Bearing water-proof mechanism of water-cooling single screw compressor

A single-screw compressor and bearing technology, applied in the direction of machine/engine, mechanical equipment, piston pump sealing device, etc., can solve the problems of low assembly and disassembly efficiency, reduced product reliability, economic loss, etc., to ensure the service life. , Improve the reliability of use and ensure the effect of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

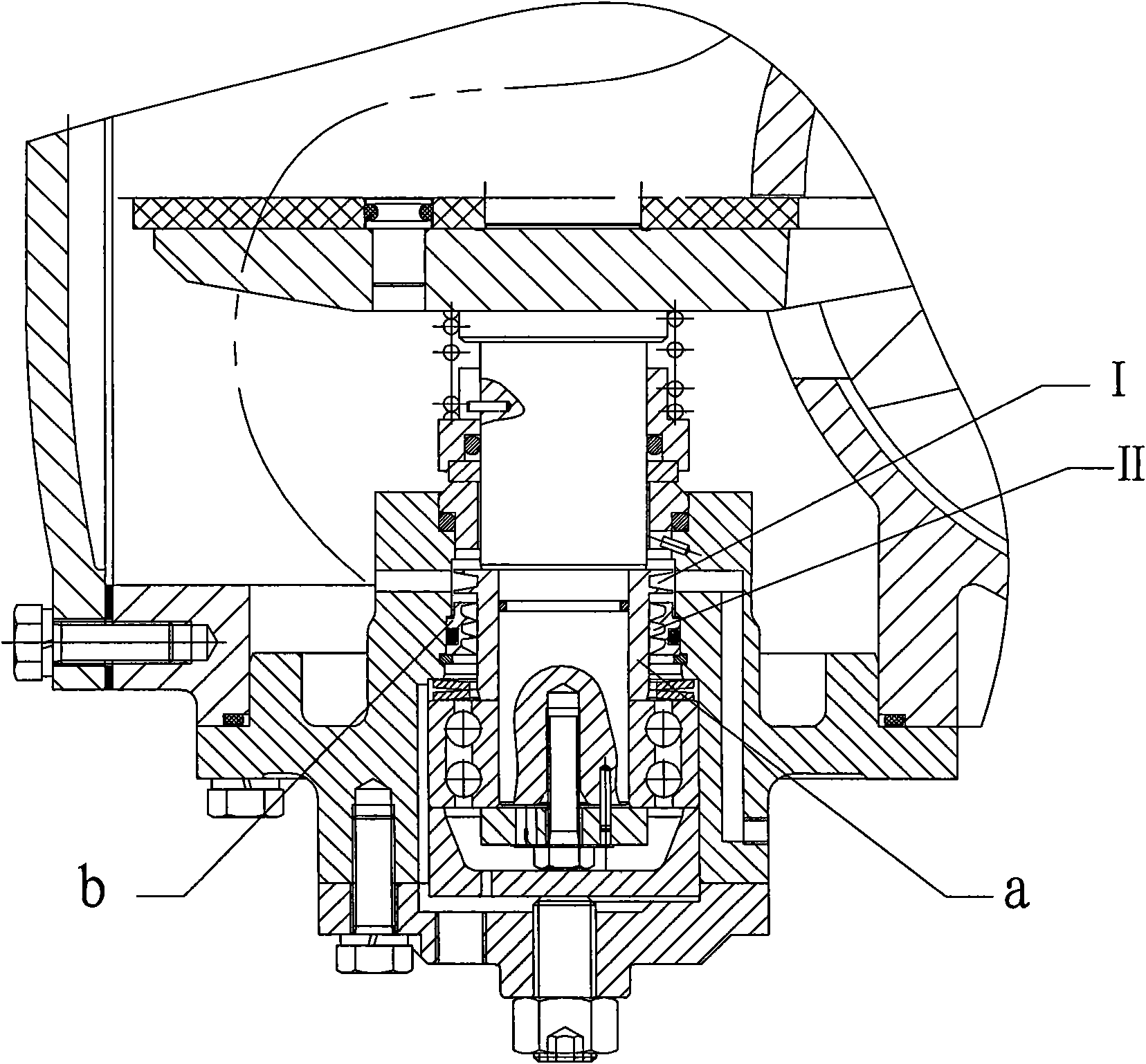

