Device and method for processing slag by seawater and application of processed slag

A slag and seawater technology, applied in the field of slag treatment, can solve problems such as structural damage, steel corrosion, reinforced concrete failure, etc., to improve air quality and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

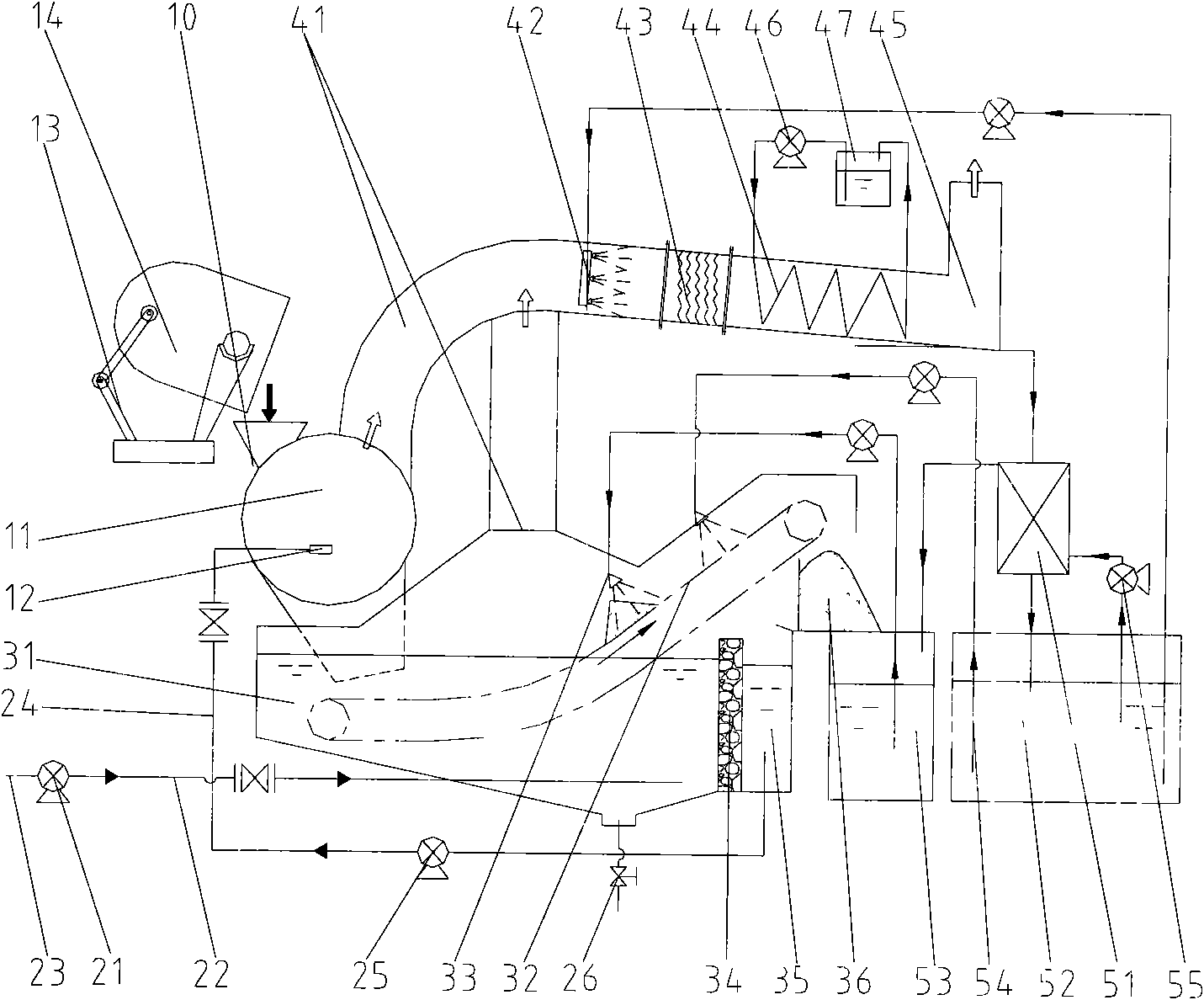

[0031] The invention is composed of five major systems: a molten slag granulation system, a seawater circulation system, a slag-water separation system, a steam collection system, and a captured water purification system.

[0032] Such as figure 1 As shown, the slag granulation system consists of a slag granulator 11 and a spray device 12 . The slag discharge device 13 pours the high-temperature slag 10 out of the slag container 14 (such as a slag pot or a slag tank), and discharges it to the slag granulator 11 . At this time, the seawater circulation system also continuously provides seawater to the spraying device 12. The arrangement of the spraying device 12 enables the sprayed seawater to impact on the molten slag to complete the cooling and granulation of the molten slag, while the seawater absorbs the heat in the slag. The temperature of the water therein is increased to become steam, and the seawater also has the effect of cooling the slag granulator 11 .

[0033] The...

Embodiment 2

[0043] Except that the steam collection system is composed of a steam collector 41, a condenser 44 and a discharge pipe 45, the others are the same as in Embodiment 1.

[0044] The device of the present invention has the functions of granulating slag by using seawater, steaming (desalination) and purifying the seawater, and the seawater can be recycled in the device; the desalinated and purified fresh water is used for the granulation in the device. In addition to using the slag flushing system, the excess fresh water can also be provided to users outside the system, and the backwash sewage can also be used to wash the slag. While completing the slag treatment, a large amount of waste heat in the slag is fully used to desalinate seawater, and seawater polluted by heat and impurities is not discharged to the sea, and the composition of the slag is less affected by the composition of seawater, so it can be directly Application is an intensive technology that integrates energy sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com