Wicket-type electric adjusting valve for flow control

An electric regulating valve and flow control technology, applied in sliding valves, valve details, valve devices, etc., can solve the problems of high product cost, difficulty in reducing power, and reducing mechanical efficiency, saving materials and energy consumption, Improved mechanical efficiency and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

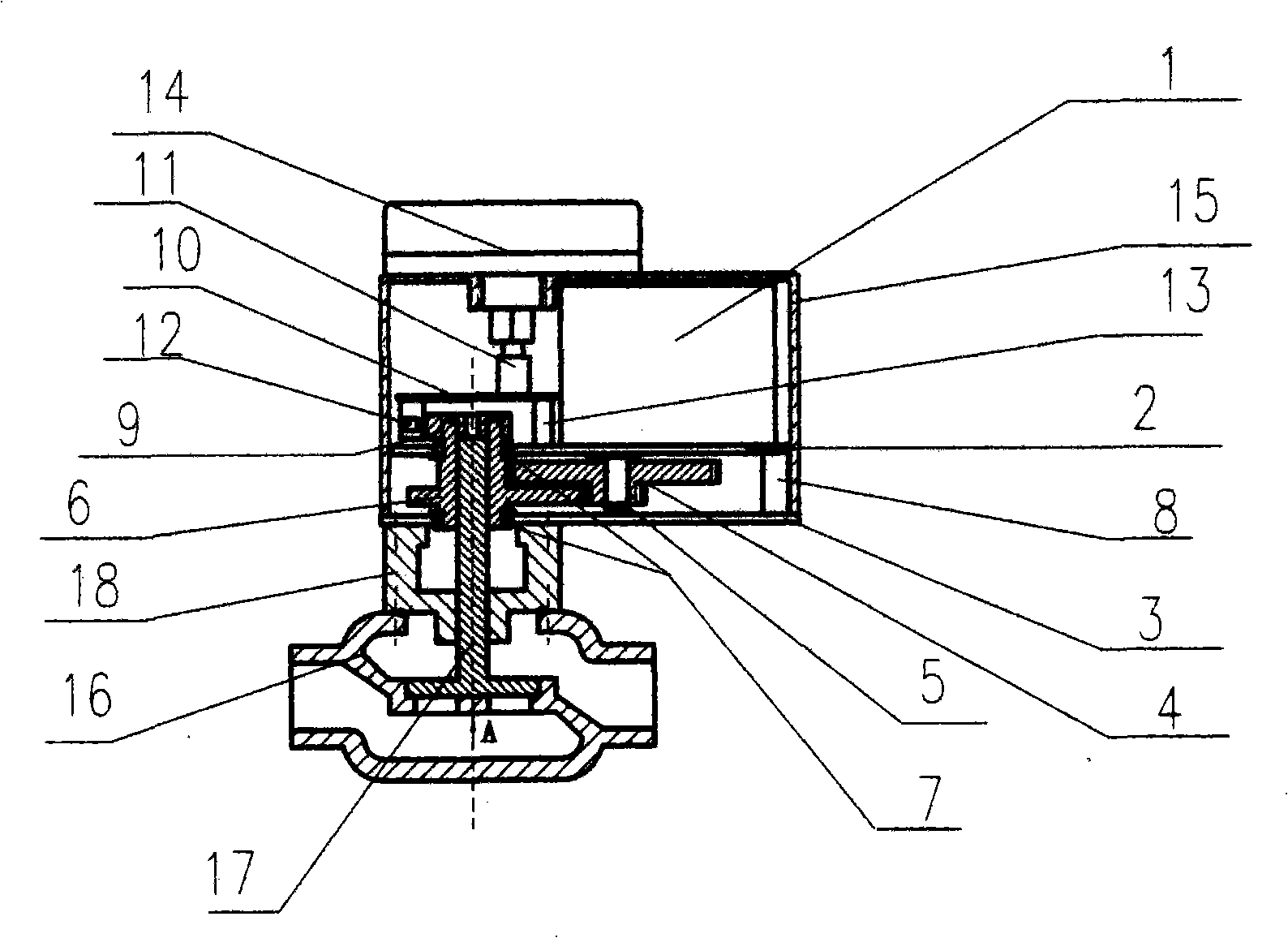

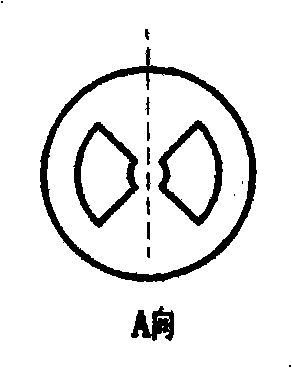

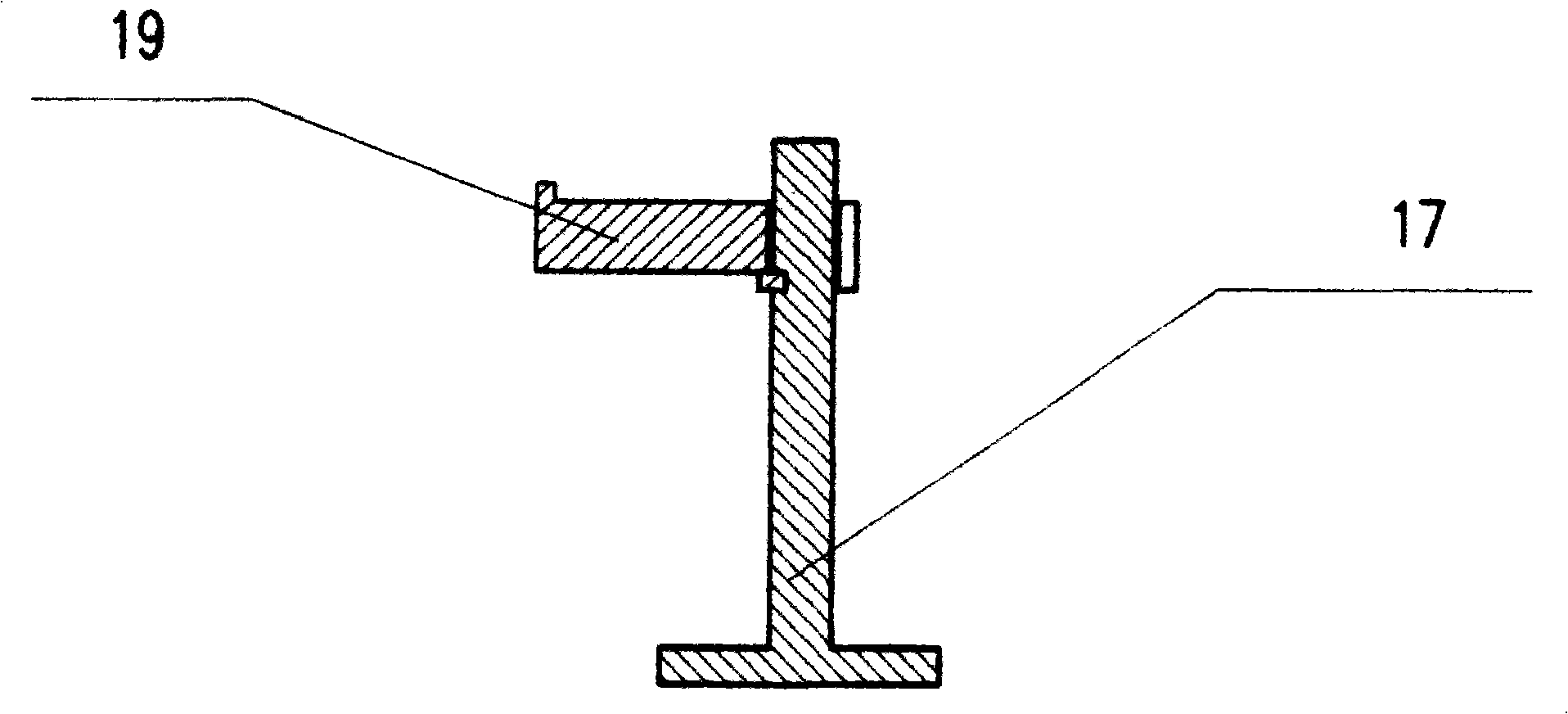

[0014] Such as figure 1 As shown, a swing gate electric control valve for flow control includes a motor 1, an upper support plate 2, a lower support plate 3, a double gear 4, a retaining ring 5, an output gear shaft 6, a bearing 7, and a pillar 8, swing arm cover 9, circuit board 10, manual switch, travel switch, circuit board pillar 13, handle 14, shell 15. The motor 1 is installed on the upper support plate 2, the double gear 4 is fixed on the output shaft of the motor 1 by the circlip 5, the bearing 7 is respectively embedded on the upper support plate 2 and the lower support plate 3 and is set with 6 output gear shafts Then, the output gear shaft 6 meshes with the duplex gear 4, the four pillars 8 rivet and position the upper support plate 2 and the lower support plate 3, the swing arm cover 9 is buckled on the upper end of the output ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com