Austenitic stainless steel, steel tube thereof and manufacturing method thereof

A technology of austenitic stainless steel, manufacturing method, applied in the direction of manufacturing converter, temperature control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

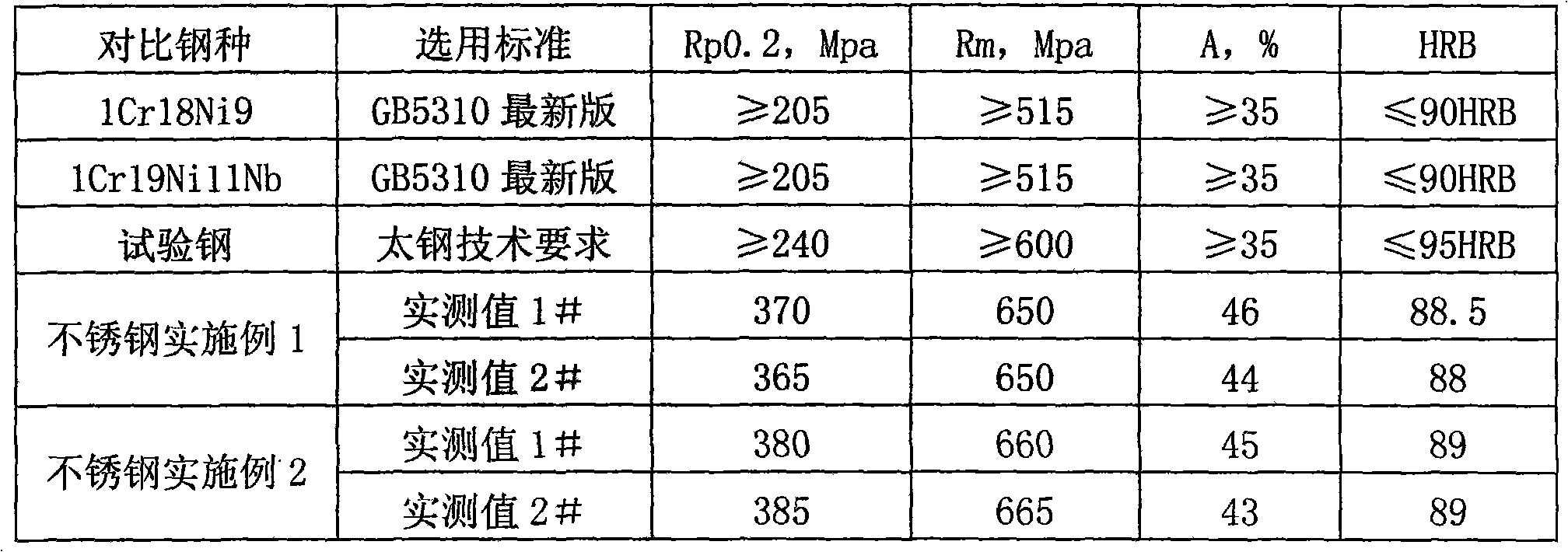

Examples

Embodiment 1

[0085] The composition mass percent of this austenitic stainless steel embodiment is:

[0086] C 0.080% Si 0.25% Mn 0.80% P0.015% S<0.001%

[0087] Cr 18.10% Ni 9.0% Cu 3.0% Nb 0.45% Mo 0.20%

[0088] Co 0.18% N 0.011% B 0.005 The rest is Fe and unavoidable impurities.

Embodiment 2

[0090] The composition mass percent of this austenitic stainless steel embodiment is:

[0091] C 0.08% Si 0.19% Mn 0.72% P 0.0012%

[0092] S 0.002% Cr 18.32% Ni 9.11% Cu 2.88%

[0093] Nb 0.52% Mo 0.19% Co 0.22% N 0.095%

[0094] B 0.004%, the rest is Fe and unavoidable impurities.

