Position measuring device and position measuring method

A measurement device and measurement method technology, applied in the direction of measurement device, optical device, instrument, etc., can solve the problems of low measurement sensitivity and complex overall structure of the measurement system, and achieve the effects of simple structure, reduced impact, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

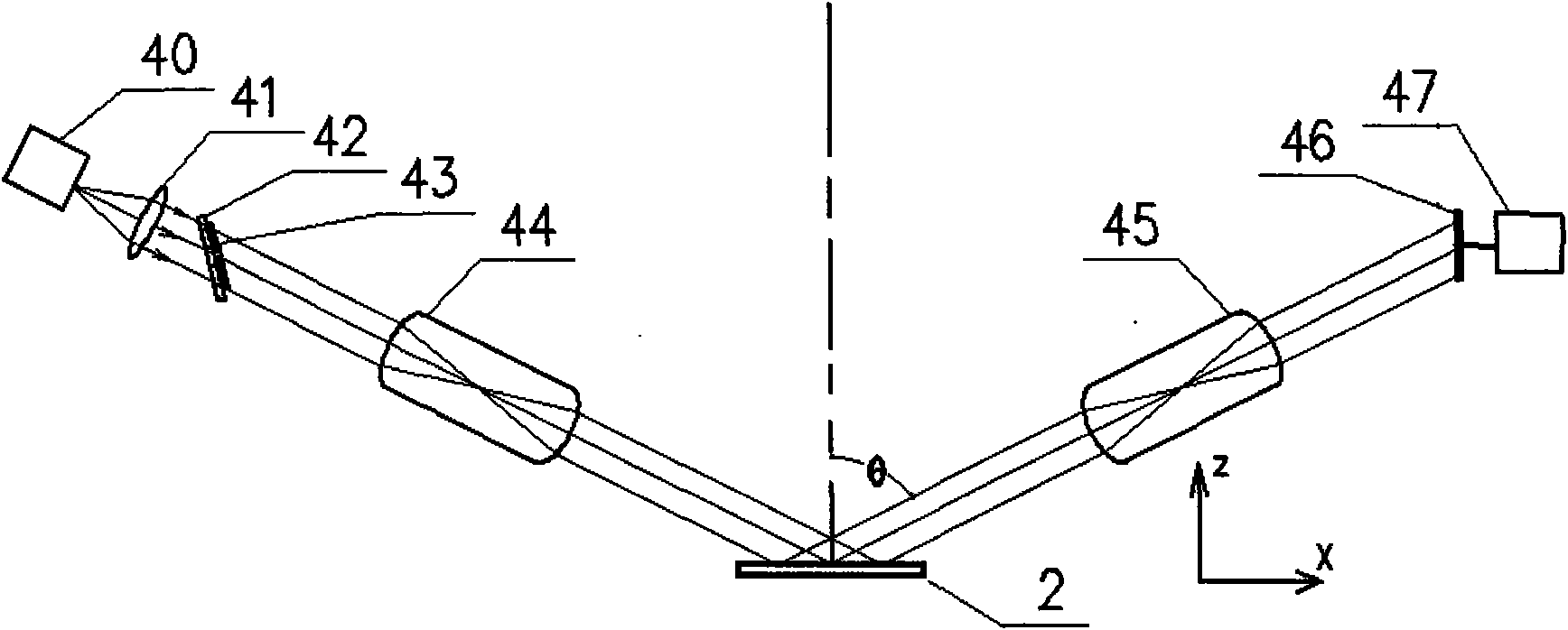

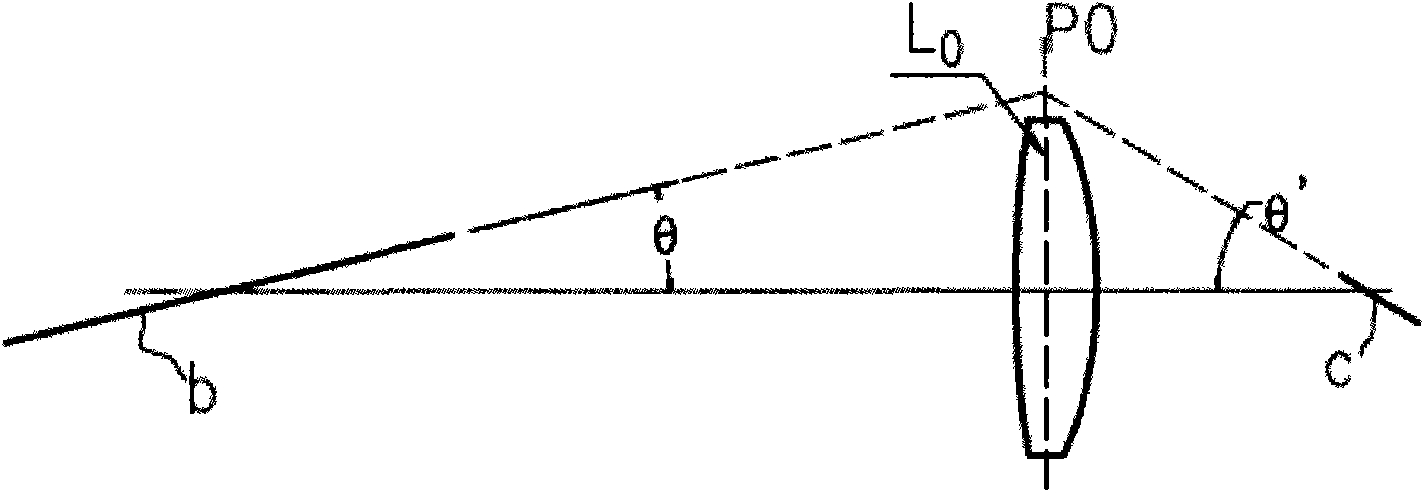

[0030] Hereinafter, the present invention will be further described with reference to the accompanying drawings.