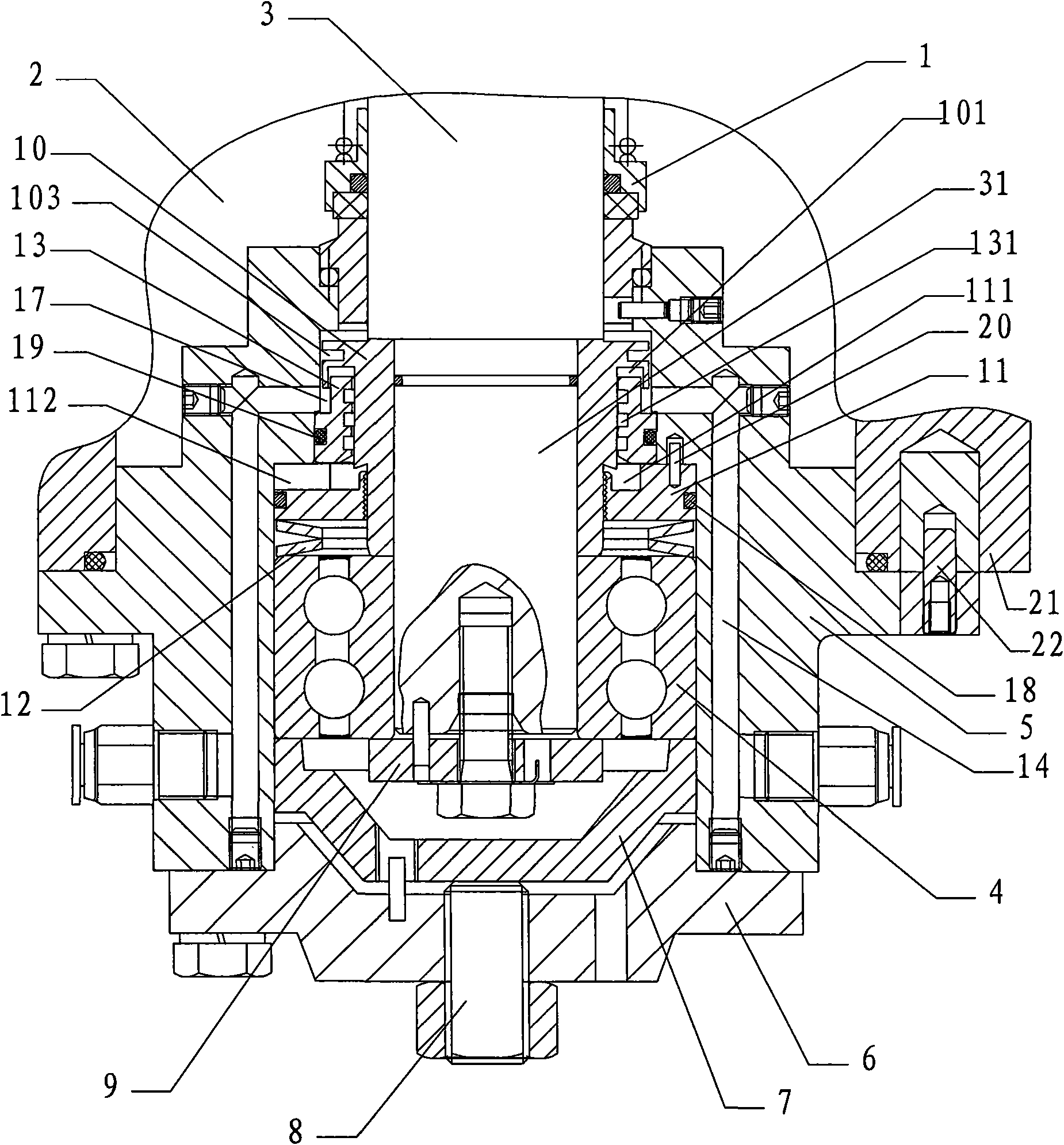

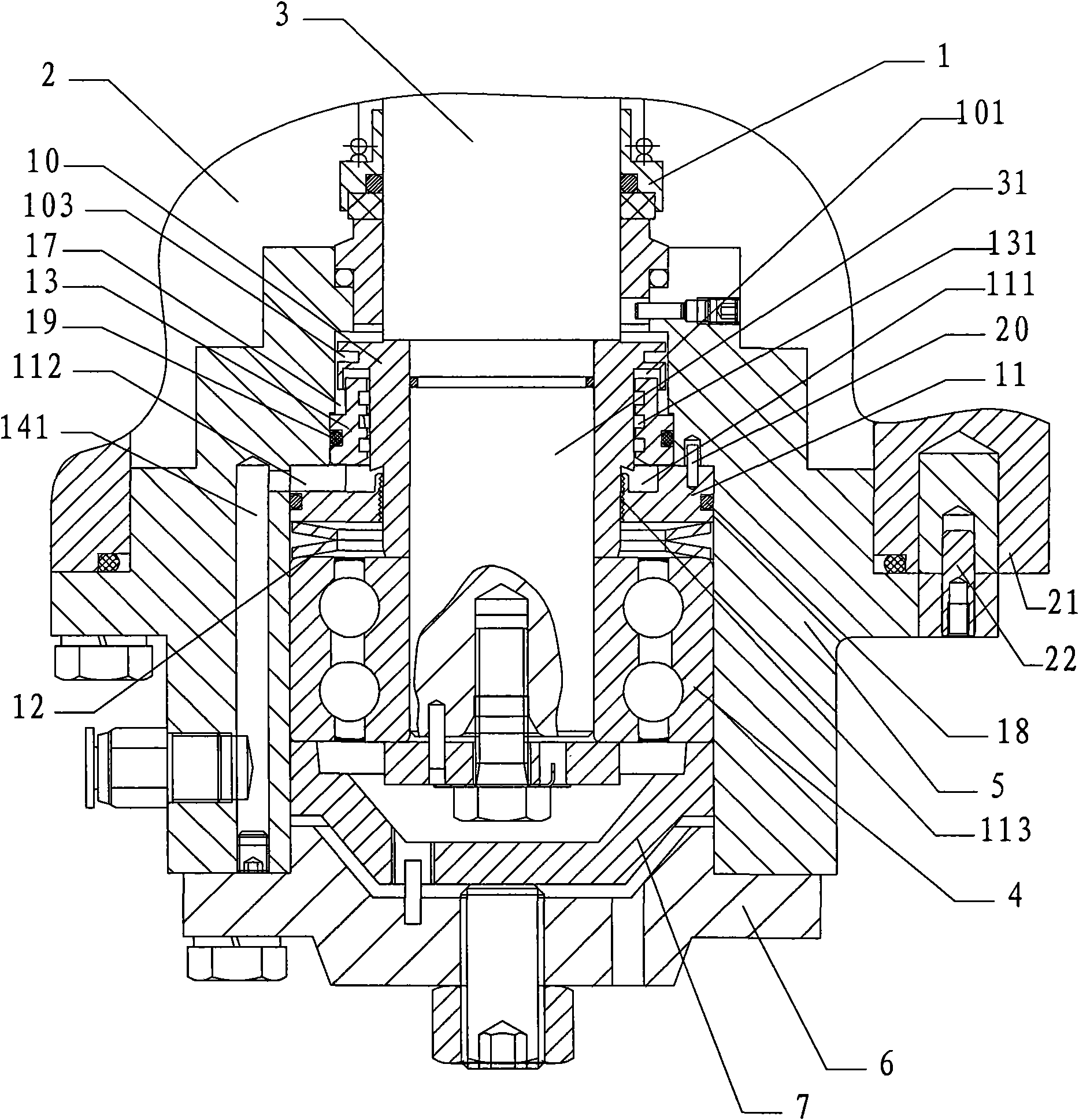

[0022] According to attached Figure 2 to Figure 3As shown, the bearing waterproof mechanism of the water-cooled single-screw compressor according to the present invention includes a bracket shaft 3 that is isolated from the cooling water in the cooling chamber 2 through a pre-sealing device 1. The pre-sealing device 1 generally adopts a mechanical seal or Labyrinth seal, generally speaking, the pre-sealing device 1 is used to isolate the cooling water in the cooling cavity 2 from leaking to the surface of the bracket shaft 3 , and it forms the main sealing structure of the bracket shaft 3 . The shaft diameter of the end 31 of the bracket shaft 3 is smaller than the shaft diameter of the bracket part, and the end 31 is supported on the bearing seat 5 through the bearing 4, and the inner ring of the bearing 4 is inserted into the end 31 of the bracket shaft 3, And the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com