Engine oil pump construction

An oil pump and engine technology, applied in the direction of pressure lubrication of the lubricating pump, etc., can solve the problems of the large meshing noise of the driven gear of the oil pump and the large internal space of the engine, and achieve the effect of compact assembly structure, compact structure and reduced space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

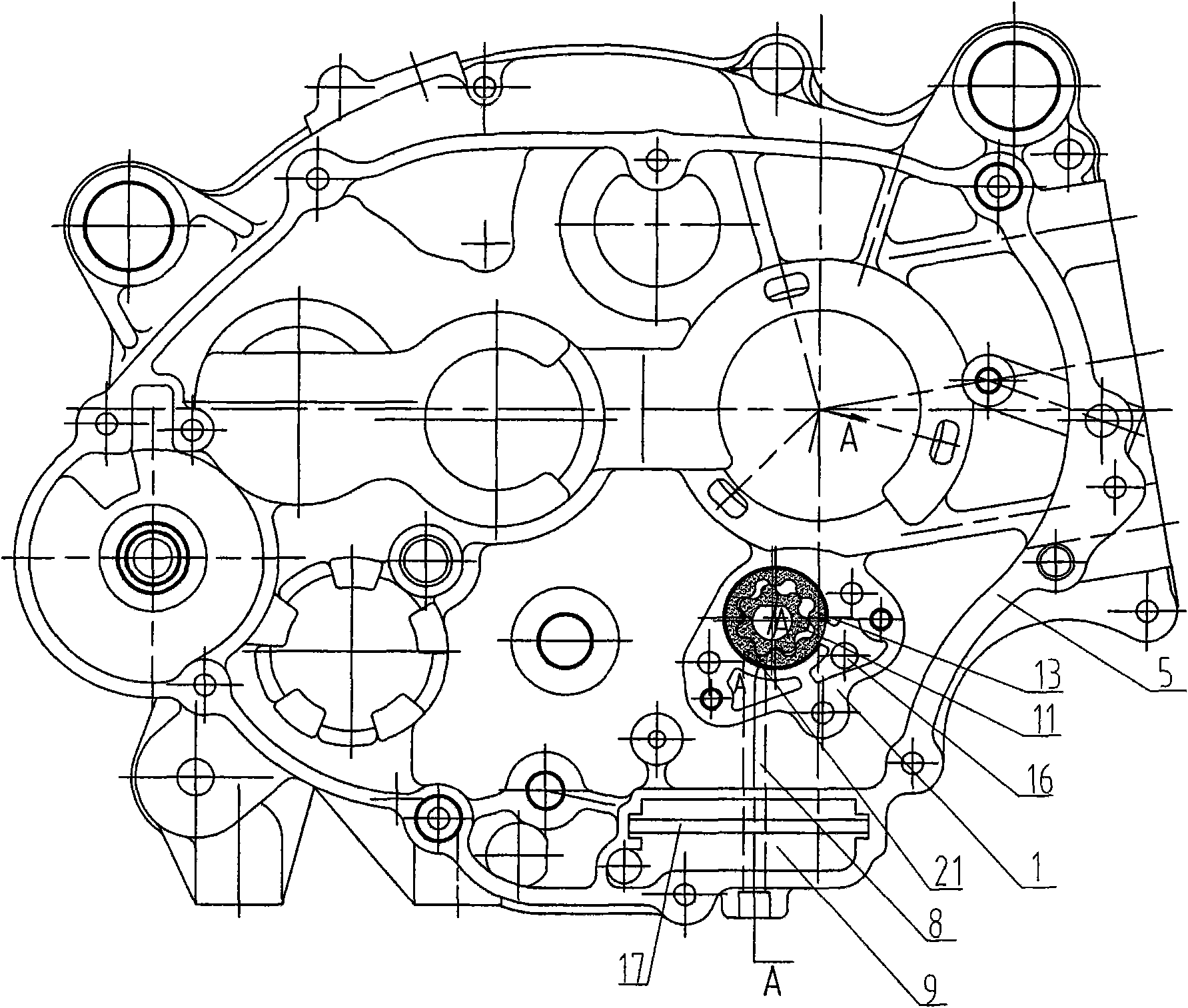

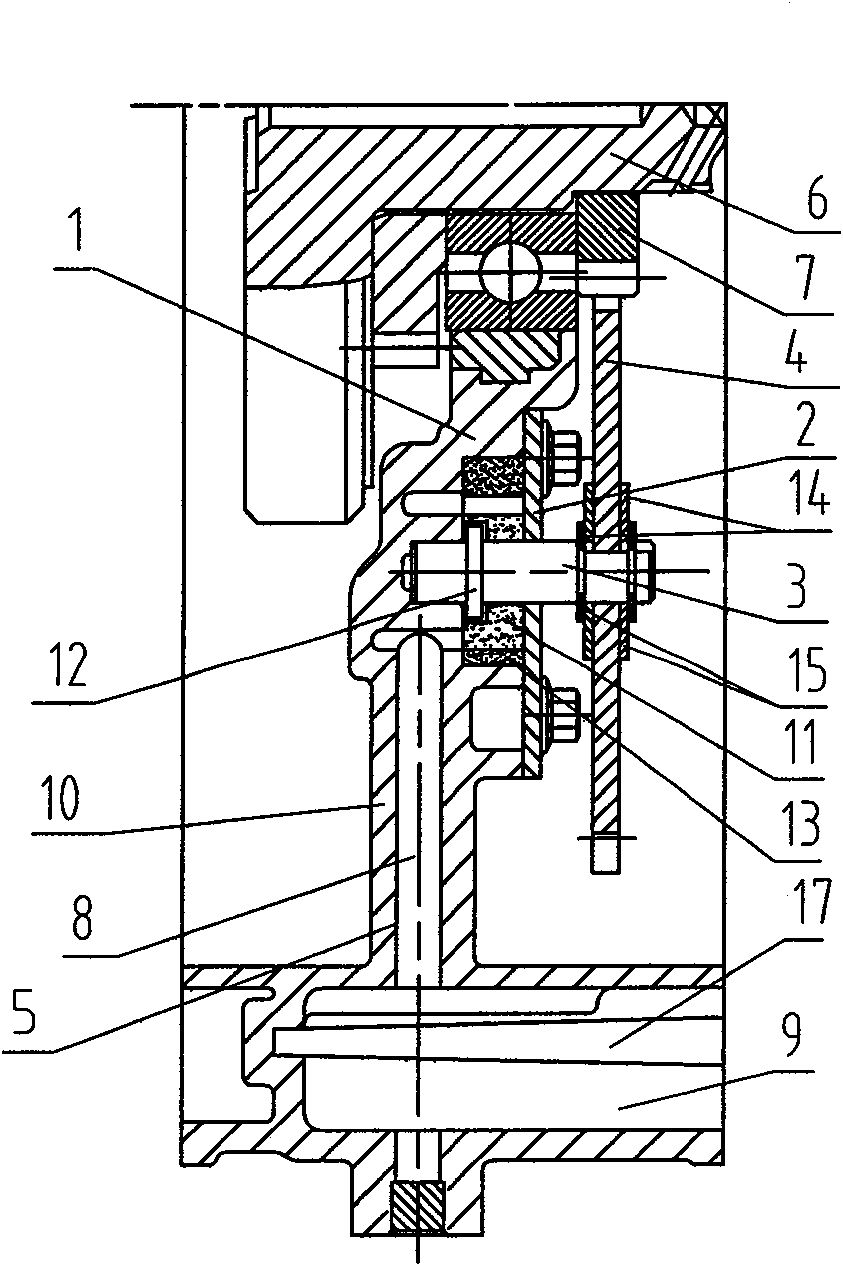

