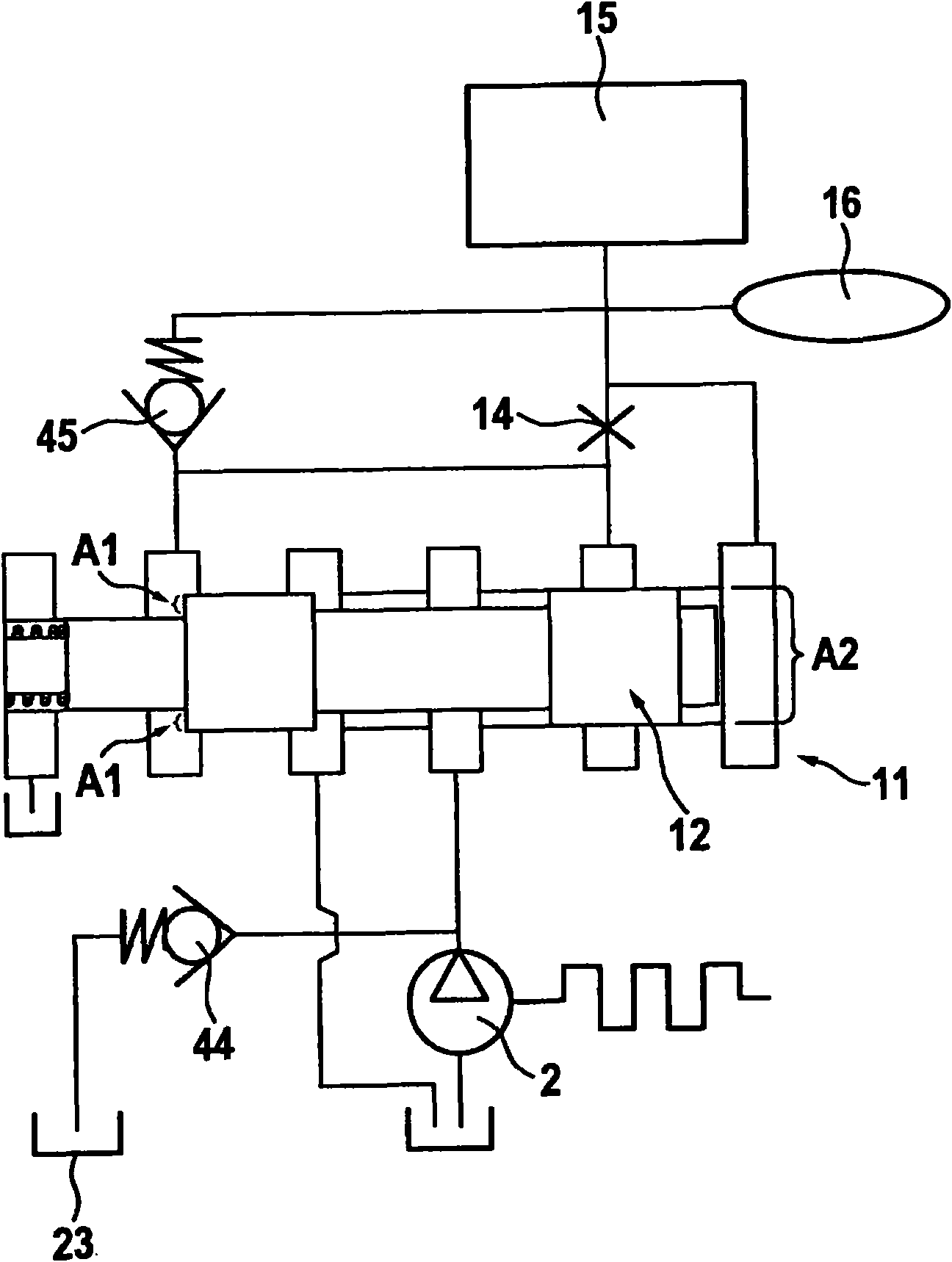

[0019] figure 1 A circuit diagram of an exemplary embodiment of a hydraulic system 1 according to the invention is shown. The hydraulic system includes a pump 2 which is driven by an internal combustion engine 3 . The drive takes place, for example, in that the drive shaft of the pump 2 is driven directly or indirectly via the crankshaft of the internal combustion engine 3 . The drive shaft 4 can be connected directly to the crankshaft, for example, but can also be driven via the crankshaft, for example via a gear transmission or a winding contact transmission. As soon as the internal combustion engine 3 is activated, the pump 2 is driven. The pump 2 comprises a suction side 5 and a pressure side 6 . The suction side 5 of the pump 2 is connected to an unpressurized storage tank 23 for hydraulic fluid. “Unpressurized” here means that the storage tank can be at ambient pressure, but in the case of a closed hydraulic system it can also be at a pressure higher or lower than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com