Method and device for chain velvet making of multi-crystalline solar cell

A technology of solar cells and chains, which is applied in the manufacture of circuits, electrical components, and final products, etc., to achieve the effects of easy temperature control, reduced temperature rise, and faster flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

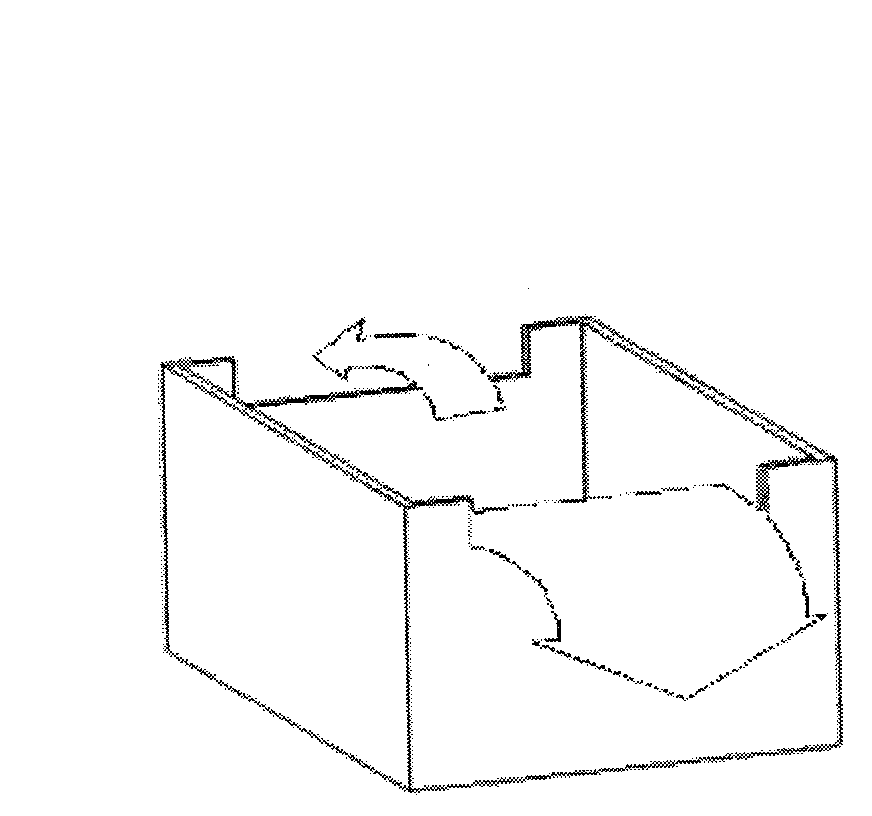

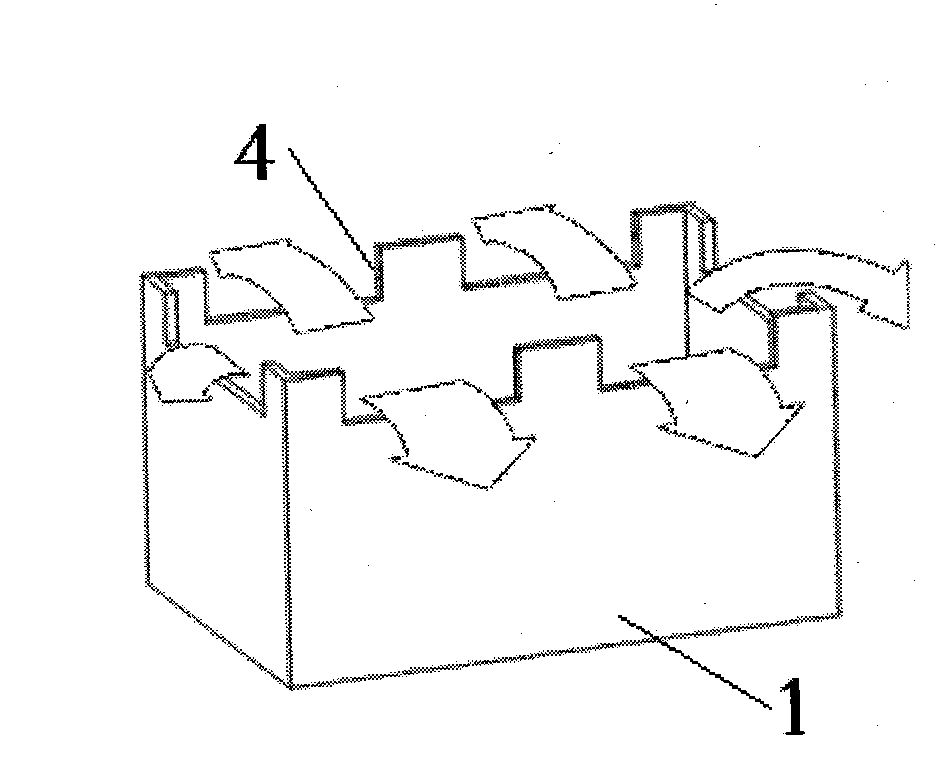

[0026] Embodiment 1: as image 3 As shown, the form of four-sided overflow is adopted to accelerate the flow and renewal of the liquid, take away the heat released by the reaction of the silicon wafer, and ensure the uniformity of the reaction temperature and concentration of the silicon wafer, thereby ensuring a better texturing effect.

