Electric heater

An electric heater and shell technology, applied in the field of electric heaters, can solve the problems of decreased heat dissipation effect, troublesome product assembly, complicated maintenance and other problems, and achieve the effect of easy fixing and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

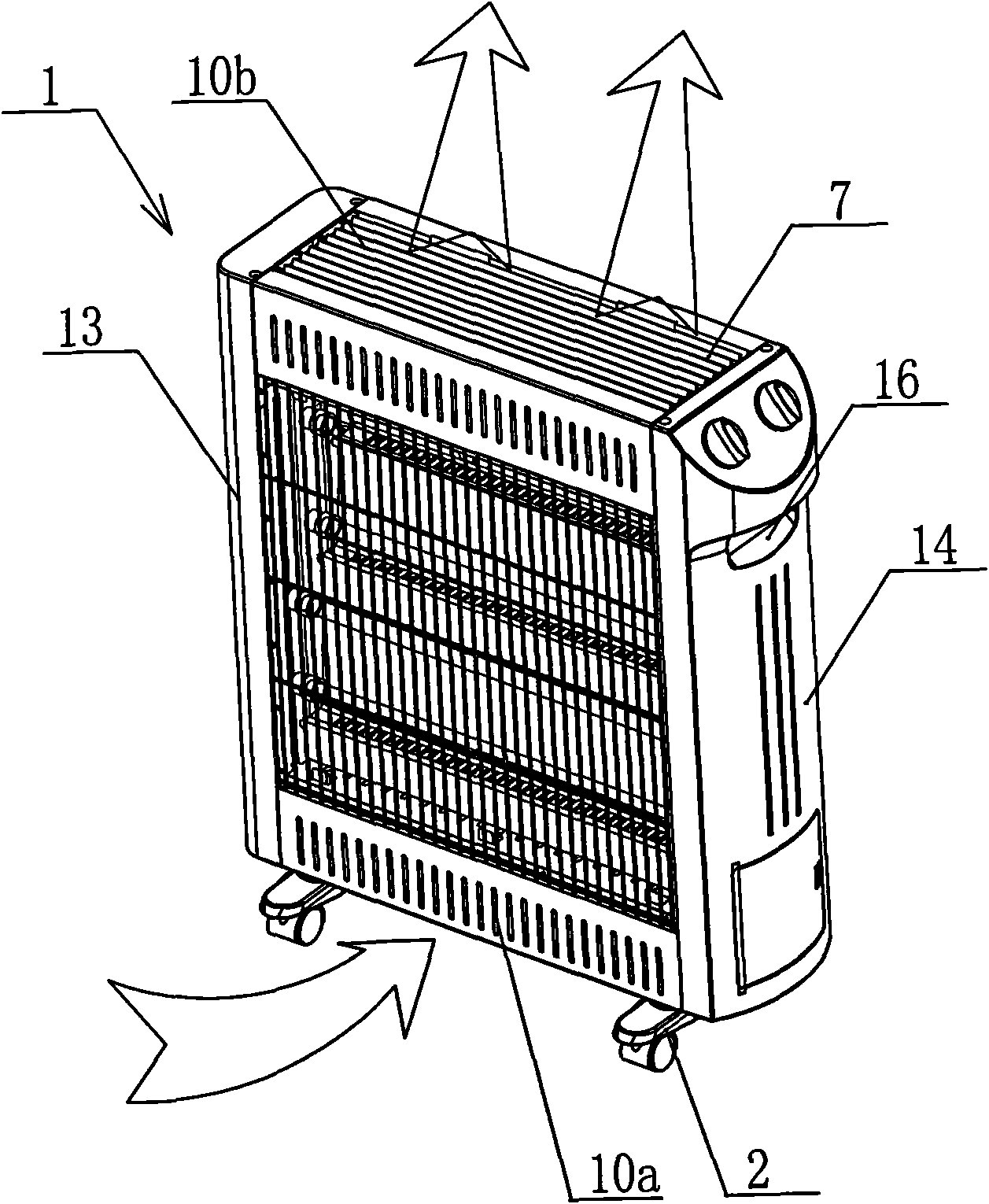

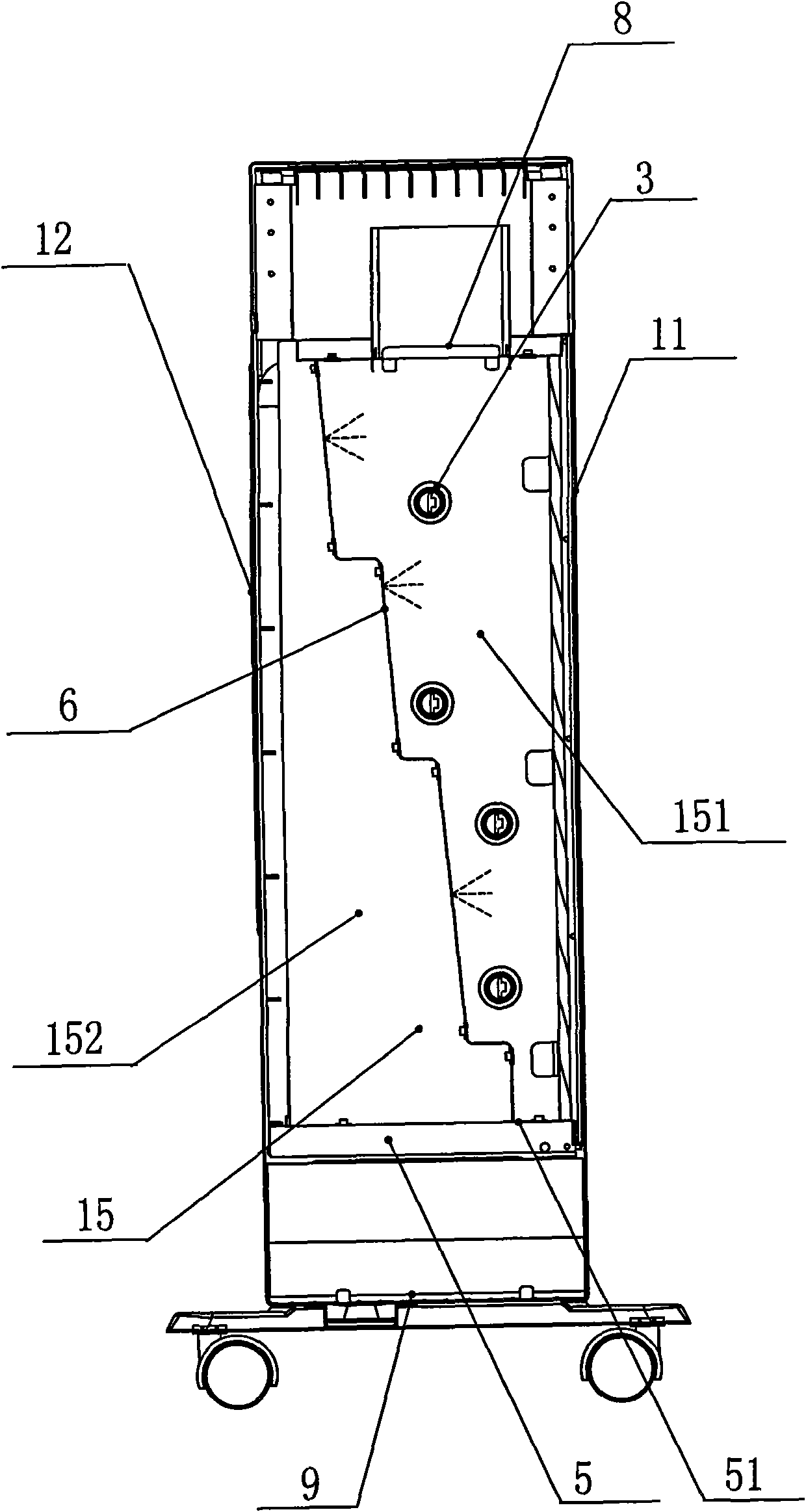

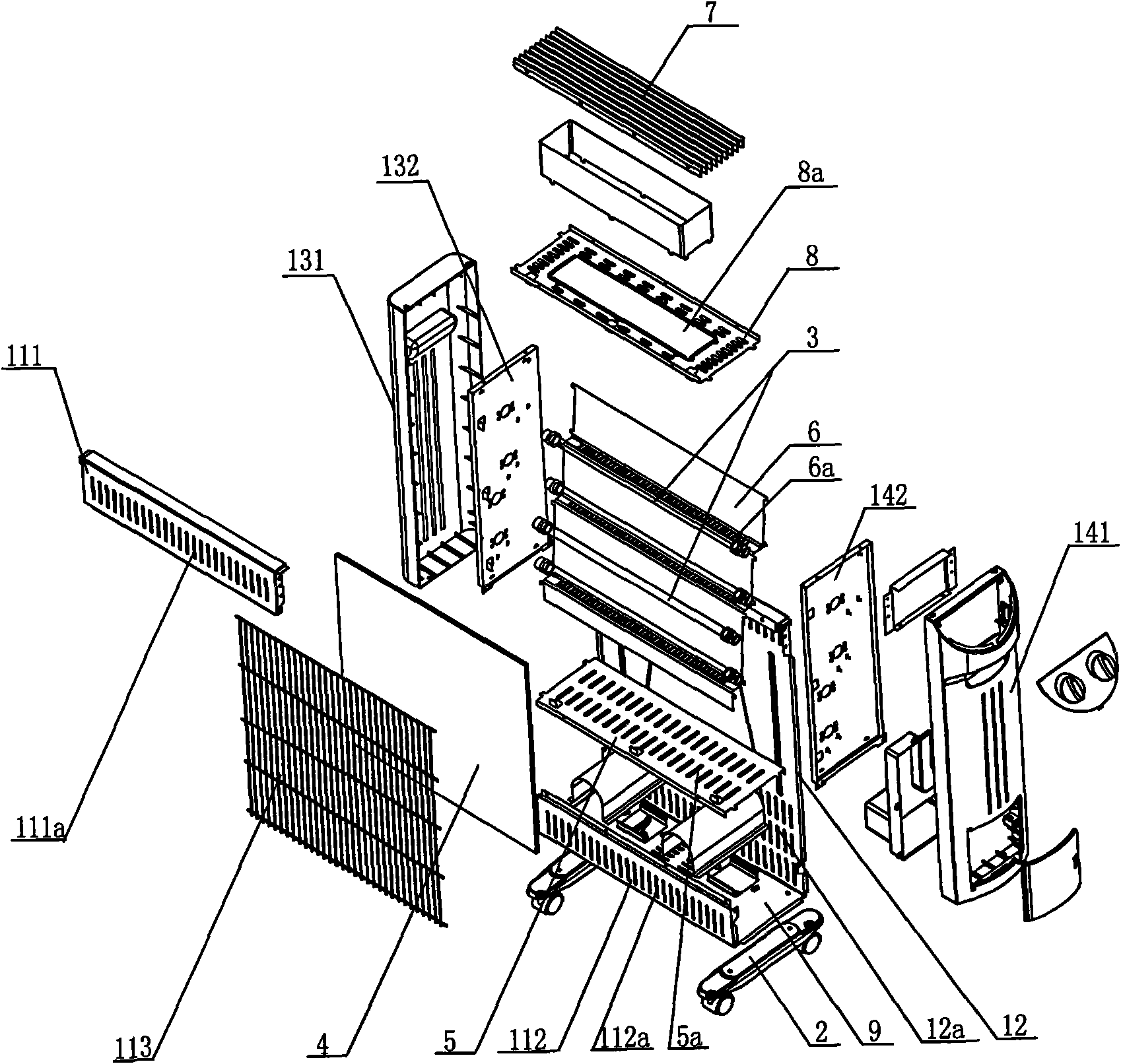

[0049] Such as figure 1 , figure 2 or image 3 As shown, an electric heater includes a housing 1 having an accommodating cavity 15 surrounded by a front outer wall 11 , a rear outer wall 12 , a left side wall 13 and a right side wall 14 . The lower part of the housing 1 is provided with an air inlet 10 a of the accommodation chamber 15 , and the top of the housing 1 is provided with an air outlet 10 b of the accommodation chamber 15 . A concave handle 16 is provided on the outside of the left side wall 13 and the right side wall 14 of the housing 1 ; a detachable caster 2 is provided on the bottom wall 9 of the housing 1 . The caster 2 is disassembled during production or transportation, and the caster 2 is installed on the bottom wall 9 of the housing only before the electric heater is actually used, which can save packaging materials and transportation volume and Dosage.

[0050] Such as image 3 As shown, the front outer wall 11 located at the front side of the housin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com