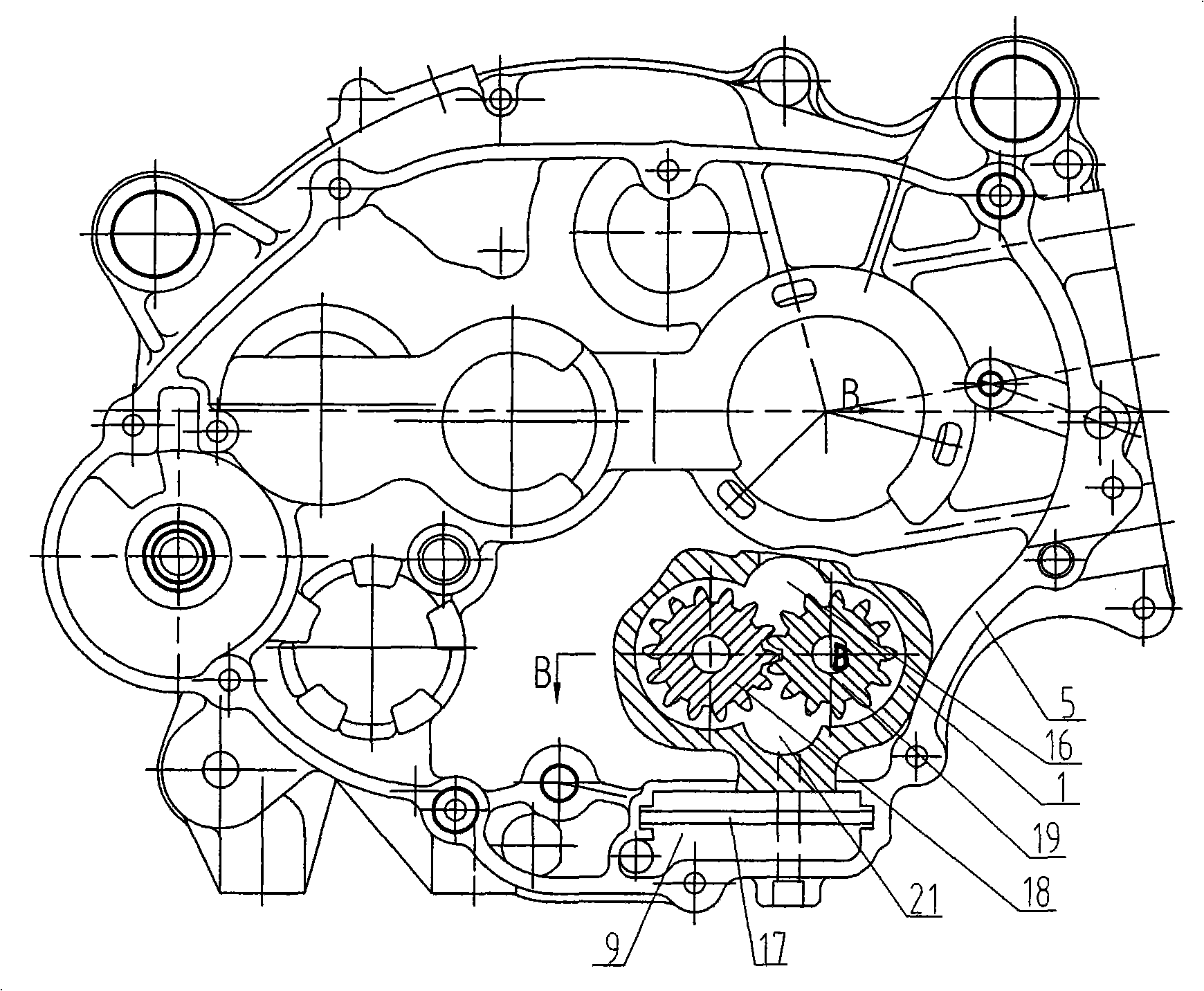

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0015] Such as Figure 1 to Figure 4 As shown, the engine oil pump structure of the present invention has an oil pump base body 1, an oil pump cover 2, an oil pump shaft 3, an oil pump driven gear 4, and a gear assembly mounted on the oil pump shaft 3 and located in the inner cavity of the oil pump base body 1 Or the rotor assembly, the oil pump base body 1 and the inner wall of the crankcase body 5 are integrally formed integral structure, and the oil pump driven gear 4 installed on the oil pump shaft 3 end meshes with the oil pump driving gear 7 on the crankshaft 6 . The oil pump seat 1 is formed by extending the boss from the inner wall of the crankcase body 1, and processing the oil pump cavity, oil inlet hole and oil outlet hole on the boss, and is processed and assembled separately with the traditional oil pump to form an assembly. Then, compared with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com