[0027] A method for chain texturing of polycrystalline solar cells, comprising the following steps:

[0028] Step 1: Adopt the four-sided overflow method of the tank body, so that the liquid overflows quickly after the reaction;

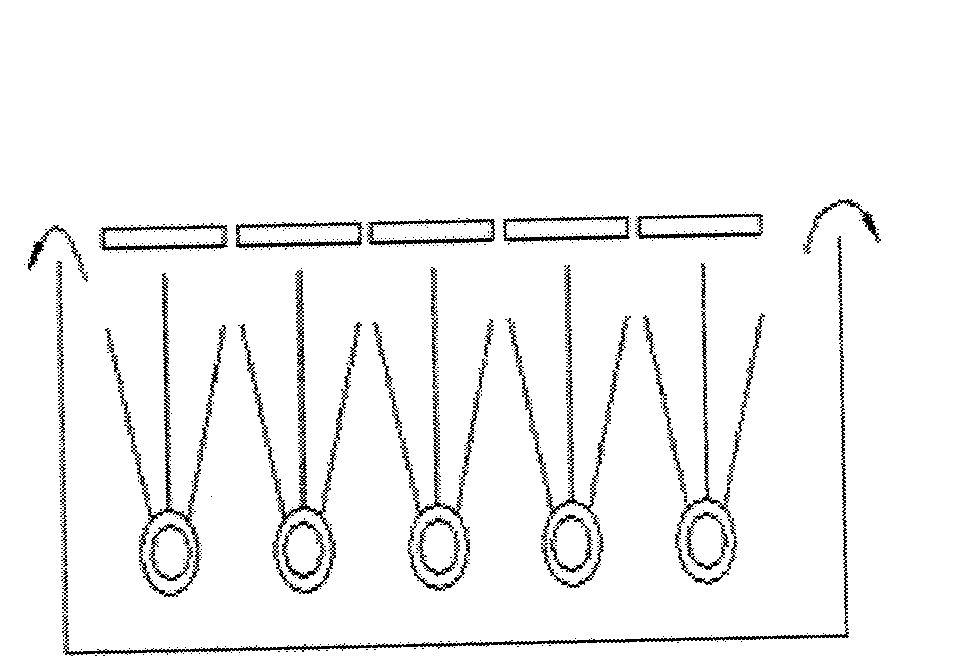

[0029] Step 2: adopt the upper spray method; in the upper part of the liquid medicine tank, a certain number of spray pipes 2 are added, and the liquid medicine is directly replenished around the silicon chip 3 from the upper part; this makes the liquid medicine and the Wafer contact more fully, and at the same time It also makes it easier to control the temperature of the liquid medicine, keep it uniform and impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com