Spilt amounting type universal robot rotary joint and spilt amounting method thereof

A technology of rotary joints and robots, which is applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of complex structure of robot joints, limitation of sensor shape and size, easily damaged or loose tendons, etc., to achieve easy use and on-site maintenance, and constant transmission ratio , the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in more detail below in conjunction with accompanying drawing example:

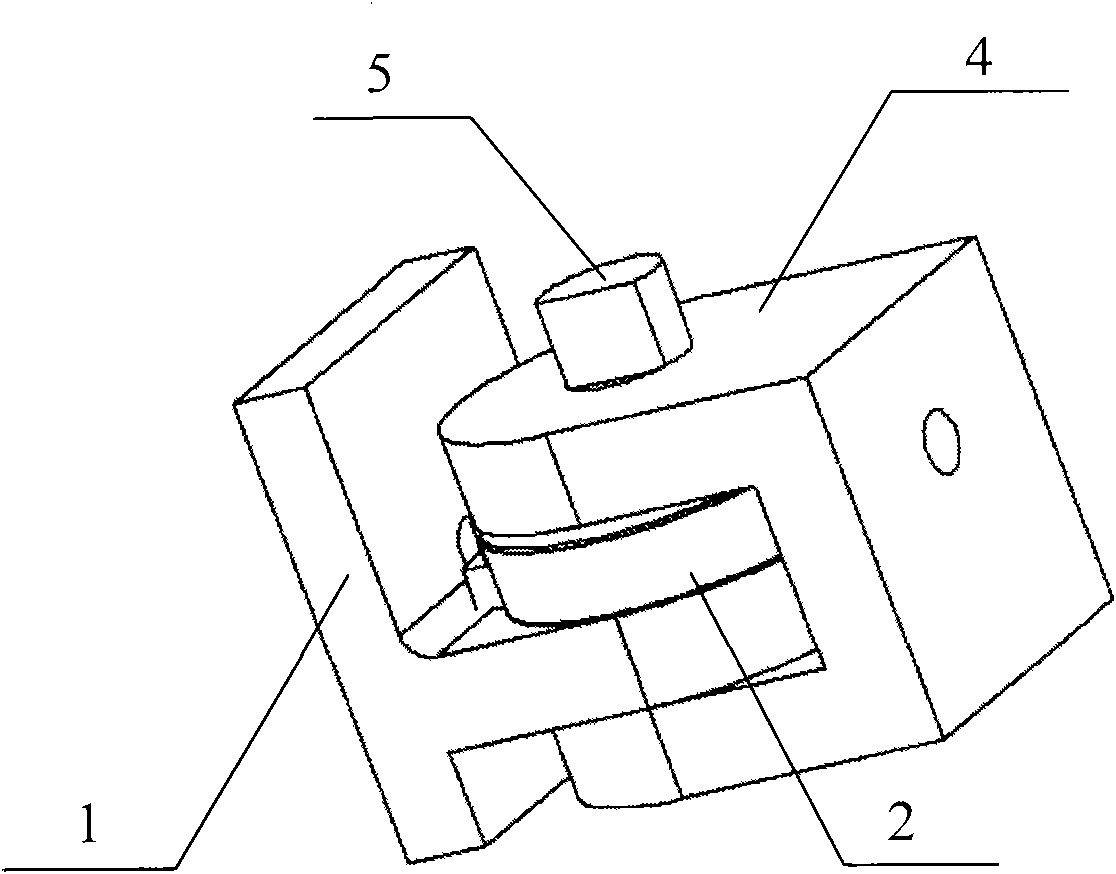

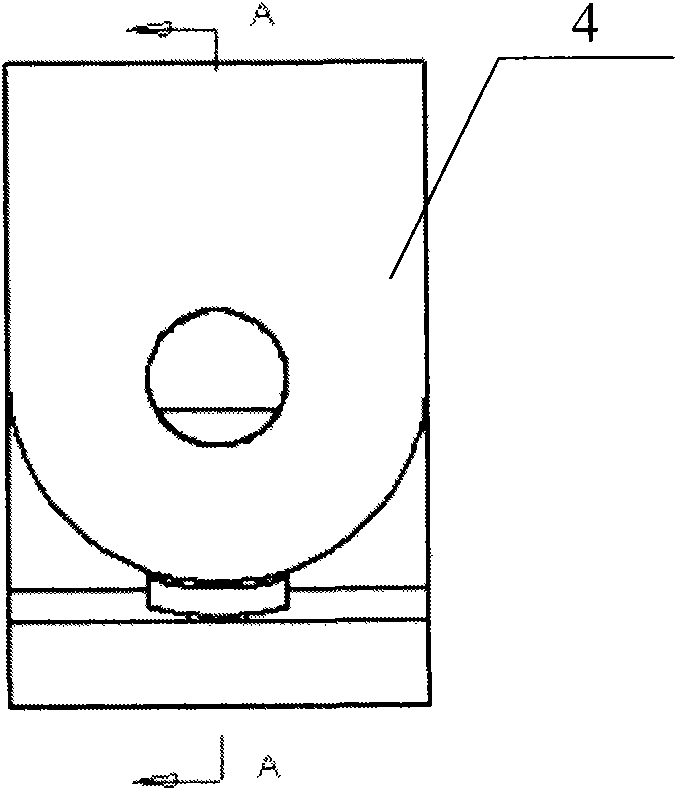

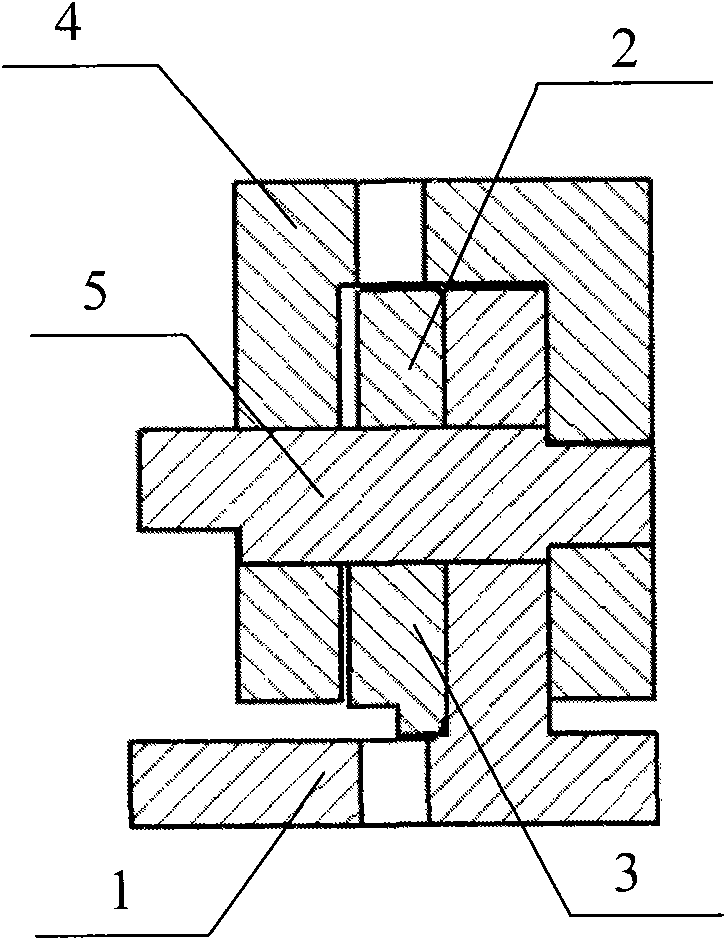

[0036] to combine Figure 1-Figure 8 , The main components of the assembled universal robot joint of the present invention include the articular process 1, the pulley piece 2, the locking pin 3, the glenoid socket 4 and the rotating shaft 5. If the processing is convenient, the pulley piece and the articular process can be combined into one part for processing, making it a whole. Due to the adoption of the assembly structure idea, each part cooperates with each other to limit the position, and no screws are needed. Each of the parts can be processed by light alloy, plastic or steel, such as the shaft), the locking pin 3 can be made of hardened steel, and the rest of the parts can be made of YL7075; the shape and size are determined by the needs of the use; the angle sensor can be a potentiometer Type angle sensors, such as RDC506 or PVS01, etc., can also use oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com