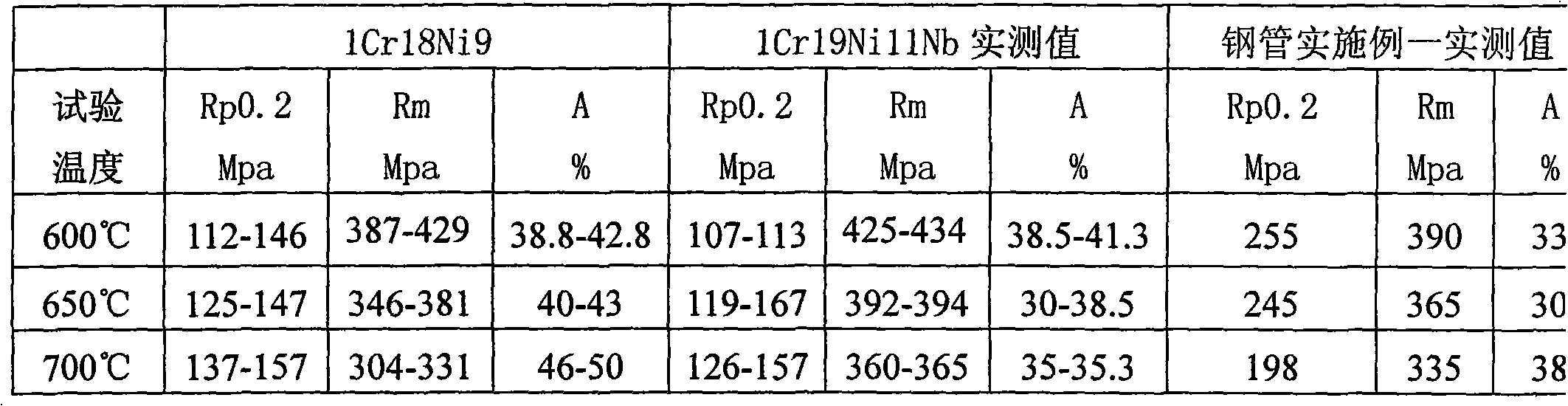

[0095] Example 1 of austenitic stainless steel seamless steel pipe

[0096] The specifications of this austenitic stainless steel seamless steel pipe embodiment are Φ54×8mm, and the length is 10000mm, and its composition mass percentage is:

[0097] C 0.080% Si 0.25% Mn 0.80% P0.015% S<0.001%

[0098] Cr 18.10% Ni 9.0% Cu 3.0% Nb 0.45% Mo 0.20%

[0099] Co 0.18% N 0.011% B 0.005 The rest is Fe and unavoidable impurities.

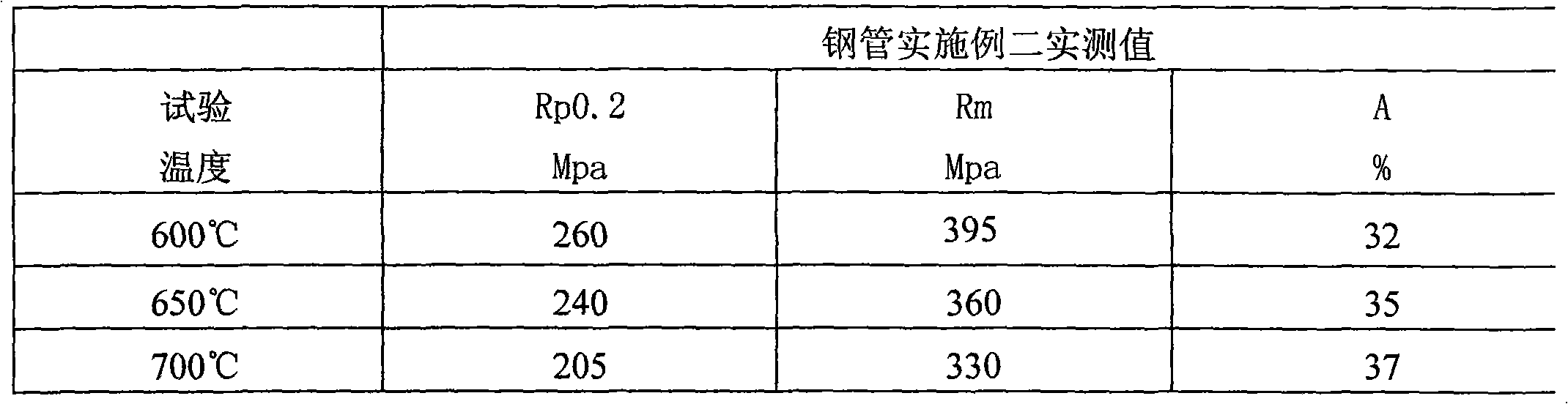

[0100] Example two of austenitic stainless steel seamless steel pipe

[0101] The specifications of this austenitic stainless steel seamless steel pipe embodiment are Φ54×8mm, and the length is 10000mm, and its composition mass percentage is:

[0102] C 0.08% Si 0.19% M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com