Combined type anchor padding plate and method for manufacturing same

A manufacturing method and anchor pad technology are applied in the field of pressure-bearing plates, which can solve the problems of high consumption of steel materials and high production costs, and achieve the effects of improving safety, low cost and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

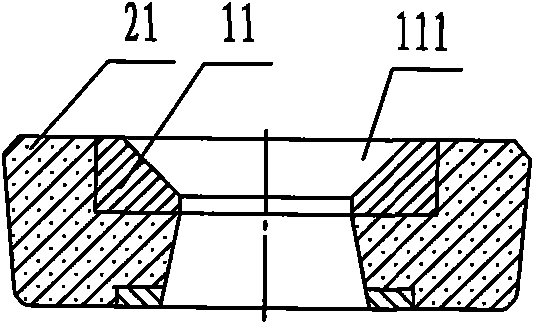

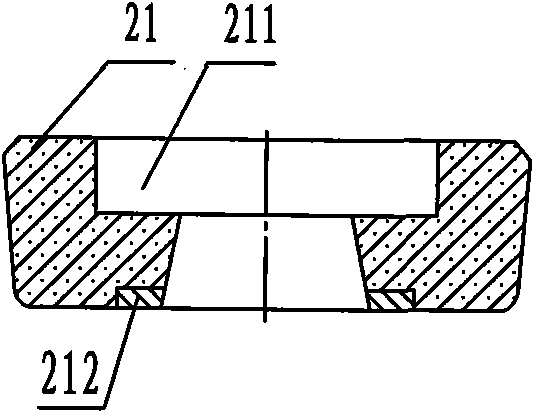

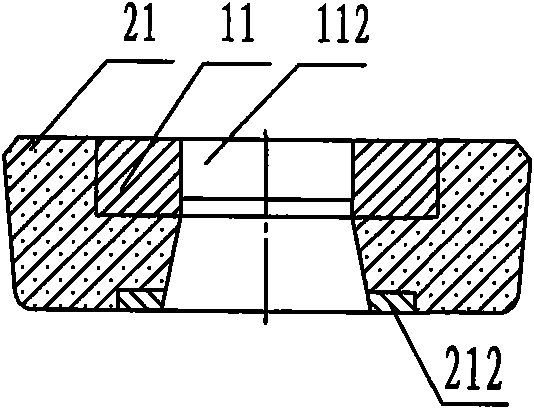

[0067] A composite anchor plate, such as Figure 1 ~ Figure 3 Shown: the profile of this anchor backing plate is a disc shape, and the middle steel backing plate is a flat cylindrical middle steel backing plate 11 (see figure 1 , image 3 ), and what is coated on the outer periphery of the flat cylindrical middle steel backing plate 11 is a disc-shaped ultra-high-strength concrete pressure-bearing member 21 with a stepped through hole 211 in it (see figure 2 ), the flat cylindrical steel backing plate 11 is placed on the step of the stepped through-hole 211 of the disc-shaped ultra-high-strength concrete pressure-bearing member 21 and is combined with it, and the other step of the stepped-shaped through-hole of the ultra-high-strength concrete pressure-bearing member 21 One end is trumpet-shaped, and there is a ring-shaped steel connecting plate 212 in the center of the bottom.

Embodiment 2

[0069] A composite anchor plate, such as Figure 4 ~ Figure 5 As shown: the shape of the anchor backing plate is a hollow disc-shaped structure, the middle steel backing plate is a disc-shaped hollow cast iron or steel casting 12 with grouting holes 122, and the outer circumference is tightly wrapped in the middle The outer edge of the steel backing plate and the approximately disk-shaped ultra-high-strength concrete pressure bearing parts 22, 121 are shallow grooves on the middle steel backing plate.

Embodiment 3

[0071] A composite anchor plate, such as Figure 6 ~ Figure 7 As shown: the shape of the anchor backing plate is a hollow structure approximately disc-shaped, and the middle steel backing plate is a thin circular middle steel backing plate 13 with a shallow groove; Ultra-high-strength concrete pressure-bearing part 23, the upper center of this approximately disk-shaped super-high-strength concrete pressure-bearing part 23 has a groove 231, and there is a grouting channel 241 formed by an iron bend on the disc (see Figure 6 ), the upper part of the iron elbow 242 is connected with the middle steel backing plate 13, and the lower transverse opening is connected with the central hole 232 of the ultra-high-strength mortar concrete pressure bearing part 23, and the oblate steel backing plate 13 is placed in the ultra-high-strength concrete pressure-bearing On the groove 231 of part 23 top center, and be connected with high-strength mortar concrete pressure bearing part 23, there i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com