Calibration method for infrared moisture meter system

A system calibration and moisture meter technology, applied in the measurement of color/spectral characteristics, etc., can solve the problem of low detection accuracy of infrared moisture detection with hysteresis, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Calibration method of the static infrared moisture meter system, the method includes in sequence:

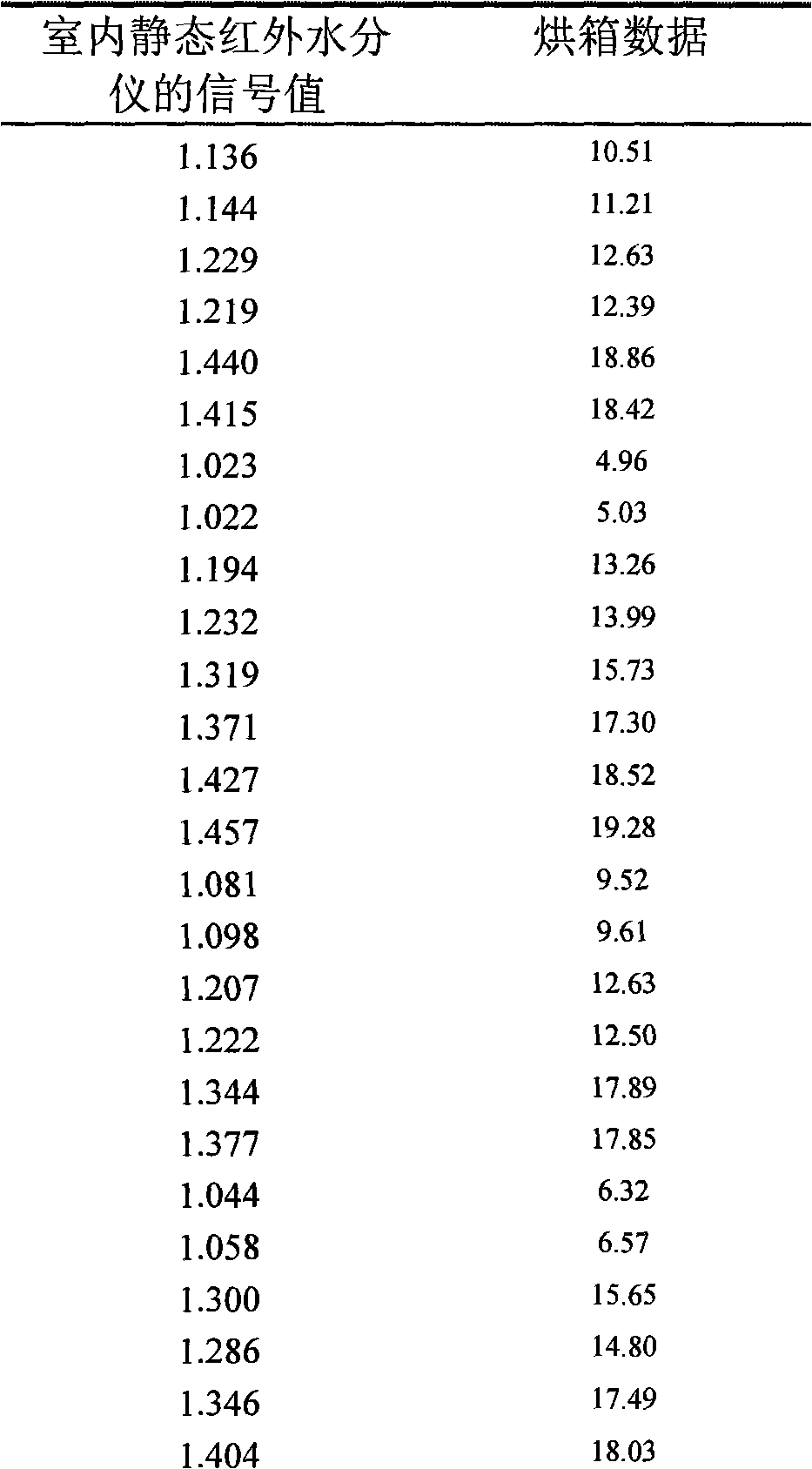

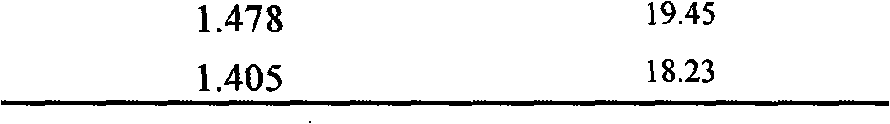

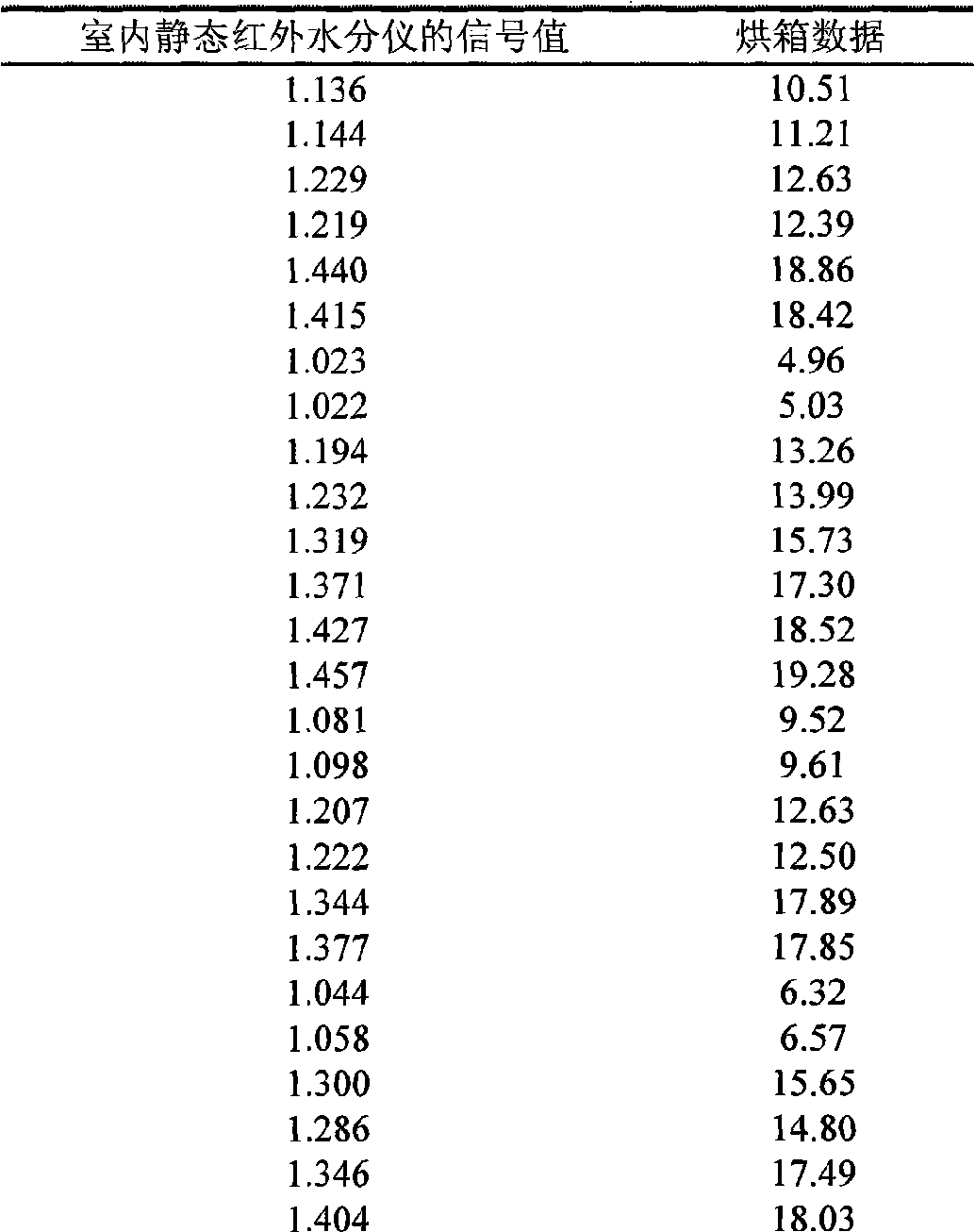

[0034] (1) Establish a wide-area model on the static infrared moisture meter: within the actual working moisture range of the material, select different points on the production line that cover the possible range of moisture content of the actual material to sample separately. The samples taken are at least five samples, each The samples were detected by an indoor static infrared moisture meter and the detection signal value was recorded, and then the moisture content of the sample was detected by an oven and the detection data was recorded. The oven detection data and the infrared moisture meter detection signal value were regressed to establish a relationship function y wide domain = f1(x static);

[0035] In the actual working moisture range, the data measured according to the above steps are shown in Table 1. The data are divided into three groups, each group has se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com