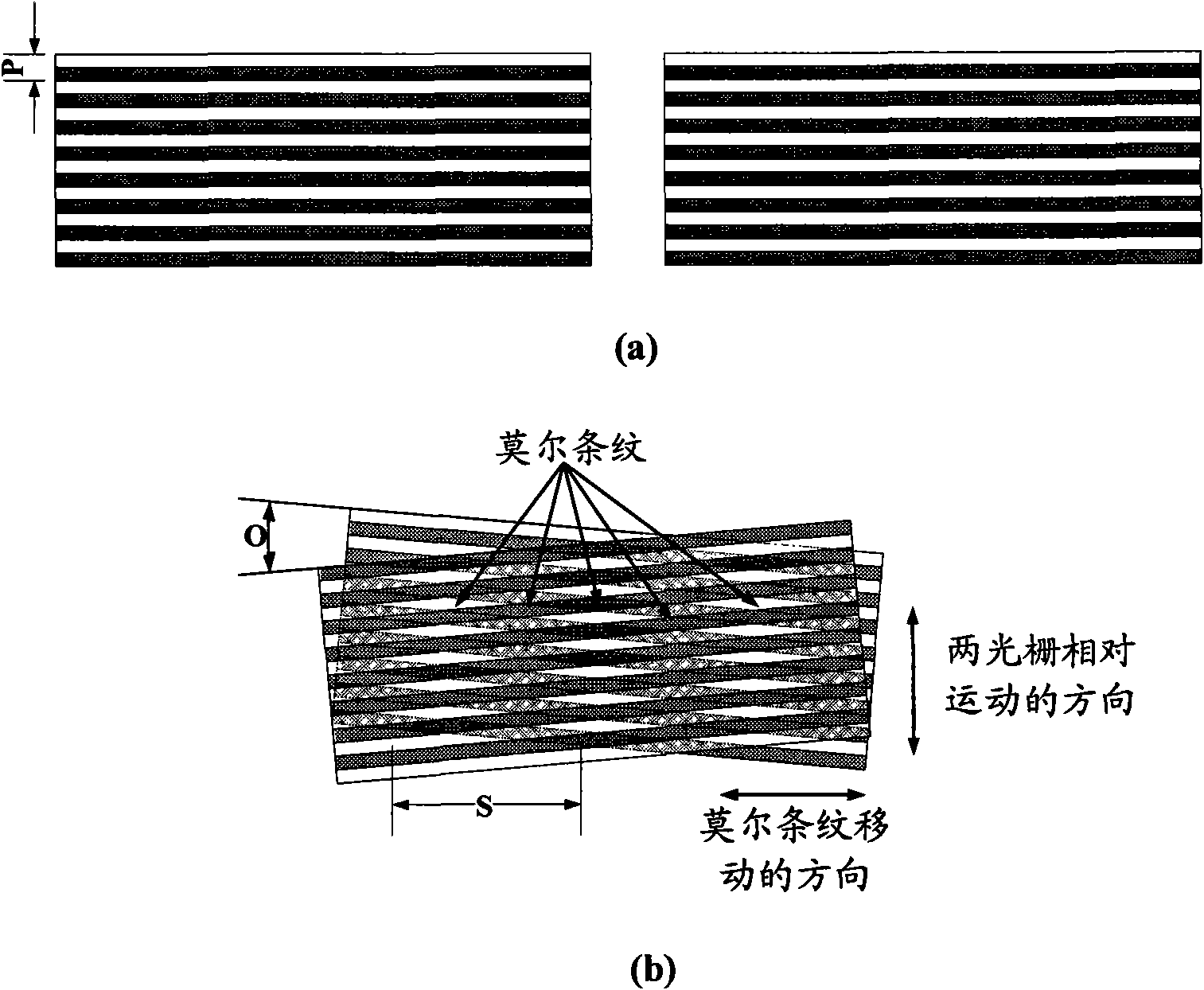

[0031] Since the position measuring device and method of the present invention are designed based on the principle of Moiré fringe detection, before introducing the position measuring device and method of the present invention, the formation and characteristics of the moiré fringes will be introduced first. figure 1 A schematic diagram of the formation of Moiré fringes is shown. in, figure 1 (a) shows the amplitude grating when the two periods are P, figure 1 (b) shows figure 1 Two amplitude gratings with period P in (a) are superimposed at a certain angle (such as o) and illuminated to form moire fringes with period S. When the angle o between the two amplitude gratings with period P is small, the following relationship is satisfied between the period P of the amplitude grating and the period S of the moiré fringes formed by it:

[0032] S=P / o (1)

[0033] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com